Proces-Data PD 3260 PMM User manual

502 069 02

GB February 1997

PROCES-DATA A/S, Navervej 8, 8600 Silkeborg, Denmark, Phone +45-87 200 300, fax + 45-87 200 301

POWER MONITOR MODULE

PD 3260 PMM

Manual

502 069 02

II/IV Power Monitor, PD 3260 Manual

© Copyright 1997 by PROCES-DATA A/S. All rights reserved.

PROCES-DATA A/S reserves the right to make any changes without prior notice.

P-NET, Soft-Wiring and Process-Pascal are registered trademarks of PROCES-DATA A/S.

502 069 02

Manual Power Monitor, PD 3260 III/IV

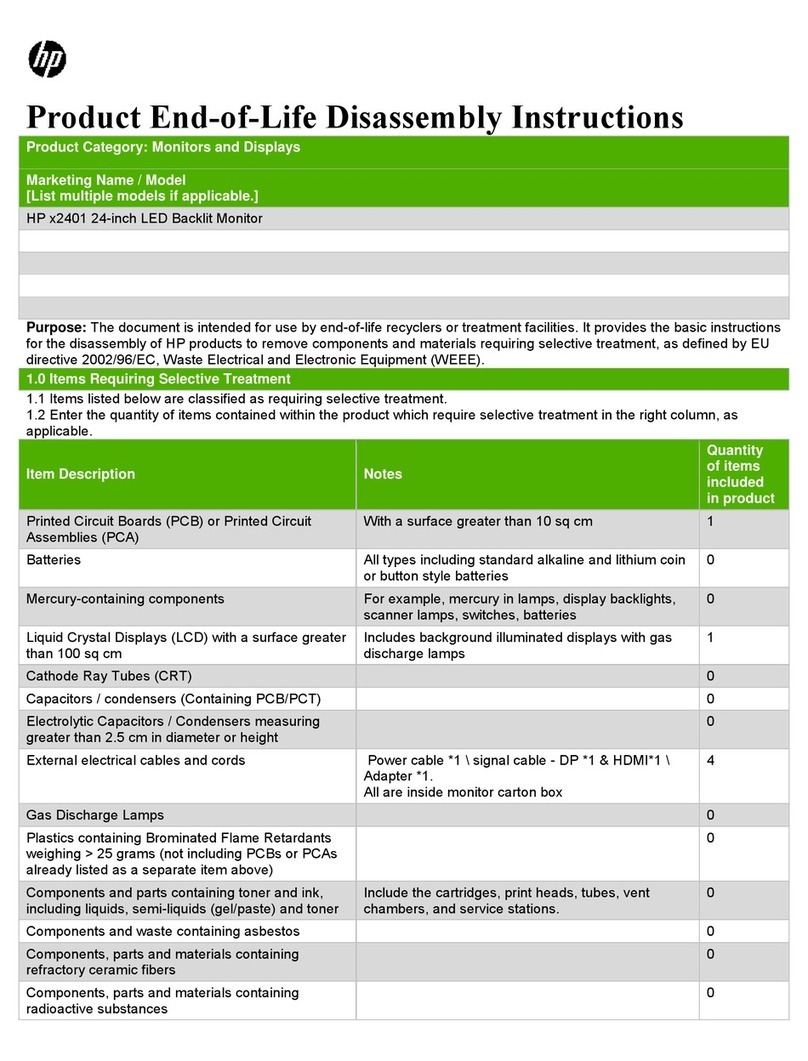

Contents Page

1 General information. ................................................... 1

1.1 Features. ........................................................ 2

1.2 System description. ............................................... 2

1.3 Channels/registers. ............................................... 4

1.4 Connections. .................................................... 5

1.5 Memory types. ................................................... 6

2 Service Channel (channel 0). ............................................. 8

3 Digital I/O Channel (channel 1 - 8). ...................................... 15

4 Common I/O Channel (channel 9). ....................................... 26

5 Power Monitor Channel (channel A). ..................................... 30

5.1 Connections to the Power Monitor Channel. .......................... 39

6 Generator Switch Channel (channel B). ................................... 41

6.1 Connections to Generator Switch Channel. ........................... 49

7 Thyristor Switch Channel (channel C). .................................... 51

7.1 Connections to Thyristor Switch Channel. ............................ 57

8 Calculator program. ................................................... 58

9 Program Channel (channel D). .......................................... 59

10 Data Channel (channel E). .............................................. 71

11 Construction, Mechanical. .............................................. 74

12 Specifications. ....................................................... 75

12.1 Power supply. .................................................. 75

12.2 Digital Input. ................................................... 75

12.3 Digital Output. .................................................. 75

12.4 Power Monitor. ................................................. 76

12.5 Generator Switch. ............................................... 76

12.6 Thyristor Switch. ................................................ 76

12.7 Calculator program. .............................................. 76

12.8 Ambient Temperature. ........................................... 77

12.9 Humidity. ...................................................... 77

12.10 Approvals. ..................................................... 77

13 Survey of variables in the PD 3260 module. ............................... 78

502 069 02

IV/IV Power Monitor, PD 3260 Manual

502 069 02

Manual Power Monitor, PD 3260 1/79

1 General information.

The PD 3260 Power Monitor is a member of the 3000 series of modules from PROCES-DATA.

It provides a three-phase Power

Line Monitor and Generator Switch

Controller interface to the P-NET

Fieldbus EN50170 Vol 1.

The monitoring functionsoffered by

the module are useful for assessing

the operation of electric generators,

and for monitoring loads connected

