Pro-safe 31238165 Manual

PRO-SAFE® SHELTERS

OPERATION / MAINTENANCE MANUAL

PLEASE READ THIS INSTRUCTION MANUAL

CAREFULLY BEFORE ASSEMBLING YOUR PRO-SAFE

SHELTER.

CONTENTS

INTRODUCTION……………………………………………………………………………………1

SAFETY INSTRUCTIONS…………………………………………………………………………2

PRINCIPLES OF OPERATION…………………………………………………………………..4

SHELTER PACKING LIST ………………………………………………………………………..6

SET UP SHELTERS…………………………………………………………………………………..7

CONNECTING MULTIPLE SHELTERS……………………………………………………..10

PRO-SAFE SHOWER…………………………………………………………………………….12

STOWING SHELTERS AFTER USE………………………………………………………….13

MAINTENANCE…………………………………………………………………………………...15

TROUBLESHOOTING / REPAIRS ……………………………………………………..…15

WARRANTY…………………………………………………………………………………………18

1

INTRODUCTION

Thank you for buying a portable inflatable shelter. They have been

designed for rapid deployment and ease of use in emergency hazmat

incidents, offering a top quality multi use compact inflatable structure

constructed with heavy-duty and UV/chemical resistant material for

prolonged use and safety. Shelters could be served as portable points of

dispersal for vaccinations, emergency supplies and other tented function

or situation requiring a rapidly deploy-able shelter like relief shelter,

temporary space and warehouse and decontamination place, etc.

Important Notes

1. Please keep this manual in a secure place and keep it with the unit

permanently.

2. This operation manual should be thoroughly and completely studied

and understood prior to initial use of the unit. If this is your first air

inflatable Shelter, for your own comfort and safety, please ensure that

you obtain handling and operation experience before assuming

command of the unit. Your PRO-SAFE authorized distributor will be

pleased to advise you with competent instruction.

3. If there are any questions or concerns, please contact PRO-SAFE prior

to operation.

4. Please note that we cannot be held responsible for any damage and/or

equipment malfunction, which may result from lack of reviewing and

following instruction manual instructions, and/or from lack /absence of

proper care and maintenance.

5. PRO-SAFE operates a policy of continual product development, and as

such both the product and this manual may be subject to technical

alterations without notice.

6. On scene coordinators are responsible at all times for the correct and

proper use, movement, carry/lift weight per person, cleaning & use in

various dangerous environments. PRO-SAFE® merely supplies set-up,

care, use & maintenance guidelines.

2

ATTENTION: This warning symbol appears in the operating

manual next to operating and safety instructions dealing

with rules, regulations and instructions for the proper

operation of the shelter.

SAFETY INSTRUCTIONS

1. This operation manual should be reviewed and thoroughly

understood prior use of the unit.

2. Products should not be used for other purposes except for the

original design, such as floating equipment.

3. Before setting up, on scene coordinators should assess the safety

of the site environment, and be sure to stay away from landslides,

fire sources, floods and other dangerous environments.

4. When removing shelters from the carrying bag, ensure there are

no sharp objects or glass on the floor that might tear or puncture

the inflatable structure.

5. Shelters require a compressed air/electric inflator/deflator

source to inflate them. Operators should be familiar with the

use of the air source utilized, and aware of any risks associated

with it.

6. The weight of the units varies dependent on the model

purchased. The units are supplied in a carrying bag fitted with

handles to permit two or more people to carry the unit. The

carrying bag is not to be dragged but lifted and carried by the

number of personnel on-sight coordinators deem appropriate.

3

7. When used in a hazmat incident, shelters may come in

contact with substances ‘hazardous to health’. Should this

happen, they should be thoroughly cleaned to prevent

contamination of personnel. Operators should be aware of this

risk, and wear appropriate personal protection to avoid

coming in contact with these substances. On scene

coordinators must manage and be completely responsible

herein.

8. Shelters are fitted with an over pressure valve on the

inflatable structure, to prevent the unit from over-inflating and

possibly bursting. This valve is fully automatic in operation and

must not be blocked or adjusted in any way. If using

compressed air to inflate unit, an operator must stand by at all

times and immediately turn off compressed air source when the

over pressure valve is activated as noted by the “hissing”

sound of escaping air.

