PRO-DESIGN B-SAFE 140 User manual

page 2 of 15

PRO-DESIGN version 1.1 04.08

TABLE OF CONTENTS

1-6 GENERAL INSTRUCTIONS

1. General guidelines

2. Use with hanggliders

3. Use with paragliders

4. Limitations

5. Duration of use

6. Technical data

7-8 OPERATING INSTRUCTIONS

7. Deployment instructions

8. Packing instructions

Photo instructions

9. MAINTENANCE

Disclaimer and

Safety Notice

Warranty

page 3 of 15

PRO-DESIGN version 1.1 04.08

1. GENERAL GUIDELINES

The reserve parachute B-SAFE 140 was developed for the use with Paragliders or

Hanggliders. Our first principle when developing this chute was to make a rescue

device with quick deployment time, low sink rate and high loading capacity of the

canopy. Because of the high shock loads during deployment only materials with high

elasticity and stability are used.

The special packing method, which was tested in different trials, guarantees a fast

deployment. Immediately after the opening of the inner container the opening of the

chute starts, which means the basis starts to fill with air. The special packing ensures

a fast and symmetrical opening. DHV certification test: The B-SAFE 140 was

dropped from an altitude of 60 meters at zero acceleration with a load of 70 kg. After

two thirds of the dropping distance the rescue chute was fully deployed already. In

normal use the deployment will be even faster, because pilots in most cases throw

the chute away and accelerate the deployment this way.

The comparatively big area of the canopy reduces the sink rate. Because of the long

lines the B-SAFE 140 is much more stable than normal rescue systems. This also

reduces the pendulum effect and the touch down speed of the pilot on ground is

lower.

The construction of the inner container supports the fast deployment. A pilot chute is

attached to the container. This small chute ensures that the rescue chute moves

away from the pilot immediately even if the container has not been thrown away

powerfully and helps to pull away the inner container from the folded canopy. The

container's four-leaf-system guarantees a fast deployment and makes packing easy.

B-SAFE 140

Flat round canopy (annular) with 2 center lines and big skirt opening. Because of that

the projected area is bigger at the same normal area, wich means lower sink rate and

faster opening. Also the canopy is made of two different materials: The upper

material has more porosity than the lower material. That means a more reduced

pendulum effect.

2. USE WITH HANGGLIDERS

Not described in this manual.

3. USE WITH PARAGLIDERS

The B-SAFE 140 is equipped with a dampening part sewn in S-loops, where seams

brake during a hard deployment and dampens the shock load. It is important that the

pilot after the opening of the rescue chute pulls down the Paraglider with one of the

rear risers. This avoids a V-position of the two canopies and the pilot to move into a

horizontal position. It is also important that the rescue chute is correctly attached with

a V- attachment bridle at two points, either at both carbines or at the shoulder straps.

page 4 of 15

PRO-DESIGN version 1.1 04.08

4. LIMITATIONS

The B-SAFE 140 may only be used as a rescue system with Paragliders or

Hanggliders. It is not permitted to use this rescue device as a skydiving chute or as a

normal flying chute.

5. DURATION OF USE

The permissible duration of use is 10 years with an inspection by the manufacturer

every two years. If it is packed you are allowed to use it for 4 months then it is

recommended to re-pack (DHV recommendation).

6. TECHNICAL DATA

model: B-SAFE 140

number of panels: 22

layout area m2: 41

load with 6,8m/s in kg: 143

type: round annular canopy

recomm. load in kg: 140

max. load in kg: 140

load with 5,5m/s in kg: 115

weight in grams: 2600

7. DEPLOYMENT INSTRUCTIONS

Explanation:

If you decide to use the rescue system, follow the below described

sequence:

1. Look for the handle.

2. Grab the handle.

3. Wait for an appropriate moment and throw the container

into the free airspace powerfully.

4.The releasing power which the container needs for opening has a range

between 5 and 7 kg due to the break link (knotted thread), and depending on

the harness/handle design

Explanation:

Not much power is necessary to release the rescue package and to throw it away.

Even if you have to react very quickly in a dangerous situation, you should grab the

handle and then make sure that the opening of the rescue chute is not obstructed by

your glider. Wait for an appropriate moment and throw the container into the free

airspace powerfully.

