Prochem LEGEND GT User manual

Operating Instructions (ENG)

MODELS: LEGEND GT

1.001-119.0

1.001-138.0

1.001-141.0

1.001-162.0

Read instructions before operating the machine.

86313050 - CV

01/16/17

MOBILE CLEANING UNIT

LEGEND GT

Left intentionally blank

1

Overview

Welcome…and congratulations on the purchase of your Mobile Cleaning Unit. This instruction manual is a guide

for operating and servicing your unit. Read this manual completely before installing or operating this unit.

This unit offers you personal convenience. All of your instrumentation and controls have been positioned to give

you easy access for operation and daily maintenance.

Proper operation and service are essential to the efficient functioning of this unit. When maintained correctly, this

unit will have a long, trouble-free life.

The service methods described in this manual are explained in such a manner that servicing may be performed

accurately and safely. Proper service varies with the choice of procedure, the skill of the mechanic, and the tools or

parts available. Before attempting any repair, make certain that you are thoroughly familiar with this equipment and

are equipped with the proper tools. Any questions pertaining to operating or servicing this unit should be directed

to your nearest dealer.

THIS UNIT MUST BE INSTALLED BY THE DEALER FROM WHOM YOU PURCHASED IT IN ACCORDANCE

WITH THE PRESCRIBED INSTALLATION PROCEDURES.

Information in this document is subject to change without notice and does not represent a commitment on the part

of PROCHEM.

86313050 LEGEND GT

Model:

Date of Purchase:

Serial Number:

Dealer:

Address:

Phone Number:

Sales Representative:

Machine Data Label

2 86313050 LEGEND GT

Table of Contents

Overview . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

Machine Data Label . . . . . . . . . . . . . . . . . . . . . . . . . 1

Table of Contents. . . . . . . . . . . . . . . . . . . . . . . . . . . 2

Receiving Your Unit . . . . . . . . . . . . . . . . . . . . . . . . . 4

Acceptance of Shipment . . . . . . . . . . . . . . . . . . . . . 4

Equipment List. . . . . . . . . . . . . . . . . . . . . . . . . . . . . 4

How to Use This Manual . . . . . . . . . . . . . . . . . . . . . 5

Safety

IMPORTANT SAFETY INSTRUCTIONS. . . . . . . . . 6

Hazard Intensity Level . . . . . . . . . . . . . . . . . . . . . . . 8

Safety Labels. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 9

Installation

Dealer Responsibility. . . . . . . . . . . . . . . . . . . . . . . 10

Vehicle Requirements . . . . . . . . . . . . . . . . . . . . . . 10

Lifting Unit Onto Vehicle . . . . . . . . . . . . . . . . . . . . 10

Positioning Unit In Vehicle. . . . . . . . . . . . . . . . . . . 10

Bolting Down Unit And Waste Tank. . . . . . . . . . . . 11

Electrical Wiring. . . . . . . . . . . . . . . . . . . . . . . . . . . 11

Layout with 60 Gallon Waste Tank . . . . . . . . . . . . 12

Layout with 60 Gallon Waste Tank & Optional

Auxiliary Water Tank . . . . . . . . . . . . . . . . . . . . . 13

Layout with 100 Gallon Waste Tank . . . . . . . . . . . 14

Layout with 100 Gallon Waste Tank & Optional

Auxiliary Water Tank . . . . . . . . . . . . . . . . . . . . . 15

Waste Tank To Console Connection. . . . . . . . . . . 16

Fuel Pump Assembly Installation. . . . . . . . . . . . . . 16

Van Bulkhead Installation . . . . . . . . . . . . . . . . . . . 17

Fuel Supply & Return Line Installation. . . . . . . . . . 18

Battery Connection . . . . . . . . . . . . . . . . . . . . . . . . 19

Initial Operational Settings. . . . . . . . . . . . . . . . . . . 20

Operations

Technical Specifications . . . . . . . . . . . . . . . . . . . . 21

Fuel Requirements. . . . . . . . . . . . . . . . . . . . . . . . . 22

Engine Oil Requirements. . . . . . . . . . . . . . . . . . . . 22

Altitude Requirements . . . . . . . . . . . . . . . . . . . . . . 22

Chemical Requirements. . . . . . . . . . . . . . . . . . . . . 22

Water Requirements . . . . . . . . . . . . . . . . . . . . . . . 23

Components. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Vacuum System. . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Water Pumping and Heat Transfer System . . . . . . 28

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

Chemical Injection System. . . . . . . . . . . . . . . . . . . 30

Pre-Run Inspection / Setup . . . . . . . . . . . . . . . . . . 31

Check For Adequate Fuel . . . . . . . . . . . . . . . . . . . 31

Remove Tools From Vehicle . . . . . . . . . . . . . . . . . 31

Water Supply Connection . . . . . . . . . . . . . . . . . . . 31

High Pressure Solution Hose. . . . . . . . . . . . . . . . . 31

Vacuum Hose . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Filters. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 31