9. When deflate, be sure all the people inside the shelter had

left, otherwise it may cause asphyxia.

TEMPERATURE USE GUIDELINES

At different temperatures, the compressed air in the air berm

expands as the temperature rises and shrinks as the

temperature decreases, so temperature affects the use of the

shelter.

COLD WEATHER USE:

Recommended for use in temperatures to -20 degrees C (-4 degrees

F) Fully inflate to the point of the over pressure valve almost being

activated (if activated cease air fill immediately) if being used in

extreme cold weather since the cold air will actually contract

inside the berms and the air berms may feel slightly ‘soft’ to the

touch.

4

WARM WEATHER USE:

Recommended for use in temperatures to +56 C (+132.8 F)

When temperatures during use are to exceed 30 degrees C (86 F) be

aware hot air expands and so manually reduce the air pressure in the

air berms or allow over pressure valves to activate. As the evening

shift arrives in continued use, and air temperature drops re-inflate

the unit as colder air causes internal air pressure to decrease.

AT THE COMMENCEMENT OF EACH SHIFT PRO-SAFE STRONGLY

ENCOURAGES AND RECOMMENDS THAT THE AIR PRESSURE

INTERNALLY BE CHECKED AND ADDRESSED AS ABOVE, AND THAT A

COMPLETE SYSTEMS CHECK OCCUR ON ALL ITEMS IN USE WITH THE

SHOWER OR SHELTER SYSTEM.

ATTENTION: When removing shelter from the carrying bag, ensure

there are no sharp objects or glass on the floor that might tear or

puncture the inflatable structure. Avoid dragging the

unit over rough surfaces. The use of a tarp/groundsheet

is strongly recommended for inexpensive protection

and maximum longevity of the floor and berms.

PRINCIPLES OF OPERATION

Shelters are inflated via the use of a compressed air source/electric

inflator/deflator and inflation time is approximately 45 seconds to 5+

minutes (size of unit dependent). Over-inflation of the structure is

designed to be prevented via the inclusion of a pressure relief valve fitted

to the unit. If using compressed air to inflate unit, an operator must

stand by at all times and immediately turn off compressed air source

when the pressure relief valve is activated as noted by the “hissing”

sound of escaping air. The structure has reinforced air inflated berms.

The structure is usually fitted with two external zipped doors, the first is

the entrance door, and the second is the exit door as determined by on-

scene coordinators.

5

To deflate the unit a valve is so equipped to release the air in the structure,

allowing the shelter to deflate. We suggest using the inflator/deflator

to empty the air berm to minimize the packing volume. The unit can then

be carefully folded and packed into the carrying bag supplied for safe

transportation and storage.

SHELTER DIAGRAMS

AUXILIARY INFLATION

VALUE (for air cylinder & air

guard)

ELECTRIC INFLATOR /

DEFLATOR INLET AND DUMP

VALVE: push in and quarter

turn clockwise to lock valve open. To

deflate, push in and quarter turn

counter clockwise to allow valve to pop

up and close.

SAFETY OVER PRESSURE

VALVE

REMOVABLE CANOPY

TIE DOWNS FOR FASTENING

ROPES TO TIE SHELTER

DOWN IN STRONG WINDS

SIDE DOOR

ENTRANCE / EXIT DOOR

INFLATABLE

STRUCTURE

REMOVABLE FLOOR

6

SHELTER PACKING LIST

Shelters consist of the following items:

1. Shelters in carrying bag

2. Electric inflator/deflator

3. Air guard

4. Stakes bag

5. Stake (qty Depending on the

shelter size)

6. Hammer

7. SCBA High Pressure Air inlet

hose

8. Repair material swatches

(sliver/blue/white for canopy, one

for air tube, one for the floor)

