PRO-DESIGN Twin User manual

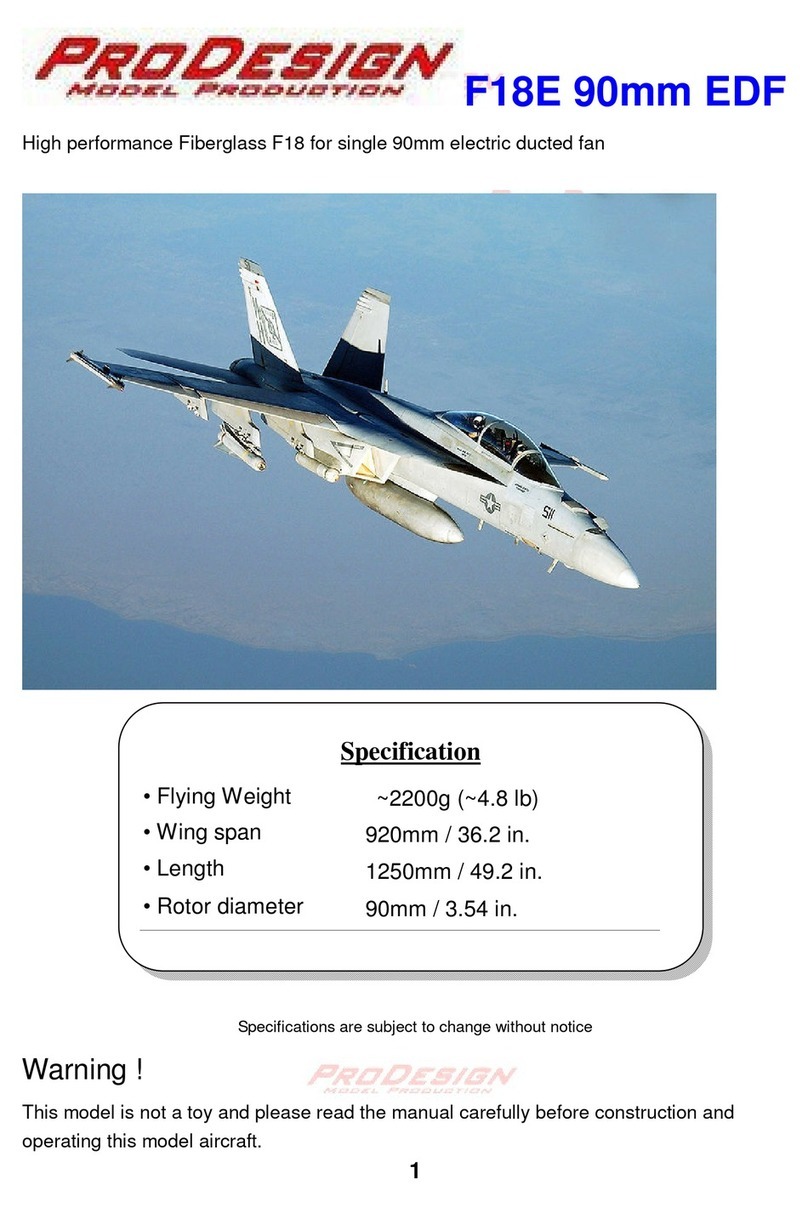

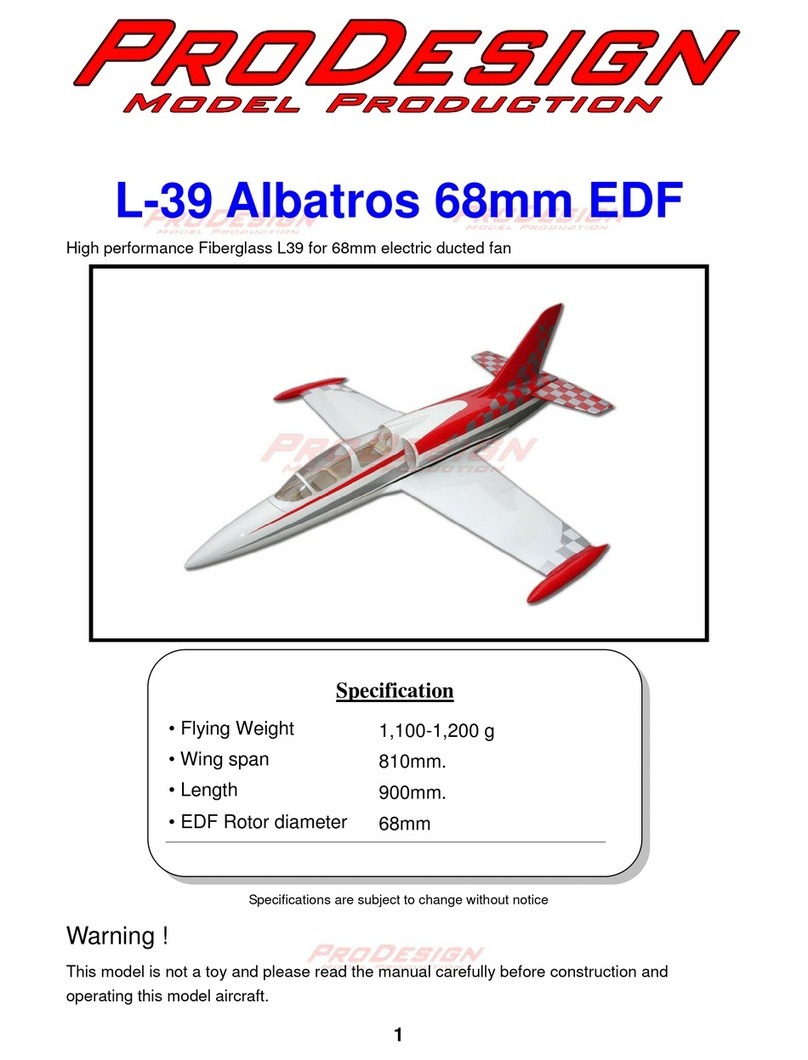

This manual suits for next models

1

Table of contents

Other PRO-DESIGN Toy manuals

Popular Toy manuals by other brands

Spinmaster

Spinmaster BOOM BOOM BALLOON instructions

FREE AIR

FREE AIR Mig-29 Fulcrum Assembly instructions

De Agostini

De Agostini Millennium Falcon 3 Series Assembly instructions

Sebart

Sebart KatanaS 30E Assembly manual

V-tech

V-tech 80-067848 user manual

Top R/C Hobby

Top R/C Hobby F4U Corsair Assembly manual

LaserPegs

LaserPegs MUD BOG RACER ZD 110B instruction manual

Spinmaster