Priming the Chemical Pump . . . . . . . . . . . . . . . . . 32

Waste Pump (Optional) . . . . . . . . . . . . . . . . . . . . . 32

Cleaning. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 32

Upholstery Cleaning. . . . . . . . . . . . . . . . . . . . . . . . 33

Shutdown and Daily Maintenance . . . . . . . . . . . . . 33

De-Flooding Operations. . . . . . . . . . . . . . . . . . . . . 33

Freezing Protection . . . . . . . . . . . . . . . . . . . . . . . . 33

Overheating Protection . . . . . . . . . . . . . . . . . . . . . 33

Winterizing the Unit . . . . . . . . . . . . . . . . . . . . . . . . 34

Removing Anti-Freeze From the Unit . . . . . . . . . . 35

86313050 LEGEND GT 3

Table of Contents

Maintenance

Service Schedule . . . . . . . . . . . . . . . . . . . . . . . . . .36

Key Checkpoints. . . . . . . . . . . . . . . . . . . . . . . . . . .38

External Fuel Pump Maintenance. . . . . . . . . . . . . .38

Chemical Supply System Maintenance . . . . . . . . .38

Heat Exchanger System Maintenance . . . . . . . . . .38

Vacuum Pump Maintenance. . . . . . . . . . . . . . . . . .39

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .39

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . .40

Solution Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . .41

Vacuum Inlet Filter (in Waste Tank) . . . . . . . . . . . .41

Vacuum Relief Valve. . . . . . . . . . . . . . . . . . . . . . . .41

Vacuum Pump Drive Belts . . . . . . . . . . . . . . . . . . .41

Solution Pump Drive Belts . . . . . . . . . . . . . . . . . . .42

Float Valve (Water Box) . . . . . . . . . . . . . . . . . . . . .42

Waste Tank Float Valve . . . . . . . . . . . . . . . . . . . . .42

Waste Tank Strainer Basket . . . . . . . . . . . . . . . . . .42

Waste Tank Vacuum Inlet Filter . . . . . . . . . . . . . . .42

Check Valve (Outlet). . . . . . . . . . . . . . . . . . . . . . . .43

Chemical Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . .43

Chemical and Temperature Control Valves . . . . . .43

Pressure Regulator. . . . . . . . . . . . . . . . . . . . . . . . .43

Vacuum Hoses . . . . . . . . . . . . . . . . . . . . . . . . . . . .43

High Pressure Solution Hoses . . . . . . . . . . . . . . . .43

Optional Waste Pump-Out . . . . . . . . . . . . . . . . . . .43

General Service Adjustments. . . . . . . . . . . . . . . . .44

Engine Speed . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Check Valve (Solution Outlet). . . . . . . . . . . . . . . . .44

Water Box. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Chemical Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . .44

Solution and Vacuum Pump Drive Belts. . . . . . . . .44

Packing Nut Adjustments for Chemical Valves. . . .45

Pressure Regulator. . . . . . . . . . . . . . . . . . . . . . . . .45

Troubleshooting . . . . . . . . . . . . . . . . . . . . . . . . . . .46

Parts

Frame . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 52

Side Panel. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 54

Control Panel - Upper . . . . . . . . . . . . . . . . . . . . . . 56

Control Panel - Upper . . . . . . . . . . . . . . . . . . . . . . 58

Engine. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 60

Vacuum Pump . . . . . . . . . . . . . . . . . . . . . . . . . . . 62

Solution Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . 64

Heat Exchanger . . . . . . . . . . . . . . . . . . . . . . . . . . 68

Pressure Regulator & Temperature Control Valve 70

Solution Outlet . . . . . . . . . . . . . . . . . . . . . . . . . . . 72

Water Box . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 74

60 Gallon Waste Tank - From Serial Number *(1) 76

60 Gallon Waste Tank - To Serial Number *(1) . . 78

100 Gallon Waste Tank . . . . . . . . . . . . . . . . . . . . 80

Fuel Pump. . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 82

Battery Floor Mount . . . . . . . . . . . . . . . . . . . . . . . 84

Chemical Jug Floor Mount . . . . . . . . . . . . . . . . . . 86

Wiring Diagram . . . . . . . . . . . . . . . . . . . . . . . . . . . 88

Hose Diagram. . . . . . . . . . . . . . . . . . . . . . . . . . . . 89

Options

Hose Accessories . . . . . . . . . . . . . . . . . . . . . . . . . 92

Exhaust - Optional . . . . . . . . . . . . . . . . . . . . . . . . 94

Automatic Pumpout - Dual Diaphragm - Optional. 96

Wand - Titanium Six Jet - Optional . . . . . . . . . . . . 98

Wand - Ergo Titanium Six Jet - Optional. . . . . . . 100

Wand - Quad Jet - Optional . . . . . . . . . . . . . . . . 102

Wand - Tri Jet -Optional . . . . . . . . . . . . . . . . . . . 104

Stair Tool - Optional . . . . . . . . . . . . . . . . . . . . . . 106

Upholstery Tool - Optional . . . . . . . . . . . . . . . . . 108

Shelf Assembly - Optional. . . . . . . . . . . . . . . . . . 110

Water Tank Dual with Demand Pump - Optional 112

Water Tank - Demand Pump - Optional . . . . . . . 114

Auxiliary Water Tank with Pump-Optional . . . . . 116

Auxiliary Water Tank - Optional . . . . . . . . . . . . . 118

Hose Reel - Optional. . . . . . . . . . . . . . . . . . . . . . 120

Motorized Hose Reel - Tank - Optional. . . . . . . . 122

Motorized Hose Reel - Optional . . . . . . . . . . . . . 124

E Z - Charge Water Softener - Tank & Tray -

Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . 126

E Z - Charge Water Softener - Filter - Optional . 128

E Z - Charge Water Softener - Brine System - . . . .

Optional . . . . . . . . . . . . . . . . . . . . . . . . . . . . 130

Serial Numbers . . . . . . . . . . . . . . . . . . . . . . . . . . 132

4

Receiving Your Unit

Acceptance of Shipment

Every part of your cleaning unit was carefully checked,

tested, and inspected before it left our manufacturing

plant. Upon receiving the unit, make the following

acceptance check:

1. The unit should not show any outward signs of

damage. If damaged, notify the common carrier

immediately.

2. Check your equipment and packing list. The stan-

dard cleaning unit should arrive equipped with the

following items (unless otherwise specified) and

any optional accessories which were ordered:

Equipment List

1. Console.

2. Waste tank.

3. Fuel pump assembly.

4. 100 ft. of 2” vacuum hose.

5. 1 vacuum hose connector.

