29. Mark out where the carbon reinforcement ribbons are to be placed. They should be centered

approximately 25mm (1”) behind the marked location for the fin slots and aligned so that

each one is roughly parallel with the main spar on their half of the wing.

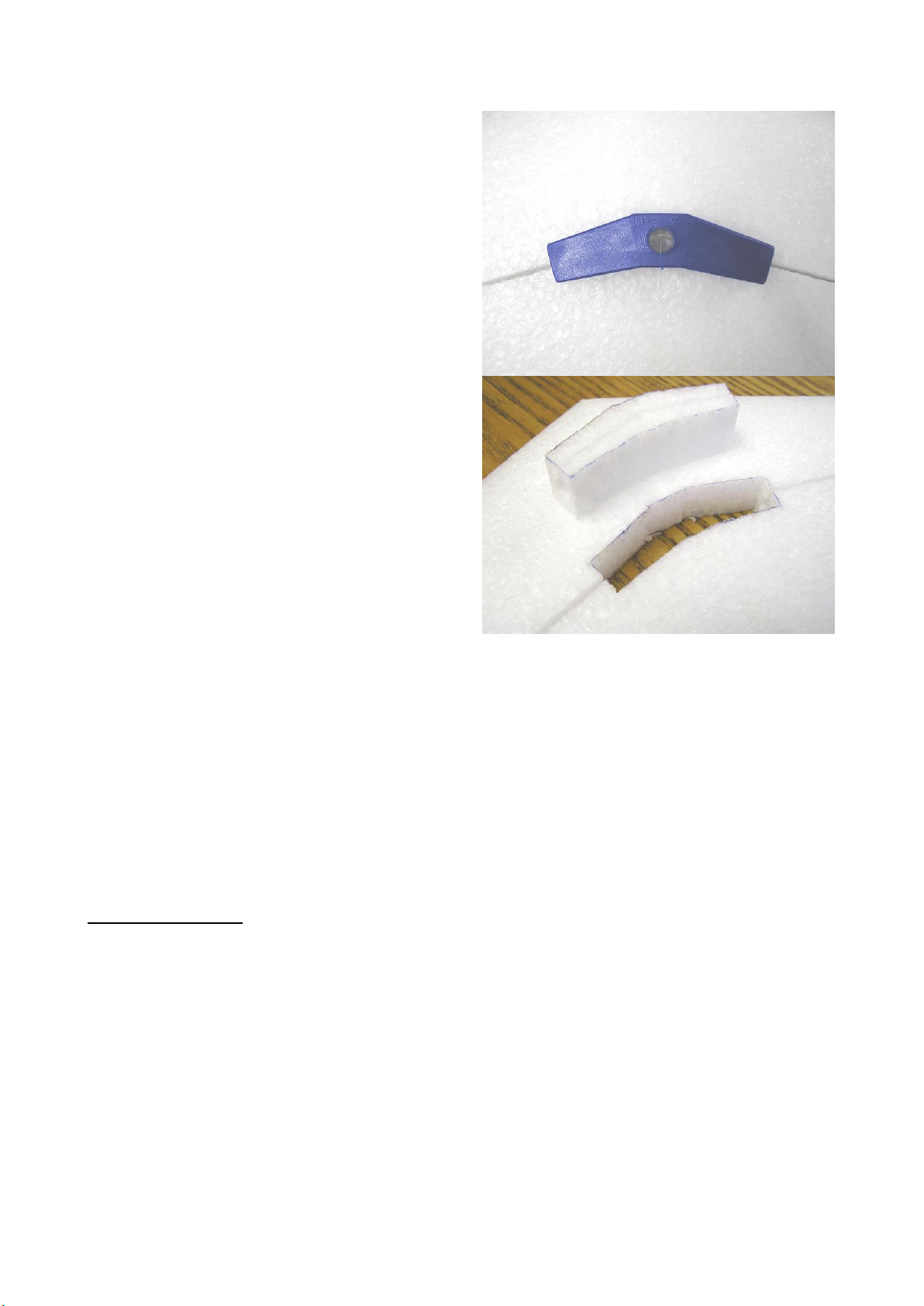

30. Cut vertical slits about 10mm (3/8”) deep for the carbon ribbon along the lines marked and

test fit to ensure correct depth (they should be flush with the top surface of the wings at

either end).

31. Once you’re happy that the carbon reinforcement ribbons fit nicely, glue them in place with

thin CA glue or epoxy. It’s a good idea to place the wing back in its beds while the glue

cures to ensure correct alignment.