to three-phase power lines, or those

having up to 3 single phases.

The generator switch functions are

designed to perform phase, speed

and acceleration controlled switch-

ing of synchronous or asynchronous

generators, connected to three-

phase power lines.

Switching is performed using the Digital Output Channels or via the Thyristor Switch Channel.

P-NET is a fieldbus network, designed for process control and data collection. The PD 3260

module has been developed to directly interface with digital process signals.

Configuration of the module for the functions required, and communication between the module

and a control computer, is carried out via the P-NET fieldbus. The PD 3260 module can be

controlled via P-NET, or it can operate as an autonomous unit.

The module possesses a programmable Calculator, which can be purpose programmed to control

the digital outputs and monitor the digital inputs. The Calculator can operate on a variety of

variable types, such as reals, integers, bytes, booleans, timers and arrays. User programmes can

be devised to produce application specific functions, such as digital control loops, and PLC

functions may be set up for use in a wide variety of local autonomous process applications.

The compact design and outstanding environmental specifications for the Power Monitor, makes

it an ideal process component in industrial, as well as less stringent environments.

502 069 02

2/79 Power Monitor, PD 3260 Manual

1.1 Features.

&

Power Monitor Channel with three-phase current and voltage inputs.

&

Generator Switch Channel with tachometer and voltage inputs.

&

Thyristor Switch Channel with six modulated outputs for a three-phase thyristor switch.

&

8 Digital I/O Channels with automatic output functions.

&

Output current measurement and overload protection.

&

Common I/O Channel.

&

Programmable Calculator and Internal Data Channel.

&

Continuous self test.

&

Watch Dog Timer.

&

P-NET Fieldbus Communication (EN50170, Vol. 1).

&

Rail mounting module (DIN / EN).

&

EMC approved (89/336/EEC).

1.2 System description.

Power Monitor Channel

The Power Monitor channel has current and voltage inputs for the monitoring of a three-phase

power line. RMS current, RMS voltage, Power factor, Power and Energy are continuously

measured for each of the three phases. Input overload alarms, for the current and voltage inputs,

can be enabled.

Total effective power is calculated, and the level can be monitored by enabling user presettable

HighLevel and LowLevel alarms. In addition, the total effective power is integrated over time,

to provide Total, Produced and Consumed Energy values. The line frequency is continuously

measured.

Generator Switch Channel

The Generator Switch channel can be used to connect accelerating synchronous or asynchronous

generators to a power line. The channel measures generator phase, speed and acceleration in order

to calculate the moment in time when the generator should be connected to the power line. The

generator switch channel can be used to control a digital output channel driving a circuit breaker,

or the Thyristor Switch Channel. A configurable switch-on period value can be used to

compensate for relay contact delay.

Thyristor Switch Channel

The Thyristor Switch Channel performs ramp controlled thyristor triggering for three-phase

thyristor switches. The digital outputs I/O 1 to I/O 6 are used as the controlled outputs for this

channel.