6. 100 ft. of 1/4” high pressure hose with quick

connects.

7. 50 ft. water supply hose with quick connect.

8. Installation bolting kit.

9. Installation mounting plates.

10. Operation and service manuals for engine, solution

pump, and vacuum pump.

86313050 LEGEND GT

5

How to Use This Manual

This manual contains the following sections:

• How to Use This Manual

•Safety

• Installation

• Operations

• Maintenance & Service

• Parts List

The HOW TO USE THIS MANUAL section will tell you

how to find important information for ordering correct

repair parts.

Parts may be ordered from authorized dealers. When

placing an order for parts, the machine model and

machine serial number are important. Refer to the

MACHINE DATA box which is filled out during the

installation of your machine. The MACHINE DATA box

islocatedon theinsideof thefront cover ofthis manual.

The model and serial number of your machine is

located approximately where shown

The SAFETY section contains important information

regarding hazardous or unsafe practices for this

machine. Levels of hazards are identified that could

result in product damage, personal injury, or severe

injury resulting in death.

The INSTALLATION section contains information on

how to properly install the unit in your vehicle.

The OPERATIONS section is to familiarize the operator

with the operation and function of the machine.

The MAINTENANCE section contains preventive main-

tenance to keep the machine and its components in

good working condition. They are listed in this general

order:

•Engine

• Vacuum Pump

• Solution Pump

• Drive Belts, Pulleys & Hubs

• Chemical Pump

• Hoses

• Exhaust Heat Exchanger

• General Service Adjustments

• Machine Troubleshooting

The PARTS LIST section contains assembled parts

illustrations and corresponding parts list. The parts lists

include a number of columns of information:

•REF – column refers to the reference number

on the parts illustration.

•PART NO. – column lists the part number for

the part.

•PRV NO. – reference number.

•QTY – column lists the quantity of the part used

in that area of the machine.

•DESCRIPTION – column is a brief description

of the part.

•SERIAL NO. FROM – If this column has an (*)

and a Reference number, see the SERIAL

NUMBERS page in the back of your manual. If

column has two asterisk (**), call manufacturer

for serial number. The serial number indicates

the first machine the part number is applicable

to. The main illustration shows the most current

design of the machine. When a boxed illustra-

tion is shown, it displays the older design.

•NOTES – column for information not noted by

the other columns.

NOTE: If a service or option kit is installed on your

machine, be sure to keep the KIT INSTRUCTIONS

which came with the kit. It contains replacement parts

numbers needed for ordering future parts.

NOTE: The manual part number is located on the

lower left corner of the front cover.

Model:

Date of Purchase:

Serial Number:

Dealer:

Address:

Phone Number:

Sales Representative:

86313050 LEGEND GT

6

Safety

IMPORTANT SAFETY INSTRUCTIONS

When using this machine, basic precaution

must always be followed, including the following:

READ ALL INSTRUCTIONS BEFORE USING THIS MACHINE.

Read the operator's manual before installing or starting this unit. Failure to adhere to instructions could result

in severe personal injury or could be fatal.

Operate this unit and equipment only in a well-ventilated area. Exhaust fumes contain carbon monoxide which

is an odorless and deadly poison that can cause severe injury or fatality. DO NOT run this unit in an enclosed area.

DO NOT operate this unit where the exhaust may enter any building doorway, window, vent, or opening of any type.

Gasoline is extremely flammable and its vapors can explode if ignited. Store gasoline only in approved

containers, in well-ventilated, unoccupied buildings away from sparks or flames. Never carry any gasoline or

flammable material in the vehicle. Fumes may accumulate inside the vehicle and ignite, causing an explosion.

DO NOT store any type of flammable material in the vehicle.

This unit must be operated with the vehicle or trailer doors open in order to ensure adequate engine ventilation.

DO NOT operate engine if gasoline is spilled.Avoid creating any ignition until the gasoline has been cleaned up.

Never use gasoline as a cleaning agent.

DO NOT place hands, feet, hair, or clothing near rotating or moving parts. Avoid any contact with moving

parts! Rotating machinery can cause injury or fatality.

Never operate this unit without belt guards. The high speed moving parts, such as belts and pulleys, should be

avoided while this unit is running. Severe injury, damage, or fatality may result.

DO NOT service this unit while it is running. The high-speed mechanical parts as well as high temperature

components may result in severe injury or severed limbs.

Never touch electrical wires or components while the engine is running. They can be sources of electrical

shock.

Engine components can get extremely hot from operation. To prevent severe burns, DO NOT touch these

areas while the engine is running or immediately after the engine is turned off.

DO NOT touch any part of the exhaust system while this unit is running. Severe burns may result.

Before servicing this unit, allow it to cool down. This will prevent burns from occurring.

Water under high pressure at high temperature can cause burns, severe personal injury, or fatality. Shut

down machine, allow to cool down, and relieve system of all pressure before removing valves, caps, plugs,

fittings, filters, and bolts.

Always wear hearing protection when unit is running. Always comply with your company’s Personal

Protection Equipment (PPE) plan. Always comply with local noise ordinance when operating units.

86313050 LEGEND GT

These symbols mean WARNING or CAUTION. Failure to follow warnings and

cautions could result in fatality, personal injury to yourself and/or others, or

property damage. Follow these instructions carefully!

7

Safety

DO NOT leave the vehicle engine running while operating this unit.

Dangerous Acid, Explosive Gases! Batteries contain sulfuric acid. To prevent acid burns, avoid contact with skin,

eyes and clothing. Batteries produce explosive hydrogen gas while being charged. To prevent a fire or explosion,

charge batteries only in well ventilated areas. Keep sparks, open flames, and other sources of ignition away from

the battery at all times. Keep batteries out of the reach of children. Remove all jewelry when servicing batteries.

