Pro-Cut KG-12-SS User manual

MEAT GRINDER

OWNER´S MANUAL

OPERATION INSTRUCTIONS MODEL

KG-12-SS

READ THIS MANUAL BEFORE USING THE EQUIPMENT FOR THE FIRST TIME. 507134-A

KG-12-SS

MEAT GRINDER

INSTRUCTIONS FOR OPERATION, SERVICE AND MAINTENANCE OF THIS EQUIPMENT

I.- INTRODUCTION:

Congratulations!, you have acquired a Meat Grinder, which is made of high quality long lasting materials that should give you

years of trouble free operation and durable service. This slicer is made of parts of anodized aluminum, a material with a type of

superficial coat that maximizes the appearance, reduce the oxidation and it is also the best for the contact with food products.

IMPORTANT!: it is of vital importance that you and any person that will operate this unit thoroughly read this manual.

WARNING!:

This machine is designed to grind food products only and is dangerous by

nature. For optimum safety please use and maintain this grinder properly.

This equipment must be connected to a thermal connection. Do not use the equipment if it is not properly grounded.

1

The appliance is not be used by persons (including children) with reduced physical, sensory or mental

capabilities, or lack of experience and knowledge, unless they have given supervision or instruction. Children

being supervised not play with the appliance.

Never perform service, cleaning or maintenance on this unit while connected to a power source.

Never use hands or fingers to feed products to cut; or introduce hands into the blade track area, within 4 " ( four

inches ) close to the blade, while in operation.

Do not leave the machine unattended while in operation & turn it off when it is not being used.

CONTENTS: PAGE

I. INTRODUCTION 1

II. UNPACKING 2

III. INSTALLATION 2

IV. OPERATION 4

V. KEY ELEMENTS IN GRINDING QUALITY PRODUCT 6

VI. CLEANING 6

VII. MAINTENANCE 8

VIII. EQUIPMENT SPECIFICATIONS 9

IX. ELECTRICAL DIAGRAM 9

2

MEAT GRINDER KG-12-SS

II.- UNPACKING:

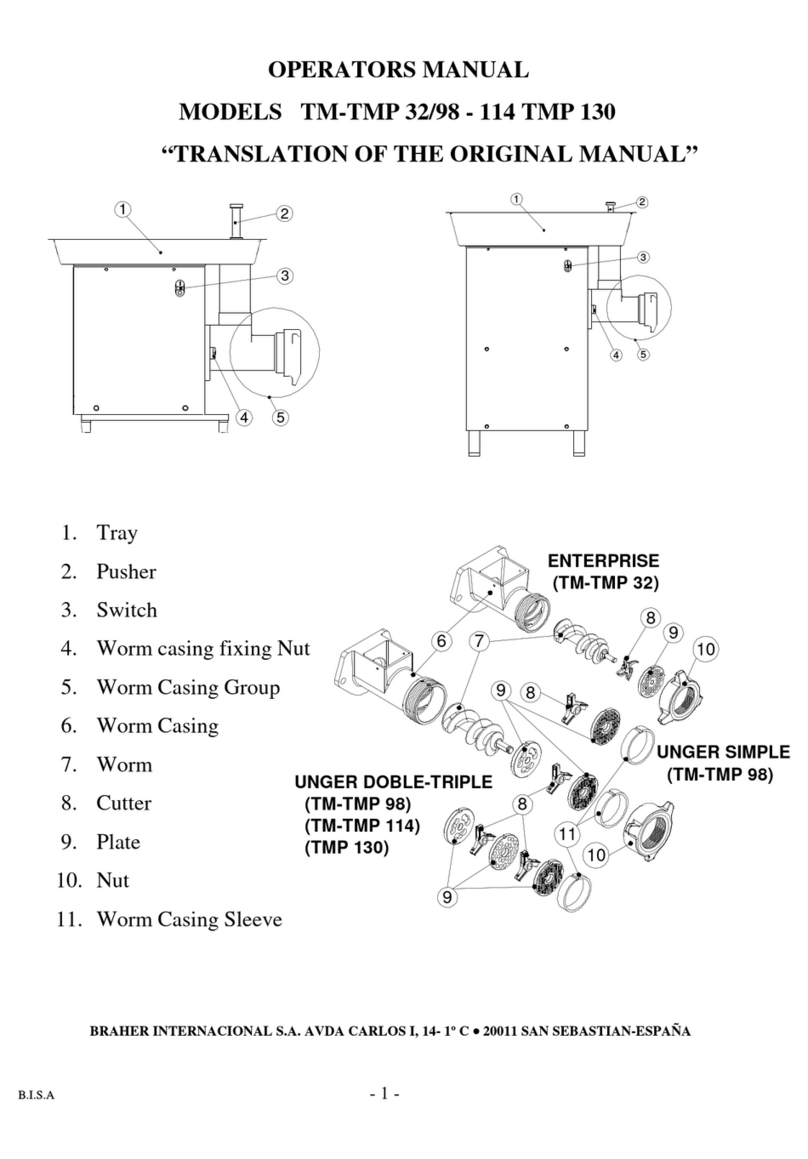

While unpacking the machine, take special care and make sure that all of the following components are accounted for*. They will

be assembled later

*Note: for reference numbers see “Meat grinder diagram for components” (central pages).

III.- INSTALLATION:

The Meat grinder is ready to use. Before installation, you only need to verify the following points:

1. Electrical installation meets the required specification of the equipment.

2. The Room must have adequate lighting and level floor/work table.

3. Room is clean and meets the hygienic conditions for food processing.

The

grinding unit includes:

Also

:

1

Headstock

(8)

1

Pusher

(1)

1

Worm

(7)

1

Product

tray (2)

1

Ring

(3)

4

Support

Legs (11)

1

Blade

or kinfe (5)

1

Plate

(4)

IMPORTANT!:

Unit must be washed before using it for the first time, especially the grinding

unit. Also, use the included food grade mineral oil to lubricate the plate (4)

and knife (5) -See Cleaning section for more details.

