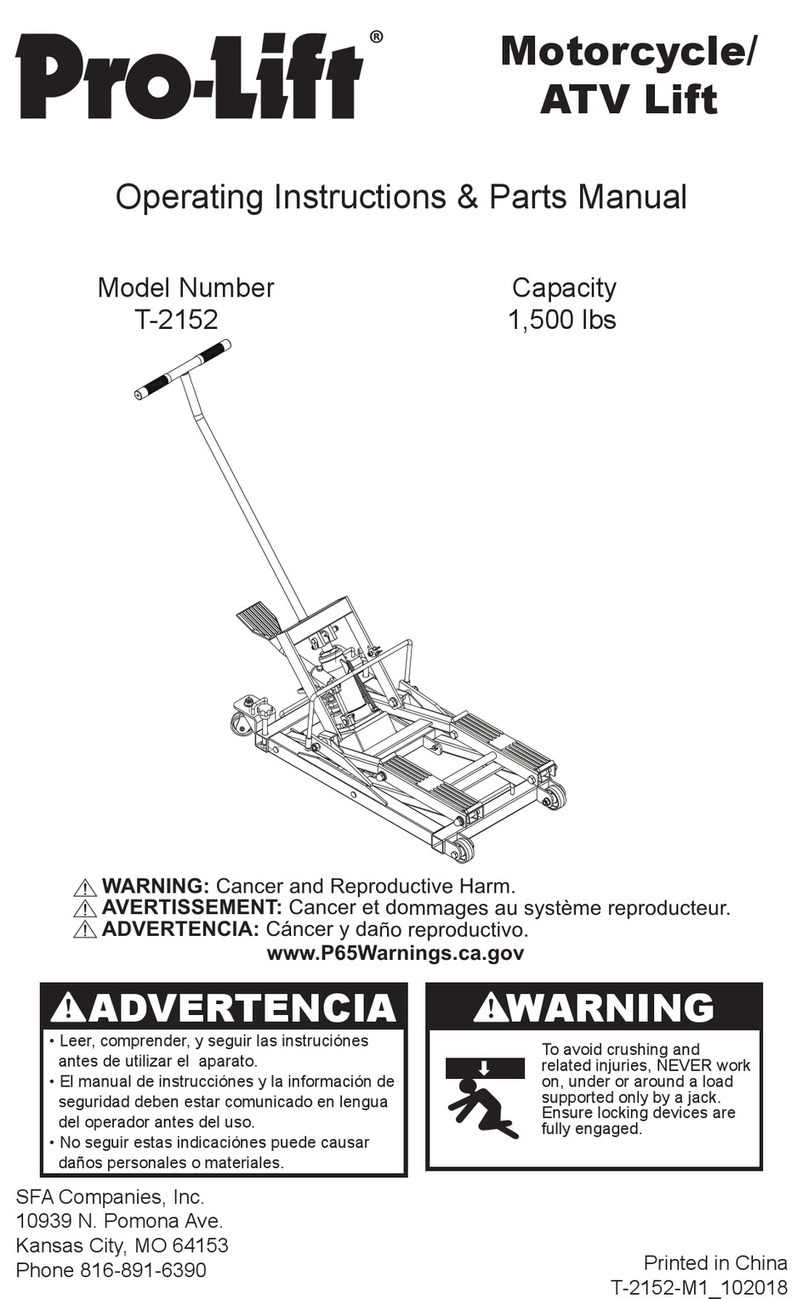

Pro-Lift T2151 User manual

1

To avoid crushing and related injuries:

NEVER work on, under or around a load supported only by

a jack. Ensure locking devices are fully engaged.

WARNING

!

Model: T2151

Imported by

SHINN FU AUSTRALIA PTY. LTD.

15 Viewtech Place, Rowville 3178 VIC Australia

WORKING LOAD LIMIT 680 KG

UTILITY LIFT

OWNER’S MANUAL

2

SAVE THESE INSTRUCTIONS

For your safety please read, understand and follow the information contained within before use. The owner and operator

shall have an understanding of this product and safe operating procedures before attempting to use. Instructions and

safety information shall be conveyed in the operators native language before use is authorized. Make certain that

the operator thoroughly understands the inherent dangers associated with the use and misuse of the product. If any

doubt exists as to the safe and proper use of this device as outlined in this factory authorized manual, remove the lift

from service until safe and proper use is clearly understood.