Before disconnecting the negative (-) ground cable, make sure all switches are OFF. If ON, a spark will occur at the

ground cable terminal which could cause an explosion if hydrogen gas or gasoline vapors are present. When

disconnecting the battery, ALWAYS disconnect the negative (-) terminal FIRST.

DO NOT smoke around the unit. Gas fumes may accumulate and be ignited. The battery is also extremely flam-

mable. This will prevent possible explosions.

DO NOT damage the vehicle in any manner during installation. When routing fuel lines DO NOT place the

hose in any location where damage may occur to the hose or vehicle. Avoid any contact with moving parts, areas

of high temperature, brake lines, fuel lines, muffler, catalytic converter, or sharp objects.

Use only Prochem supplied fuel installation kits. Ensure to use the kit specific for the truckmount model and

van model being used. When traversing the vehicle floor with fuel lines, always use a bulkhead adapter. This will

prevent leakage and ensure that the hose is not punctured by vehicle vibration abrasion.

DO NOT exceed your vehicle's weight limit. The console with empty 60 gallon waste tank and accessories

weighs approximately 810 lbs (900 lbs. if mounted on water tank). Make certain to account for any additional acces-

sories in your weight and balance calculations. Make certain that the vehicle has the correct axle rating. This will

prevent unsafe vehicle driving conditions.

We require high-back seats on all vehicles in which units are to be installed for head and neck protection.

We recommend using a metal partition between the seats and equipment.

DO NOT operate this unit without the water supply attached and turned on. The solution pump and other vital

components may be seriously damaged if this unit is permitted to operate dry without water.

Keep your vehicle work area clean. Wands, stair tools, and other accessories must be securely fastened before

driving the vehicle.

All high pressure hoses must be rated for 3000 PSI at 250°F. Thermoplastic hoses do not meet these specifica-

tions and should not be used. Severe burns and injury may result if the hoses do not meet these requirements.

The winterizing loop hose assembly, Part # 86260700, is for winterizing use only. If used improperly, live

steam may escape from this hose, causing it to whip around. Burns or injury may result.

Make certain that you receive complete training by the distributor from whom you purchased this unit.

This unit uses high pressure and temperature. Improper or irresponsible use may result in serious injury.

Do not modify this unit in any manner. Improper modification can cause severe personal injury or fatality.

CALIFORNIA PROPOSITION 65 WARNING: Engine exhaust from this product contains chemicals known to the

State of California to cause cancer, birth defects, or other reproductive harm. Running with out adequate water

supply could damage water pump. Ensure always to have an adequate water supply.

86313050 LEGEND GT

8

Safety

The following symbols are used throughout this guide as indicated in their descriptions:

Hazard Intensity Level

There are three levels of hazard intensity identified by signal words - WARNING and CAUTION and FOR SAFETY.

The level of hazard intensity is determined by the following definitions:

WARNING - Hazards or unsafe practices which COULD result in severe personal injury or death.

CAUTION - Hazards or unsafe practices which could result in minor personal injury or product or property damage.

FOR SAFETY: To Identify actions which must be followed for safe operation of equipment.

Report machine damage or faulty operation immediately. Do not use the machine if it is not in proper operating

condition. Following is information that signals some potentially dangerous conditions to the operator or the equip-

ment. Read this information carefully. Know when these conditions can exist. Locate all safety devices on the

machine. Please take the necessary steps to train the machine operating personnel.

FOR SAFETY:

DO NOT OPERATE MACHINE:

Unless Trained and Authorized.

Unless Operation Guide is Read and understood.

In Flammable or Explosive areas.

In areas with possible falling objects.

WHEN SERVICING MACHINE:

Avoid moving parts. Do not wear loose clothing; jackets, shirts, or sleeves when working on the machine. Use

Prochem approved replacement parts.

