Pro-Cut KG-12-FS Installation and user guide

KG-12-FS

1

INSTRUCTIONS FOR

OPERATION, SERVICE, AND MAINTENANCE

KG-12-FS

PRO-CUT MEAT GRINDER

507127-0

KG-12-FS

2

INSTRUCTIONS FOR

OPERATION, SERVICE, AND MAINTENANCE

KG-12-FS PRO-CUT MEAT GRINDER

CONTENT

PAGE

I. INTRODUCTION

II. UNPACKING

III. INSTALLATION

IV. OPERATION

V. KEY ELEMENTS FOR HIGH QUALITY PRODUCT GRINDING

VI. CLEANING

VII. MAINTENANCE

VIII. ELECTRICAL SPECIFICATIONS KG-12-FS

IX. ELECTRICAL DIAGRAM KG-12-FS

X. PARTS LIST KG-12-FS

2

3

3

4

4

4

5

6

7

8

I.- INTRODUCTION:

CONGRATULATIONS YOU HAVE ACQUIRED A PRO-CUT MEAT GRINDER, WHICH IS MADE

OF HIGH QUALITY LONG LASTING MATERIALS THAT SHOULD GIVE YOU YEARS OF

TROUBLE FREE OPERATION AND SERVICE.

BEFORE YOU UNPACK YOUR NEW PRO-CUT GRINDER, IT IS VITAL THAT YOU AND ANY

PERSON THAT WILL OPERATE THIS UNIT THOROUGHLY READ THIS MANUAL.

WARNINGS:

THIS MACHINE IS DESIGNED TO GRIND AND CUT FOOD PRODUCTS AND IS BY

NATURE DANGEROUS IF NOT USED AND MAINTAINED PROPERLY FOR OPTIMUM

SAFETY.

DO NOT ALLOW UNTRAINED, UNQUALIFIED PERSONNEL OR CHILDREN TO OPERATE

THIS EQUIPMENT.

NEVER PERFORM SERVICE, CLEANING OR MAINTENANCE ON THIS UNIT WHILE

CONNECTED TO A POWER SOURCE.

KG-12-FS

3

NEVER USE HANDS OR FINGERS TO FEED PRODUCT INTO THE BOWL AREA, ALWAYS

USE THE STOMPER OR PUSHER (1)* INCLUDED IN PACKAGE.

DO NOT LEAVE THE MACHINE UNATTENDED WHILE IN OPERATION.

THIS EQUIPMENT MUST BE CONNECTED TO A THERMALLY PROTECTED OUTLET.

NOTE: FOR ID NUMBERS REFER TO THE CORRESPONDING DRAWING AT THE END OF

THIS MANUAL

II.- UNPACKING:

1.-WHILE UNPACKING MACHINE TAKE SPECIAL CARE IN REMOVING THE COMPONENTS

AND MAKE SURE THAT ALL ARE ACCOUNTED FOR.

LOOK FOR THE FOLLOWING ITEMS:

1 COMPLETE GRINDING UNIT; INCLUDING HEADSTOCK (13), FEED SCREW (16),

HEADSTOCK RING (20), KNIFE (18) AND PLATE (19) .

1 STOMPER OR PUSHER (1).

1 PRODUCT TRAY (2).

4 RUBBER LEGS (4) (FOR MODEL KG-12-FS).

1 SUPPORT TRAY (10) (FOR MODEL KG-12-FS).

1 WRENCH (29) FOR SUPPORT TRAY NUTS (FOR MODEL KG-12-FS)

1 BOTTLE (25) OF FDA APPROVED GREASE.

III.- INSTALLATION:

1.-BEFORE CONNECTING THE MACHINE TO THE POWER SUPPLY, PLEASE FOLLOW

THESE EASY ASSEMBLY AND PREPARATION STEPS:

A.-REMOVE HEADSTOCK RING(20) FROM HEADSTOCK(13) BY ROTATING

COUNTERCLOCKWISE, PULL OUT KNIFE(18) , PLATE(19) AND FEED SCREW(16).

ALSO UNSCREW THE KNOB(8) TO ALLOW REMOVAL OF GRINDING HEADSOCK(13).

B.-WASH WITH AN APPROVED DETERGENT, RINSE AND DRY THE FOLLOWING

COMPONENTS: HEADSTOCK(13), FEED SCREW(16), HEADSTOCK RING(20),

KNIFE(18), PLATE(19) , STOMPER(1), AND TRAY(2).