502 069 02

Manual Power Monitor, PD 3260 3/79

Digital I/O Channels:

Various automatic functions can be selected within each digital channel, such as automatic

feedback control (single, as well as double), one-shot output and pulse output. This reduces such

basic operations having to be performed at a remote central control point.

The output current (Sink), is measured continuously on each channel, and can be read as a value

in Amps. If the current exceeds the specified max value, the output is switched off, and an error

code (overload) is generated in the module.

The common I/O channel in the module, provides the ability to read/set all inputs/outputs, using

a single P-NET transmission.

General

The unit offers comprehensive self-testing features, which enables the reporting of disconnection,

overload and process failure. All outputs are protected against overload.

The watchdog timer ensures the safe shut down of a process following a communication error or

power failure.

The PD 3260 is approved in compliance with the EMC-directive no 89/336/EEC. Test limits are

determined by the generic standards EN 50081-1 for emission and EN 50082-2 for immunity.

The PD 3260 is approved in compliance with the IEC 68-2-6 Test Fc standard for vibration.

502 069 02

4/79 Power Monitor, PD 3260 Manual

1.3 Channels/registers.

The PD 3260 module contains:

1 Service channel (channel $00) 8 Digital I/O`s (channel $01-08)

1 Common I/O channel (channel $09) 1 Power Monitor (channel $0A)

1 Generator Switch (channel $0B) 1 Thyristor Switch (channel $0C)

1 Program channel (channel $0D) 1 Data channel (channel $0E)

A set of 16 variables, numbered from 00 - $0F, is associated with each channel. For addressing

a variable within a particular channel, a logical address called a SoftWire Number (SWNo), is

used. The SWNo is calculated as: (channel number

$10 + variable number within the channel).

Example: Variable 4 on channel 3 needs to be addressed.

The SWNo will therefore be $34.

Throughout the manual, the variables are depicted as tables. The variable names are standard

identifiers, as defined in Process-Pascal.

