PRO-DOME PD-15 User manual

PD15 Page 1

Technical Innovations

1271 La Quinta Dr. Ste 6

Orlando, FL 32809

407-601-1975

www.homedome.com

Assembly Instructions for PRO-DOME Observatory PD-15

S/N ________________

Congratulations.

You have purchased a PRO-DOME® observatory, which will serve you well in the

years to come. We are sure your new dome will increase your enjoyment of observing,

and help you be a more active astronomer.

Even though you will be constructing the equivalent of a small building, the PRO-

DOME is easy to assemble. However, it is essential that you read these instructions

because the assembly involves the handling of fairly large structural pieces, use of power

tools, and the need to perform mechanical assembly. Assembly should be an enjoyable

experience, so take your time and be careful.

We hope and believe that you will be happy with this product. We ask that you let us

know of any suggestions or criticisms of our products. We have incorporated many ideas

from customers into these instructions, and into the PRO-DOME design. We thank all

who contributed (and you are the beneficiary!) If, at any time, you have questions, please

feel free to give us a call so we can help you. Our aim is for you to be satisfied!

JERRY SMITH

Technical Innovations

PD15 Page 2

CAUTION

Handling fiberglass improperly can result in skin injury, while failure to perform

several easy, but crucial, steps in the PRO-DOME assembly can cause the PRO-DOME

not to operate properly. In addition, failure to follow recommended assembly may result

in injury during or after construction. Please at least scan all parts of these instructions,

even those parts covering skills you already have.

Technical Innovations is not responsible and assumes no liability for any damage

or injury arising from assembly or use of this product. While the instructions include

cautions and warnings, it is ultimately the customer who must exercise good judgment

and care in the assembly and while the observatory is in use to avoid damage to materials

or persons, and it is the customer who assumes all risk and liability.

NOTICE

All portions of this instruction manual are copyrighted by Technical Innovations, 1998, and are protected

under the laws of the United States. This document may not be reproduced without the consent of

Technical Innovations, except for use by the purchaser during assembly.

This observatory is patented, US Patent 5,448,860.

PD15 Page 3

Table of Contents

Table of Contents.........................................................................................................................3

PARTS LIST PD-15 ....................................................................................................................5

BOLT COUNT FOR BASIC PD-15............................................................................................6

1. Introduction to Instructions..........................................................................................7

Building Permits...........................................................................................................................7

Foundation....................................................................................................................................7

Foundation bolts...........................................................................................................................7

Installation Practices ....................................................................................................................8

2. Safety Precautions........................................................................................................9

Fiberglass .....................................................................................................................................9

Construction and Operation Cautions...........................................................................................10

3. Special Assembly Instructions.....................................................................................11

Nomenclature...............................................................................................................................11

Locating Holes .............................................................................................................................11

Drilling and Bolting .....................................................................................................................12

Leveling the Foundation, Wall, and Base Rings ..........................................................................12

Leveling with Carpenter Level.....................................................................................................13

Leveling with Water Level...........................................................................................................13

Making the Observatory Circular, and maybe Centered...............................................................13

4. Foundation ..................................................................................................................15

Ring Foundation...........................................................................................................................15

Pier Foundation............................................................................................................................15

Concrete Pad ................................................................................................................................16

Wood Deck ..................................................................................................................................16

5. Wall and Base Ring Assembly.....................................................................................17

Wall/Base Ring and Semi-Door Assembly Instructions...............................................................17

First Ring Assembly.....................................................................................................................18

Installing First Ring on Foundation..............................................................................................19

Door and Stub Sections Assembly ...............................................................................................20

Completing the wall .....................................................................................................................20

Base Ring Installation ..................................................................................................................21

Roller Mounting...........................................................................................................................21

Dome Drive Preparation...............................................................................................................22

Base Ring Assembly.....................................................................................................................22

Hinge Installation.........................................................................................................................22

Latch Installation..........................................................................................................................22

Wall Bracing ................................................................................................................................24

6. Dome PRE-Construction .............................................................................................25

Dome Support Ring (DSR) ..........................................................................................................26

Rear Cover Preparation................................................................................................................26

Front Shutter Preparation .............................................................................................................26

Top Shutter Preparation, Latch, Wind Restraint ..........................................................................28

Dome Quadrants Sub-Assembly...................................................................................................28

Shutter Cable Pulley Installation..................................................................................................29

7. Dome assembly and shutter installation.......................................................................30

Rear Cover Installation.................................................................................................................31

Dome Inspection ..........................................................................................................................31

Final Dome Bolting......................................................................................................................31

Shutter Catchers ...........................................................................................................................33

Shutter Installation .......................................................................................................................33

Initial Manual Shutter Operation..................................................................................................33

PD15 Page 4

Shutter Latch Check.....................................................................................................................34

8. Electric Shutter Installation..........................................................................................35

Introduction..................................................................................................................................35

Electric Shutter Theory ................................................................................................................35

Power Supply Installation.............................................................................................................36

Cable Pulley Installation ..............................................................................................................36

Drive Motor Installation...............................................................................................................37

Cable Installation..........................................................................................................................37

Contact Plate Installation..............................................................................................................38

Motor Drive Wiring .....................................................................................................................38

Cable Adjustment.........................................................................................................................38

Operation......................................................................................................................................39

Electric Shutter Maintenance .......................................................................................................39

Manual Operation.........................................................................................................................40

Emergency Entry..........................................................................................................................40

9. Electric Dome Drive Installation .................................................................................42

Introduction..................................................................................................................................42

Drive Plate Installation.................................................................................................................42

Drive Plate Wiring .......................................................................................................................42

Dome Drive Operation.................................................................................................................42

10. Shutter Lock Installation (Option).............................................................................44

PRO-DOME Lock Installation.....................................................................................................44

11. Finish Work & Accessories .......................................................................................46

Shutter Restraint System ..............................................................................................................46

DSR Safety Brackets....................................................................................................................48

Soffit.............................................................................................................................................48

Safety Device. ..............................................................................................................................48

Anti-rotation Bolts........................................................................................................................48

Caulking.......................................................................................................................................48

12. Problem Solving.........................................................................................................50

Dome Rotation Problems .............................................................................................................50

Shutter Engagement Problems......................................................................................................51

Shutter Dis-engagement Problems ...............................................................................................51

Shutter Blow-off...........................................................................................................................52

Base Ring Service ........................................................................................................................52

13. Use and Care of your PRO-DOME............................................................................53

APPENDIX 1 BOLT HOLE DRILLING GUIDE..........................................................

