3 -INSTALLATION

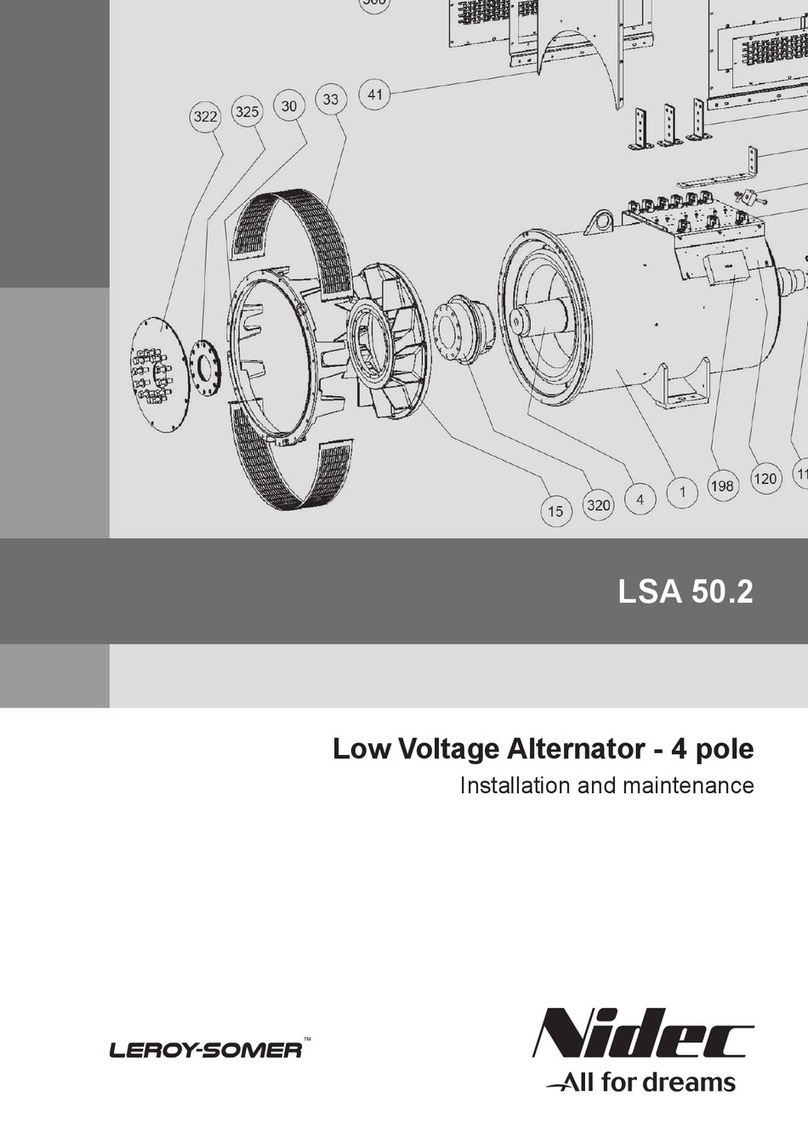

3.1 Assembly

3.1.2 Coupling

3.1.2.1 Single bearing ac generator

WARNING

All mechanical handling operations must be

While being handled, the machine should

remain horizontal.

undertaken using approved equipment.

3.1.1 Handling

The generously- sized lifting rings are for handling

the AC Generator alone, They must not be used to

lift the genset. Choose a lifting system which

respects the positioning of the rings.

Before coupling to the prime mover, check that both

are compatible by:

- Undertaking a torsional analysis of the transmission.

- Checking the dimensions of the flywheel and its

housing, the flange, coupling discs and offset.

When coupling with ac generator to the prime mover,

the holes of the coupling discs should be aligned with

the flywheel holes by cranking the engine. Do not use

the alternator fan to turn the rotor.

Tighten the coupling discs screws to the recommended

torque and check that there is lateral play on the

crankshaft.

3.1.2.2 Double bearing ac generator

Careful alignment of the machines by measuring

the concentricity and parallelism of the two parts

of the coupling is recommended, the difference

between the readings should not exceed the

pecified values (say 0.1 mm)

-Semi-flexible coupling

WARNING

This ac generator has been balanced with a ½key.

3.1.3 Location

Ensure that the ambient temperature in the room where

o

the ac generator is place cannot exceed 40 C for standard

o

power ratings (for temperatures above 40 C, apply a

derating coefficient). Fresh air, free from damp and

dust, must be able to circulate freely around the air

input louvers on the opposite side from the coupling, It

is essential to prevent not only the recycling of hot air

from the machine or engine, but also exhaustfumes.