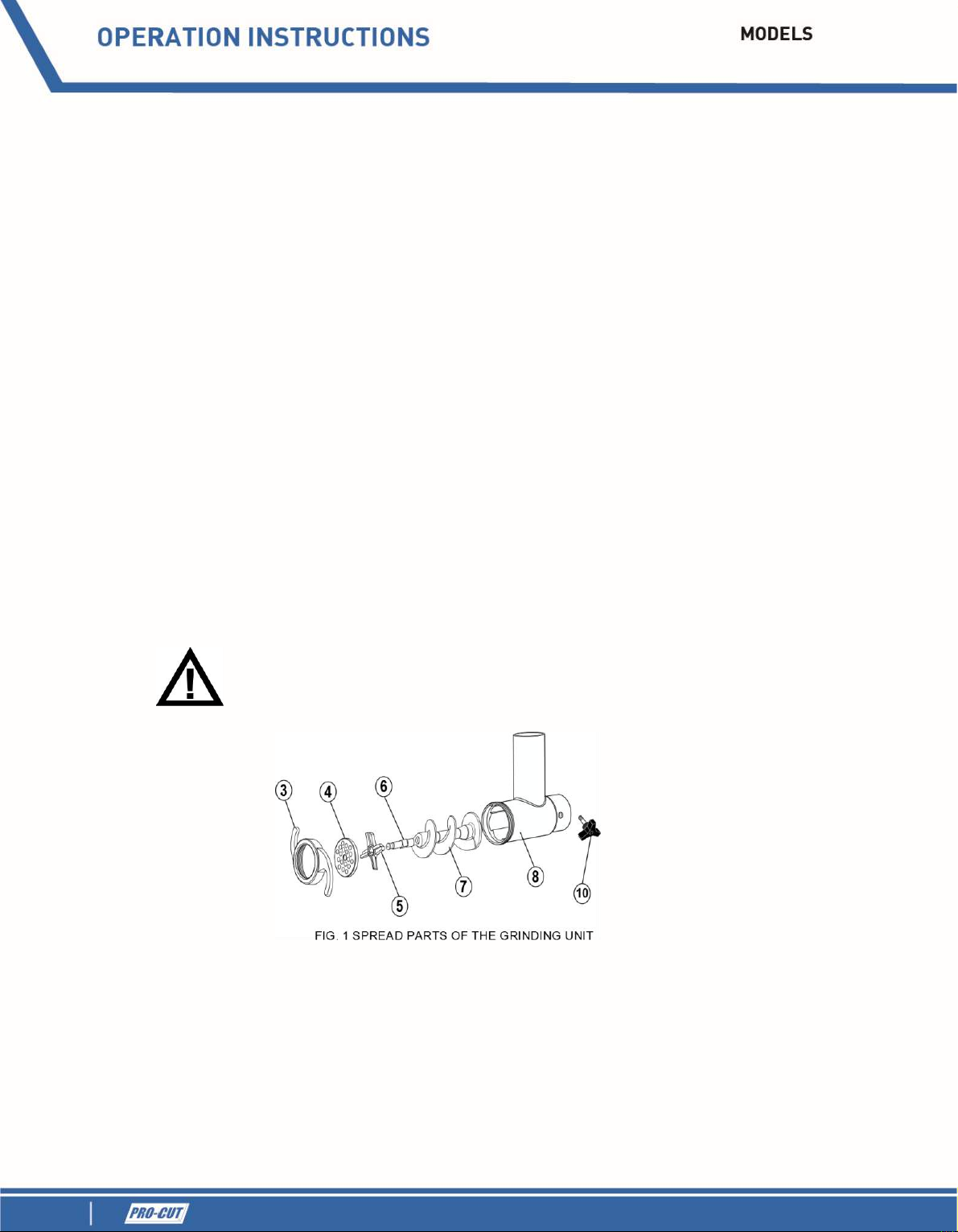

HOW TO REMOVE GRINDING UNIT .

1.- Remove the ring (3) turning it counterclockwise and extract the plate (4), Knife (5) and worm (7) (see Fig 1).

2.- Release the headstock (8) by turning the knob (10) counterclockwise and pull the headstock backward to remove it from the

equipment. (see Fig 2).

Reverse the steps and sequence to install the grinding unit again, taking special attention to the next points :

a) After assembling the headstock (8), turn the knob (10) clockwise to fix the headstock (See Fig 2).

b) The knife (5) must be inserted into the worm’s shaft. The sharp end must face forward.

3

MEAT GRINDER KG-12-SS

c) Place the plate (4) centered against the knife (5) assuring the notch matches the Headstock’s inserted pin.

IMPORTANT!:

Before fixing the knob, be sure that both headstock (8) and transmission

cover (9) are joined with no gap between them.

IMPORTANT!

Do not assemble the whole unit at the same time, this could damage the gears of

transmission. Assembling component by component extends the life and guarantee the

correct operation of the headstock and its components.

HOW TO INSTALL THE PRODUCT TRAY.

1.- Place the opening on the bottom of tray (2) over the top of the headstock (8)

2.- Push down, firmly and smoothly on the tray (2) to set it on the headstock.

IV.- OPERATION:

1.- Before starting, be sure to stand on either side of machine - (see Fig. 3)

2.- Place product on the rear of feed tray (2).

3.- Turn on the machine.

4.- Feed the product into the opening of the Headstock (8).

5.- When grinding product, make sure to only use the provided pusher (1) to push product into the headstock, without forcing it.

6.- Any time the motor is overloaded or blocked the internal thermal protection feature might turn off the motor of the meat

grinder. If this happens, please wait 15 seconds for the thermal protector is reset by itself and then turn on the meat grinder

again.

IMPORTANT!

If the meat grinder is going be used for long working hours, It is recommended to grind it for 20 minutes and let

stand the meat grinder for 15 minutes before next grinding cycle.