9. Repair clear patch & glue &

brush

10. Manual

7

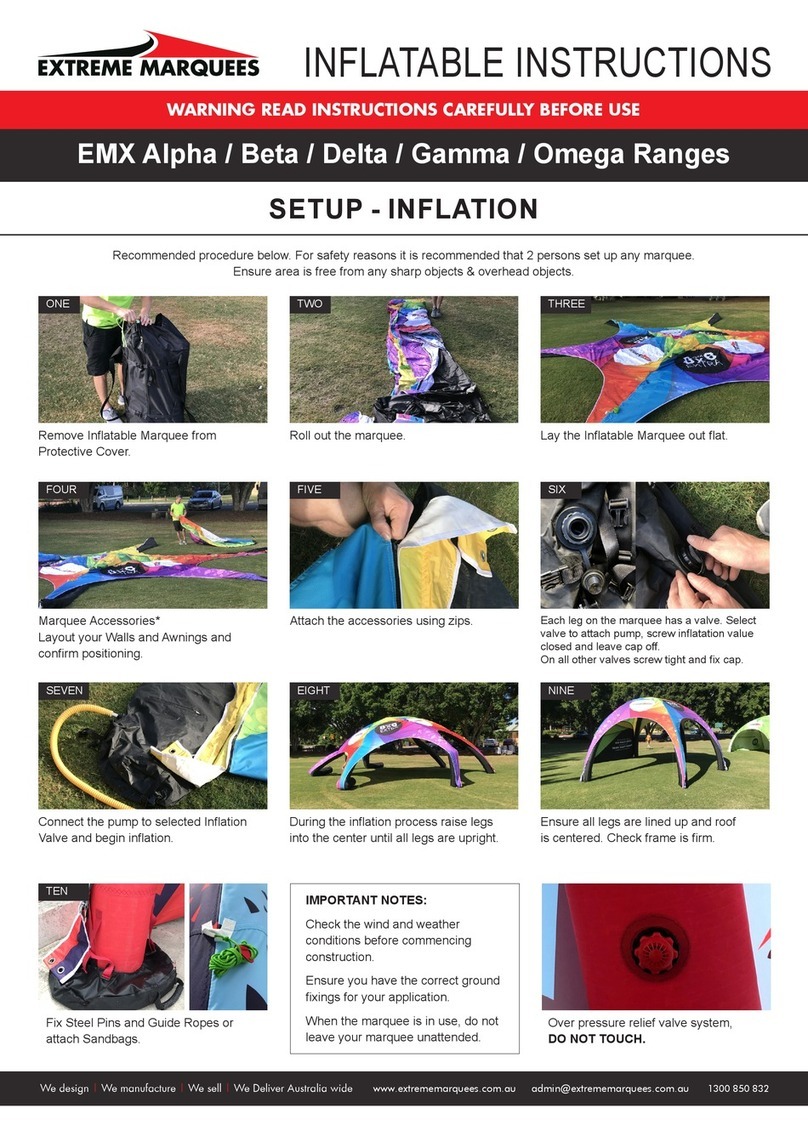

SET UP SHELTERS

1. To unpack shelter and make ready for

inflation. Undoing carrying bag, roll the

bag upside down, and remove unit.

ATTENTION:

Before undoing the carrying bag, be sure

that:

A:Check the environmental safety, be far

away from fire sources, disaster areas, and falling trees etc.

B:Ensure surface is flat and free of sharp objects, place groundsheet on

ground (if supplied as an option).

NOTE! Do not drag on ground!

C:The carrying bag is not to be dragged but lifted and carried by the

number of personnel on-sight coordinators deem appropriate.

D:Place the unit to suit all site and incident requirements, ensuring

entry/exit doors are aligned in right direction. On-scene coordinator

must make these decisions.

2. Unroll the shelter either onto

groundsheet or onto ground carefully,

pull the four corners flat.

Attention: At any time, do not wear shoes on the shelter.

When open and fold the shelter where it needs to stand on

it, please remove your shoes first, or the sand on the shoes

may pierce the air tube or canopy;

8

3. Locate and open the “Air Control”flap. You will see 3 valves located

on the tube vertically. From top to bottom, they are auxiliary inflation

valve (for air cylinder & air guard), safety over pressure valve and electric

inflator/deflator inlet and dump valve. Inflating the shelter according to

the method of inflating.

METHOD OF INFLATING

USE THE ELECTRIC INFLATOR/DEFLATOR

Please be noticed the direction of the air

flow (see the arrow on the inflator/deflator).

Manufacture supplies 110V 1800W electric

inflator/deflator. Locate and open the

“AIR CONTROL”flag. Remove the twist

cap on the inlet and dump valve. Make the

valve remaining in the close position at this

point.

Extend the hose of the inflator/deflator so

that it is straight. Insert the sharp head

nozzle of the inflator/deflator into the

valve opening, press down and turn right,

then the nozzle will be locked into the valve.