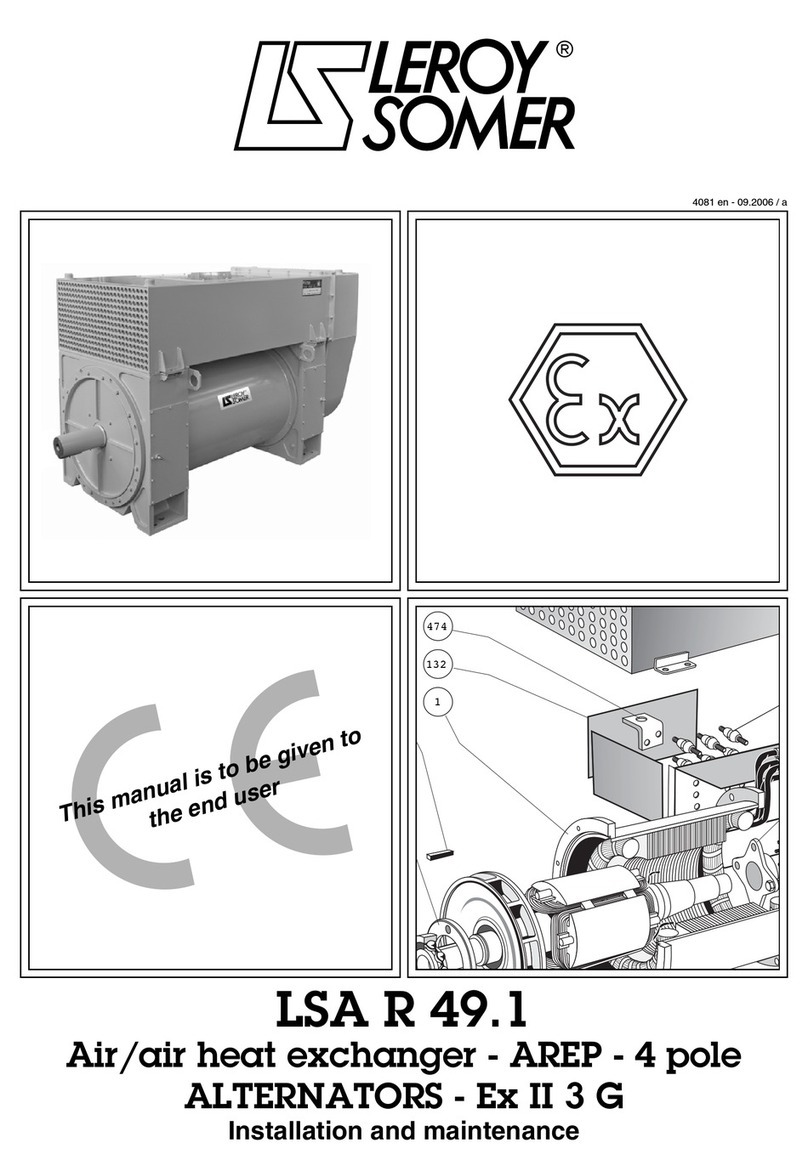

3.2 Inspection prior to first use

0.2.1 Electrical checks

Under no circumstances should an ac generator, new

or otherwise, be operated if the insulation value is less

than 1 megohm for the stator and 100,000 ohms for the

other windings.

There are two possible methods for restoring the

above minimum values.

a) Dry out the machine for 24 hours in a drying oven

0

at a temperature of approximately 110 C.

b) Blow hot air into the air input, having made sure

that the machine is rotating with the exciter field

disconnected.

c) Run in short-circuit mode (disconnect the AVR)

- Short-circuit the output phases using connections

capable of supporting the rated current (try not to

exceed) 6A/mm2)

- Insert a clamp ammeter to monitor the current

passing through the short-circuit connections.

- Connect a 48 Volt battery in series with a rheostat

of approzimately 10 ohms (50 Watts), to the exciter

field terminals, respecting the polarity.

- Open fully all the ac generator louvers.

- Run the ac generator a rated speed. Adjust the

exciter field current using the rheostat to obtain the

rated output cuttent in the short-circuit connections.

6

TM

LSAP 40 / 42.3 / 44.3 / 45 / 46.2-4 POLE

A.C. GENERATORS

INSTALLATION AND MAINTENANCE

Electric Power Generation