Introduction 3

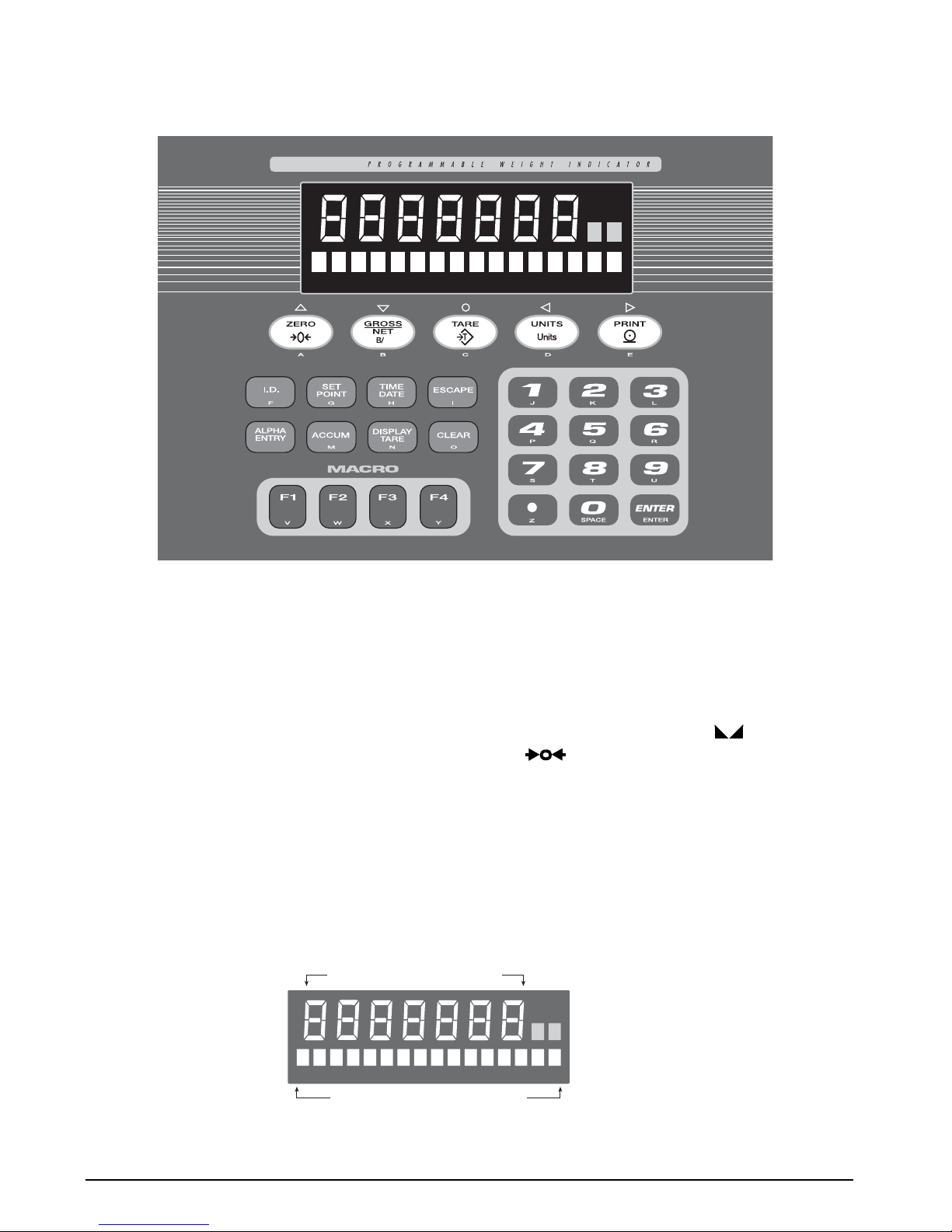

1.3 Indicator Operations

Basic IQ plus 710 operations are summarized below:

1.3.1 Toggle Gross/Net Mode

Press the GROSS/NET key to switch the display mode

from gross to net, or from net to gross. If a tare value

has been entered or acquired, the net value is the gross

weight minus the tare. If no tare has been entered or

acquired, the display remains in gross mode.

Gross mode is indicated by the word Gross (or

Brutto in OIML mode) on the secondary display; net

mode is indicated by the word Net.

1.3.2 Toggle Units

Press the UNITS key to switch between primary and

secondary units. The units identifier is shown to the

right of the primary display. Troy ounces and troy

pounds are indicated by the word troy on the

secondary display.

1.3.3 Zero Scale

1. In gross mode, remove all weight from the

scale and wait for the standstill annunciator

().

2. Press the ZERO key. The center of zero

() annunciator lights to indicate the

scale is zeroed.

1.3.4 Acquire Tare

1. Place container on scale and wait for the

standstill annunciator ( ).

2. Press the TARE key to acquire the tare weight

of the container.

3. Display shifts to net weight and shows the

word Net on the secondary display.

To display the current tare value, press the DISPLAY

TARE key.

1.3.5 Remove Stored Tare Value

1. Remove all weight from the scale and wait for

the standstill annunciator ( ).

2. Press the TARE key (or, in OIML mode, the

ZERO key). Display shifts to gross weight and

shows the word Gross on the secondary

display.

1.3.6 Print Ticket

1. Wait for the standstill annunciator ( ).

2. Press the PRINT key to send data to the serial

port.

1.3.7 Display or Change Time and Date

To display the date, press the TIME/DATE key once;

press TIME/DATE a second time to display the time.

To set the date, press the TIME/DATE key once. Use the

numeric keypad to enter the date, then press the

ENTER key. The date must be entered in the date

format configured for the indicator: MMDDYY,

DDMMYY, or YYMMDD.

To set the time, press the TIME/DATE key twice. Use

the numeric keypad to enter the time in 24-hour

format, then press the ENTER key.

1.3.8 Display or Change Setpoint Value

To display a setpoint value, use the numeric keypad to

enter the setpoint number, then press the SETPOINT

key. Or, you can display a setpoint value by pressing

the SETPOINT key a number of times equal to the

setpoint number. For example, to display the value of

setpoint 4, press the SETPOINT key four times.

To change the setpoint value, display the current

value, then use the numeric keypad to enter the new

value and press the ENTER key.

NOTE: Some indicator configurations may not allow setpoint

values to be changed through the front panel or may require a

password to display or change the setpoint value.

1.3.9 Turn Setpoint On or Off

To turn a setpoint off at the front panel, use the

numeric keypad to enter the setpoint number, then

press the SETPOINT key (or, press the SETPOINT key a

number of times equal to the setpoint number). With

the correct setpoint displayed, press CLEAR to turn the

setpoint off.

To re-enable a setpoint on that has been turned off at

the front panel, press the SETPOINT key until the

correct setpoint is displayed, then press ENTER to turn

the setpoint back on.

NOTE: Some indicator configurations may not allow setpoints

to be turned off through the front panel or may require a

password to turn the setpoint on and off.

1.3.10 Display or Clear Accumulator

If the accumulator function is enabled, the current net

weight is added to the accumulator each time the

indicator performs a print operation.

• To display the current accumulator value,

press the ACCUM key.

• To clear the accumulator, press ACCUM to

show the current value, then press the CLEAR

key twice to reset the accumulator.