C.-REASSEMBLE THE COMPONENTS THAT WERE REMOVED FOR WASHING BY

FOLLOWING THE REVERSE ORDER IN LETTER “B", BE SURE THAT THE SHARP END

OF THE KNIFE(18) FACES FORWARD, AND THAT THE NOTCH OF THE PLATE(19)

ALIGNS WITH THE PIN(9) ON THE BOTTOM OF THE HEADSTOCK (SEE DETAIL "B"). PIN ON THE BOTTOM OF THE HEAD.

WHEN TIGHTENING THE HEADSTOCK RING(20), TENSION SHOULD BE FIRM BUT NOT

TOO TIGHT, USE ONLY HAND FORCE.

E.- INSTALL THE PRODUCT TRAY(2):

MODEL KG-12-FS: WITHDRAW THE NUTS(22) AND WASHERS(21), PUT THE SUPPORT

TRAY(10) AND REPLACE WASHERS(21) AND SCREW NUTS(22) WITH WRENCH(29)

INCLUDED WITH THE UNIT, NOW INSERT THE NECK OF THE TRAY(2) INTO THE

HEAD STOCK (13) AND PLACE THE BACK PART OF THE TRAY(2) ONTO THE SUPPORT

TRAY(10).

F.- PLACE THE STOMPER(1) INTO THE TRAY’S NECK.

KG-12-FS

4

2.-PLACE THE GRINDER ON A FIRM AND CLEAN SURFACE THAT HAS ACCESS TO AN

ELECTRICAL POWER SOURCE, AND BE SURE IT MEETS THE POWER REQUERIMENTS

OF THE UNIT. (IF YOU HAVE ANY QUESTIONS PLEASE CONTACT YOUR PRO-CUT

DEALER).

3.- ASSURE THAT ALL LOCAL ELECTRICAL CODES ARE COMPLIED WITH.

4.-AFTER PREVIOUS STEPS WERE FOLLOWED, CONNECT THE GRINDER TO THE POWER

SOURCE, MAKING SURE THAT IT IS PROPERLY GROUNDED AND IF YOU HAVE ANY

QUESTION, PLEASE CONTACT A QUALIFIED ELECTRICIAN.

IV.- OPERATION: IMPORTANT:

FOR THE FIRST TIME USAGE, GRIND 2 POUNDS OF SCRAP CLEAN PRODUCT TO REMOVE

ANY FOREIGN DEBRIS.

THE NORMAL PROCEDURE TO OPERATE A GRINDER IS AS FOLLOWS:

1.-TURN ON THE MACHINE. (DO NOT LEAVE MACHINE UNASSISTED WHILE IN

OPERATION).

2.-PLACE PRODUCT ON THE REAR OF FEED TRAY(2).

3.-SCOOP PRODUCT TOWARDS THE FEED OPENING AND LET IT FALL.

4.-IF IT IS NECESSARY PUSH THE PRODUCT DEEPER INTO THE NECK ONLY WITH THE

PROVIDED STOMPER(1) (DO NOT USE HANDS, FINGERS OR FOREIGN OBJECTS TO

FEED PRODUCT INTO THE HEADSTOCK(13) CHAMBER).

V.- KEY ELEMENTS IN GRINDING QUALITY PRODUCT:

IT IS NOT RECOMMENDED TO FORCE FEED PRODUCT INTO THE HEADSTOCK(13)

CHAMBER.

ALWAYS ASSURE THAT THE KNIFE(18) AND PLATE(19) ARE SHARP AND FREE OF

FOOD DEBRIS.

IT IS A GOOD IDEA TO USE THE KNIFE(18) AND PLATE(19) AS A SET.

THE TENSION ON THE HEADSTOCK RING(20) SHOULD BE FIRM BUT NOT TOO TIGHT.

OVERTIGHTENING CAN LEAD TO EXCESSIVE FRICTION, MOTOR(28) WEAR AND POOR

PRODUCT APPEARANCE.

VI.- CLEANING:

ALWAYS UNPLUG OR DISCONNECT THE MACHINE FROM THE POWER SOURCE BEFORE

CLEANING OR SERVICE.

ON A DAILY BASIS IT IS RECOMMENDED TO FOLLOW THESE STEPS:

1.-DISASSEMBLE MAIN COMPONENTS AS IT WAS EXPLAINED ON THE INSTALLATION

SECTION.

2.-WASH ALL COMPONENTS WITH AN APPROVED DETERGENT.

3.-RINSE, DRY AND INSPECT ALL COMPONENTS FOR WEAR AND SHARPNESS.

KG-12-FS

5

4.-TO CLEAN CASE (5) ENCLOSURE USE DAMP CLOTH WITH DETERGENT (NEVER HOSE

DOWN OR SUBMERGE CASE ENCLOSURE IN WATER OR OTHER LIQUID). RINSE WITH A

DAMP CLOTH AND DRY.