86313050 LEGEND GT

9

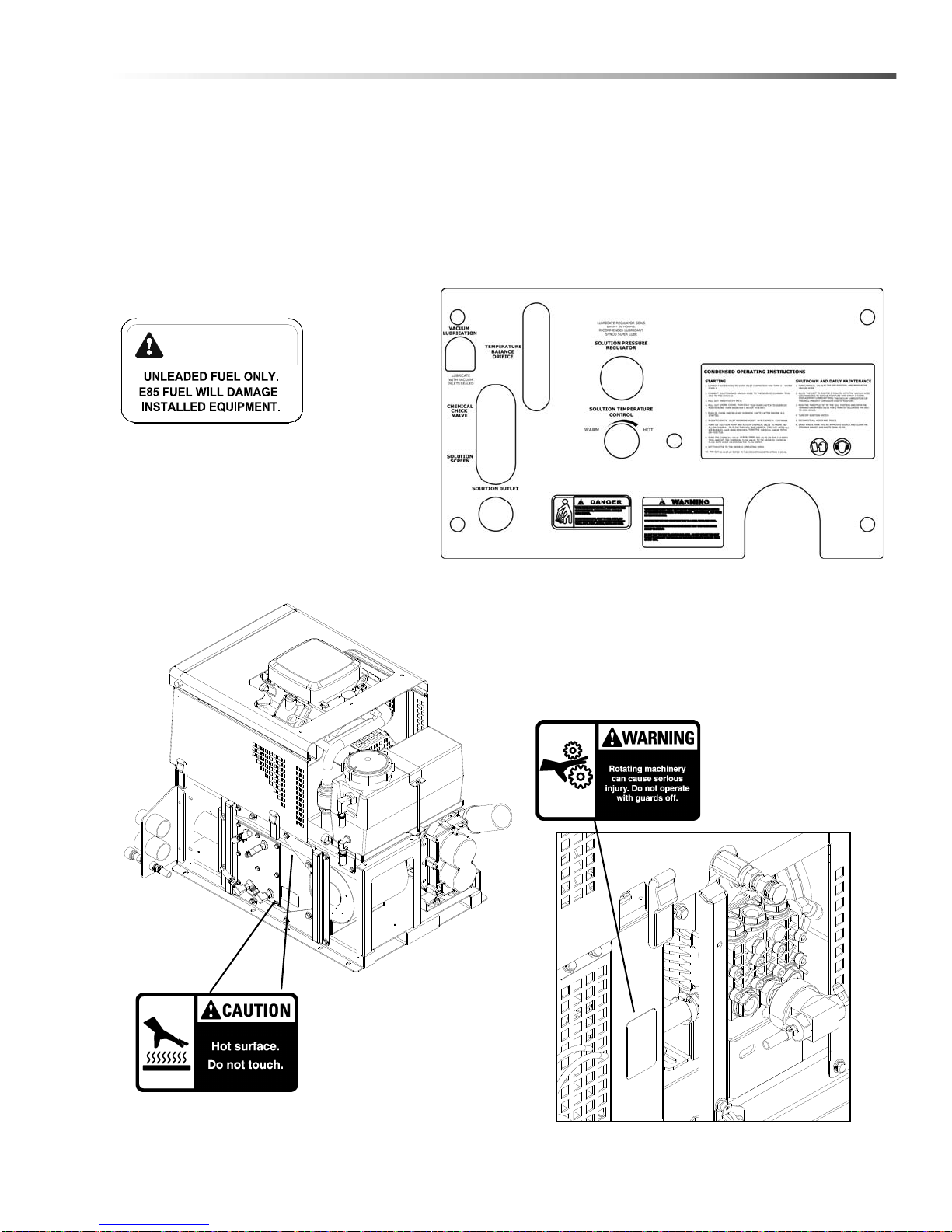

Safety Labels

The following WARNING LABELS are found on your cleaning unit. These labels point out important Warnings and

Cautions which should be followed at all times. Failure to follow warnings and cautions could result in fatality,

personal injury to yourself and/or others, or property damage. Follow these instructions carefully! DO NOT remove

these labels.

NOTE: If at any time the labels become illegible, promptly replace them.

Safety

86313050 LEGEND GT

Warning Label

P/N 86186520

Caution Label

P/N 86186530

Lower Front Panel Decal

with warning labels

P/N 86309420

Caution Label

P/N 86352580

Installation on vehicle fuel door.

CAUTION

10

Installation

Dealer Responsibility

Your distributor from whom you purchased this mobile

cleaning unit is responsible for correct installation of

this machine. The dealer is also responsible for initial

training of your operators and maintenance personnel

in proper operation and maintenance of this unit.

Vehicle Requirements

1. The unit should NOT be mounted in any motor

vehicle of less than 1/2 ton capacityor 3/4 ton if

equipped with one or more auxiliary fresh water

tanks.

DO NOT exceed the vehicle’s axle weight limit.

Include the console, full tanks, accessories, and

operators in calculations.

2. If mounting in a trailer, make certain that trailer is

rated for the total weight of UNIT AND TRAILER.

Electric or hydraulic brakes should be provided,

and a strict compliance with any State and Federal

vehicle laws must be maintained.

3. The vehicle tires should have a load rating above

the combined vehicle and unit weight.

4. We do not recommend using flooring materials that

absorb water. This could result in rust and

corrosion of the vehicle floor.

5. Padding under rubber floor mats should be

removed before installing this unit.

6. We highly recommend using a drip tray under

console (Part #86050370, or Part # 86050380 for

units mounted on a water tank).

7. If using a trailer, console should be positioned so

that it balances properly with respect to axle. Ten

percent (10%) of the overall unit weight, should be

on tongue.

Example: If loaded trailer weight is 2,000 lbs.,

tongue weight needs to be a minimum of 200 lbs.

to tow properly.

Lifting Unit Onto Vehicle

Since console weighs approximately 600 lbs. pounds,

(690 lbs. if mounted on water tank) we recommend

using a forklift to lift unit onto vehicle. Position forks

under unit from front and make CERTAIN that forks are

spread to insert into frame slots.

Positioning Unit In Vehicle

Because vehicles vary in size and openings, individuals

have their own preference as to where they want their

units installed. We strongly recommend a side door

installation for this and DO NOT recommend a rear

door installation.

1. Enough space should be provided to assure

adequate engine ventilation and room for service

and maintenance.

2. The unit with waste tank and accessories must

NOT exceed vehicle's axle weight limit. An empty

60 gallon waste tank and console weighs 810 lbs

(900 lbs. if mounted on water tank).

3. DO NOT position the console closer than 12" from

bottom of driver and passenger seats.