Connect power and start

inflation/deflation. Once the shelter

reaches to rated pressure, remove the

nozzle first, then turn off the power.

Otherwise some air will escape from the air

berm. When finish, please close the valve

cap.

When use electric inflator/deflator to inflate the shelter, the air pressure

inside the tube will reach 2.2-2.5PSI and the pressure relief valve (rated

pressure 4PSI) will not be activated. If the electric inflator/deflator works

for a long time (over 10 minutes) or works under strong sunlight, the

temperature of the machine will rise to 60 ℃(140 ℉) and being

9

overheated. Once the machine overheated and it will stop and should

work again once it cools down.

INFLATION USING HIGH PRESSURE COMPRESSED AIR:

With on-scene coordinator oversight,

carefully attach hose to SCBA/dive air

cylinder and lock hose to air berm. Then turn

on cylinder air VERY slowly. Then inflate unit

until pressure relief valve operates - indicated

by sound of escaping air, which can be felt by

hand. IMMEDIATELY turn off compressed air

supply. The pressure relief valve will close

automatically when excess air has escaped

from unit.

NOTE! Never cover/block the pressure relief

valve, as the unit may burst!

Allow a steady, clean flow of air to inflate the unit. It will

take approx. 45 seconds to 5+ minutes to inflate the unit

(size of unit dependent) from an SCBA cylinder, and slightly longer if

using a compressor or the electric inflator/ deflator. Remove inflator /

deflator once unit is fully inflated.

NOTE! Support roof of shelter as it inflates! (helps unit stand)

4. After the

shelter stands up,

pull the four

corners and the

floor flat.

10

Make the following final checks:

1. Check that the unit is upright, and not leaking. If a leak is discovered,

deflate unit and repair before using. (See instructions for notes on how

to repair punctures.)

2. In the event of/in case of windy

conditions, always tie off unit to the

ground using supplied tie down

ropes and stakes, and/or lash to solid

objects (e.g. vehicles).

CONNECTING MULTIPLE SHELTERS

Position and unpack all the shelters in the selected configuration. Inflate

and secure each shelter. Locate the Velcro attachments at the end of each

entrance and connect them together.

All shelters can be connected together directly or through item

NO.31238165 anteroom to connect the entrance/exit door or side door

(if available) of each shelter.

Item NO.31238165 anteroom itself could be a normal shelter. It could also

work as a connection shelter to connect multiple shelters

entrance/exit/side doors into a large area.

11

1. On-scene coordinator should decide

shelters placement and the location of

the zipper door;

2. Pull the two doors need to be

connected closely (distance 10-20 cm).

Shelters should be in a straight line.

3. Roll up the zipper door and fasten it

by the door webbing.

4. Pull the Velcro flag off the door.

5. Locate the stitching line

vertically which shows the center of

the flag. Connect the two Velcro

flags from this center point. Do the

connecting smoothly and avoid

wrinkles as far as possible.

6. line up the floor and connect the

floor Velcro smoothly.

12

PRO-SAFE SHOWERS

Showers have been designed for use by personnel with some knowledge

or training in decontamination procedures. On-scene coordinators must

always determine correct use.

The zipper head of the shower will be equipped with a pulling rope made

of webbing to facilitate the operation of the cleaning personnel.

On the outside of the shower,

two small holes will be found,

which are used for sprinkler

and sewage fittings.

After the shower is inflated,

pay attention to the

removable independent

pool inside the shelter. This

pool needs to be inflated

separately, and the valves

are located on one side of

the pool.

The decon liner inside the shower can be taken out separately. When you

think it has been polluted and needs to be replaced, you can untie the

bandage on the liner and install a new one for replacement.

13

There are Velcro

and straps on the

inside and on the

top of the liner,

which are used to

fix the sprinkler

system. Velcro on

the bottom liner

can be attached to

the pool to

prevent sewage

from spilling.

When used in a hazmat incident, shelters may come in contact with

substances ‘hazardous to health’. Should this happen, they should be

thoroughly cleaned to prevent contamination of personnel. Operators

should be aware of this risk, and wear appropriate personal protection to

avoid coming in contact with these substances. On scene coordinators

must manage and be completely responsible herein.