502 069 02

Manual Power Monitor, PD 3260 5/79

1.4 Connections.

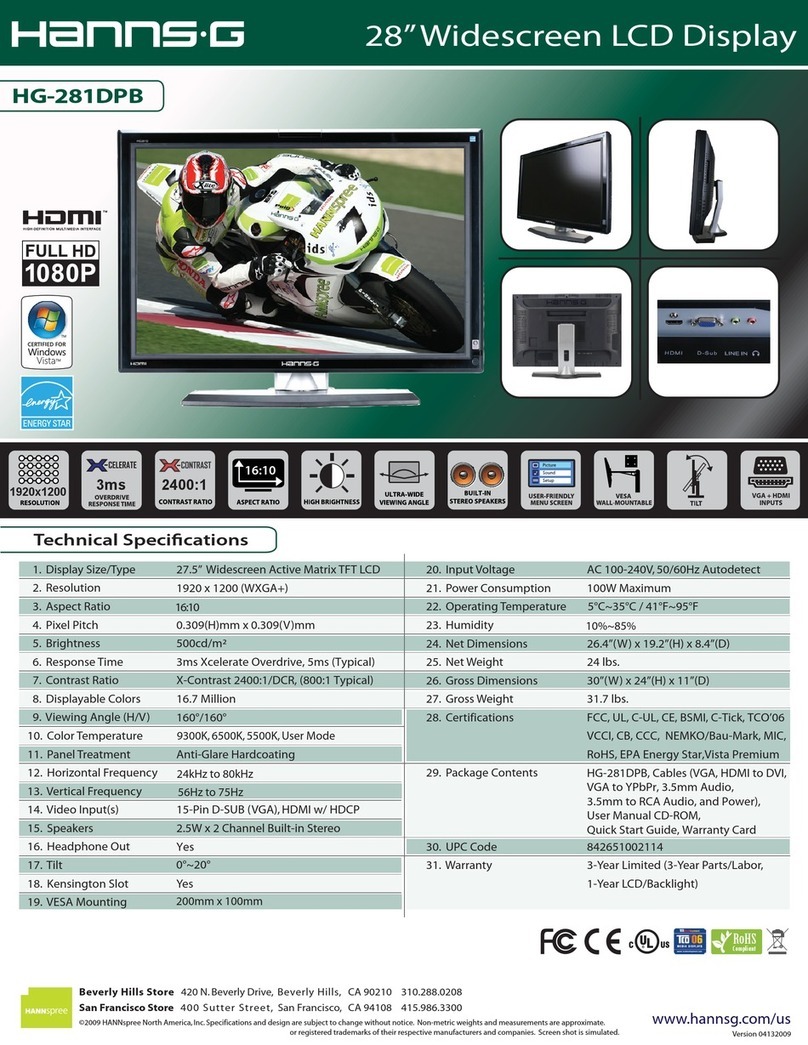

The PD 3260 Power Monitor is

physically designed as a black box,

having two 14 pin connectors with

screw terminals. The connectors are

removable and equipped with a key

pin, to avoid reversed connections.

Connection identities are printed on

the top of the module. The module

wiring should be designed with a

maximum of 2 wire connections in

each screw terminal.

The module has a built in fuse,

which is used to protect the module,

and externally connected wiring and

equipment. When connecting exter-

nal equipment, the additional fuse

protected +24 V screw terminals

should be used (see hardware dia-

gram).

Hardware diagram, principle.

502 069 02

6/79 Power Monitor, PD 3260 Manual

1.5 Memory types.

The PD 3260 stores data in different types of memory, depending on the value of a control

variable following a reset or a power failure, and the state of write protection.

Some variables are stored in both non-volatile and volatile memory. The state of the module's

WriteEnable register, determines whether the contents are changed in both types of memory, or

only in the volatile type.

The following memory types are listed in the channel definition tables.

Read Only

PROM ReadOnly

The PROM is always write protected and can never be changed.

RAM ReadOnly

The variable is stored in RAM and is only accessible for Reading.

Read Protected Write

EEPROM RPW (Read, Protected Write)

The EEPROM is always write protected directly following a reset. By setting

WriteEnable to TRUE, the contents of the EEPROM can be changed. The contents

of the EEPROM will remain unchanged during and after a power failure.

Read Write

RAM ReadWrite

The variable can be changed instantly. After reset or a power failure, it's value is

set to zero.

502 069 02

Manual Power Monitor, PD 3260 7/79

Read Write, Protected BackUp Write

RAM InitEEPROM

The variable is stored in both RAM and EEPROM. After a reset, the variable is

copied from EEPROM into RAM. When the variable is changed via P-NET, the

value is changed in RAM. If WriteEnable is TRUE, the value is changed in both

RAM and EEPROM when the variable is modified via P-NET.

RAM AutoSave

Has the same function as RAM InitEEPROM, with the addition that the contents

of RAM are automatically copied to EEPROM, at a frequency of approximately 10

hours.

After copying to EEPROM, a new sumcheck value is calculated. The new

sumcheck value is stored in the EEPROM, unless an EEPROM error has already

been set (CommonError.ChError.Act[2]).

502 069 02

8/79 Power Monitor, PD 3260 Manual

2 Service Channel (channel 0).

PD 3260 has a service channel, containing variables and functions common to the entire module.

Variables on Service channel (channel 0). Channel identifier: Service

SWNo Identifier Memory type Read out Type

0 NumberOfSWNo PROM Read Only Integer

1 DeviceID PROM Read Only - - - - - - - Record

2

3 Reset RAM Read Write Hex Byte

4 PnetSerialNo Special function - - - - - - - Record

5

6

7 FreeRunTimer RAM Read Only Decimal LongInteger

8 WDTimer RAM Read Write Decimal Real

9 ModuleConfig EEPROM RPW - - - - - - - Record

A WDPreset EEPROM RPW Decimal Real

B

C

D WriteEnable RAM Read Write Binary Boolean

E ChType PROM Read Only - - - - - - - Record

F CommonError RAM Read Write - - - - - - - Record

SWNo 0: NumberOfSWNo

This variable holds the highest SWNo in the module

SWNo 1: DeviceID

The purpose of this record is to be able to identify the device. The record includes a registered

manufacturer number, the type number of the module and a string, identifying the manufacturer.