INTENDED USE

This lift is specifically designed to lift and support up to rated capacity loads consisting of a single Motorcycle, ATV,

Snowmobile, Water Craft or Riding Lawn Mower whose frames are compatible with the lifting members of the lift.

Incompatibility is evident when the loaded motorcycle, ATV, etc wobbles, feels unstable, and/or does not securely on

the lift’s padded lift arms. Tying down incompatible loads will not make the loads secure and may cause unexpected

loss of load resulting in personal injury and/or property damage. These lifts are NOT suitable for lifting, leveling and/or

positioning cars, trucks, SUV’s or conveyances other than those specifically listed and approved above. These lifts

are NOT suitable for lifting, leveling and/or positioning houses, construc-tion trailers and dwellings in general. This

product does not contain independent lifting devices, but is designed to be permanently assembled. Hydraulic unit

is not to be used independently of the motorcycle lift.

WARNING

Study, understand and follow all printed materials provided with and on this device. Do not exceed rated capacity.

Ensure load is compatible with lift’s lifting pad. Center load on lift pads. After lifting load to desired height, ensure lift

arm locking mechanism is engaged. Secure load to lift using apropriate straps. Engage locking caster mechanism

before working on or around loaded lift. Move loaded lift over smooth, level, seam-less surfaces only. Before moving,

ensure load has been lowered completely. Use only on hard, level surfaces capable of sustaining rated capacity

loads. Lift only on areas of the load as specified by it’s manufacturer. Do not alter this product in any way. Do not

use for any purpose other than that for which this device is intended. Failure to heed these messages may result in

personal injury and/or property damage.

SPECIFICATIONS:

Rated Capacity: 680 kg

Height Lowered: 135 mm

Height Raised: 420 mm

Net Weight: 38 kg

3

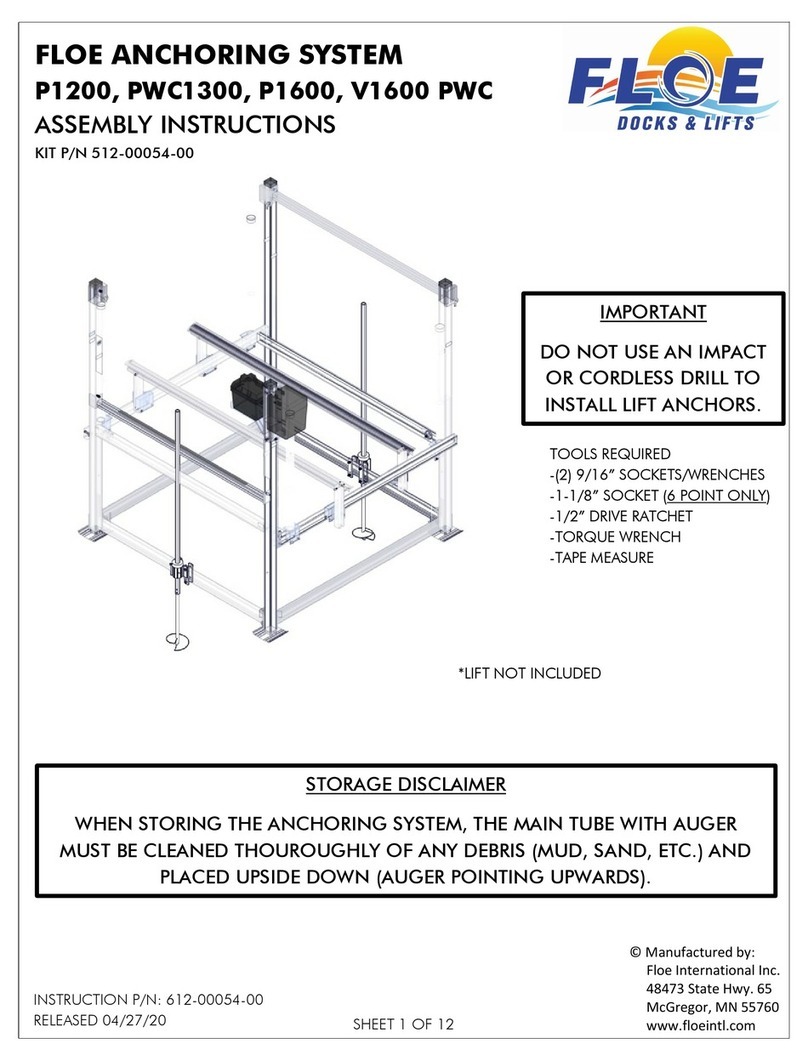

4. Align the holds between the clevis and the jack. If necessary, use lift pedal to pump up the saddle of

the bottle jack and / or lift up the saddle for the alignment.