STOWING SHELTERS

1. If using accessories such as air/water heaters/ decon showers,

disconnect and remove all showers, heating, air cooling units and so forth

from inside the shelter or in close proximity to.

2. Wipe up any residual water inside the unit, and make sure interior is

completely dry.

3. Remove all stakes;

4. To deflate unit, make sure the entrance and exit doors are dropped

down and zipped to half of the height.

5. Ideally with one person or more at each end of shelter, open the main

inflation valve. Push and turn the center valve core 1/4 clockwise. The air

will come out automatically.

6. The shelter will rapidly deflate (within 1 minute or so). As the unit

collapses, each person should pull inwards on the end pillars, so the roof

collapses neatly on top of the lower part of the unit.

7. It is best to use the supplied electric inflator/deflator to fully remove

14

air from the unit (1-8 minute, depending on shelter size). After fully

deflate, push and turn the center valve core to pop up, and cover with

the valve cap.

Folding:

1. After fully deflate, put the shelter along the length direction

(perpendicular to the front and rear doors), then fold it inwardly for

two or three times according to the size of the shelter.

→

→

↑

2. Roll from end.

3. Put it in carrying bag and fasten it.

When folding the shelter, be sure below items:

1. Ensure all air has been evacuated from frame. Otherwise could not put

back into the carrying bag.

2. Allow your air shelter to dry thoroughly in the shade before storing,

never in bright sunlight. Store your air shelter in a cool, flat and dry place

with some air in the air chambers if possible.

3. It is important to dry off the unit completely before final packing into

the carrying bag. This may not be feasible immediately after use, and

might be better done back at base. Please note that storing wet shelters

with either water and/or detergent residue on the canopies may result in

the growth of surface mold and an accompanying mold odor on the

surface of the canopies. The canopies themselves will not rot or mildew,

but the growth of surface mildew/mold in/on the residue may occur.

4、You may fold your shelter 3-4 times, depending on actual demands.

15

Cleaning:

The surface of the air shelter should be cleaned with a solution of mild

soap and fresh water after each use. To avoid abrasion and wear, be sure

that all the sand, small rocks, oil and dirt have been flushed away from

the air shelter surfaces, and particularly the inside floor next to the berms.

** WARNING: NEVER USE PETROL OR SOLVENT

FOR CLEANING

MAINTENANCE:

Clean your unit with just fresh water and normal soap.

To get your air berms looking ‘like new’ apply wax for artificial

leather/or use Armor All type products and apply to the unit with a dry,

clean cloth.

When you store the unit for a long time without use, we would

recommend you inflate it monthly and check if it all is as originally left.

Use the enclosed repair kit for small punctures. Clean the fabric around

the area to be repaired using MEK or acetone, then re-clean as

before. Apply a coat of glue to the damaged part and to the patch

material, allowing it to dry for 2 - 3 minutes. It is strongly

recommended that all patch work be allowed to cure at least 24 hours

before re-inflating the unit.

It is recommended that the air shelter be returned to PRO-SAFE or an

authorized PRO-SAFE dealer for all large repairs.

TROUBLESHOOTING / REPAIRS

Your shelter should provide a long and trouble free operational life span.

It has been designed such that no spares need be kept other than

consumable items and accessories you may elect to purchase. However,

under certain circumstances the potential exists for faults to occur; and

their identification and possible rectification are as listed below:

16

INFLATABLE BERM LEAKS:

Identified by the shelter collapsing with time. A “hissing” sound

might be heard if leak is severe.

TO FIND LEAK:

1. Listen for “hissing” sound.

2. Check likely sources of leaks, such as valves. Check

over pressure valve and inflation valve for escaping air.

3. Check that the deflation valve is closed and not

leaking.

4. If valves are OK, check inflatable structure for

obvious signs of damage.

5. If leak cannot be traced, mix a solution of soap and

water. Using a brush, paint solution onto welding joints,

around valves, etc., until solution forms bubbles. This is

the source of the leak.

IF INFLATION/DEFLATION VALVE LEAKS:

Valve may have dirt or dust contamination, preventing

valve spring from closing the valve completely.

Carefully LIFT center of valve with small blunt object,

and clean with high pressure compressed air.

IF OVERPRESSURE VALVE LEAKS:

Valve may have dirt or dust contamination, preventing

valve spring from closing the valve completely.