APPENDIX 2 ILLUSTRATIONS..................................................................................

Figures (Some numbers intentionally left blank)

Circular Skirt Installation (optional)

Terms, Warranties, Disclosures

Operating Instructions

PD15 Page 5

PARTS LIST PD-15

Fiberglass Pieces

Front Quadrants, one each Left & Right

Rear Quadrants (with notch in slot edge), one each Left & Right

Dome Support Ring Sections (4 pcs including door swingout)

Rear Cover (1)

Top Shutter (1)

Front Shutter (1)

Base Ring Sections (7 including molded door, stub sections)

Fittings and hardware

Stainless Steel Carriage Bolts

Stainless Steel Flat Head Bolts

Nuts, washers

Front Latch (40 in long)

Rear Latch (27 in. long)

Shutter Catcher/Wind Restraint Brackets (2)

Wheels (48) and Side Rollers (24)

Handles (2)

Shutter Restraint System (cables, bolts, etc.)

Shutter bearing strips (5 pcs) & surface cleaner

Front Shutter Edge Molding

Rear Opening Cover (Soffit)

Semidoor hardware (upper and lower latches, piano hinge, safety latchers, bolts)

Electric Dome Drive (4 motor plates, hardware, cable)

Electric Shutter (drive motor, cables, pulleys)

Power supply (PS-2) w/ hardware

Caulk

Instructions

Tools Required by Purchaser (not included with PD-15)

3/8 in electric drill, bits

(two drills are even more efficient)

Countersink (82 deg. preferred)

File or rasp

Metal rule (25 ft. or longer)

Carpenter level or water level

Hand tools: clamps, screw drivers, socket wrench set, etc.

Large metal square & straight edge

Duct tape

Caulking gun

Gloves, Eye Protection

Stepladders (6 ft., 12 ft.)

Worktable - Sawhorses & plywood OK

Extension cords

Foundation bolts, fender washers

Shims & spacers for leveling**

PD15 Page 6

** Shims –have several thicknesses available (such as 1/8”, ¼”). The design shown

here is useful because you can slide it in under the fiberglass and around a bolt without

having to remove everything.

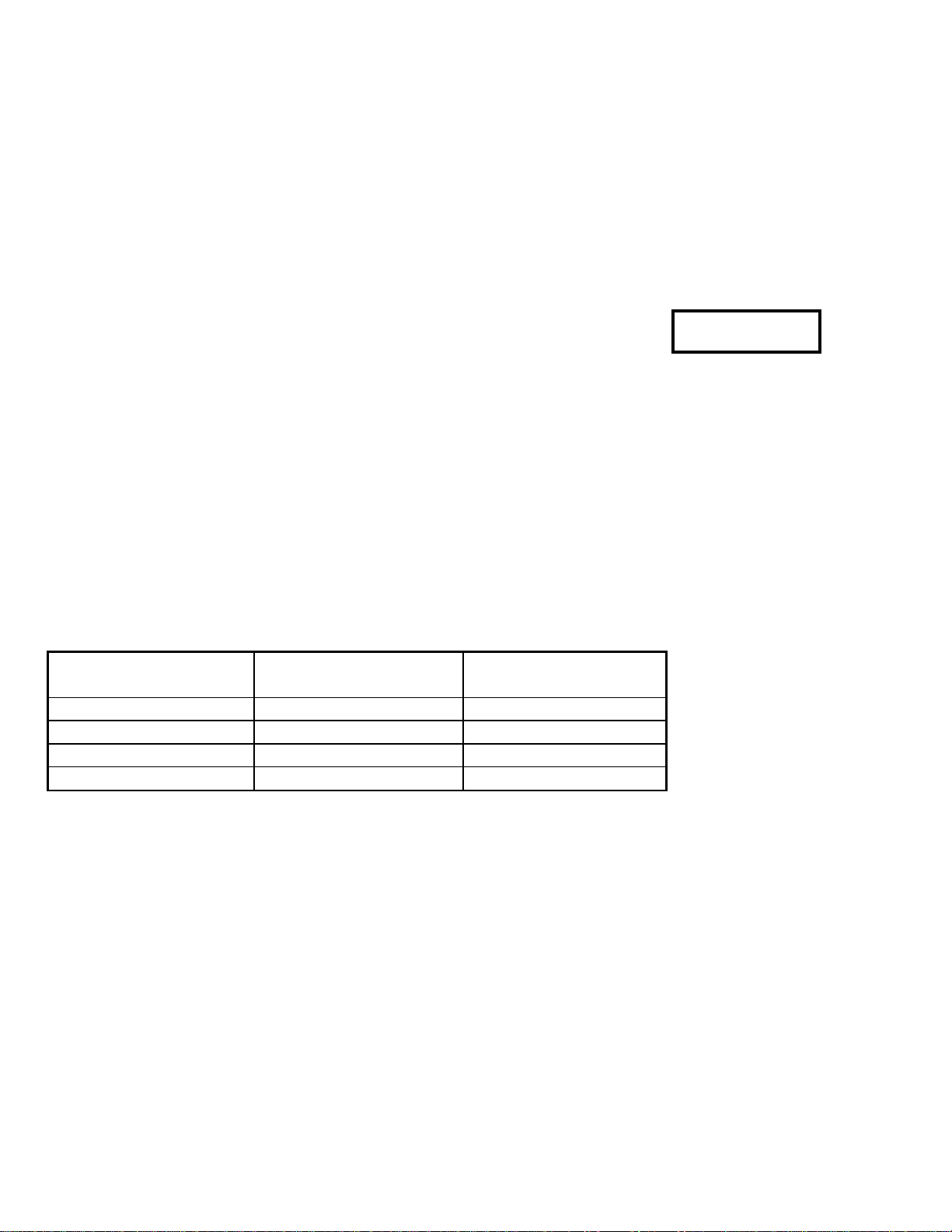

BOLT COUNT FOR BASIC PD-15

BOLT LOCATION

Flat

1½"

Carr

1¼"

Flat

1"

Carr

1"

Flat

3/4"

NUTS

WASHERS

Special

Greenwich Flange

20

20

20

Base Ring

5

5

10

10

DSR safety

4

4

4

Equatorial Flange

40

40

40

Rear Cover

20

20

20

Shutter Latches

9

9

9

Shutter Catchers

6

6

6

Shutter Stop

2

2

2

Handles

4

4

4

Rollers

48

49

0

Side Rollers

25 self

tap

TOTALS

69

22

5

28

40

168

15

Wall Ring (Opt)

34

34

34

Notes: 1. Non-1/4-20 hardware for Semidoor, latches, etc. not shown

2. Extra bolts, nuts, etc. are provided

SCREW LESSON

The outer diameter of small

screws is a number such as #6,

or #8. #8 is bigger than #6. In

larger sizes, the diameter is in

fractions of an inch (e.g., 1/4

inch). The second number

(e.g., 6-32, 1/4-20) is the

number of threads per inch.