1. Install hydraulic unit into

receiver and secure with

provided 7.5mm x 22mm

bolt, using appropriate tool

(not provided).

2. Install lift foot pedal into

sleeve,secure with bolt.

3. Swing the top frame.

5. Insert the shaft to holes. 6. Insert the locking pin on the shaft.

8. Install the return spring by fixing both its

ends across the height of the hydraulic unit.

CAUTION: Beware of the tensile force of

the spring during installation.

9. Install handle into frame and secure using the provide pins

10. Ensure assembly rolls freely, locks, and lowers easily. Get to know how the release pedal, lift pedal, and the height

locking and unlocking mechanism work prior to loading the lift.

ASSEMBLY

7.5mm x 22mm bolt

Shaft Locking Pin

Return Spring

The Bolt

7. CAUTION: USE PROTECTIVE EYE WEAR

Before installing the return spring ensure that the

bolt is secured to a minimum depth of 7 threads or

7mm and that the nut is tightened.

4

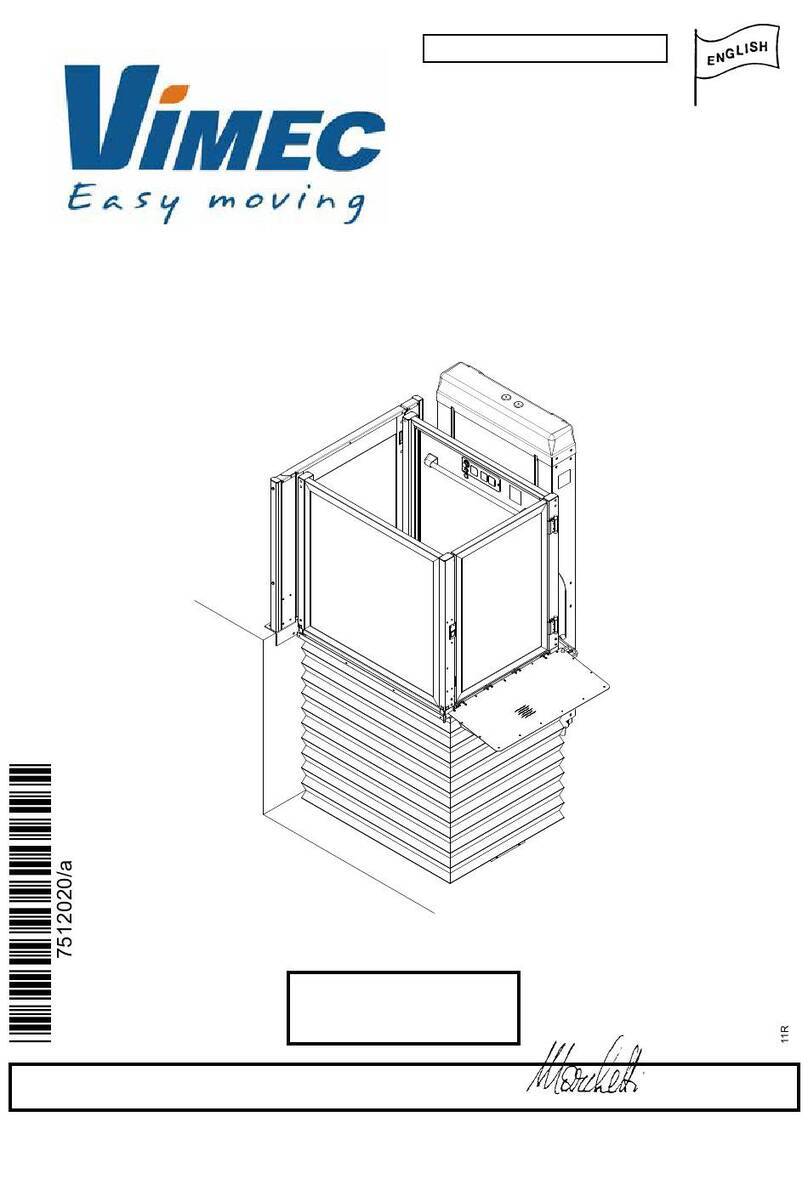

KNOW YOUR LIFT

To Engage Locking Mechanism, press

Height Locking Lever forward against

Lift Frame. To disengage locking

mechanism, pull Lever back against

Hydraulic Unit.

