4

PREPARATION (cont.)

NOTICE: The T-5501 is equipped with a 1/4” NPT air

coupler. If installing a different air coupler, ensure thread

tape or compound is used when servicing connections.

To ensure dependable, trouble free operation an inline air

dryer and oiler is recommended.

5. Pump mechanism should operate smoothly before

putting jack into service. Replace worn or damaged parts

and assemblies with Pro-Lift authorized replacement

parts only.

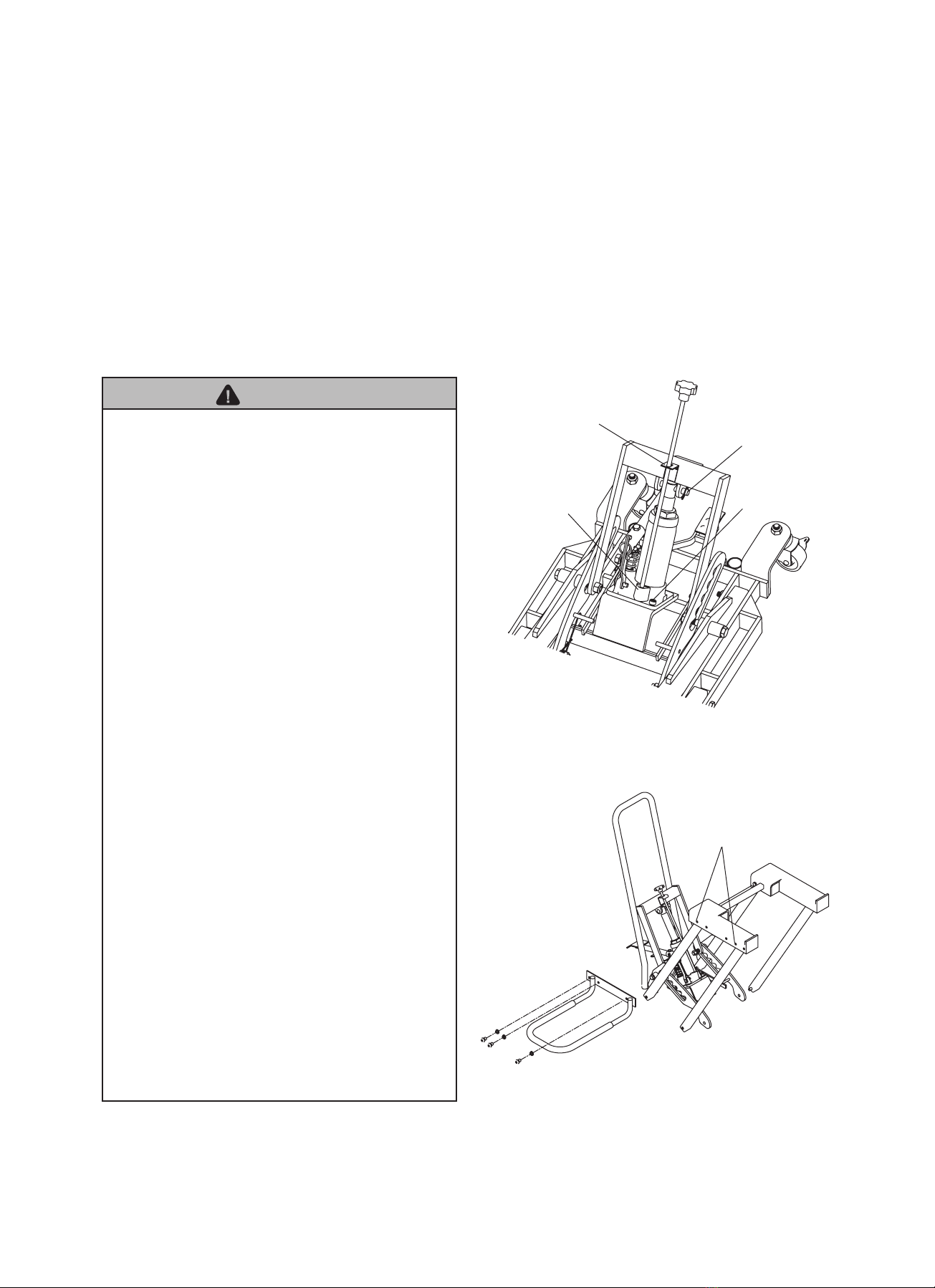

Bleeding/Venting Trapped Air

With the Release Knob in the OPEN position (step 3b,

pg. 3) and Ram fully lowered, locate and remove the oil

ller screw. As screw is removed, pressurized air may be

heard escaping from the reservoir.