The third number (e.g., 6-

32x1/2) is the length in inches.

PD15 Page 7

1. INTRODUCTION TO INSTRUCTIONS

The assembly of the PRO-DOME involves several steps. These include:

* obtaining necessary permits

* building the foundation

* assembling the wall (if any)

* assuring that the top of the wall is level

* installing the base ring and rollers

* assembling the dome

* installing the shutters

* installing the fittings and hardware

Building Permits

In some areas, building permits are needed for the installation of the PRO-DOME, although there are sometimes

exemptions for small accessory structures. If you need a permit, you will need to apply for it, and include a

sketch of the proposed location, and a sketch of the proposed installation. If the PRO-DOME is to be installed

on a school or house or other inhabited building, special fire or other codes may apply in addition to structural

integrity requirements. Check with the local officials: it is much easier to handle the questions before you build,

than to find out later you are in violation of the local law.

Foundation

The PRO-DOME must rest on a secure foundation if it is on the ground, or framing support if it is to be

installed on a deck or other structure. The major purpose of the foundation is not to support the weight, since

the PRO-DOME only weighs about 650 pounds. Rather, its purpose is to provide stable support under all

environmental conditions.

The foundation must support the observatory so that the walls and dome do not twist as the ground freezes or

thaws or becomes dry vs. wet (this could cause the dome to become hard to

turn).

The foundation must hold the PRO-DOME down in the case of severe wind.

Depending on the area of the country, hurricane or other winds 80 mph (or more!) can occur, so building codes

require that buildings and their foundations resist such winds. (An 80 mph wind on the PRO-DOME can

generate a force of over 1500 lb.!). In addition, in most cases, the foundation system must provide some means

of leveling the observatory.

The foundation may be part of a building or house, a deck, a ring foundation, piers into the ground, or a concrete

pad (often with wood or carpet covering). If you want suggestions, please contact us for more information on

constructing foundations.

Foundation bolts

Selecting the appropriate foundation bolts to hold the bottom ring to your surface is your responsibility. The

most common bolts are lag bolts into anchors in a concrete pad, or carriage bolts through a wood deck. In all

cases, it is absolutely necessary to use washers at least 1 1/2 inch diameter under the bolt heads. In general, we

recommend using 3/8 inch diameter bolts spaced about 16-18 inches apart along the bottom flange. Lag bolts

FIG 4,5,6

PD15 Page 8

should penetrate the pad or deck at least two inches. Be sure to allow enough length in case you need to use

shims under the wall or base.

Installation Practices

Many of the installation steps take longer to read than to do. While no complex carpentry or other skills are

needed, you will need to perform some measurements, locate and drill holes, and install bolts. Sometimes edges

of fiberglass may need to be sanded or trimmed. However, no experience is needed in working with fiberglass,

and no application of fiberglass needs to be done. None of the pieces weigh more than about 75 pounds, so

even though they are bulky, they are relatively easy to handle.

We would strongly urge that you have several workers to help you assemble the PD-15. This allows you to

check on each other, and will help avoid mistakes. A second person can help a great deal in holding items in

place while the first drills holes and installs bolts. Certain steps in the PD-15 assembly normally require four or

more persons working in concert.

Before beginning construction, all workers should read through the directions and study the pictures. Note

especially the terminology that we use for the various parts. We urge that you not try to build the dome in an

order different from that in the instructions: some of the short cuts that look attractive have traps in them (we

know - we've gotten stuck!)

Finally, if you make a mistake, don't panic. In most cases you can just take the components apart, drill new

holes, and do it over. If you want to, you can always go back later and patch any mistakes with resin (that is one

of the virtues of fiberglass!) And if you get really stuck, give us a call and we will try to help.

Bolt Hole Drilling Guide

Some of the assembly steps inside this manual refer to “marks” on the fiberglass to identify hole locations for

drilling that may or may not still show up on the fabricated fiberglass sections. We strongly recommend that the

Bolt Hole Drilling Guide be reference every time you start an assembly step that involves drilling holes. This

guide will reflect the prorper measurements and locations and will eleiminate some confusion that may arising

in the step description. Some holes are drilled as “guide” holes (where two sections of fiberglass overlap) and

are then used for the “final” hole drilling when the two sections are properly aligned abd are ready to be bolted

together. This is the way that the drilling guide is broken out.

PD15 Page 9

2. SAFETY PRECAUTIONS

Constructing a PRO-DOME requires you to follow several safety precautions and use common sense, since the

activity does include mechanical and manual operations. Care is needed in the use of tools and you should

follow the precautions provided by the manufacturers of any tools you may use. Since you will be constructing

a small building, you will need to use step ladders: be careful. While the fiberglass parts are not very heavy,

they are bulky: use care in handling them so that neither you nor the parts are injured. Carefully read all the

instructions, and think through your activities before you commence. Make liberal use of props, tape, clamps,

or other aids in the construction.

CAUTION

If the dome is to be installed on any support or wall more than three feet above the ground, or in a location with

difficult outside access, we STRONGLY recommend that you pre-assemble the base ring, dome, shutters, and

all fittings on the ground. You can then assemble the dome in a convenient and safe situation. Once pre-

assembled, it only takes an hour or two to disassemble the parts. You can then reassemble in place, knowing

how the parts fit together, and with direct experience in handling the pieces.