Release Pedal

Hydraulic Unit

Lift Pedal

Sleeve

Handle

Lift Saddle

Height

Locking/Unlocking

Lever

Oil Filler

Plug

Casters

INSPECT BEFORE EACH USE

Do not use if cracked, broken, bent or otherwise damaged parts are noted or if the lift is suspected to have been

subjected to a shock load. A shock load is caused by rapidly opening and closing the release valve while the lift is

loaded. Such operation may result in a hydraulic overload which may disable the hydraulic unit. Owner and operators

of this device shall be aware that no serviceable or replaceable parts are available for this device other than those

parts listed on page 6. Any lift that appears to be damaged in any way, is worn or operates abnormally shall be

removed from service immediately until such time as repairs can be made. Do not attempt to weld, rivet or otherwise

repair this device. DO NOT modify or alter this device. It is recommended that an annual inspection be done to this

device by qualified persons and that missing or damaged labels, warning safety decals be replaced with ones that

are factory authorized.

OPERATING INSTRUCTIONS

1. Position Lift under appropriate lift point, centering load on lift platform.

2. Locate and pump the lift pedal until the lift platform comes into contact with an appropriate lift point.

3. After centering the load, slowly and carefully raise the lift platform by pumping the lift foot pedal.

4. Lock both swivel casters by pressing down on the caster lever marked ‘lock’.

5. Continue pumping until the load has reached desired height. Secure the load using appropriate tie down means.

Four tie down loops have been provided on the frame of the Lift. Make sure that the height locking mechanism is

fully engaged before working on or around the loaded Lift.

WARNING: Clear all tools and personnel before lowering load.

6. To lower, disengage height locking lever and depress release pedal. It may be necessary to slightly raise the lift

platform before disengaging the height locking lever.