5.-REASSEMBLE THE MAIN COMPONENTS TAKING CARE OF THE PIN(9) ALIGNMENT IN

THE HEAD WITH THE NOTCH ON THE BOTTOM OF THE PLATE . (SEE DETAIL “B”)

VII.- MAINTENANCE:

ALWAYS UNPLUG OR DISCONNECT THE MACHINE FROM THE POWER SOURCE BEFORE

CLEANING OR SERVICE.

1.-TO ASSURE QUALITY PRODUCT, YOUR KNIFE(18) AND PLATE(19) MUST HAVE SHARP

EDGES, REGULARLY REPLACE OR SEND FOR SHARPENING THESE COMPONENTS.

2.-RELUBRICATE THE NYLON WASHER (15) REGULARLY WITH THE GREASE INCLUDED IN

THE BOTTLE(25) INSPECT AND REPLACE WHEN NO LONGER SERVICEABLE.

NOTE: A SYMPTOM TO RECOGNIZE A WORN NYLON WASHER(15) IS BY TIGHTEN THE

RING TOTALLY WITHOUT OBTAINING PROPER TENSION BETWEEN PLATE(19) AND

KNIFE(18) .

3.-THE GEAR BOX OF THIS GRINDER IS SEALED AND SHOULD BE SERVICED ONLY BY

APPROVED TECHNICIAN, THE TRANSMISSION OIL SHOULD BE CHANGED AT LEAST

EVERY TWO (2) YEARS OF NORMAL OPERATION.

4.- TO INSURE QUALITY PRODUCT, REGULARLY REPLACE OR SEND FOR SHARPENING

THESE COMPONENTS:

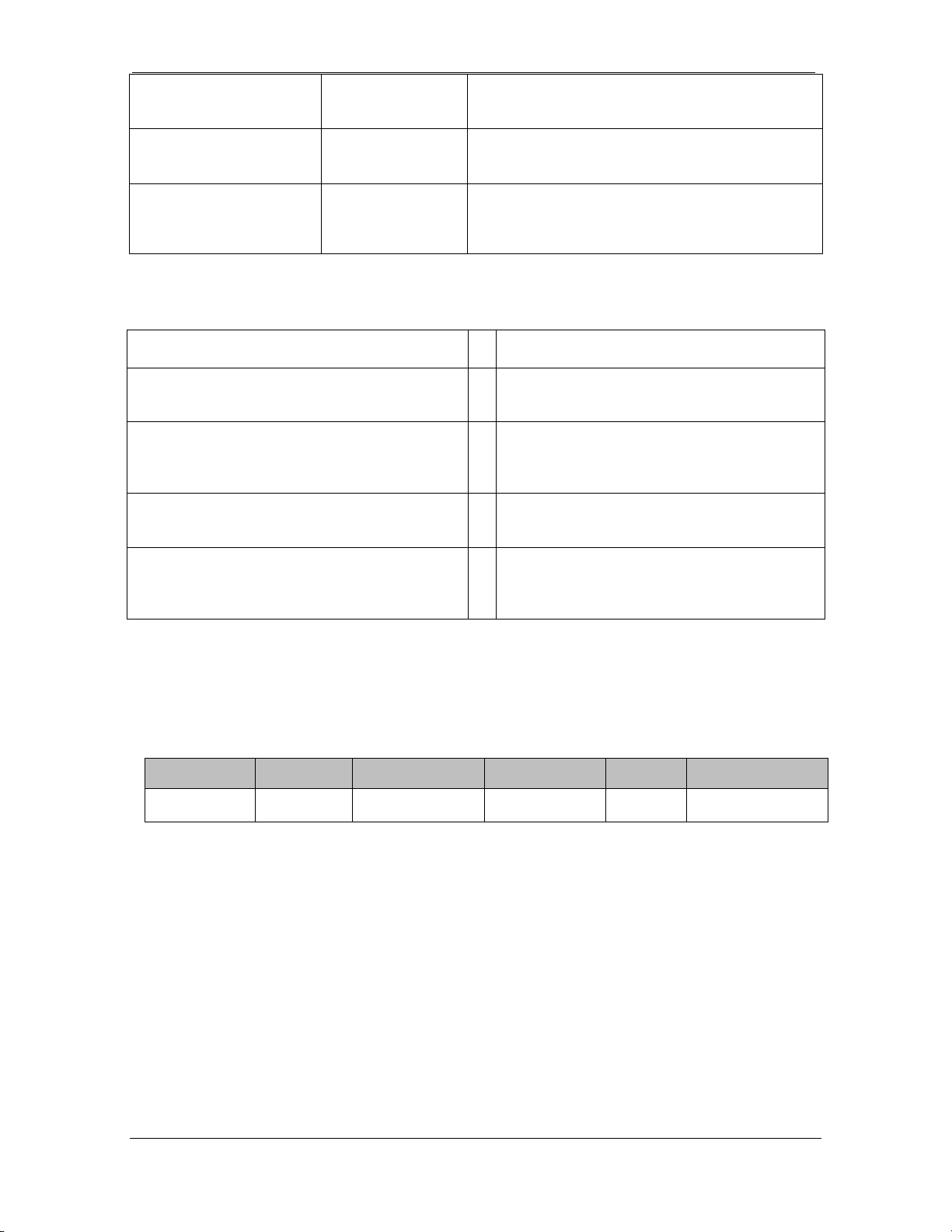

REVIEW BY CONSUMER

FREQUENCY OF

VERIFICATION

COMMENTS

BLADE (18)

PLATE (19)

ONCE A MONTH

CHECK THE APPEARANCE OF THE PLATE AND

THE EDGE OF THE KNIFE. THESE MUST BE

SUBMITTED NO SCRATCHES. IF THE MEAT HAS A

BAD PRESENTATION PLATE AND BLADE.

MEMBRANES (ON-OFF)

DAILY

CHANGE IS REQUIRED IMMEDIATELY MEMBRANE

SWITCH BREAK IN CASE OF FAILURE TO

PREVENT POST ON OR OFF THE INTRODUCTION

OF MOISTURE OR OTHER DEBRIS.

TRANSMISSION OIL

EVERY YEAR AND A

HALF

ASSESS OIL LEVEL IN ORDER TO VERIFY THE

VOLUME (SEE INSTRUCTIONS FOR EVALUATION).

IN THE ABSENCE FILL AND / OR BENEFIT FOR

NEW OIL CHANGE (CHECK WITH YOUR DEALER).

WORM (16)

ONCE A MONTH

VALIDATE THAT THERE IS NO EXCESS OF GAME

THAT ALLOWS THE BLADE CAN ROTATE ABOUT

THE PIN (DOWEL THEN REPLACE). SPIKE REAR.

REVISION APPLY BETWEEN ITSELF AND REAR

SPINDLE GEAR FRAME.

HEADSTOCK (13)

ONCE A MONTH

CHECK FRONT HEAD SCREW TO PREVENT

ACCIDENTS BAD NUT ASSEMBLY.

SURE GRIP LEVER NOT BE A STICKING WITH THE

CABINET WHEN "HOLD THE HEAD", IF THE HEAD

IS SAFARCE COULD LOOSE, IT INDICATES THAT IT

IS TIME TO CHANGE THE HEAD.

KG-12-FS

6

REVIEW BY CONSUMER

FREQUENCY OF

VERIFICATION

COMMENTS

HEADSTOCK RING (20)

ONCE A YEAR

PART REVIEW THREAD SO PREVENT ACCIDENTS

BAD JOIN IN THE HEAD

MOTOR AND SWITCH

DAILY

NOT ON THE TEAM WITH THE HEAD FULL OF

PRODUCTS AND / OR BECAUSE THIS CAUSES

ATOR HIGHER AMPERAGE PEAKS ENGINE

DAMAGE AND /OR SWITCH.

5.- PARTS TO CARE FOR WEARING OUT:

TIME

PARTS TO REVIEW

AND CHANGE

1 MONTH

NYLON WASHER (15)

6 MONTHS

KNIFE (18)

PLATE (19)

2 YEARS

TRANSMISSION OIL

4 –5 YEARS

WORM (16)

HEADSTOCK (13)

NOTE: THE TIME IS AN AVERAGE PERIOD, ITS DEPEND ON THE USAGE.

The kind of oil is SAE 80W90 or equivalent, the quantity is ¾ of liter.

VIII.- ELECTRICAL SPECIFICATIONS

MODEL

VOLTAGE

FRECUENCY

CURRENT

PHASES

MOTOR POWER

KG-12-FS

115 V~

60 HZ

10,4 A

1 Ø

559 W 3/4 (HP)

KG-12-FS

7

IX.- ELECTRIC DIAGRAM KG-12-FS:

DIAGRAMA ELECTRICO

ELECTRICAL DIAGRAM

KG-12-FS

PRO-CUT

KG-12-FS

8

X.- PARTS LIST KG-12-FS:

THANK YOU FOR READ THIS MANUAL.

ANY QUESTION PLEASE CONTACT YOUR PRO-CUT DEALER.

MODEL: KG-12-FS:

Table of contents

Other Pro-Cut Meat Grinder manuals