Fiberglass

Fiberglass is really a misnomer: the material is fiberglass reinforced plastic (FRP). In our case, the plastic is

polyester resin (not epoxy). In its "raw" state, polyester resin is a syrupy liquid, After mixing about 15 drops of

catalyst per ounce of resin, it hardens in about an hour. Because the hardened resin is somewhat brittle, it is

reinforced with fiberglass for strength, and to prevent the propagation of cracks. The fiberglass can be in the

form of woven material which has the resin spread onto and into it, or long fiberglass strands which are chopped

into 2 inch pieces, then mixed with resin that is sprayed into a mold.

Fiberglass has many virtues, but also two potential problems:

FIBERGLASS IS FLAMMABLE

FIBERGLASS CAN IRRITATE THE SKIN

Yes, fiberglass will burn, or rather, the plastic in it will burn. Once started, it does burn very hot (you might

want to try a 1 square inch piece in a fireplace to see). Therefore, use common sense as you would with wood

or any other flammable construction material. Keep fire and open flame away from all parts of your PRO-

DOME. Also, do not let fiberglass dust or trimmings accumulate. Be especially careful about this where there

is any risk of flame or fire.

The fiberglass within the FRP is glass, and it can cut or abrade the skin. Sharp edges of the dome pieces can

cut, so be careful. Whenever handling FRP pieces, always wear gloves to be on the safe side. Of course, the

surfaces of the FRP are smooth, because they have been coated with a layer of resin (called Gel-coat) that covers

the glass.

Fiberglass dust can irritate the eyes and skin. When cutting or trimming or filing or drilling -- in short,

whenever doing something to the FRP that makes dust -- always use gloves and eye protection. Also, wear a

long sleeved shirt and long pants. In addition, be sure to change your clothes and wash thoroughly when you are

done the dusty part. If there is lots of dust, change how you are doing things to reduce the dust exposure!

Reasonable care is all that is needed; however, failure to follow reasonable care could lead to eyes or skin that

itches for a day or so. Hand lotion can help relieve itchy skin. If itching persists, see your physician.

PD15 Page 10

Construction and Operation Cautions

During construction and operation, there are specific cautions that must be followed. The PRO-DOME

observatory is not a toy, so be sure that children (and adults) do not climb upon it. Since the observatory does

contain moving parts, users must be careful to avoid injury. Keep your fingers away from the moving parts

where they might become caught.

The shutters CAN BE DANGEROUS. Each shutter weighs about 50 lb., and slides on the slot edges. They are

normally interlocked, and under control of the user. However, if they should not latch properly, or if they are

separated for maintenance work, the shutters (especially the front shutter) can begin sliding with little warning.

It is ESSENTIAL that care be used never to let the top or front shutter rest by itself at the top of the dome

without proper anchoring (if the two are latched together as they normally are, there is no risk). To help prevent

injury, you should consider installing a safety device on the front of the dome to limit unexpected downward

movement of the front shutter.

To prevent high winds from damaging the dome, it is essential that the shutters be fully latched and the front

shutter fastened when the dome is not in use.

PD15 Page 11

3. SPECIAL ASSEMBLY INSTRUCTIONS

This section contains special instructions that apply to several parts of the assembly. We have written these for

the relatively unskilled assembler. However, even those who are skilled in carpentry or other mechanical

assembly SHOULD read and follow these instructions, especially concerning leveling the structure.

Nomenclature

Parts of the PRO-DOME observatory have special names. These include the following.

Reverse Flange - This is the curved topmost flange that is a part of the top flange of the base ring or wall.

The purpose is to hold the dome down in case of wind, and also to provide a drain for any water that might

enter the dome.

Equatorial Flange - This is the internal flange at the "base" of the dome quads where the equator would be on

the earth.

Front of Dome - The dome is that portion of the observatory that rotates. The front of the dome is the

location of the front shutter.

Front of Observatory - The observatory wall (or observatory building) is stationary and does not rotate.

Usually, we define the entrance door to be the "front" of the observatory. These considerations are

important when you install the foundation and walls, since you will want the door to be in the proper

location relative to where you want to enter the observatory.

Home Position - When the slot opening is lined up with the door, it is in the HOME position.

Base Ring –the ring that has the rotation rollers.

Foundation Ring –the bottom most ring of the wall that bolts to your foundation. It will be the

same as the base ring if you are not using extra wall rings.

See later chapters for details.

Locating Holes

In assembling the PRO-DOME, you will need to drill holes and insert bolts to hold the various pieces together.

But how will you find where the holes are to be and what is the hole drilling procedure?

In some cases, we have marked the hole locations with dimples or with small cross marks on the smooth side of

the fiberglass. These holes are to be drilled before assembly. During assembly, if some of the holes do not

quite line up, and if you are SURE no assembly mistake has been made, you can use your drill to "open up" the

holes to accommodate a bolt. Hole sizes will be given in the instructions (most will be 5/32”, 1/4", 9/32", 3/8"

or 5/16").

We have includes a Bolt Hole Drilling Guide at the end of this manual. We highly recommend that this

guide be referenced every time a step calls for locating or measuring hole locations prior to actual

drilling.

FIG 13

PD15 Page 12

Drilling and Bolting

Many PRO-DOME parts are held together with carriage bolts or flat head bolts, 3/4

or 1 inch long. Carriage bolts have round tops, with a square shank that catches in the hole, preventing turning

of the bolt. Flat head bolts are installed in a countersunk hole. We provide stainless steel carriage and flat head

bolts, washers, and nuts to minimize corrosion.

In most cases, bolt holes are drilled before pieces are assembled. Drilling in fiberglass requires use of eye and

skin protection, but otherwise presents no problems except that bits become dull after 50-100 holes. If a flat

head screw is to be used, you will also need to use a "countersink" to create the sloping hole to accommodate

the screw head. If available, use an 82 degree countersink, and cut the material just enough to recess the flat

head.

Once the holes are drilled, assemble the pieces by installing the carriage bolt or screw in the proper direction

(the instructions will tell you in each case). Be sure the bolt head is snug into the hole. Install a 1/4 inch washer

and nut, and tighten. If the nut will not turn, check for fiberglass dust in the threads -- clean the nut and bolt and

try again. Do not force the nut! A drop of oil may help as well.

If you drill a hole in the wrong location, either re-drill a new hole in the correct location, or, for small errors,

enlarge the hole on the "nut end" piece, and install one or more large washers, or metal or wood plates, before

installing the nut.