Spinmaster AIR HOGS MISSION APLHA Instruction guide

KNEX

KNEX Power Tower Crane 63149 Instruction book

Hobby King

Hobby King Mellizo-50e manual

V-tech

V-tech Go!Go! Smart Wheels Park & Learn Deluxe... user manual

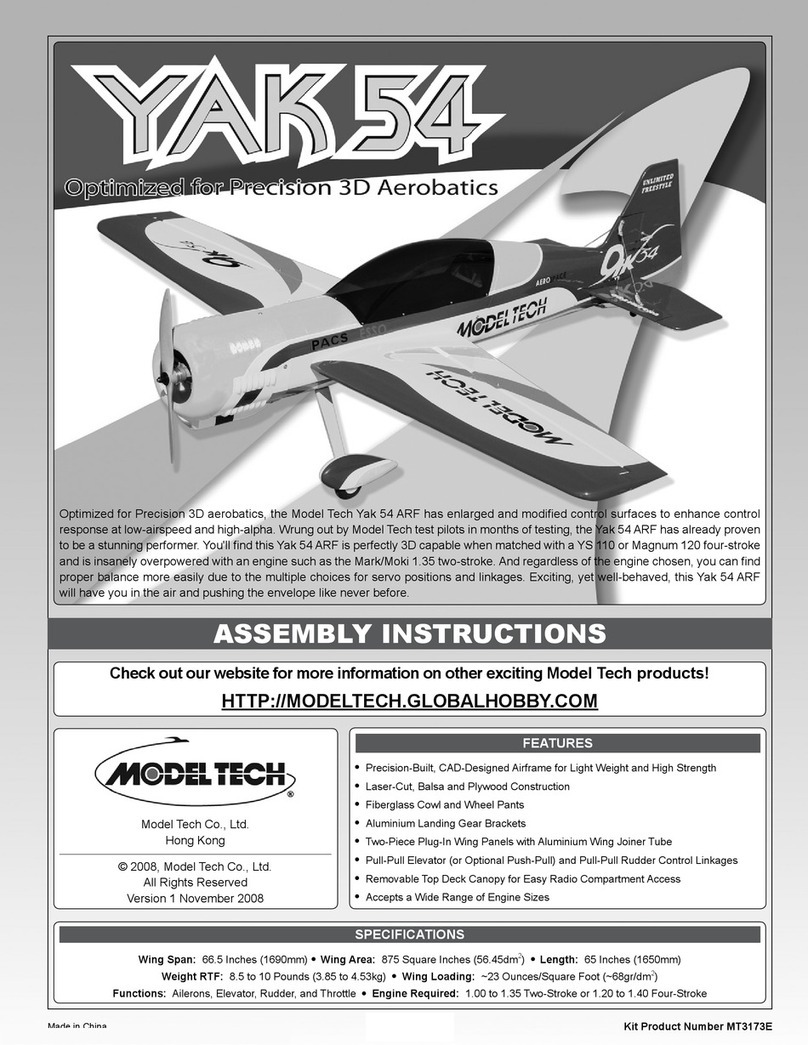

Modeltech

Modeltech Yak 54 Assembly instructions

V-tech

V-tech Grip & Go Steering Wheel Parents' guide

V-tech

V-tech V.Reader user manual

LaserPegs

LaserPegs Speed record PB216OB Assembly instruction

V-tech

V-tech GearBuddies Lion & Mouse Parents' guide

V-tech

V-tech Voyager Adventure System user manual

V-tech

V-tech V.Smile Baby: Learn & Discover Home user manual