2

GENERAL INFORMATION

Save these instructions. For your safety,

read, understand, and follow the informa-

tion provided with and on this lift. The owner

and operator of this equipment shall have

an understanding of this lift and safe oper-

ating procedures before attempting to use.

The owner and operator shall be aware that

use and repair of this product may require

special skills and knowledge. Instructions

and safety information shall be conveyed in

the operator’s native language before use

of this lift is authorized. If any doubt exists

as to the safe and proper use of this jack,

remove from service immediately.

Inspect before each use. Do not use if

broken, bent, cracked, or damaged parts

(including labels) are noted. Any lift that

appears damaged in any way, operates

abnormally or is missing parts, shall be

removed from service immediately. If the

lift has been or suspected to have been

subjected to a shock load (a load dropped

suddenly, unexpectedly upon it), imme-

diately discontinue use until lift has been

checked by a factory authorized service

center. It is recommended that an annual

inspection be done by qualied personnel.

Labels and Owner’s Manuals are avail-

able from manufacturer (see Replacement

Parts, page 5).

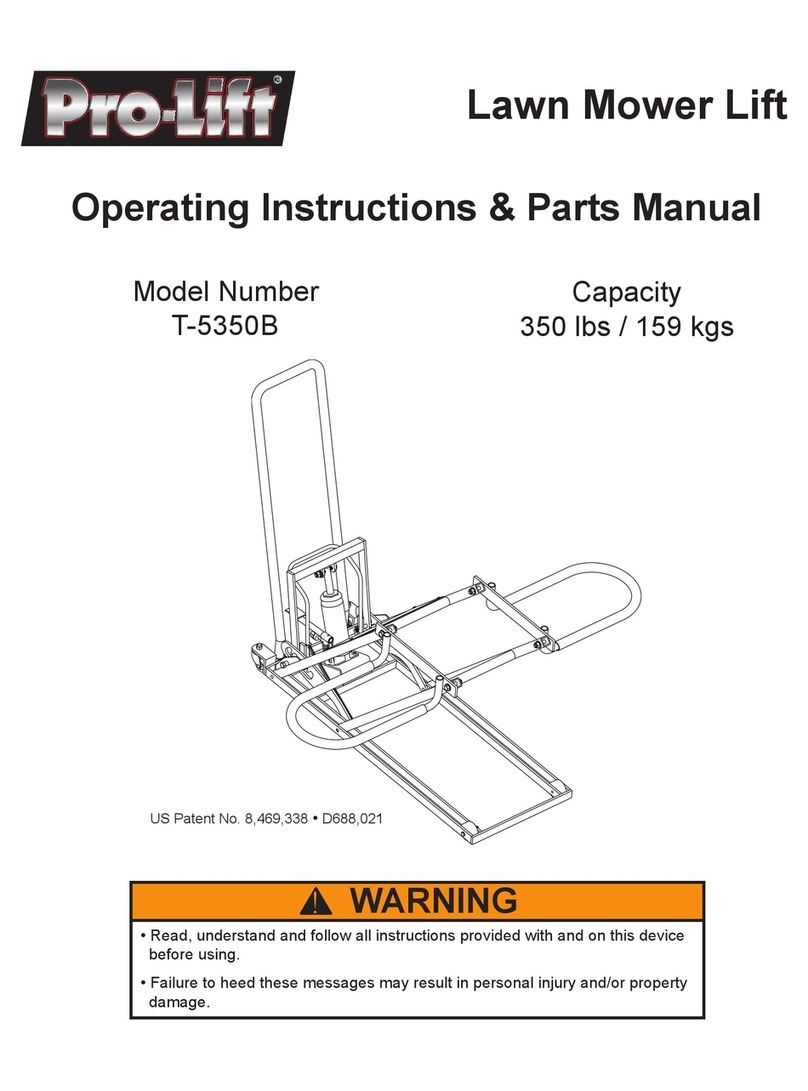

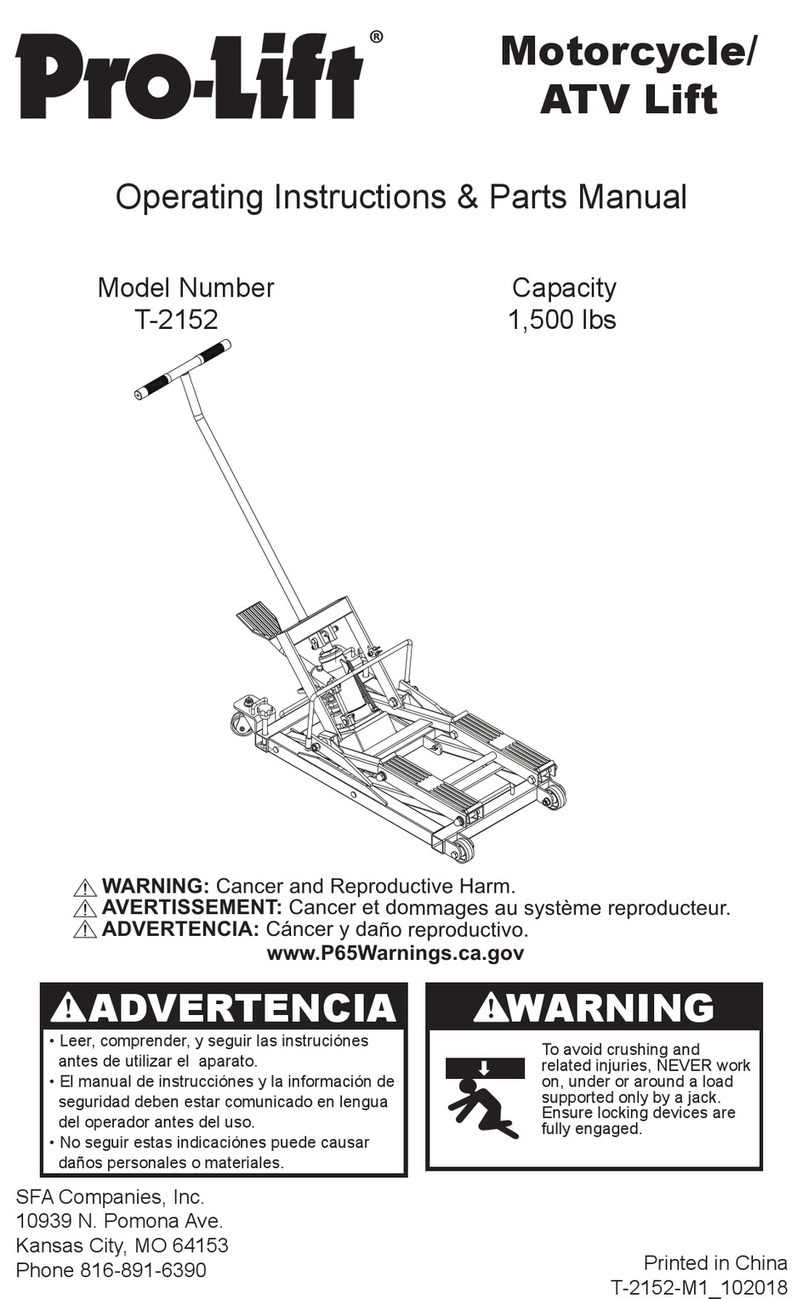

PRODUCT DESCRIPTION

Pro-Lift Utility Lift is specically designed

to lift and support up to rated capacity

loads consisting of a single Motorcycle,

ATV, Snowmobile, Water Craft or Riding

Lawn Mower whose frames are compatible

with the lifting members of the lift. This lift

is NOT suitable for lifting, leveling and/or

positioning cars, trucks, SUV’s or convey-

ances other than those specically listed

and approved above. This lift is NOT suit-

able for lifting, leveling and/or positioning

houses, construction trailers and dwellings

in general. This product does not contain

independent lifting devices, but is designed

to be permanently assembled. Hydraulic

unit is not to be used independently of

the lift.