Here are some additional tips for drilling holes in fiberglass, or cutting it:

Drill a pilot hole smaller than the final hole to keep the drill from wandering during the final

drilling.

A common twist drill will produce a triangular hole. In some cases, this can cause a problem. To

prevent this, simply drill a hole a few 64ths smaller than the final hole, then finish drill with the

desired size.

Drilling fiberglass produces fine glass dust. If you leave it in the hole, the dust will get into screw

threads and make nuts hard to turn. Clean the holes (rag on a screwdriver) and use a bit of oil on

the screw to reduce the problem.

A drilled hole will usually have a ragged edge. In most places, this is not a problem; however,

you may want to know several tricks to prevent this. These include predrilling undersize holes,

back up the fiberglass with a piece of scrap wood while drilling, drill partway through on one side,

then do the other side. You can also lightly countersink every hole after drilling.

We often call for use of a countersink (makes a conical hole). If you don’t have one, you can use

a large bit (eg 1/2 inch bit on a 1/4 inch hole) to make the cut. However, be careful not to go too

deep. Also, note that the angle of the cone may not match very well the bolt that will go in it

(usually 82 deg).

Sometimes the gelcoat will chip when drilling or sawing. If this is a problem, there are tricks to

use. These include putting masking tape on the gelcoat before drilling/cutting, use high speed

cutting with low pressure, using fine toothed cutting blades, and drilling preliminary undersize

holes.

Leveling the Foundation, Wall, and Base Rings

The more level the foundation is, the easier your overall installation will be. In any case, the top of your base

ring or wall must be level (or at least planar). If the base ring is not level, the dome will not be supported

FIG 1

PD15 Page 13

uniformly on its rollers. This can cause a variety of problems not only with turning the dome, but also with the

shutter operation as the shutter opening may be distorted. At least 1/4 inch accuracy in leveling is needed;

however, 1/8 inch is even better.

While the "bottom line" is to achieve a level base ring, any wall built below the base ring should also be level

and/or provide a means of leveling the base ring. Leveling techniques using shims or adjusting bolts are

discussed below in the foundation section.

There are many ways to perform the leveling. Here are details on several of the best.

* If you have a transit or theodolite, you can use it.

* If you have a split image transit or eye held level, don't bother. It is not accurate enough and/or is too hard to

use for this application.

* String levels are not sensitive enough.

* The human eye can see out-of-plane errors in the ring; however, it is very confusing to identify which portion

is too high or low, and hard to estimate the amount. It is also hard to keep track of errors in the portions of the

ring crossways to the line of sight, versus those more parallel.

*Carpenter levels, if sensitive, can be used, but will not do the job if simply moved around the circumference.

See below.

* Water levels are far and away the easiest and best way to level the base ring or wall. They can be made or

bought (about $15), and are described below. (We once spent two frustrating hours with a carpenter level and

split image transit and could not do better than 1/2 inch, but a water level did the job to 1/8 inch in ten minutes!)

Leveling with Carpenter Level

The two to four foot carpenter level can serve to level the structure.

However, you will find that if you simply move it along the circumference, it is impossible to level the ring

accurately. The problem is the subtle shifts of the bubble as you move around the ring.

A much better method is to set up a support at the center of the dome, at a height equal to the top of the wall

ring or the item to be leveled. Use a bar from this center to the outer ring, and place the level on the bar. Now

as you swing the bar around, you can track which parts of the ring are high or low relative to the center. It is

easy then to adjust the wall ring to a level condition.

Leveling with Water Level

This is the best! A water level is made of two see-through containers, connected by a flexible, long tube, filled

with colored water. (Hint - Use food coloring.) After adjusting the water levels, one container is set on a

reference point (e.g., one spot on the ring) while the second one is moved to different points around the ring and

the difference in elevation measured. The water level in the moveable container will rise (or fall) with the fall

(or rise) of the level of the point you are measuring when compared to the reference point.

Commercial water levels read directly in inches, so it is easy to make accurate leveling corrections. Homemade

water levels will work fine, so long as they don't leak. Water levels are tough to use in freezing weather!

Making the Observatory Circular, and maybe Centered

While only the base ring MUST be accurately circular, it is highly desirable that all portions of the dome,

including the foundation and walls, be circular. On the other hand, while aesthetically desirable, it is not

FIG 2

FIG 3

PD15 Page 14

necessary that the observatory be centered on some "magic" point, with all parts concentric (note that the

telescope pier need not be at the center of the dome).

Identify the center of the observatory and mark it with a a screw driven firmly into the foundation, or a small

post sunk solidly into the ground. Mark the exact center of the screw or the post with a small nail driven into it

but projecting 1/4 inch. You can now use this as the center for marking the foundation, your foundation bolt

circle, etc.

The easiest way to start is to draw inner and outer diameters for your wall or base ring directly on the

foundation. You will match the inner edge of the foundation ring bottom flange to the inner diameter that you

drew. The outer diameter is there as a reference too, but use the inner mark because it is easier to keep in view.

To check the "centeredness" of successive (higher) wall rings, you will want a

"center point" that is at the height of your wall. We will describe one easy method of providing this center.

As you build the observatory higher, you can use a plumb bob from beneath a tripod (surveyor or camera tripod)

to establish a center at any height you want. If you have no tripod, nail a box together, or stack cinder blocks so

that you can hang a plumb bob over your center point. With a little care, you should be able to perform the

centering to about 1/8 inch. In either case, you can then use a tape measure to measure the radius to each point

around the wall, so as to show that the wall is both circular and centered.