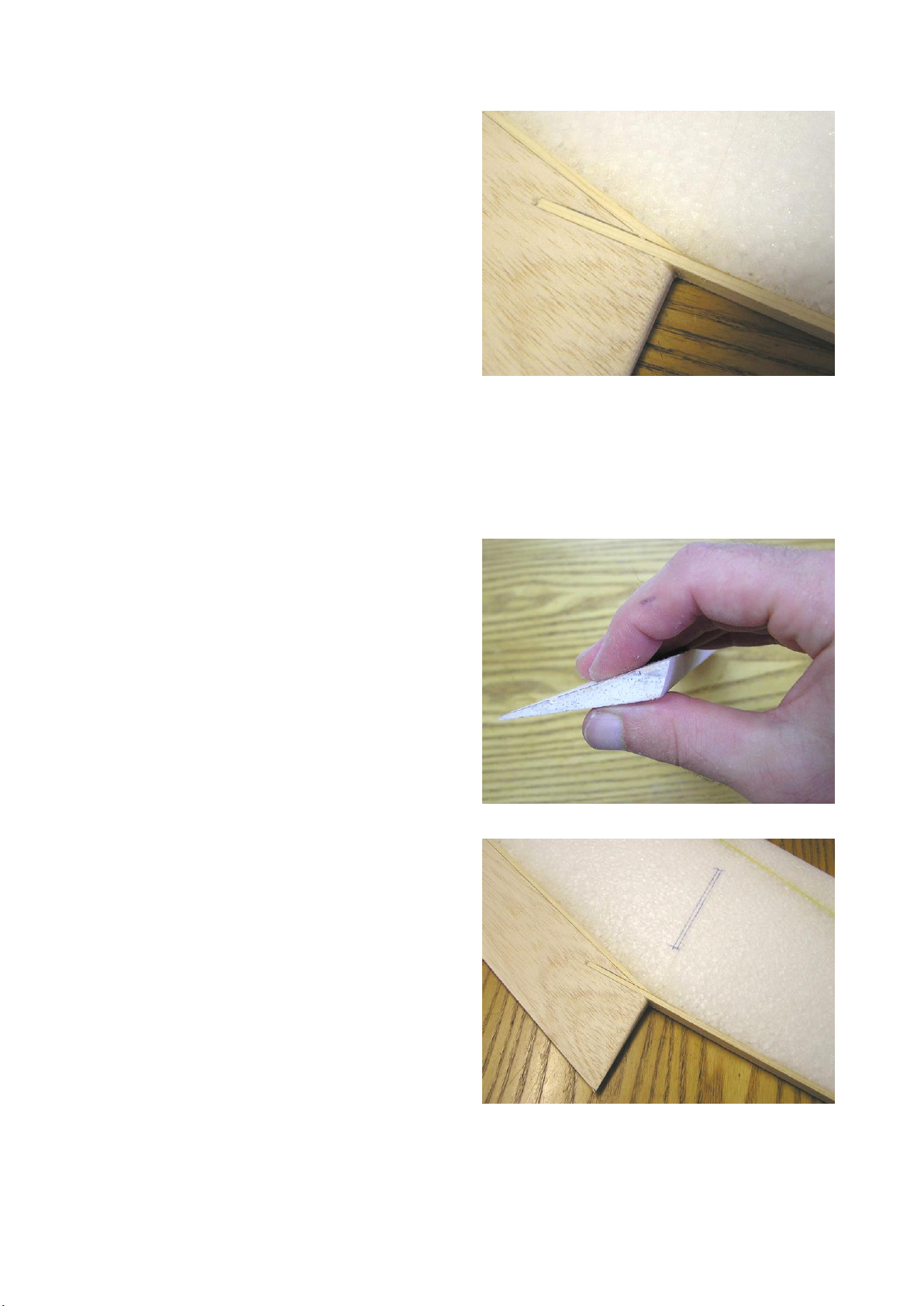

32. Use a light-weight spackle/filler to fill in any voids above the carbon reinforcement ribbons

if required. Then sand smooth to the contour of the wing.

33. Now cut out the fin slots along the outlines you marked earlier. Cut all the way through the

wing with a very sharp blade, being extra careful to keep the cuts vertical. Poke out the foam

from the slots with the end of a ruler or a metal pushrod.

34. Test fit the fins to ensure that they fit tightly into the foam in a vertical position and that

their trailing edge is in line with the wing’s trailing edge (NB: If drag spars were installed on

the inner panels, the balsa trailing edge will need to get trimmed a little to match the width

of the elevons). When pushed all the way down, the fins should butt up against the top

surface of the wing. Trim the bottom edge of the fins to match the wings contour if

necessary. Once you’re happy with the fit remove the fins and put them aside for later.

BALLAST TUBE INSTALLATION

This section of the instructions are for those with a S-15 ballast kit. These can be purchased

separately in addition the standard S-15 kit and contain the following:

•1 x length of 9/16” (14mm) diameter brass tube

•1 x length of 1/2” (13mm) diameter brass tube

•1 x length of pine dowel

•1 x EPP foam “jacket” for brass ballast tube

Installation of a ballast tube is optional but recommended so as to achieve optimum flying

performance in a wider range of conditions. Ballast weight is added to a glider to make it fly faster

through the air. The amount of ballast weight able to be added is dependent on the amount of lift

being generated by the slope you’re flying from. Increasing weight is particularly useful in windy

conditions to maintain good penetration into the wind. Ballast adjustment is also crucial for

competitive racing, enabling the glider’s wing-loading to be optimized for any given set of flying

conditions.

For “dynamic soaring” (DS) however, one should aim for as little ballast weight as possible. Extra

weight should only be added if it’s needed for penetration through turbulence and retention of

energy through the circuit. Unlike “normal”slope soaring in which the airfoil relies on gravity

(weight) as its fuel for generating speed, DS simply relies on differential airspeeds and gravity

becomes insignificant as a source of acceleration. Extra weight during DS increases the in-flight

stresses on the airframe and decreases the efficiency with which the airfoil generates the necessary

lift to counteract the centrifugal forces of its elliptical circuit, both of which lead to a lower potential

top speed and a slower rate of acceleration.

The ballast tube must be positioned exactly on the finished glider’s CG position to avoid any

balance changes with ballast adjustment, so only go ahead with the installation at this point if