Simulate the worst case on the ground by grabbing the handle until you are sure you

can find it even with your eyes closed. If you are trained well your action in a

dangerous situation will be safer and more efficient.

page 5 of 15

PRO-DESIGN version 1.1 04.08

WARNING

Manufacturer and seller of the rescue system B-SAFE 140 do not take any liability

for risks in Para- and Hanggliding. Also accidents, loss, improper handling, improper

maintenance, direct and indirect damages, which occur through the use of the rescue

system are in the responsibility of the pilot. It has to be clear to every pilot that this is

a rescue system, which was built to be used as the last chance if you are in an

emergency situation during flight. The rescue chute reduces the sink rate of pilot and

glider (Para- or Hangglider) and makes an emergency landing possible. The use of

the rescue chute has to be seen as a rescue opportunity but does not guarantee a

safe rescue. If the rescue chute is opened for no reason, serious injury for pilot and

damage for the glider can occur, especially at low altitudes.

8. PACKING INSTRUCTIONS

1. The rescue chute B-SAFE 140 is easy to pack but deviates a little bit from normal

rescue systems. Accuracy is the most important thing packing the chute. The right

sequence of the opening is the most important requirement for a fast and faultless

deployment of the rescue system. This fact was one of the important guidelines

during construction. Our experience is that a simple construction is more functional

and faultless.

Only the right way of packing ensures a fast and save opening. Keep on hold to the

instructions very accurate. Pilots, who are less experienced in packing rescue

systems are recommended to have the rescue chute packed by a professional.

2. To pack the chute in the right way, you need two persons. Moreover you need an

approx 50cm cord, two carbines and tension belts. The rest you are working on

should be clean, dry and should be an even place. The surface should not bring

static charge onto the chute because this could prevent the chute from opening.

3. First make sure that all top skirt lines have the same length and the top forms one

base (Photo 1). The middle lines have to be in the center that the top is pulled

symmetrically during the opening. Make sure that the middle lines are connected with

the top lines correctly (Photo 2). Photo 3 shows the wrong connection, which can

lead to a damage of the lines.

4. Now make sure that the bottom lines are also connected to the chute correctly.

The loops of the bottom lines have to be over the loops of the chute (Photo 4). The

B-SAFE 140 has lines, wich are sewn to the canopy. For the next step you need a

spare line, which has another color than the chute. This line has to be removed later

on. The spare-line has to be put through the packing loops (Photo 5). All together the

spare line should catch as many packing loops as the chute has panels. (B-SAFE

140, 22 panels). Count the packing loops that you do not forget one of them. Only

then the two ends of the spare line are tied together (Photo 6).

5. With the colored middle line the top has now to be towed through the canopy.

6. Attach a carbine to the spare line which runs through the packing loops as a

connection. With the tension belt fix the chute to the area you are working on. Make

sure that the middle lines are as long as the bottom lines. Use this as control for the

top to be towed far enough through the canopy. Make sure that two following bottom

lines are clear over the whole length, from the main bridle to the canopy. If so then all

other lines are also clear (Photo 7). As the next step make sure that the inner bottom

lines lie on the right and left side of the middle-line (Photo 8). Lay down the canopy

so that the panel NR. 1 is on the top of the right side and the last panel (B-SAFE 140:

page 6 of 15

PRO-DESIGN version 1.1 04.08

No 22) is on the top of the left side. Now connect the main bridle in the same way

you did with the other end at the top and tension it (Photo 9).

7. Make sure the bottom of the canopy forms one base (Photo 10). Now lay the

panels very neat and check them. With one hand you hold the bottom-lines together

to keep the bottom of the canopy in one base. With the other hand you take always

one panel, sleek it and count it to the other side. The helping person stands at the

other side at the top and takes the same panel, sleeks it and same time takes care

for a correct position (Photo 11). First count all panels to one side and then back to

the other side (Photo 12). Only then you make two halfs that there are half of the

panels on each side (Photo 10).

8. Now you fold about one third of each side in an angle of 45 degrees (Photo 13).

Then divide the canopy into three thirds. First lay the left part to the inside by one

third (Photo 14). After that you fold the right over it (Photo 15). The bottom-lines

should be in the middle of the base (bottom-edge of the canopy). Now the base

should be as wide as the inner container, in which the chute is packed later on.

9. Release the tension by releasing the tension belt at the packing-loops. Pull the

spare-line out of the packing-loops (Photo 16).