Carefully LIFT center of valve with small blunt object,

and clean with high pressure compressed air.

TO REPAIR A LEAK:

Once leak has been found, deflate unit fully, and lay unit out flat on the

ground.

Ensure area around leak is dry and free of dirt or contaminants. Clean

area around leak, or LIGHTLY rub area with fine abrasive paper.

Cut a patch approximately 25mm (1”) larger, on all four sides, than the

size of the hole. Spare material is included in the repair kit provided with

17

every shelter unit. For small holes worn out by little sands/sharp objects,

you may use the clear patch first, then cover it by blue patch.

Apply adhesive from the tube provided to BOTH surfaces, ensuring all

areas are adequately covered with glue. Leave for 2–3 minutes until

adhesive is “tacky” to the touch.

Stick the patch over the hole and apply pressure or heavy weight to both

surfaces.

Maintain pressure for several minutes, until adhesive is dry.

Once dry, inflate unit and check for leaks. If all possible, allow all patch

work to cure for at least 24 hours before fully re-inflating and using the

unit.

SEE DETAILS BELOW

SMALL TEARS, CUTS AND PUNCTURE REPAIRS

DESCRIPTION:

Use the enclosed repair kit for small punctures. Clean the fabric around

the area to be repaired using MEK or acetone, then re-clean as

before. Apply a coat of glue to the damaged part and to the patch

material, allowing it to dry for 2 - 3 minutes. It is strongly

recommended that all patch work be allowed to cure at least 24 hours

before re-inflating the unit.

Please repair the leak in a dry/clean environment. If the weather is too

wet, the glue may not be easy to dry.

LARGE REPAIRS OF BERMS AND SEAMS DESCRIPTION:

It is recommended that the air shelter/shower be returned to PRO-SAFE

or an authorized PRO-SAFE dealer for all large repairs.

18

PRO-SAFE Products

LIMITED 2 -YEAR WARRANTY

PRO-SAFE (“Warrantor”) warrants to the original purchaser of all new

PRO-SAFE equipment supplied by Warrantor and to any person to whom

such equipment is transferred, that such equipment shall be free from

defects in materials and workmanship during the two (2) year period

commencing upon the date of manufactured against defects in materials

or workmanship (see the manufacture date and item number on the AIR

CONTROL Location).

PRO-SAFE will repair or replace product at PRO-SAFE’s discretion, which

fails to satisfy this warranty at no charge.

We will not be responsible for wear and tear; any improper installation;

improper use or maintenance; negligence of the owner or user; damage;

or anything else beyond our control. Further, we will not be responsible

for any consequential, incidental or indirect damages including any

damages and loss of profits from any cause whatsoever. No person has

authority to change this warranty.

PRO-SAFE warrants all new PRO-SAFE products for a period of two (2)

year after the date of manufactured against defects in materials or

workmanship (see the manufacture date and item number on the AIR

CONTROL Location). We will repair or replace a product that fails to

satisfy this warranty. Repair/replacement shall be at the discretion of

PRO-SAFE. Products must be returned promptly to PRO-SAFE for

warranty service AT CLIENT’S COST IN PACKAGING SUITABLE AND

CORRECT TO PROPERLY PROTECT THE PRODUCTS DURING THE RETURN

SHIPMENT. DAMAGE CAUSED DURING THE RETURN PROCESS, IF ANY,

WILL BE AT CLIENT’S EXPENSE AND RESPONSIBILITY. IF THE CLAIM IS

INDEED A VALID WARRANTY CLAIM AS DEFINED SOLELY BY PRO-SAFE -

ALL FREIGHT COSTS WILL BE CREDITED BACK TO CLIENT. We will not be

responsible for: wear and tear, improper installation, use, maintenance or

storage, negligence of the owner/user, repair or modifications after

19

delivery, failure to follow instructions or recommendations, or other

misuse or activity beyond our control. PRO-SAFE reserves the right to

change the design or parts of/in its’ products from time to time without

notice and with no obligation to maintain a spare parts inventory or to

make matching changes in products previously manufactured.

Replacement products in whole or in part offered as a one-time warranty

replacement will not be eligible for a second or follow up warranty claim.