CAUTION: Reservoir may be under pressure and

hydraulic oil may be expelled.

This means trapped air has been successfully removed

from the system. With Lift Pedal in the sleeve, pump 6 to

8 full strokes. This will help release any pressurized air

still trapped within the reservoir. Oil level should be even

with the bottom of the oil ller hole. Reinstall the oil ller

plug/screw.

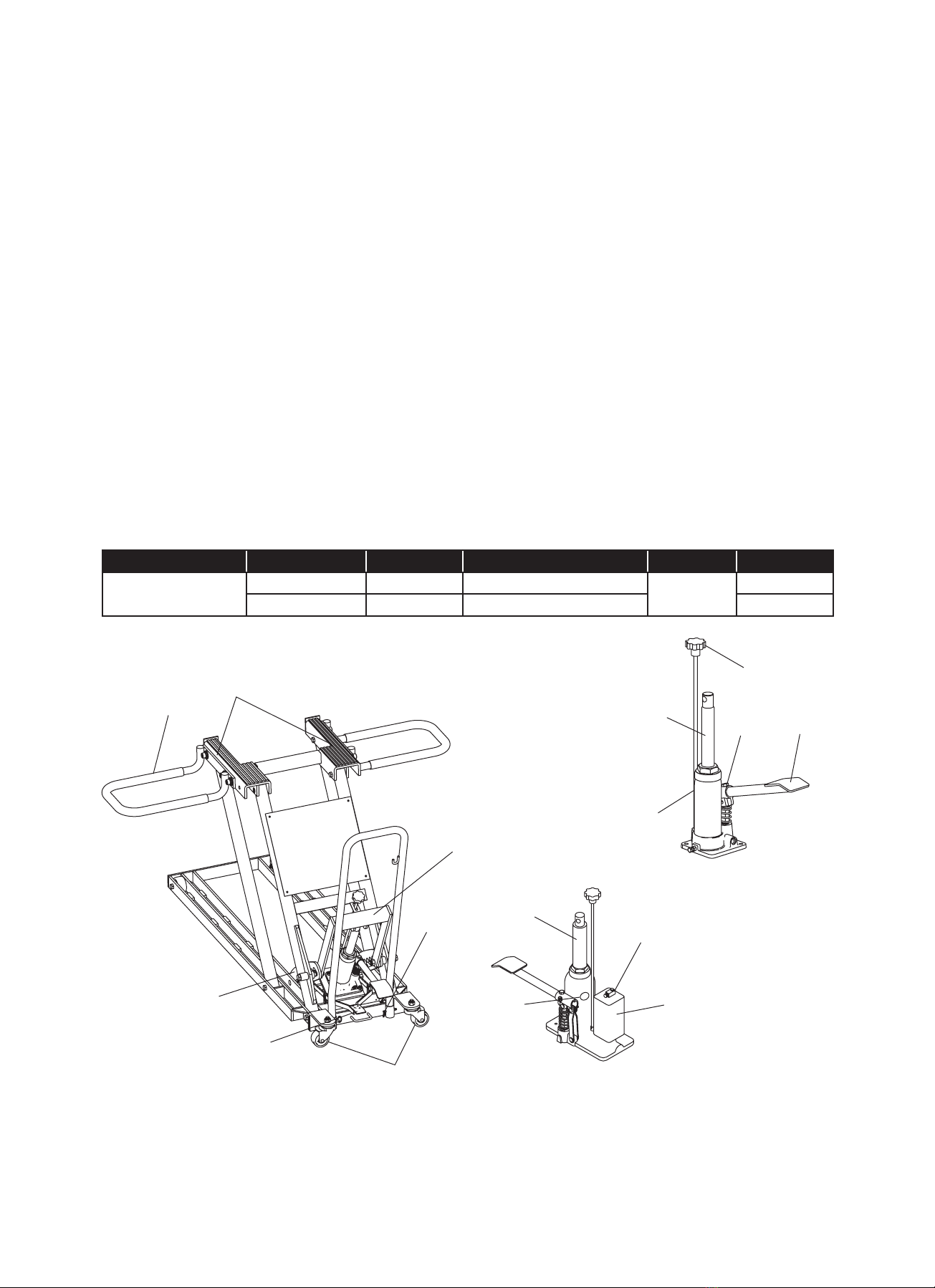

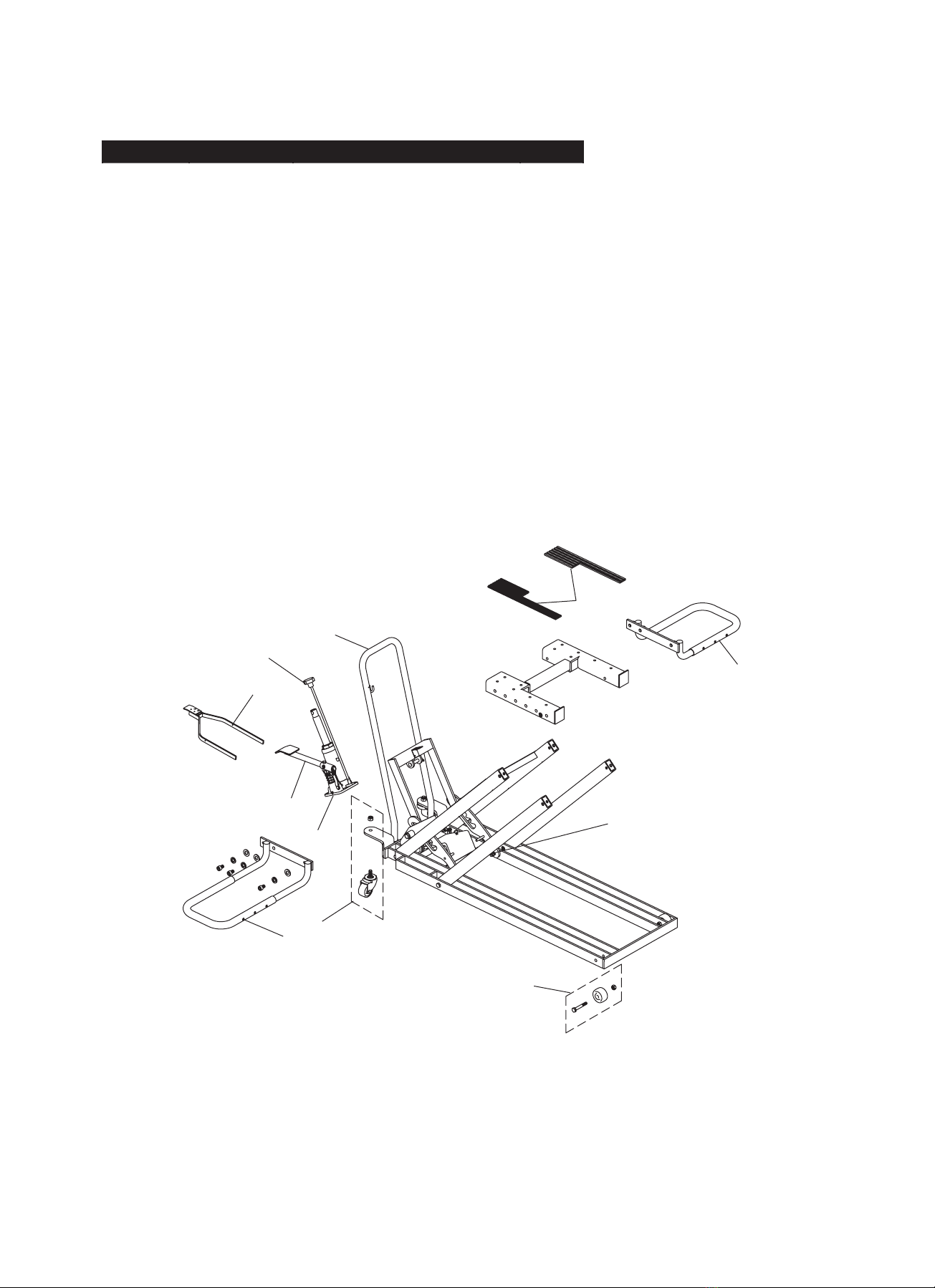

ASSEMBLY

1. Install Hydraulic Unit on receiver and secure with

provided M8 x 1.25 bolts (ref. Figure 2).

2. Insert Ram pin through Ram and Ram brackets on

crosshead assembly, then install cotter pin.

3. Insert Release Knob through Release Knob guide and

attach to Hydraulic Unit with screw and nut provided.

4. Insert Lift Pedal into Sleeve and attach with supplied

bolt.

5. Install Positioning Handle into frame and secure using

the provided pins (2).

6. Attach two Wheel Brackets to sides of Lift Platform (ref.

Figure 3).

7. After assembly, ensure that lift rolls, lifts and locks,

and that pump operates smoothly before putting into

service. Familiarize yourself with how Height Locking

Lever, Lift Pedal, and the Height Unlocking Lever