4

MEAT GRINDER KG-12-SS

V.- KEY ELEMENTS IN MIXING/GRINDING QUALITY PRODUCT

The meat grinder can grind at a rate of 7.4 lb/min (3,4 kg/min) at the first grinding using a 3/8”plate (not provided) and 5.7 lb/min

(2.6 kg/min) for the second grinding.

To extend the life of this grinder and to get ahigh quality final product it is recommended to follow these tips:

Periodically verify that both plate (4) and knife (5) are sharp.

Grinding Unit must be free of food debris.

The tension on the head ring should be firm but not too tight. Over tightening can lead to excessive friction, motor wear and/or poor

product appearance.

Be sure to remove the headstock, disassemble, and wash the grinding unit after each use.

Keep the equipment in clean and sanitary condition when not in use.

IMPORTANT!:

For the first time usage you must grind at least 2 pounds of clean scrap product to remove

any metallic or foreign debris that may be left from the manufacturing of the unit.

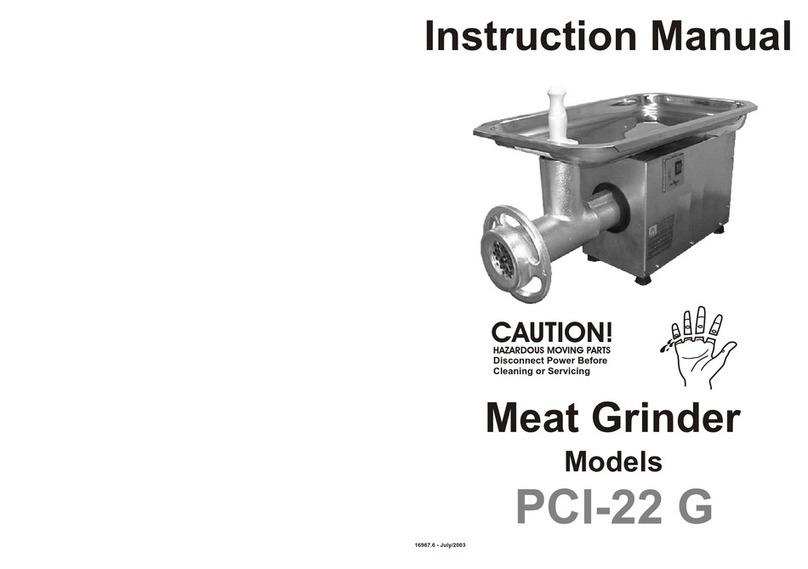

VI.- CLEANING

For cleaning the polished Stainless Steel Grinding Unit please follow the next procedures:

1.Disassemble main components as explained before in the installation section.

2.Using a soft bristle brush (not provided), -See Fig 4- clean each component with adequate detergent, especially the inside of the

headstock (8) to eliminate waste and food debris.

3.Wash every component with plenty of water.

4.Dry completely. Do not let soap cleaners dry on the surface. Rinse regularly to keep the chlorides found in most cleaners from

affecting the natural luster of stainless steel.

5.After doing this procedure it is important to lubricate both the knife (5) and plate (4) with the included mineral oil and then

reassemble.

FIG. 4 TIP FOR CLEANING ROUGHNESS PARTS

IMPORTANT!:

Avoid the use of abrasive cleaners, acid, fibers, chlorides (such as chlorine bleach), on stainless

steel surfaces, they will cause pitting, corrosion, and metal discoloration. Allowing salty solutions to

evaporate and dry on stainless steel may also contribute to corrosive conditions.

5

MEAT GRINDER KG-12-SS

VII.- MAINTENANCE

This equipment is designed to have a minimal maintenance, but, it is important to check the following:

The knife (5) and the hole’s on the plate (4) must always have sharp edges. They must be replaced after a certain period of use, or if

you noticed the quality of the ground meat is not as fine the first initial use of the knife and plate.

Replace the knife and plate when assembly becomes loose even though the Ring (3) is totally tight.

If the power cord (13)or the plug is damaged, it must be replaced by an authorized service technician or qualified personnel to avoid

risk of electrical shock.