The record is of the following type:

Record

DeviceNumber: Word; (* Offset = 0 *)

ProgramVersion: Word; (* Offset = 2 *)

ManufacturerNo: Word; (* Offset = 4 *)

Manufacturer: String[20]; (* Offset = 6 *)

end

502 069 02

Manual Power Monitor, PD 3260 9/79

An example of the field values in the DeviceID record is shown below:

DeviceNumber = 3260

ProgramVersion= 100 (the first version)

ManufacturerNo = 1

Manufacturer = Proces-Data DK

SWNo 3: Reset

By writing $FF to SWNo 3, the module performs a reset, and ExternalReset in CommonError

SWNo $F is set TRUE.

SWNo 4: PnetSerialNo

This Variable is a record having the following structure:

Record

PnetNo: Byte; (* Node Address *) (* Offset = 0 *)

SerialNo: String[20]; (* Offset = 2 *)

end

The serial number is used for service purposes and as a 'key' to setting the module's P-NET Node

address.

A special function is included for identifying a module connected to a network containing many

other modules, having the same or unknown node addresses, and to enable a change of the node

address via the P-NET.

Setting a new node address via the P-NET is performed by writing the required node address

together with the serial number of the module in question, into the PnetSerialNo at node address

$7E (calling all modules). All modules on the P-NET will receive the message, but only the

module with the transmitted serial number will store the P-NET node address.

An attempt to write data to node address $7E will give no reply. Consequently the calling master

must disable the generation of a transmission error when addressing this node.

In the module, the SerialNo = "XXXXXXXXPD", is set by PROCES-DATA, and cannot be

changed. The eight X`s indicate the serial number, and PD is the initials of PROCES-DATA.

SWNo 7: FreeRunTimer

FreeRunTimer is a timer, to which internal events are synchronized. The timer is of type

LongInteger, with a resolution of 1 /256 Second.

P-NET Watch Dog function

PD 3260 Digital I/O is equipped with a P-NET Watchdog, which switches off all the digital

outputs, by clearing OutFlags and Control flags, if P-NET communication ceases. The P-NET

watchdog uses SWNo 8 and SWNo $A.

502 069 02

10/79 Power Monitor, PD 3260 Manual

SWNo 8: WDTimer [s]

WDTimer is automatically preset with the value from WDPreset (SWNo $A), either each time the

module is called via P-NET, or following a power-up or module reset. If the WDTimer reaches

zero before it is preset again, the PnetWDRunOut flag will be set, and all the outputs will switch

OFF. The timer contains a value in sec.

SWNo 9: ModuleConfig

The variable is a record having the following structure:

Record

EnableBit : Bit8; (* Offset = 0 *)

Functions : BYTE; (* Offset = 1 *)

Ref_A : BYTE; (* Offset = 2 *)

Ref_B : BYTE; (* Offset = 3 *)

end

The EnableBit, Ref_A and Ref_B fields are not utilised in the Service channel.

The watchdog facility may be switched on and off by means of the field variable Functions, as

shown below.

ModuleConfig.Functions = 0 Watchdog

ModuleConfig.Functions = $10 No watchdog

SWNo $A: WDPreset [s]

The maximum time allowable between two calls to the module, before the watchdog is activated,

is defined in this register, in seconds.

SWNo $D: WriteEnable

Write protected variables can only be changed when WriteEnable is TRUE. After reset,

WriteEnable is set to FALSE.

After modifying the contents of module EEPROM, WriteEnable should be set FALSE. An

EEPROM sum check is calculated each time WriteEnable is changed from "TRUE" to "FALSE".

This sum check calculation period is approximately 0.25 second. Consequently, the module

should not be reset during this period, otherwise an EEPROM error can occur (see SWNo $F:

CommonError).

The WriteEnable variable may be optionally write protected, by means of a hardware lock.

If the hardware switch, marked “2" inside the module, is set to “ON”, the value in WriteEnable

becomes write protected. NB: Disconnect module power before opening the module. Using this

502 069 02

Manual Power Monitor, PD 3260 11/79

facility, and mechanically sealing the module housing, will ensure that all EEPROM variables

in the module are permanently write protected,

NB: Writing toEEPROM is limitedto 10,000 cycles for each byte, including the sum check bytes.