5

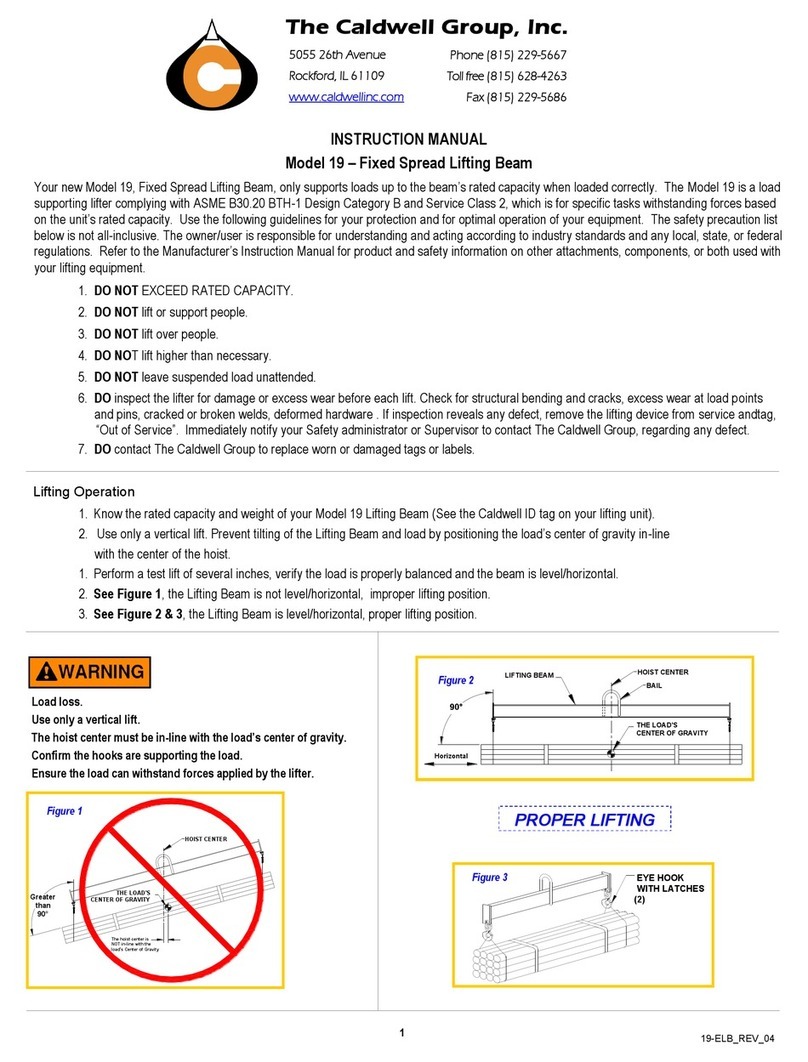

(fig. A)

(fig. B)

Strap

Press to Loosen Strap

Pull Lever to Tighten

HOW TO USE TIE-DOWN STRAP

1. After lifting the load (e.g. a motorcycle). Secure it with the provided tie-down strap. Make sure the strap is threaded

into four strap holders as shown in below figure.

2. To tighten the strap, thread the strap into the ratchet tie-down and pull the lever (open). Close and open the ratchet

tie-down until the strap is fully tightened and the load is secured (see fig. A).

3. To loosen the strap, simply press the spring clip (see fig. B).

CARE AND MAINTENENCE

NOTE: When lift is not in use, lifting arm should be stored in the fully retracted position. Keep lift clean and well

lubricated. Apply a couple of drops of light machine to all pivoting joints as needed. Thoroughly wipe up excess oil

to help prevent slipping and falling.

TO CHECK AND ADD HYDRAULIC OIL

1. To check hydraulic oil level, remove unit from lift, stand unit upright on a stable, level surface. Remove oil filler

plug. Oil should be to the level of the oil filler plug hole.

2. If low, add high quality hydraulic jack oil ONLY. Never use ANY other fluid. Use of other fluid may result in hydraulic

system failure, causing sudden and unexpected loss of load height.

3. Install oil filler plug, install hydraulic unit into receiver of lift. Secure with provided bolt.

NOTE: To get the longest life possible out of your lift, we recommend changing the hydraulic oil after 7 years of use,

sooner if used in a dust and grit filled environment. Do not expose to moisture. Dry lift completely if it gets wet. Check

pump piston and ram of hydraulic unit periodically for signs of rust and corrosion. Clean mildly affected areas with a

clean oily cloth. Never use abrasives on the pump piston and ram surfaces.

TO REPLACE HYDRAULIC OIL

1. Remove hydraulic unit from lift. Stand unit upright on a stable, level surface. Remove oil filler plug and drain old

oil into a suitable container.

2. Fill with high quality hydraulic jack oil.

NOTE: Dispose of used hydraulic oil in accordance with local regulations.

TO PURGE TRAPPED AIR FROM SYSTEM

1. Fully lower the lift arms, leave release valve open.

2. Remove oil filler plug. As you remove the oil filler plug you may hear pressurized air escaping from the reservoir.

This means you have successfully purged trapped air from the system.