Lubricate the entrance of the headstock, that fits into the transmission cover, (9) when you see that the approved grease has either

been consumed by use, or after cleaning. Only apply food contact approved grease contained in the bottle. It is important to always

have this part of the unit lubricated to ease the disassembly of headstock.”

The gear box of this grinder is sealed and should be repaired or opened only by approved technician, the transmission oil should be

changed at least every two years of normal operation.

CAUTION!:

Always unplug or disconnect the machine from the power supply before cleaning or

performing any maintenance.

GUIDE TO SOLVE TECHNICAL PROBLEMS.

The below information is a guideline to solve some problems with the equipment and it is addressed to the authorized technicians.

The user should not carry out any service to avoid injuries and damages, please contact your authorized dealer.

PROBLEMS

NOT TURNING

ON

NOT GRINDING

EXCESIVE

NOISE

OIL SPILL

HEADSTOCK

GAP/MOVING

HEADSTOCK

HOT

Verify the electrical connection X X

Change the switch X

Verify the applied voltage XX

Change Knife/Plate X X

Change gears X

Verify oil in transmission box X

Change the oil seal of transm. box and/or gear cover X

Remove and assemble the headstock again X

Avoid operating the meat grinder without product X

6

MEAT GRINDER

THESE ARE PARTS THAT NEED TO BE CHANGED AFTER SPECIFIC TIME OF USE..

KG-12-SS

STAINLESS STEEL SPECIAL CARE

This is aguideline of cleaning methods for stainless steel.