SWNo $E: ChType

Each channel in an interface module is described in an individual ChType variable. This is a

Record, consisting of a unique number for the channel type and a TRUE boolean value for each

of the registers which are represented within a channel. The register number in a channel,

corresponds to the index number in the boolean array. In addition to these fields, various other

fields can be found in the record, the contents of which depends on the channel type.

The record for the service channel has the following structure:

Record

ChannelType: WORD; (* Offset = 0 *)

Exist: Bit16; (* Offset = 2 *)

Functions: Bit16; (* Offset = 4 *)

end

For the service channel, ChType has the following value:

ChannelType = 1

Exist = 1514131211109876543210

1110011110011011

502 069 02

12/79 Power Monitor, PD 3260 Manual

Functions = 1514131211109876543210

0000000000000011

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

Not used

No Watchdog

Watchdog

SWNo $F: CommonError

The CommonError variable holds error information on all Channels. This variable is a record

having the following structure:

Record

ChError: Record

His:Array[0..7] of Boolean; (* Offset = 0 *)

Act:Array[0..7] of Boolean; (* Offset = 2 *)

End;

ComHis16:Array [0..15] of Boolean; (* Offset = 4 *)

ComAct16:Array [0..15] of Boolean; (* Offset = 6 *)

End

The 8 bits in ChError.His and ChError.Act have the following meaning:

76543210

InternalReset (Hardware)

ExternalReset (P-NET)

Program-storage fault

RAM data-store fault

PnetWDRunOut

EEPROM fault

Not used

AnyChannelError (ComHis/Act<>0)

502 069 02

Manual Power Monitor, PD 3260 13/79

Bit 7 InternalReset is set TRUE, if a reset is caused by a power failure, or if the power has been

disconnected.

Bit 6 ExternalReset is set TRUE, if a reset is caused by writing $FF to SWNo 3, Reset, via

P-NET.

Bit 5 Program-storage fault is set TRUE, if the self test finds an error in the program memory

(PROM).

Bit 4 RAM data-store fault is set TRUE, if the self test finds an error in the data memory

(RAM).

Bit 3 PnetWDRunOut is set TRUE, if the WDTimer reaches zero and the Watchdog function

is switched ON.

Bit 2 EEPROM fault is set to TRUE, if the self test finds an error in the data memory

(EEPROM). The error may be corrected by setting and resetting WriteEnable.

Bit 0 AnyChannelError = 1, means that an error, or an unacknowledged error, exists in one or

more channels.

The following function of ChError.His and ChError.Act is analogous for all Channels:

1When an error occurs the corresponding bits in ChError.Act and ChError.His is set.

2When the error disappears the corresponding bit is reset in ChError.Act.

3After reading ChError.His, ChError.Act is copied to ChError.His.

4Transmission responses from a module will include the Actual Data Error bit

(DataError) set TRUE if ChError.Act <> 0.

5The Historical DataError bit (GeneralError) will be set TRUE in all responses from

the module if ChError.His <> 0.

ComHis and ComAct are unique fields in the service channel, and hold an error status relating to

all channels, where the bit number corresponds to the channel number. Each Channel has an error

register, ChError. If ChError.His in a particular channel is<>0, the corresponding bit is set in

ComHis. If ChError.Act in a particular channel is<>0, the corresponding bit is set in ComAct in

the service channel. If the error disappears (ChError. Act = 0), the corresponding bit in ComAct

is automatically cleared.

If the channels become error free, individual bits in ComHis will be cleared when reading ChError

in each of the channels.

ComHis:=0 performs a special function, equivalent to reading all ChErrors.His in all channels.

502 069 02

14/79 Power Monitor, PD 3260 Manual

1514131211109876543210

Not used

Channel E (Data Channel)

Channel D (Program Ch)

Channel C (Thyristor Sw)

Channel B (Generator Sw)

Channel A (Power monitor)

Channel 9 (Common I/O)

Channel 8 (Digital I/O 8)

Channel 7 (Digital I/O 7)

Channel 6 (Digital I/O 6)

Channel 5 (Digital I/O 5)

Channel 4 (Digital I/O 4)

Channel 3 (Digital I/O 3)

Channel 2 (Digital I/O 2)

Channel 1 (Digital I/O 1)

Channel 0 (Service Channel)