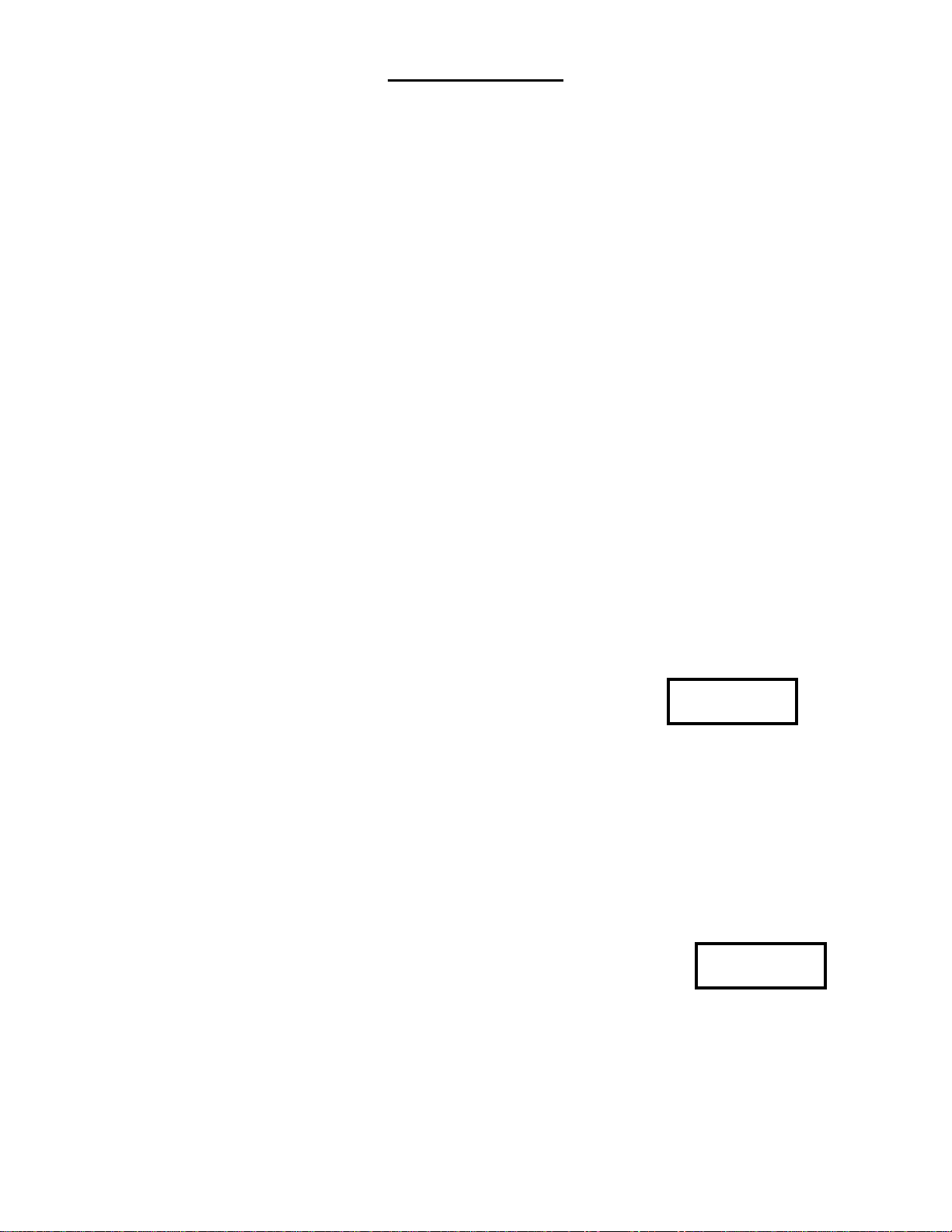

Several dimensions will be used later in the assembly of your dome. We put them in a table below, for your

reference.

ITEM

OUTER DIAMETER

AVERAGE (IN.)

CIRCUMFERENCE

(IN.)

Base Ring

179.00

562.00

DSR

180.57

567.00*

Dome

180.00 (nom)

565.00

* Measured 1 in. below upper flange of DSR

FIG 2

PD15 Page 15

4. FOUNDATION

The PRO-DOME must rest on a secure foundation if it is on the ground, or framing support if it is to be

installed on a deck or other structure. The major purpose of the foundation is not to support the weight, since

the PRO-DOME only weighs about 650 pounds. Rather, its purpose is to provide a stable support under all

environmental conditions.

The foundation must support the observatory so that the walls and dome do not twist as the ground freezes or

thaws or becomes dry vs. wet (this could cause the dome to become hard to turn).

The foundation must hold the PRO-DOME down in the case of severe wind. Depending on the area of the

country, hurricane or other winds up to 80 mph can occur, so building codes require that buildings and their

foundations resist such winds. (An 80 mph wind on the PRO-DOME can generate a force of over 1500 lb.!). In

addition, in most cases, the foundation system must provide some means of leveling the observatory (usually

using shims).

The simplest foundation fastening technique is to drill 5/8 in. holes in the foundation, install anchors, and use

3/8 lag bolts (with washers), and shims as necessary for leveling. An alternative is to use studs (threaded rod or

bolts) cast into the foundation with adjusting nuts. Both schemes are shown in figures below. In any case, the

foundation should be built to be as level as possible, so that height adjustments to level the walls are minimal

and easy to do.

Technical Innovations has supplied several sample foundation and anchoring designs, but any support or

foundation design must be approved by your local building code officials. We make no warranty that the

designs will be legal or function in your particular circumstances. These can be "mixed and matched" to meet

your needs. All these designs are suitable for do-it-yourself construction; however, if you are not comfortable

with such a project, check your local library for books on foundations and concrete construction.

Ring Foundation

An excellent foundation is a concrete ring. The thickness and depth of the ring

depend on local law and weather conditions, but typically might be five inches in radial thickness and two feet

deep. The top of the foundation should be several inches above the ground, and sloped very slightly outward for

drainage. Lag bolts with anchors or foundation bolts cast into the foundation are both feasible. Then, if using

wall rings, holes are drilled in the lower wall ring flange to match the bolt locations.

When building a ring foundation, don't forget to allow some holes through the foundation for power or other

cables! You may also want steps or a ramp cast at the same time, depending on how you wish to enter the

dome.

Pier Foundation

Instead of a continuous ring, you may want to install piers. We recommend twenty piers -- these may be

pressure treated posts, concrete, or other material. Again, your building code official must approve any design.

One advantage of wood piers is that it is easy to locate and drill holes for the foundation bolts. Also, wood piers

may be easier to install at remote locations. A disadvantage may be that digging twelve holes is a lot of work in

some soils!

FIG 4

FIG 6

PD15 Page 16

Concrete Pad

Another alternative is to pour a concrete pad that will serve both as a floor and as the foundation. This is

perfectly feasible, but may be more costly than other alternatives. You may find the floor to be uncomfortably

hard and cold; however, outdoor carpet or a wood floor will correct that. If you use a concrete pad, install your

pier before pouring the floor, or at least leave a hole so you can have a separate pier or post for the telescope.