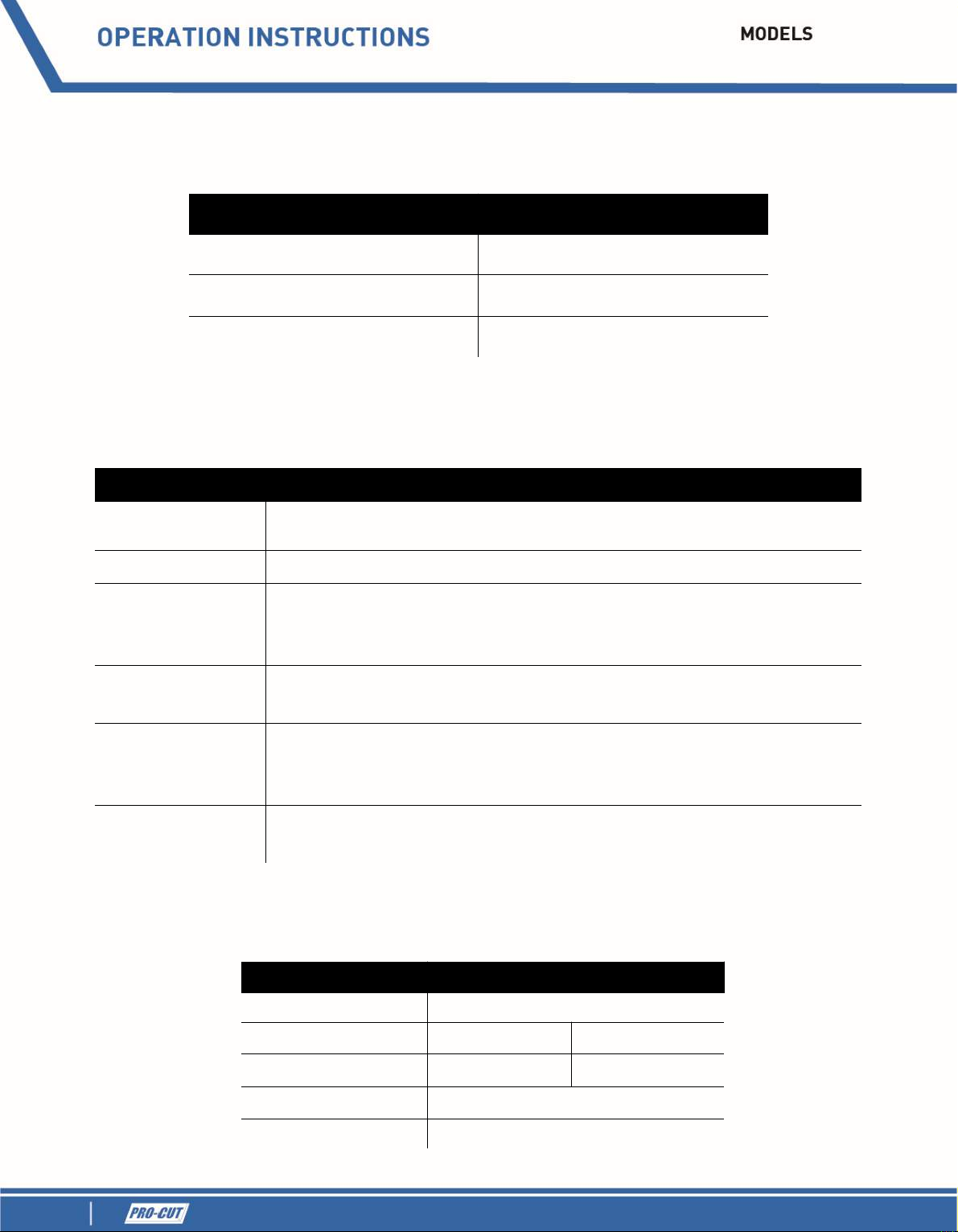

Parts to check and replace Lifetime

Knife (5) and plate (4) 3 months

Transmission oil

(See inside cabinet for oil type) 2 years

Worm (7) headstock (8) 4 to 5 years

Requirement Suggested Method

Routine cleaning of

light soiling Wash with soap or

detergent in warm clean water. Apply with a clean sponge, soft cloth or

soft-fiber brush then rinse in clean water and dry.

Fingerprints

Use detergent. Rinse with warm water. Dry totally

Watermarks

Use clean rinsing water, such as reasonable quality potable (tap) water. Drying marks

may be avoided using an air blower or wiping with clean disposable wipes.

Grease marks Use clean rinsing water, you could add white vinegar or soft water solution. Rinse with

warm water again and dry.

Rust stains Wash surface with CLR (calcium, lime & rust remover) type cleaner. Use acid free and

recommended solution. Apply using a soft non

-abrasive

sponge. Rinse surface thoroughly with clean soft water after application.

Dirt and debris

Wash surface with a mild liquid soap. Apply using a soft, non

-abrasive cloth. Rinse surface

thoroughly with clean soft water.

VIII.- EQUIPMENT SPECIFICATION

A) ELECTRICAL (Depends on your model. See ID plate)

MOTOR 3/4 HP

Capacity 0.559 kW

Frequency 60 Hz 50 or 60 Hz

Volts 120 V 220 V

RPM (Motor) 1425 (50Hz) or 1750 (60Hz)