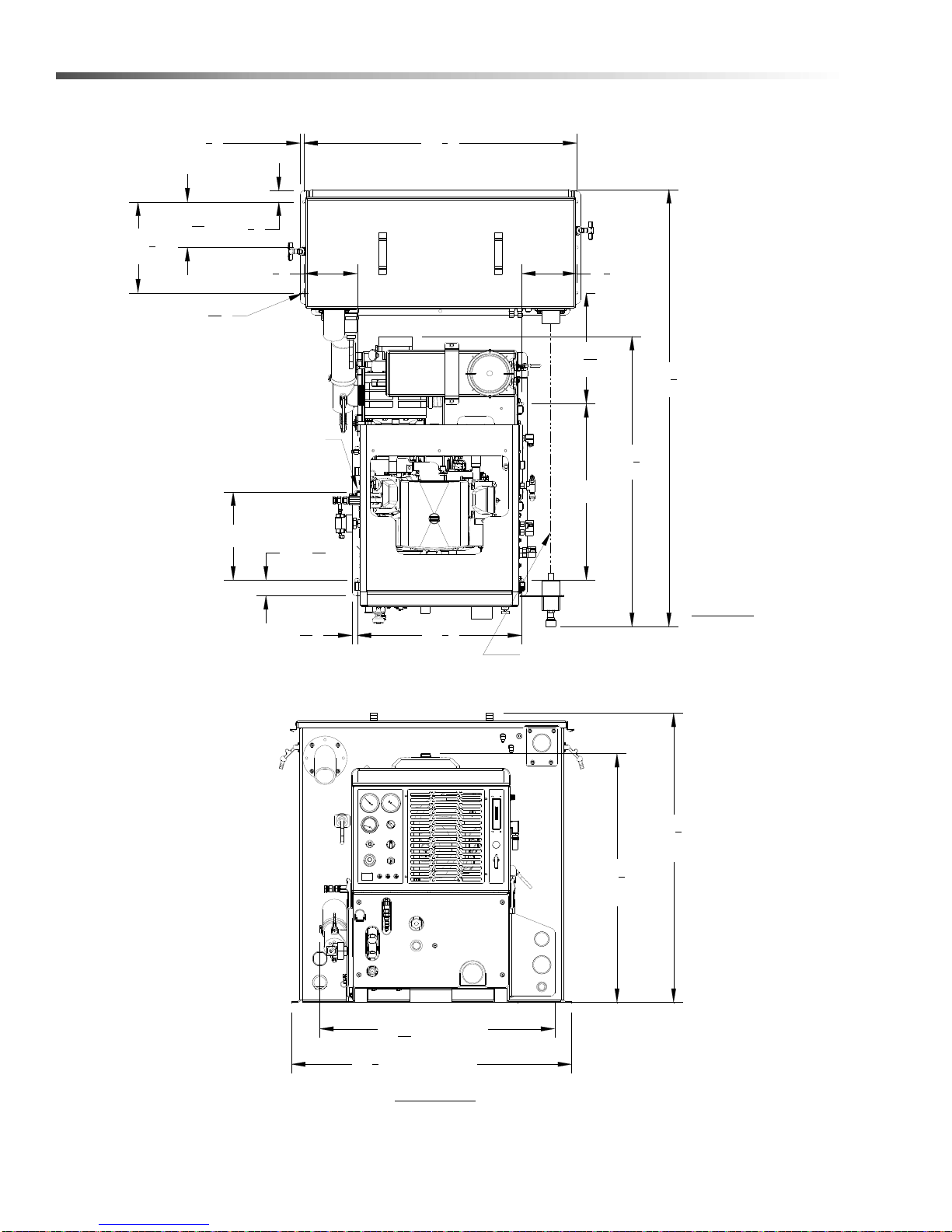

NOTE: For individuals who wish to make an

engineering layout prior to positioning unit, refer to

"Dimensional Data" illustrations for waste tank and

console dimensions.

4. Be sure to consider all accessories and their

required space prior to positioning the console and

waste tank.

86313050 LEGEND GT

11

Installation

Bolting Down Unit And Waste Tank

NOTE: When positioning waste tank with respect to

console, hook up the vacuum hose to waste tank.

This will ensure that waste tank is positioned

correctly. Proceed once unit and waste tank are

positioned in vehicle in desired location.

Before drilling any mounting holes in vehicle floor,

make certain that when drilling, you will not do any

damage to fuel tank, fuel lines, or any vital

component which might affect operation or safety

of vehicle.

1. Using console and waste tank mounting holes as a

template, drill six 13/32" diameter holes for

mounting console and six more 13/32" diameter

holes for mounting waste tank.

2. Using installation hardware kit:

a. Insert six 3/8-16 x 2" hex head cap screws with

flat washers through mounting holes in console,

and six 3/8-16 x 2" hex head cap screws with flat

washers through mounting holes in waste tank.

b. Install mounting plates underneath vehicle floor.

c. Screw 3/8-16 hex head locknuts on mounting

screws and tighten them until console and waste

tank are firmly secured to vehicle floor.

Electrical Wiring

Ensure all electrical wiring and battery cables are free

from contact with any metal edge. Engine vibration

could cause metal edge to cut wiring and possibly

result in a fire. Be aware of where battery cables are

run.