You will also want access for cables from the outside to the dome walls and to the central pier. Depending on

your local laws, you may need separate footings for the pad. In most areas, the pad should be about 4 in. thick,

should have heavy reinforcing wire in it, and should have some gravel drainage beneath it. Be sure to install a

sheet of plastic under the concrete to keep out moisture.

Wood Deck

Another type of foundation is to construct the observatory on a wood deck. This is perfectly feasible; however,

it is obviusly important that the deck be well constructed to withstand wind forces. It is also vital that the wood

be treated to prevent rot. Such an installation will normally have a hole near the center of the observatory for a

separate pier extending down to the ground. If the deck is more than a few feet above the ground, be sure to

provide strong railings. The interior floor of the deck can be left as is, or additional flooring (eg., plywood and

outdoor carpet) can be added.

FIG 7

PD15 Page 17

5. WALL AND BASE RING ASSEMBLY

Now we are ready to build the observatory! Even if your installation does not include a wall (other than the base

ring), be sure to read the material on wall rings because wall ring and base ring assembly are very similar.

If the dome is to be installed on any support or wall more than three feet above the ground, or in a location with

difficult outside access, we STRONGLY recommend that you pre-assemble the wall rings, base ring, dome,

shutters, and all fittings on the ground so that you can assemble the dome in a convenient and safe situation.

Once pre-assembled, it only takes a few hours to disassemble the parts. You can then reassemble in the final

location, knowing how the parts fit together, and with direct experience in handling the pieces.

The assembled PD15 weighs about 700 lb, including shutters, but not including any wall rings. Although the

pieces can be moved by hand and assembled in place (after preassembly), you may find it easier and safer to

assemble and test the observatory at ground level, then rent a crane to lift the entire assembly into position. This

will require the help of persons with professional rigging experience.

The wall may be constructed using your own plans or using wall rings supplied by Technical Innovations (or

both). However, if you build your own wall, you will find that it may be difficult to construct a door that will

operate properly with the PRO-DOME semidoor. Any wall must also be able to handle wind loads, prevent

twisting as the dome is turned, be water tight and resistant to the weather, look good, and, last but not least,

provide a solid, level support for the lower flange of the observatory base ring.

If you are constructing a wall of your own design, we urge that you send a copy of your proposed wall design to

Technical Innovations. We can review it, and may have suggestions or cautions that will make the wall easier to

build, or otherwise help assure a successful installation.

Wall/Base Ring and Semi-Door Assembly Instructions

Constructing all or part of a wall with PRO-DOME wall rings is very easy

because sections form a ring of the right size which can then stacked and bolted to the desired height. The wall

rings are the same design as the base ring, so the same assembly for each is followed. The base ring is different

from the wall ring by having a reverse upper flange, an access hole for aid in assembly, and holes cut into the

upper flange for the rollers and motor drives.

The PRO-DOME wall ring (and base ring) is divided into five equal length sections of the circle. Four of the

sections are single piece, full length, 72 degree sections. The fifth section contains the molded semidoor

section, a left hand stub section (left hand as seen from the outside of the wall), and a right hand stub section:

the three pieces (with spacing for the latches and hinge) are equal in length to the full length sections. The door

hinge will be on the right hand side of the door, as seen from the outside.

Because the Semi-door is made of sections with the same height as the wall sections, the wall to which the door

is mounted should be at least 1/8 in. above the foundation to allow the door to open easily. When you install the

first wall ring, if the leveling and shimming process does not result in at least this much space under the ring,

you should insert the necessary shims around the ring. After assembly of the observatory, you will seal this

space with caulk or other sealant.

We and our customers have developed two different ways to construct the wall. Each has advantages. We will

describe both, and you can pick the one you are most comfortable with.

CAUTION

FIG 9, 9B

PD15 Page 18

In general, assembly is one ring at a time, but modified for walls higher than two feet. You will bolt the four

full length sections together, clamp the door in place with spacers, and check the circumference before bolting

the stubs to the adjacent wall ring sections. You will then build the next ring similarly. You will align the door

jambs, and bolt the rings together. You can then add more rings, finishing with the base ring. NOTE: For

walls higher than two feet, you should change the order somewhat, creating the entire door, the left stubs and

right stubs as pre-built units before assembling the rings.

First Ring Assembly

To assemble your first (lowest) ring, select four full length sections, a left stub,

right stub, and molded door. You will notice that one end of each section is

"stepped" inward (the "male" end) and this fits into the plain "female" end of the next section. The male end

will aim to the RIGHT as seen from the outside of the section. The female end of each section has two marks

on the web (12 in. high portion) which are the locations for the joint bolts. The lower flange of each full length

section of the wall/base ring also has four suggested location marks for the bolts used to fasten the ring to the

foundation or to use for fastening successive rings together. The stub and door sections have two suggested

foundation/interconnect bolt locations.

You will now identify and drill holes in the sections, fit the sections together, and check the circumference

before drilling and bolting the final joint. The first ring is a little tricky, because you have to fit the pieces

together to make the ring, while fitting it to the foundation, as well.

If you are going to use the pre-marked holes to locate foundation bolts, find the four marks on the lower (not the

upper) flange, and mark the approximate locations on the upper (inside), rough, inside surface of the flange

(don't drill them yet). Do this for each piece.

Find the two marks on the outside of the female end of each piece and drill 5/16 in. joint holes.

HINT: In this case (and in others during dome construction), you may find that the marks for some pre-marked

hole locations are not present or don't fit your desires. When this is the case, simply lay out your own hole

locations while keeping at least the same number of holes specified. If you have doubts about the locations,

give us a call for advice.

Now assemble the four full length sections and the right hand (male) stub on a reasonably level surface, with

male ends pointing right. Insert a male end tightly into a female end, and using the previously drilled holes as a

guide, drill holes in the male end. Install 1 in. carriage bolts, washers, and nuts in the joint from the outside in.

Do all four joints. Be sure that both the upper and lower parts of each joint are fully seated: often the second

joint needs to be pushed together to avoid a conical shape to the wall.

Insert the left (female) stub. Place a piece of 1/8 material (such as cardboard) between the left hand door jamb

and the left hand door edge and hold the pieces together with a C-clamp. Do the same on the right hand side of

the door section.

You will now check the circumference before drilling the final holes (in the male end of the left stub).

