KVAL ON-HD Lift Manual

Table of Contents

How to Power Up the ON-HD Lift .........................................................2-3

Home the Machine Line........................................................................2-4

How to Power Down the Machine.........................................................2-4

About Emergency Shutdown and Recovery.........................................2-5

To Resume Normal Operation after an E-Stop.....................................2-5

Other Safety Controls ...........................................................................2-5

About Controls on ON-HD Lift ................................................. 2-6

ON-HD Lift Main Control.......................................................................2-6

Controls at the Main Panel ...................................................................2-6

Staging Area Controls.............................................................. 2-7

About the ON-HD Lift Process................................................. 2-8

Summary of the Interface ........................................................ 2-9

Machine Control and Calibration Screens ............................................2-9

Universal Controls ................................................................... 2-10

About Machine Status Feedback........................................................2-10

Request Access and Cancel Operation ..............................................2-10

About the Jump, Reset, and Home Buttons .......................................2-11

About the ON-HD Lift Main Screen.......................................... 2-12

About the ON-HD Lift Main Control Screen........................................2-12

About the ON-HD Lift Manual Operation Screen .................... 2-14

About the ON-HD Lift Manual Control Screen....................................2-14

About the ON-HD Lift Calibration Screen ................................ 2-16

The Calibration Screen.......................................................................2-16

Entering Calibration Offsets................................................................2-17

About the ON-HD Lift Diagnostic Screen................................. 2-20

About the ON-HD Lift Manual Control Screen....................................2-20

Description of the Light Tower ................................................ 2-21

About the Safety Curtain.......................................................... 2-22

If the Field is Broken...........................................................................2-22

To Resume Normal Operation after an Field is Broken ......................2-22

Location of Safety Curtain on the ON-HD Lift.....................................2-23

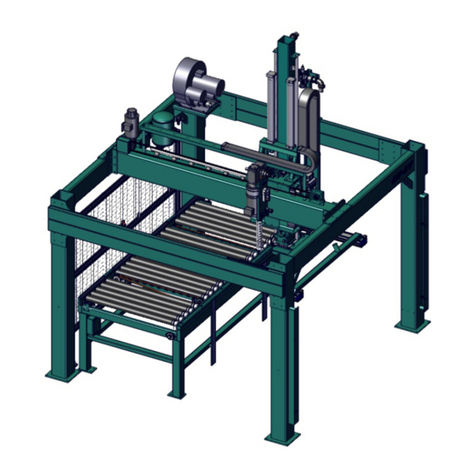

Chapter 3 Tour of the ON-HD Lift

Identification of Key Parts of the ON-HD Lift ........................... 3-2

ON-HD Lift Top View.............................................................................3-2

About the Lift Assembly ........................................................... 3-3

Boom Assembly ....................................................................................3-3

Carriage Assembly................................................................................3-4