Phases 1

7

MEAT GRINDER KG-12-SS

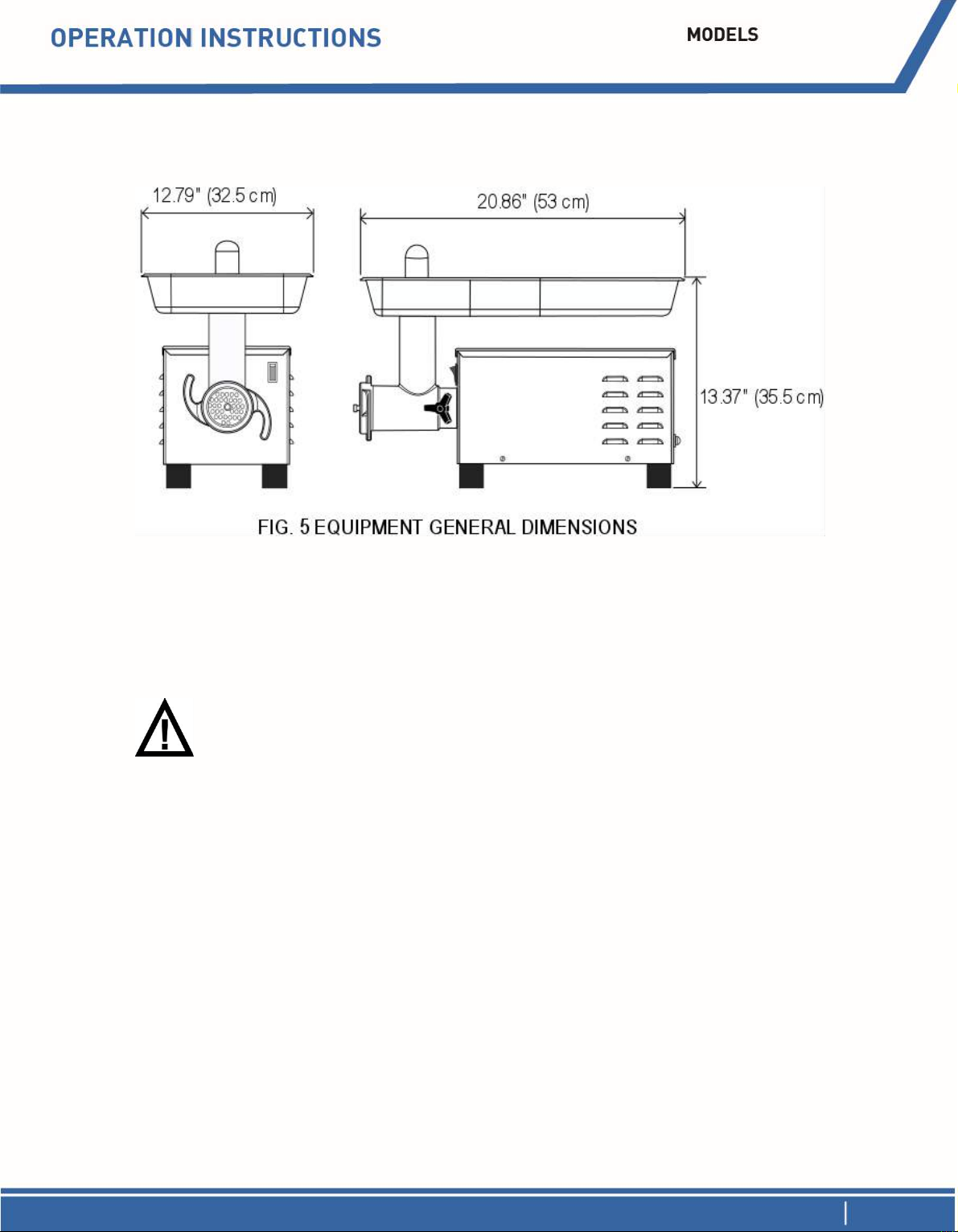

B) GENERAL DIMENSIONS

IX.- ELECTRICAL DIAGRAM

The electric diagram for this unit is located inside the cabinet.

WARNING!:

The cabinet for this equipment must be opened only by qualified personnel.

For any problem or doubt related to electrical specifications and connections, please call

to your authorized dealer.

8

MEAT GRINDER KG-12-SS

MEAT GRINDER DIAGRAM FOR COMPONENTS (SEE CENTRAL PAGES)

ITEM DESCRIPTION QTY

1

PUSHER

1

2

TRAY

1

3

HEAD

STOCK RING 1

4

PLATE

1

5

KNIFE

1

6

FRONT

ROD 1

7

WORM

1

8

HEADSTOCK

1

9

TRANSMISSION COVER

1

10

HEADSTOCK

KNOB 1

11

LEGS

4

12

SWITCH (INTERRUPTOR)

1

13

POWER CORD

1

14

THERMAL

PROTECTION 1

15

MOTOR (3/4HP

–NOT SHOWN) 1

16

CABINET

1

17

TRAY SUPPORT

1

THANKS FOR READING THIS MANUAL. IF YOU HAVE ANY DOUBT REGARDING

THE OPERATION OF THIS MEAT SAW, PLEASE CONTACT TO YOUR PRO CUT

AUTHORIZED DEALER.

Table of contents

Other Pro-Cut Meat Grinder manuals