Measure the circumference (i.e., the distance around the ring about one inch down from the top) with a metal

tape rule. Your goal is a circumference of 562.00 inches (+/- 1/4 in.), corresponding to an average diameter of

179 inches. If the circumference is too small, pull the sections apart as necessary. If too large, push the last

FIG 9B

PD15 Page 19

joint closer together (cut some of the female end if necessary). When you are satisfied, drill the final two holes

in the male end and install the bolts.

Note that while your wall ring has an average diameter of 179 inches, it is likely not to be an exact circle. That

is, across one diameter it will be 178 while another may be 180 inches. Wall rings can easily be "nudged" two

inches out of circular shape (and conversely, are easy to nudge INTO circular shape). To gain a bit of

experience, take a few minutes with the wall ring on a level surface, and measure -AND WRITE DOWN THE

RESULTS- the diameter for at least six different "diameters" (directions) across the ring.

The easiest way to take diameter measurements is use a steel tape from the inside (blue) surface to the opposite

blue side of the ring. If you swing the tape measure a few inches left and right, you will note the spot with the

longest measurement, which is the diameter.

Try adjusting the ring to become circular to within about 1/2 in. maximum range (e.g., 178 3/4 to 179 1/4). This

is an easy task, but only if you keep track of your work with a drawing!

Installing First Ring on Foundation

Now the job is to put the first completed wall ring on the foundation with the door section at the desired front

(i.e., the entrance) of the observatory. You will need to provide at least 20 3/8 or 1/2 in. bolts or anchors into

the foundation to hold the observatory in place during high winds.

The challenge is to mount the ring onto the foundation, while assuring that it is circular, and getting holes in the

lower flange to line up with your foundation bolts or anchors! If you are going to have a semi-door, you will

also want to have a minimum of about 1/4 in. of shim under the wall so that the door will open easily.

If you have a PD15 with a door, you should also consider shims under the wall. Because the door sections are

the same height as the wall ring sections, the door height is the same as the wall. Therefor, if the bottom of the

wall is on the base, the bottom of the door will scrape the floor, and the door will be difficult to open. Most

floors are not flat, and require some shimming to produce a level wall. To give door clearance, you should have

about ¼ in. of shim under the wall.

Lag Bolts and Anchors. If you are going to use lag bolts and anchors, you will already have marked the holes

on the inside of the lower flange (but don't drill them yet). You can't simply drill holes in the flange, mark the

concrete, and drill the concrete because when you drill into concrete the hole will wander away from the mark as

the bit hits stones in the concrete. Proceed as follows.

Place the ring on the foundation, and adjust it to be circular to within about 1/4 in.

or better.

Use a magic marker and draw the inner and outer outline of the base flange onto the foundation. Mark the

azimuth locations around the ring on the foundation for the foundation holes. After marking the ring so that you

can reinstall it in the same position, remove it.

Mark and drill your anchor holes with a masonry bit. Install the anchors.

You will likely find that the drill bit will have wandered, but not to worry. Draw a pair of 12 in. guidelines to

the actual location of each anchor on the foundation.

Reinstall and re circularize (ugh, what a word) the ring. Using the guidelines and a straightedge, you can

easily mark the wall ring flange for the exact hole locations to match the anchors in the foundation.

Remove the ring and drill your foundation bolt holes in the lower ring. Once the holes are drilled, again make

sure the ring is circular, and install the bolts and washers into your anchors.

FIG 7

FIG 5

PD15 Page 20

Cast Foundation Bolts. If you are using foundation bolts already cast into the foundation, proceed as follows.

Set the ring lightly on top of the foundation bolts. Make the ring circular, then mark the bolt locations on the

underside of the wall ring flange.

Drill your foundation bolt holes in the lower flange of the wall ring

Install the wall ring on the foundation bolts as shown on the sketch.

Whichever fastening method is used, you will want at least 20 bolts to fasten the lowest ring to the foundation.

You must install washers under the bolt heads or nuts as shown, so that the wind and other forces will be spread

out on the flanges. Use steel washers at of at least 1 in. diameter. As noted above, you should also assure that

the stub sections next to the door must end up shimmed at least 1/8 in. above the foundation, to allow the door

to open and close easily.

Using your level, adjust the foundation nuts or insert shims to level the wall ring to an accuracy of at least 1/4

inch (preferably 1/8 in). You might also use upside down DSR sections to help guide leveling the wall. Tighten

all bolts.

You now have the first wall ring bolted to the foundation, with the door section clamped in place in the ring.

Door and Stub Sections Assembly

If your observatory has just one ring, there is no door assembly to be done (although you will need to install the

hinge and latches as described below). If you have two rings, you just drill 5/16 holes in the lower flange of the

base ring door section and stubs, align the parts with the corresponding wall ring pieces, and use 1 in. carriage

bolts to assemble. However, if you have three or more rings, you will want to be more accurate in your

assembly of the door and stub sections to accomplish a good looking installation.

The challenge is that as you build the stubs or door higher, small assembly errors or shape imperfections in the

pieces will add cumulatively, and cause the door or stubs to lean in or out, or to one side. The easiest way to

avoid this is to assemble the entire door and stub sections using an alignment jig on a flat surface where you can

keep the stacked pieces more nearly square and in line.

You can make an alignment jig as shown in Fig. 22. Or, working on a flat surface,

you can clamp a straight 2x6 to the vertical end of the stack of sections (e.g. on the

closed end of the stubs). Apply additional clamps to join the sections together while pressing them down

against the flat surface. With care and rechecking, you will find it easy to keep the pieces aligned as you drill

and bolt each section. You will find, of course, that the sections will not form a perfectly flat surface. Don't

worry, slight variations will not affect either appearance or operation: your purpose here is to assure that the

door and stub edges and face are, on the average, in the correct planes.

You should attach the hinge to the right side of the door (as seen from outside). Because you may need to adjust

its location, we suggest only a few screws be used. The outer surface of the hinge should be even with the outer

wall surface (i.e., the hinge pin will be slightly within the door/stub space). It is usually easier to wait until later

to attach the hinge to the right hand stub.

Completing the wall

This section will suggest how to assemble the additional wall rings and final base ring. Normally, the leveling

does not need to be repeated with successive wall ring (until you get to the base ring) unless you want to do it.

Proceed as follows.

FIG 22

Table of contents