3. Install oil filler plug.

6

TROUBLESHOOTING

Symptom Possible Causes Corrective Action

Hydraulic unit will not lift load • Release valve not tightly closed

• Overload condition

• Ensure release valve tightly closed

• Remedy overload condition

Hydraulic unit bleeds off after lift

• Release valve not tightly closed

• Overload condition

• Hydraulic unit malfunction

• Ensure release valve tightly closed

• Remedy overload condition contact

• K/M Australia

Lift will not lower after unloading • Reservoir overfilled

• Linkages binding

• Drain fluid to proper level

• Clean and lubricate moving parts

Poor lift performance • Fluid level low

• Air trapped in system

• Ensure proper fluid level

• With ram fully retracted, remove oil

filler plug to let pressurized air es-

cape, reinstall oil filler plug

Will not lift to full extension • Fluid level low • Ensure proper fluid level

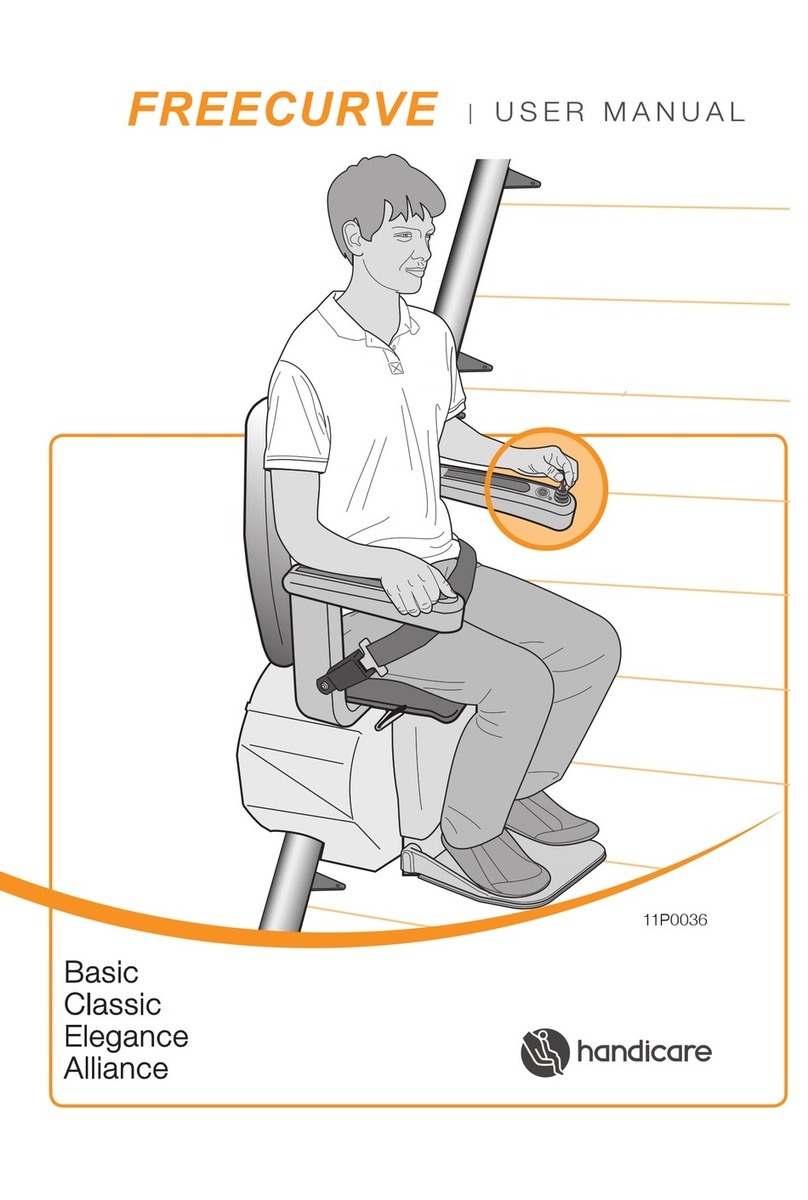

REPLACEMENT PARTS

When ordering replacement parts, please refer to the model number / serial number found on the product, then give

the part number and description.

Available Parts: Not all components of the lift are replacement items, but are illustrated as a convenient reference of

location and position in the assembly sequence.

Model T2151

Part No. Description Quantity

1 Front wheel assembly 2

2 Rear caster assembly 2

3 Hydraulic unit assembly 1

4 Oil filler plug 1

5 Locking lever assembly 1

6 Handle 1

-- Tie-down Strap (not shown) 2

-- Complete hardware kit (not shown) 1

-- Labels 3

-- Owner’s manual 1

1

2

4

3

5

6

Table of contents

Other Pro-Lift Lifting System manuals

Pro-Lift

Pro-Lift T-5350B Instructions for use

Pro-Lift

Pro-Lift T-5350 Instructions for use

Pro-Lift

Pro-Lift F1800-B User manual

Pro-Lift

Pro-Lift T-2300A User manual

Pro-Lift

Pro-Lift T-2151 Instructions for use

Pro-Lift

Pro-Lift C-2036 Instructions for use

Pro-Lift

Pro-Lift PL5500 Instructions for use

Pro-Lift

Pro-Lift T-3101 Instructions for use

Pro-Lift

Pro-Lift T-5500 Instructions for use

Pro-Lift

Pro-Lift F-798 Instructions for use