PRO-SAFE shelters are offered with carrying bags designed to offer a

basic method to move and transport the product from point A to B. The

bags may also provide basic product protection. In such a capacity PRO-

SAFE carrying bag s are subject to scuffs, rips, tears, stitch pulls, et al.

These are not considered warranty items. Further PRO-SAFE carrying bag

s/SHELTER SLEEVES are not considered a product in and of themselves

and so no limited 2-year warranty is offered on carrying bag s/ shelter

sleeves.

NO OTHER WARRANTIES, EXPRESS OR IMPLIED, OTHER THAT THOSE

INCLUDED IN THE STATEMENT ARE OFFERED. FURTHER, WE DISCLAIM

ANY IMPLIED WARRANTY OF MERCHANTABILITY OR FITNESS FOR ANY

PURPOSE.

Table of contents

Popular Tent manuals by other brands

Chinook

Chinook Santa Ana 3 Assembly instructions

GrowSpan

GrowSpan Gothic Premium H5CRU Assembly instructions

Khyam

Khyam Hub Pitching & Striking Instructions

Mammoth Tents

Mammoth Tents Classic+ 240L Assembly guide

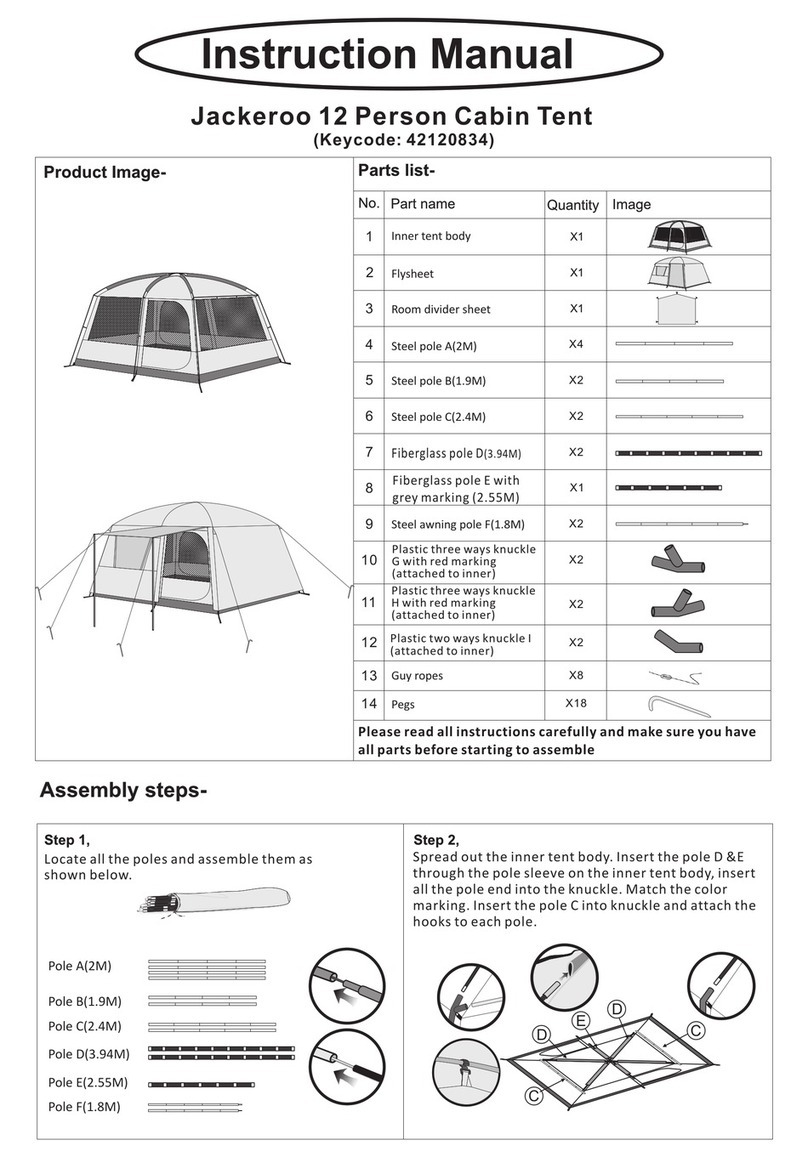

Jackeroo

Jackeroo 42120834 instruction manual

RidgeMonkey

RidgeMonkey ESCAPE BIVVY XF1 instructions