operate prior to loading lift. Replace worn or damaged

parts and assemblies with authorized replacement

parts only (ref. Replacement Parts, pg. 6). Lubricate

as instructed in Maintenance Section.

OPERATION

1. Adjust Wheel Bracket width for mower track.

2. Drive mower onto Wheel Brackets.

WARNING: Use only on hard, level surfaces capable

of sustaining rated capacity loads.

3. Leave mower transmission in neutral, close Hydraulic

Release Valve and carefully pump jack until mower

reaches desired height. Final height must correspond

with the locking teeth on the Height Locking Lever.

4. Carefully turn the Release Knob counterclockwise until

the Lift Platform engages the Height Locking Lever,

then close the Release Knob by turning it fully clock-

wise. Do not work around or under load unless Height

Locking Lever is properly engaged.

5. Secure the mower by setting the parking brake, putting

transmission in gear and chocking the wheels.

CAUTION: Clear all tools and personnel before

lowering load. Only attachments and/or adapters

supplied by the manufacturer shall be used with this

device.

6. To lower the Lift Platform, release the mower’s parking

brake, place transmission in neutral and remove

chocks. Pump the Lift Pedal several times to disengage

the Height Locking Lever, then depress the Height

Unlocking Lever pedal. Carefully turn the Release

Knob counterclockwise to lower the load slowly.

MAINTENANCE

Keep lift clean and well lubricated. Apply a couple of

drops of light machine oil to all pivoting joints as needed.

Thoroughly wipe up excess oil.

NOTICE: Use premium quality hydraulic jack oil. Avoid

mixing different types of uid and NEVER use brake

uid, turbine oil, transmission uid, motor oil or glycerin.

Improper fluid can cause failure of the jack and the

potential for sudden and immediate loss of load.

Adding oil

1. To check hydraulic oil level, unload lift, lower Lift

Platform completely, then remove Hydraulic Unit from

lift. Place Hydraulic Unit upright on a stable, level

surface. Locate and remove Oil Filler Plug.

2. Ensure the oil level is even with the Oil Filler Plug hole.

Reinstall the Oil Filler Plug, then install Hydraulic Unit

onto receiver. Secure with provided bolts.

Changing oil

For best performance and longest life, completely replace

the hydraulic uid supply at least once per year.

1. With Lift Platform fully lowered, remove Hydraulic Unit

from lift. Place Hydraulic Unit upright on a stable, level

surface. Remove the Oil Filler Plug.