Do not forget to remove the spare-line; otherwise the chute will not open!

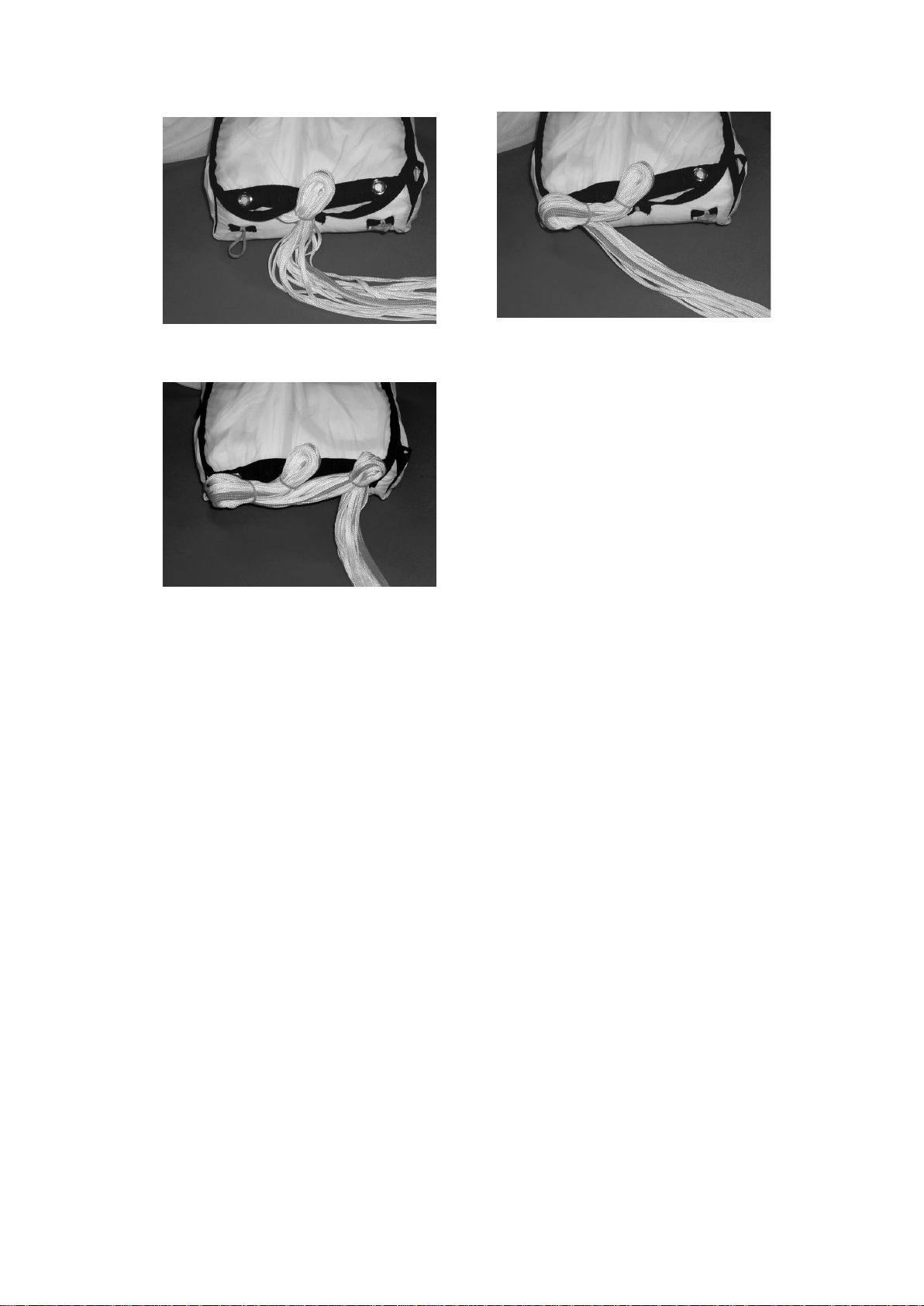

10. Now the bottom-lines are put in S-loops. The S-loops have to be as wide as the

base. With special packing-rubbers (15 x 1 x 1 mm) fix the five ends of the loops

(Photo 17). It is important that the bottom-lines keep the same length and lie flat. The

free part of the lines remains for the closure of the container.