BEFORE USE

Inspect lift before each use:

1. Before using this product, read the

owner’s manual completely and familiar-

ize yourself thoroughly with the product

and the hazards associated with its

improper use.

2. Ensure that casters/wheels and lift arms

move freely. Check for and tighten any

loose assemblies. Do not use if cracked,

broken, bent or otherwise damaged

parts are noted or if the lift is suspected

to have been subjected to a shock load.

A shock load is caused by rapidly open-

ing and closing the release valve while

the lift is loaded. Such operation may

result in a hydraulic overload which may

disable the hydraulic unit.

3. Verify that the product and the application

are compatible. Incompatibility is evident

when the loaded

WARNING: Do not use for any pur-

pose other than that for which this

device is intended.

4. Owner and operators of this device shall

be aware that no serviceable or replace-

able parts are available for this device

other than those parts listed on page 4.

Any lift that appears to be damaged in

any way, is worn or operated abnormally

shall be removed from service immedi-

ately until such time as repairs can be

made. Do not attempt to weld, rivet or

otherwise repair this device.

5. DO NOT modify or alter this device. It is

recommended that an annual inspection

be done to this device by qualied per-

sons and that missing or damaged la-

bels, warning/safety decals be replaced

with factory authorized labeling.

ASSEMBLY

1. Install hydraulic unit into receiver and

secure with provided 7.5mm x 22mm

allen head bolts (2).

2. Insert pin conecting hydraulic unit to lift

arm with slot in pin to the left as viewed

from rear of lift.

3

CAUTION: Beware of tension force

of return spring.

4. Install lift foot pedal into sleeve and

secure with provided hex head bolt.

5. Install handle into frame and secure

using the provided pins (2).

6. Ensure assembly rolls freely, lifts, locks,

and lowers easily. Get to know how the

release pedal, lift pedal, and the height

locking and unlocking mechanism work

prior to loading the lift.

OPERATION

1. Position lift under appropriate lift point

centering load on lift saddle.

2. Locate and pump the lift foot pedal until

the lift saddle comes into contact with

an appropriate lift point.

3. Only after centering the load, slowly and

carefully raise the lift arm by pumping

the lift foot pedal.

4. Lock both swivel casters by press-

ing down on the caster lever marked

‘lock’.

5. Continue pumping until the load has

reached desired height. Secure the

load using appropriate tie down means.

Four tie down loops have been provided

on the frame of the lift, 2 fore and 2

aft. Make sure that the height locking

mechansim is fully engaged before

working on or around the loaded lift.

WARNING: Safety tie-downs, sold

separately, are required for safe

operation of this device. Purchase

and use tie-downs with sufcient

capacity to hold motorcycles placed

on this jack.

WARNING: Be sure all tools and

personnel are clear before lowering

load.

6. To lower lift, disengage height

locking lever and depress release

pedal.