86313050 LEGEND GT

12

Installation

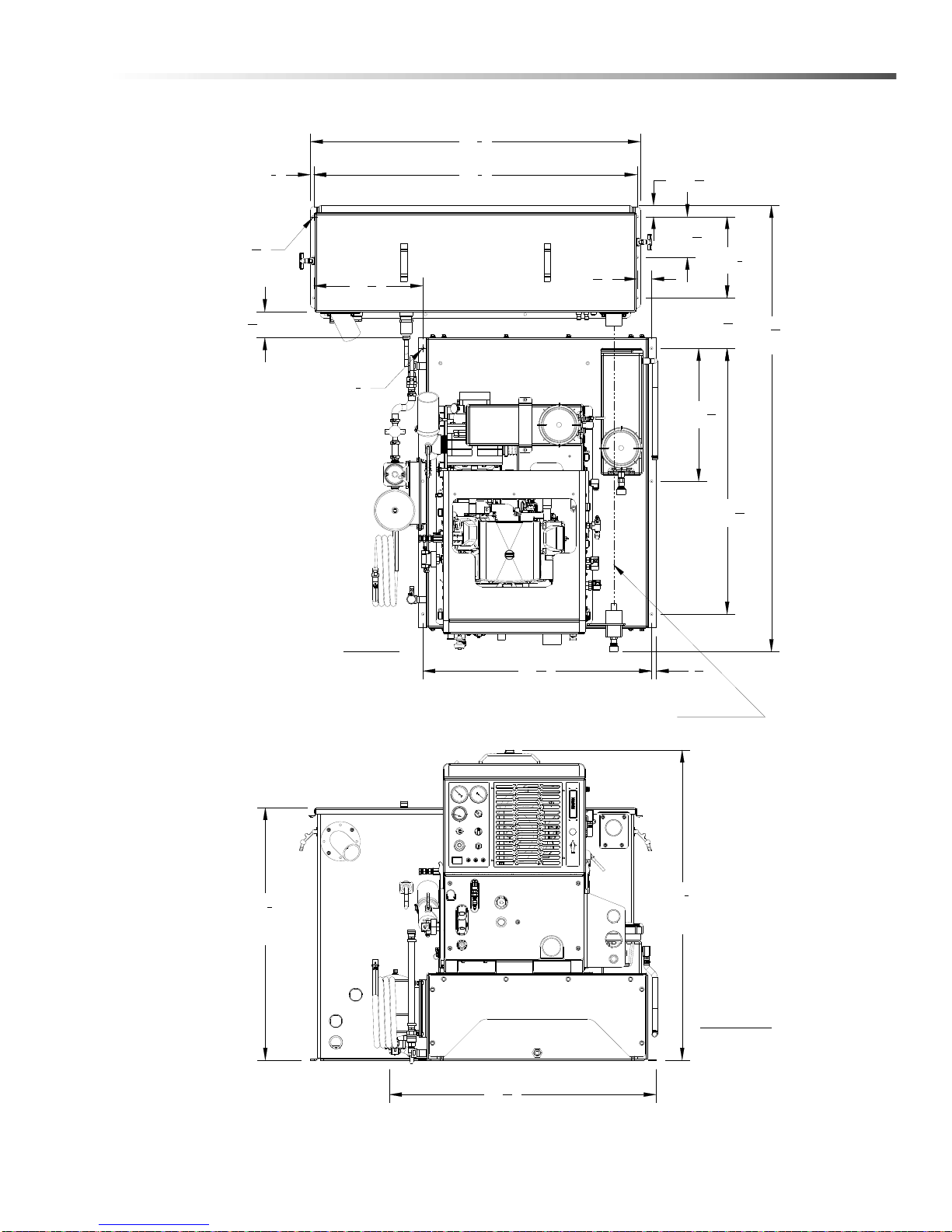

Layout with 60 Gallon Waste Tank

391

2"

337

8"

CONSOLE

393

8"

WASTE TANK

381

8" WASTE TANK

3131

32" CONSOLE

223

8"

6X Ø7/16" X 5/8" SLOT

371

8"

2X 11

2"

2X 63

16"

2X 123

8"

2X 2 3

32"

2X 12"

2X 24"

591

2"

6X Ø13

32"

TOP VIEW

FRONT VIEW

AND WASTE TANK ARE ALIGNED

ENSURE THAT VAC INLETS ON CONSOLE

1

2"

11

16"

71

4"

15 3

32"

71

2"

86313050 LEGEND GT

13

Installation

Layout with 60 Gallon Waste Tank & Optional Auxiliary Water Tank

6713

16"

LENGTH

383

8"

WASTE

TANK

AUXILIARY WATER TANK

FRONT VIEW

TOP VIEW

WASTE TANK

CONSOLE

381

8"

AND WASTE TANK ARE ALIGNED

ENSURE THAT VAC INLETS ON CONSOLE

2X 4013

32"

6X Ø13

32"

2X 123

8"

2X 63

16"

2X 111

16"

1

2"371

8"

11

16"

37

8" MIN.

6X Ø3

8"

3425

32"

2X 203

16"

471

8"

OVERALL

HEIGHT

4017

32"

721

32"

49

16"

721

32"

27

32"

86313050 LEGEND GT

14

Installation

Layout with 100 Gallon Waste Tank

9X Ø7/16" X 5/8" SLOT

191

4"

71

2"

153

32"

2X 123

8"

2X 12"

591

2"

LENGTH

ENSURE THAT VAC INLETS ON CONSOLE

AND WASTE TANK ARE ALIGNED

223

8"

11

16"

2X 6"

2X 111

16"

2X 63

16"

491

8"

1

2"

6X Ø13

32"

TOP VIEW

CONSOLE

WASTE TANK

333

8"

CONSOLE

HEIGHT

501

8"

FRONT VIEW

383

8"

WASTE

TANK

3131

32"

2X 24"

431

32"

86313050 LEGEND GT

15

Installation

Layout with 100 Gallon Waste Tank & Optional Auxiliary Water Tank

2X 12

3

8

"

2X 40

13

32

"

67

13

16

"

LENGTH

ENSURE THAT VAC INLETS ON CONSOLE

AND WASTE TANK ARE ALIGNED

34

25

32

"

11

16

"

2X 20

3

16

"

2X 1

11

16

"

2X 6

3

16

"

49

1

8

"

1

2

"

50

1

8

"

6X Ø

3

8

"

3

31

32

" MIN.

6X Ø

13

32

"

TOP VIEW

CONSOLE

AUXILIARY WATER TANK

WASTE TANK

47

1

8

"

OVERALL

HEIGHT

40

17

32

"

FRONT VIEW

38

3

8

"

WASTE

TANK

16

9

16

"2

7

32

"

7

21

32

"

86313050 LEGEND GT

16

Installation

Waste Tank To Console Connection

NOTE: Before connecting any hoses to the waste

tanks, make certain the hose clamps are on each

hose.

1. Connect the section of 2-7/8" I.D. internal vac hose

between the 2-7/8" dia. vac outlet tube on the

waste tank and the vacuum pump relief valve on

the console. It may be necessary to cut this hose

to fit. Tighten the hose clamps.

2. Connect the 2" I.D. waste removal hose to the 2"

dia. tube at the bottom corner of the waste tank.

Cut to desired length. Install brass ball valve on

other end.

3. Connect 2-1/2" I.D. hose between waste tank

vacuum inlet (upper right of waste tank) and

vacuum inlet on lower side panel of console.