11. Then put the inner container into a position to the chute that the double-leaf faces

the base (Photo 18). Now you can start to pack the inner container (Photos 19/20).

12. Fold the chute in S-loops; the first S-loop should include the base and the

bundled lines and should have the same width like the other S-loops (Photo 19/20).

13. Turn around the chute by 180° (turn it that it lies on the top) and put it into the

inner container that the lines are on top (Photo 21).

14. Now start to close the container. First you close the leaf with the smaller eye. The

rubber band is pulled through the eye from the inside. Make sure that the rubber knot

has enough size that it cannot move through the eye even if you pull it. Maybe you

have to strengthen the knot with a washer. Now close the opposite leaf and pull the

rubber band through the eye by using a spare-line (Photo 22).

15. Then the leaf has to be closed on which the lines run out of the container (Photo

23). It is important that you hold on to this sequence because nothing should work

against the pulling direction during the opening.

16. After you have closed the container with the fourth leaf, bolt it by blocking the

rubber band by the lines (Photo 24). Test the tension of the rubber band. If it is too

loose it is too easy to open the bolt; if it is too strong it will be too hard to open.

17. Now close the second part of the double leaf. First pull the packing rubber in the

middle through the middle eye. (Photo 25). The packing rubbers on the right and left

side are now pulled through the eyes in the cover and each has to be fixed with a S-

loop of the bottom-lines (about 3cm) (Photo 26/27).

page 7 of 15

PRO-DESIGN version 1.1 04.08

1. same length?

5. spare line...Attention! Dont forget

to remove afterwards!

4. control the bottom lines...

6. dont forget one of them.

and fix it.

2. correctly connected

7. inner bottom lines left and right... 8. ...are free.

3. wrong connection..take care of

damage..

page 8 of 15

PRO-DESIGN version 1.1 04.08

9. ...and tighten it. 10. all in one base?

11. Count every panel 12. until one half is on the right

one on the left.

13. fold about one third in 45° 14. fold left side inside (one

third)...

15...after the right side. Fix it 16.! Remove the spare line!

page 9 of 15

PRO-DESIGN version 1.1 04.08

17. S-loops. 5 packs.

19

18. Fold canopy the same width

like the container...

20

21. turn 180° and put it in the

container. 22. pull the rubber through the

middle eye...

23. ...leaf by leaf... 24. ...and fix it.

page 10 of 15

PRO-DESIGN version 1.1 04.08

25. close the container... 26. in the right order!

27. ready!

18. There is also the opportunity to put a swivel-joint in between, which avoids

twisting of the rescue chute if you get into a rotation (Hanggliders).

19. Put the main connecting cord into the outer container so that everything can open

one after the other. Put the rescue container into the outer container like it is

mentioned in the owners manual of your harness!

DO NOT FORGET TO REMOVE THE SPARE-LINES.

20. Check the function by a test opening!

page 11 of 15

PRO-DESIGN version 1.1 04.08

9. MAINTENANCE

To keep the rescue system in good condition, keep hold on to the following advices:

- Store the rescue system in a dry room with normal temperature. If the

humidity is too high the canopy will stick together what could prevent an

opening.

- Every four months you should open the chute check and pack it. The

periodical packing makes sure that the rescue system is always ready to use

and you get more confident with packing.

- Every two years you should bring your rescue system to PRO-DESIGN or to

a proffessional packer to have it checked.

- After each rescue opening the rescue chute has to be checked by the

manufacturer.

- Under no circumstances you should try to repair the chute yourself. Even

small damages have to be repaired by the manufacturer.

- Oils, fats and paints may not get close to the rescue system because this stuff

could damage the material.

- Protect the rescue system against direct sunshine because Nylon can get

damaged by UV-radiation.

- If the canopy or the lines are soiled clean them only with water and give them

enough time to dry before you pack again. Do not use detergents. Hang up

the chute in a dry room in which the air can circulate (Not in the garage or in

the basement!) Do wait until the chute is dry before you pack it.

- If the chute gets in contact with salt water it has to be swept with normal

water.

- Make sure that there are no grass, insects or other items between the widths

before you pack the chute.

- The surface you are packing on should not damage the rescue system and

should not charge it statically.

- On the last page of the included packing proof you find the checking proof in

which all repairs and checks have to be recorded.