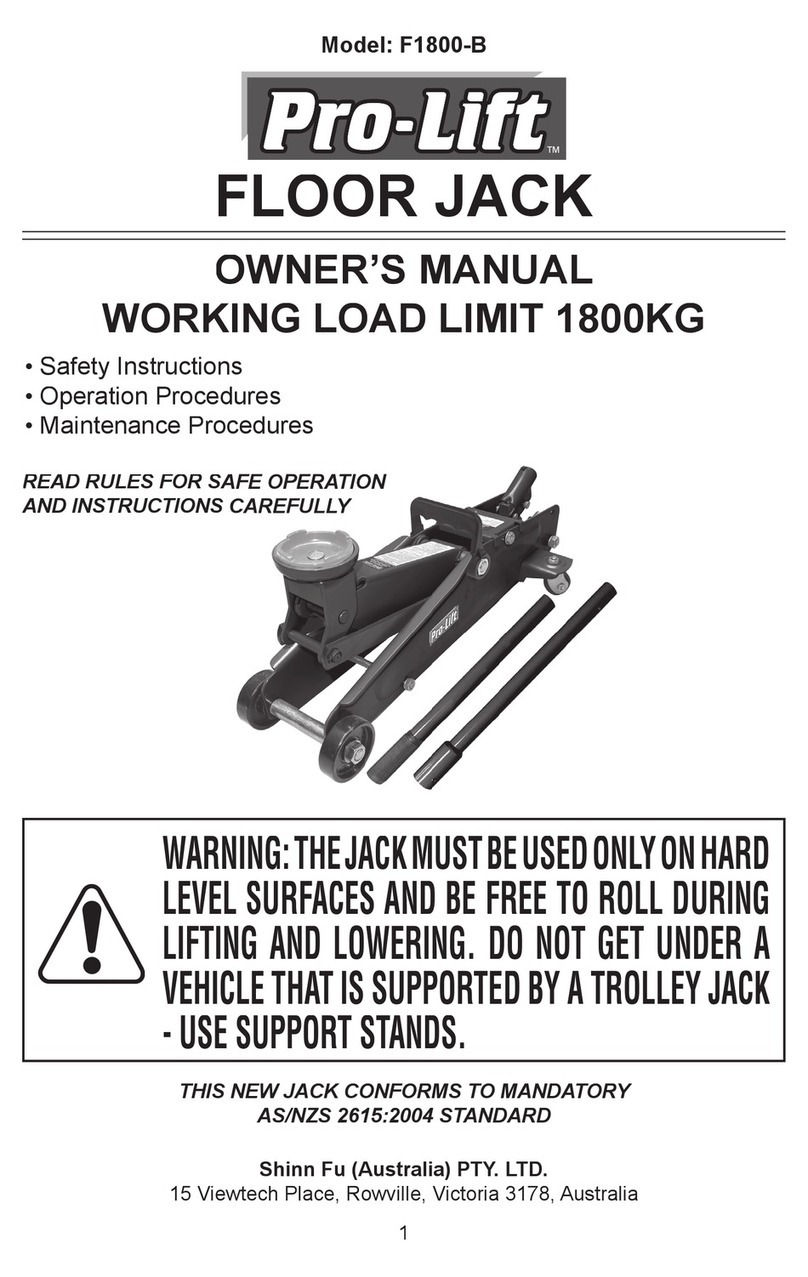

• Study, understand and follow all instruc-

tions before operating this device.

• Do not exceed rated capacity.

• Use only on hard, level surfaces.

• Center load on lift pads.

• Lift only on areas of the vehicle specied

by it’s manufacturer.

• Immediately after lifting load, ensure

lift mechanical load holding means is

engaged.

• Before moving, lower the load to lowest

possible point.

• Secure load with appropriate restraint

device.

• Use of this product is limited to lifting,

lowering, transporting and storing in

the lowered position, loads consisting

of a single vehicle whose lift points are

compatible with the lift platform. In-

compatiblity is evident when the loaded

motorcycle/ATV wobbles, appears un-

stable, and/or does not securely engage

the lift platform.

• Restriaining an incompatible load will

not make the load secure and may

cause unexpected loss of load.

• Never work on, around or under a load

that is not secured and stable.

• Keep operator’s and bystander’s head,

hands and feet away from lift arms when

raising and lowering.

• No alterations shall be made to this

product.

• Only attachments and adapters supplied

by the manufacturer shall be used.

• Failure to heed these markings may

result in personal injury and/or property

damage.

WARNING

!

!

!

!

3. Install return spring by slipping one

spring loop into slot on pin with the

other spring loop onto bolt stub at

base on hydraulic unit.

!