4. Connect the 3/16" blue hose from the water box to

the lower flare fitting (angled downward) on the

waste tank.

5. Run the 5/8" water box overflow hose through the

van floor. Prior to drilling through the van floor,

ensure that no damage will occur in drilling area.

Ensure that you are in compliance with all local

environmental laws.

6. Connect the console engine shut-off cord to the

waste tank level sensor cord.

7. Connect the 3/16" blue hose from the solution

temperature control valve to the other flare fitting

(angled downward) on the waste tank.

Fire Extinguisher

We recommend that a fire extinguisher, preferably

rated for A, B, & C type fires, be installed inside the

vehicle.

Fuel Pump Assembly Installation

Before drilling the fuel line holes in the vehicle

floor, make certain that when drilling you will not do

any damage to the fuel tank(s), fuel lines, brake

lines, heat shields, or any other vital component

which might affect the operation or safety of the

vehicle.

Do not mount this assembly, any hoses or compo-

nents near the catalytic converter, exhaust, or any

areas of high temperature. Avoid any contact with

moving parts, areas of high temperature, brake

lines, fuel lines, muffler, catalytic converter, or

sharp objects.

1. Determine the position where the fuel pump

assembly will be mounted. Check to ensure that

the power cord length will support the mounting

location. The pump should be mounted as low as

possible and still be protected by the frame from

road hazards. Mount the fuel pump with the

discharge side of the pump higher than the

suction side to eliminate the possibility of

trapped air in the pump. Additional mounting

holes are provided to allow for different mounting

options.

2. Drill a 5/8" (.625) diameter hole in the vehicle floor

for routing the fuel pump power cord to the truck-

mount console. Check to ensure that the cord

length will support the location of the hole.

3. Route the power cord and install the hole grommet.

4. Do not connect the power cord to the truckmount

console wiring harness until installation is

complete.

86313050 LEGEND GT

17

Installation

Van Bulkhead Installation

1. Select a location on the vehicle floor to drill the hole for the bulkhead adapter. This location should be situated

in a position that eliminates the possibility of fuel line contact by either the operator(s) or accessories during the

working hours or maintenance periods. Make certain that the supplied hoses will reach the location and work

with the configuration you choose.

2. Drill a 5/8" (.625) diameter hole through the vehicle floor at the installation point chosen for the bulkhead.

3. Install the 1/8 NPT bulkhead adapter by inserting the adapter and tightening the nut on the opposite side of the

van floor.

4. Attach the 1/8 NPT x 1/4 Hosebarb 90 degree elbow to the bulkhead inside the van to connect the fuel system

to the console.

5. Attach the 1/4" fuel hose from the console to the 1/4” Hosebarb 90 degree elbow on the bulkhead.

TO CONSOLE

USE AS NEEDED

BULKHEAD ADAPTER

BULKHEAD NUT

HOSEBARB ELBOW

HOSEBARB ELBOW

HOSE MOUNTING CLAMPS

FUEL HOSE

HOSE CLAMP

VEHICLE FLOOR

5/8" DIA HOLE

LOCTITE

BYPASS FUEL FILTER

FUEL HOSE FROM

BULKHEAD GASKET

BULKHEAD GASKET

86313050 LEGEND GT

18

Installation

Fuel Supply & Return Line Installation

(Underneath Van)

1. Attach the 1/8 NPT x 5/16 Hosebarb 90 degree elbow to the bulkhead adapter underneath the van to be used

for the fuel supply line.

2. Cut to length the 6' piece of 5/16" 50 PSI fuel hose used for the supply line from:

a. Bulkhead adapter to the outlet side of the bypass fuel filter.

b. Inlet side of the bypass fuel filter to the discharge side of the fuel pump.

c. Inlet side of the fuel pump to the outlet side of the inline fuel filter.

3. Cut to length the 6' piece of 1/4" fuel line to connect the bypass fuel filter with the fuel tank return using the

appropriate fuel tap kit.

4. Check all hose clamps for tightness.

NOTE: Fuel tap kit installation instructions are found with appropriate fuel tap kit. Refer to Fuel Tap Kit

Information Sheet (8.634-994.0)

CHECK VALVE

5/16" SUPPLY HOSE

BYPASS FUEL FILTER

HOSE MOUNTING CLAMP

FRONT OF VAN

BULKHEAD CONNECTOR

BUSHING

ELECTRICAL CORD

PUMP ASSEMBLY

ELECTRICAL FUEL

USE AS NEEDED

5/16" SUPPLY HOSE

5/16" SUPPLY HOSE

FUEL SUPPLY

RETURN TO VEHICLE

FROM VEHICLE

FUEL SUPPLY

FUEL FLOW

FUEL FILTER

1/4" RETURN HOSE

86313050 LEGEND GT

Other manuals for LEGEND GT

1

Table of contents

Other Prochem Water System manuals

Popular Water System manuals by other brands

sylber

sylber SN 150/1 T Installer, technical assistance centre and user manual

Kenmore

Kenmore 625.347001 owner's manual

Pentair

Pentair SIATA V132 SFE-EV VIRIDION user manual

Reo-Pure

Reo-Pure 90403 Installation, operation & maintenance manual

Ace

Ace ACE.BOIL manual

EXTREME HEAT SOLAR

EXTREME HEAT SOLAR Geyser instruction manual

Pura

Pura QCUF Installation & operation manual

Irrigatia

Irrigatia SOL-K12 Instructions for use

AquaLiv

AquaLiv A305 Usage & installation instructions

Pelican

Pelican Advantage Series owner's manual

Watts

Watts FEBCO 765 INSTRUCTION, INSTALLATION, MAINTENANCE AND REPAIR MANUAL

BWT

BWT STARDECK INEO Installation and maintenance instructions