DISCLAIMER AND SAFETY NOTICE

By the purchase of our equipment, you are responsible for being a certified

paraglider pilot and you accept all risks inherent with paragliding activities including

injury and death. Improper use or misuse of equipment greatly increases these risks.

Neither PRO-DESIGN nor the seller of equipment shall be held liable for personal

or third party injuries or damages under any circumstances. The pilot is in charge for

the start-up of the product. The operating licence and warranty expires, if any

inappropriate repairs or technical changes are being done.

The airworthiness is to be controlled before each flight. Launching is only allowed

with a flightworthy equipment. Moreover the pilot must catch up on the present

weather conditions before each start and constantly observe weather development.

Launch should only be proceeded, if the further weather development allows for a

safe flight operation.

This product was developed for Paragliding and is not suitable for Free-fall and

therefore not suitable for sky diving.

Moreover we disclaim liability, if one or several of the following points apply:

page 12 of 15

PRO-DESIGN version 1.1 04.08

- Launching beyond permitted weight range

- wind velocities more than 15 km/h and/or turbulent weather conditions

- Launching into lee sides

- Launching in rain, fog or snow fall

- Flying in clouds

- Aerobatics

- Extreme flying manoeuvre with angles over 30°

- Less experience or training of the pilot

- Incomplete, not certified or damaged equipment (helmet, emergency chute,

etc..)

- Winch towing with non-certified winch or non-certified Pilot and/or winch

operator

- Non-certified changes on harness

Please note:

If any aspect of the use of our equipment remains unclear, please contact your local

paragliding instructor, reseller or the importer in your country.

WARRANTY

Extent of the Guarantee

1. PRO-DESIGN guarantees for every product which has been delivered after

01.01.2008 for the period of 1 year. This guarantee covers failures caused by

material or production problems for which PRO-DESIGN should be responsible.

2. This Guarantee is valid for all DHV-certified products from PRO-DESIGN, that are

used for leisure flights. The guarantee does not include products which are used for

educational or professional purposes.

The following points are also excluded from the guarantee:

a) Color fading from the fabric

b) Damage by solvents, fuel, chemicals, sand or sea water.

c) Accidental damage before, during and after the flight caused by accidents and

emergency situations

d) Damage caused by negligence

e) Damage caused by force majeure

Terms of Guarantee

1. The product is to be used and maintained in accordance with the instructions that

are part of the manual and other documents. This includes in particular careful

drying, cleaning and storage of the product.

2. All prescripted checks and repairs are to be carrried out exclusively by

PRO-DESIGN or by technical aviation companies that have been explicitly charged

with such repairing or checking by PRO-DESIGN. Every modification or repair has to

be documented completely and correctly according the guidelines issued by PRO-

DESIGN.

Warranty

Any claim under the warranty which is accepted will be handled as follows:

1. If a warranty claim is accepted for a product which is not more than 6 months old, it

will be repaired at no charge.

2. If a warranty claim is accepted for a chute which is more than 6 months old or

which has had more use, it will be replaced by a used product which is either at least

equal in value to, or better than, the original product.

page 13 of 15

PRO-DESIGN version 1.1 04.08

3. The customer also has the option of acquiring a new product if an appropriate

amount is paid to make up the difference in value.

Good faith

PRO-DESIGN is under no obligation beyond those described above. It is possible,

however, that it will make a good faith settlement.