502 069 02

Manual Power Monitor, PD 3260 15/79

3 Digital I/O Channel (channel 1 - 8).

Variables on digital I/O Channel x. Channel identifier: Digital_IO_x

SWNo Identifier Memory type Read out Type SI Unit

x0 FlagReg RAM Read Write Binary Bit8 - - -

x1 OutTimer RAM Read Write Decimal Real s

x2 Counter RAM AutoSave Decimal Long integer - - -

x3 OutCurrent RAM Read Write Decimal Real A

x4 OperatingTime RAM AutoSave Decimal Real s

x5 UserByteArray RAM Init EEPROM - - - - - Array4Byte - - -

x6 FBTimer RAM Read Write Decimal Real s

x7 FB Preset EEPROM RPW Decimal Real s

x8 OutPreset EEPROM RPW Decimal Real s

x9 ChConfig EEPROM RPW - - - - - Record - - -

xA MinCurrent EEPROM RPW Decimal Real A

xB MaxCurrent EEPROM RPW Decimal Real A

xC UserRealArray EEPROM RPW - - - - - Array2Real - - -

xD Maintenance EEPROM RPW - - - - - Record - - -

xE ChType PROM Read Only - - - - - Record - - -

xF ChError RAM Read Only Binary Record - - -

SWNo x0: FlagReg 76543210

OutFlag

InFlag

InAFlag

InBFlag

Control

FBStatus

Error

Not used

Bit 7: OutFlag

This flag controls the output, if the P-NET WDRunOut bit is FALSE, and the channel is

configured as an output. The special output functions control the output flag, in the same way as

a P-NET transmission.

OutFlag:=True => Output ON

PnetWDRunOut = True => OutFlag:=False => Output OFF

502 069 02

16/79 Power Monitor, PD 3260 Manual

Bit 6: InFlag

The input flag is controlled by the input detector, and shows the logic level on the input terminals.

The input flag is true, when the input is connected to 24V-. If the channel is used as an output, the

input flag will follow the output flag. If the output terminals are short-circuited, the input flag will

not follow the output flag. The input signal can be simulated, by setting the channel in input

simulation mode (ChConfig.Enablebit[0] =TRUE), and subsequently writing the state to the input

flag. The input flag is FALSE after reset in simulation mode.

Feedback Control

Many process components are equipped with feedback contacts. A typical example is a valve with

1 or 2 micro switches, which indicate the mechanical position of the piston. In this application,

in addition to the output, one or two inputs are needed. The inputs to be used by the feedback-

control, are selected in ChConfig.Ref_A and ChConfig.Ref_B in the output-Channel.

Bit 5 and Bit 4: InAFlag, InBFlag

The InAFlag is identical to the input flag for the channel selected as Feedback input A. Feedback

input A is the input signal which should correspond with the same state as the output signal.

Therefore, Feedback input A must be TRUE when the output is TRUE, to indicate a correct

feedback signal. The Feedback input A channel is selected in ChConfig.Ref_A. The InBFlag is

identical to the input flag for the channel selected as Feedback input B. Feedback input B is the

input signal which should correspond with the inverse state of the output signal. This input signal

is selected in ChConfig.Ref_B. The feedback signals can be simulated, by setting

ChConfig.Enablebit[2] = TRUE. If feedback simulation is selected, the InAFlag and InBFlag are

automatically set to the correct state, to correspond with the current state of OutFlag.

Bit 3: Control

When the Control flag is set, a special output function for the channel is enabled, (one shot output,

50 % duty cycle output or timer output), which then controls the output. Clearing the Control flag

will disable the special output function, and clears the output, which may then be controlled via

P-NET. After a power-up or a reset of the module, the control flag is set FALSE, unless the

channel is configured to be controlled by the Thyristor Switch Channel, in which case, the Control

flag is always set TRUE. The state of the Control flag has no influence on the output if the

channel is configured as an output without a special output function.

Bit 2: FBStatus

The FBStatus indicates the current feedback condition. The value of FBStatus does not depend

on the FBTimer, which means that the actual valve position for example, can be ascertained as

correct, or incorrect, before the FBTimer has reached zero. If feedback is used (single or double),

FBStatus is always set TRUE when the OutFlag is changed. If no feedback is used, FBStatus

always reads FALSE.

FBStatus = TRUE, indicates that the feedback signal/s are incorrect.

Table of contents