PRO-DESIGN

Hofbauer GmbH., PRO-DESIGN & SUNFLIGHTCRAFT

Zimmeterweg 4

A-6020 Innsbruck

Tel: +43 (0)512 546444

Fax: +43 (0)512 546445

www.pro-design.at

page 14 of 15

PRO-DESIGN version 1.1 04.08

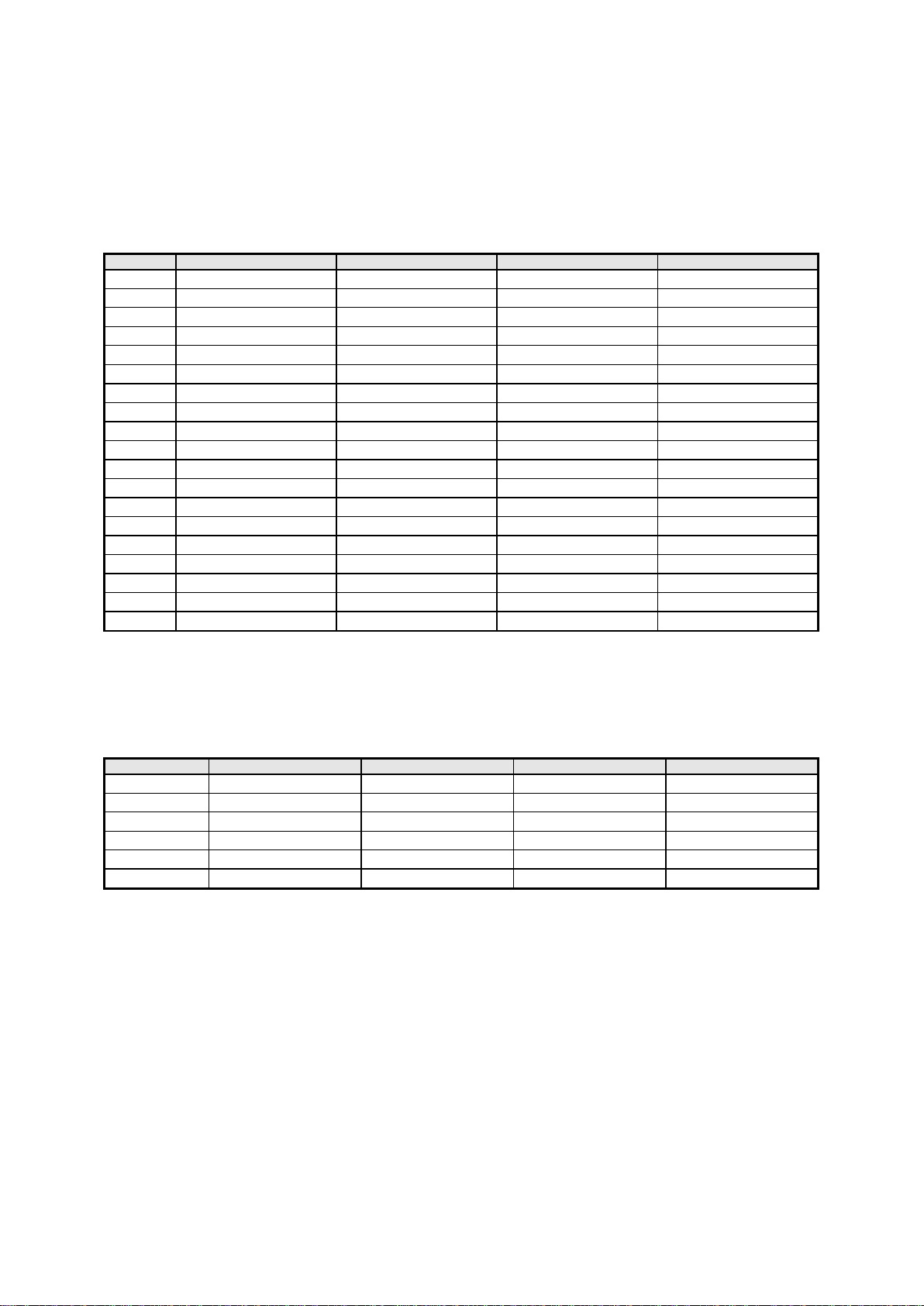

PACKING- AND CHECKING BOOKLET

RESERVE SYSTEM B-SAFE 140

Type: B-SAFE 140

Manufacturer: PRO-DESIGN

Zimmeterweg 4

A-6020 Innsbruck, Austria

page 15 of 15

PRO-DESIGN version 1.1 04.08

Date of manufacture: ........................

Serial number: ........................

Certification number: ........................

Recommended max. load: 140 kg

Max. permissibe load: 140 kg

SUMMARY OF PACKING- AND CHECKING PERIODS

DATE

WORK DONE

DEPLOYMENTS

RESULTS

SIGNATURE

It is recommended to have the reserve system re-packed and checked every 4 months. If you do not

follow this advice, slow opening or even failure of the operation may result.

CHECKS

NUMBER

WORK DONE

RESULTS

NEXT CHECK

DATE, SIGNATURE

1

First general check

To be re-checked every two years.

Changes reserved.

Table of contents

Other PRO-DESIGN Aircraft manuals