Procon MelcoBEMS MINI User manual

Procon

MelcoBEMS MINI (A1M)

FOR INSTALLERS

INSTALLATION MANUAL

Manual version 1.0.1

Firmware version 3.0.1

For safe and correct use, please read this installation manual thoroughly before installing the PROCON

MelcoBEMS MINI (A1M).

• i •

Preface

Safety warnings

Caution:

Do not expose to rain or moisture.

Shielded Signal Cables:

Use only shielded cables for connecting peripherals to any Procon MelcoBEMS MINI (A1M)

device to reduce the possibility of interference with radio communications services. Using

shielded cables ensures that you maintain the appropriate EMC classification for the intended

environment.

CE Notice:

This product has been determined to be in compliance with 2004/108/EC (EMC Directive) and

amendments of the European Union.

European Union, Class A:

Class A products are intended for use in non-residential/non-domestic environments. Class A

products may also be utilized in residential/domestic environments but may cause interference

and require the user to take adequate corrective measures.

This is a Class A product. In a domestic environment this product may cause radio frequency

interference in which case the user may be required to take adequate measures.

A “Declaration of Conformity” in accordance with the preceding directives and standards has

been made and is available on request.

If this equipment does cause interference with radio communications services, which can be

determined by turning the equipment off and on, you are encouraged to try to correct the

interference by one or more of the following measures:

Reorient the receiving antenna.

Relocate the Procon MelcoBEMS MINI (A1M) with respect to the receiver.

Move the Procon MelcoBEMS MINI (A1M) away from the receiver.

If necessary, consult a Procon MelcoBEMS MINI (A1M) technical support representative or an

experienced radio/television or EMC technician for additional suggestions.

Disclaimer

Warranty:

All products manufactured on behalf of Mitsubishi Electric UK are warranted against defective

materials for a period of three years from the date of delivery to the original purchaser.

Warning:

Mitsubishi Electric UK assumes no liability for damages consequent to the user of this product.

We reserve the right to change this manual at any time without notice. The information furnished

by us is believed to be accurate and reliable. However, no responsibility is assumed by us for its

use, nor for any infringements of patents or other rights of third parties resulting from its use.

• ii •

Amendment Register

Document

Version

Latest

Firmware

Version

Date Author Notes

1.0.0

3.0.0 08/05/15 GD Initial version for firmware V1.0.0

1.0.1 3.0.1 16/06/15 GD

Added ‘Applicable Unit Type’ columns to Air-To-Water

Modbus tables.

Other minor modifications.

Any additional notes since printing will be appended to the rear of this document on separate

sheets of paper.

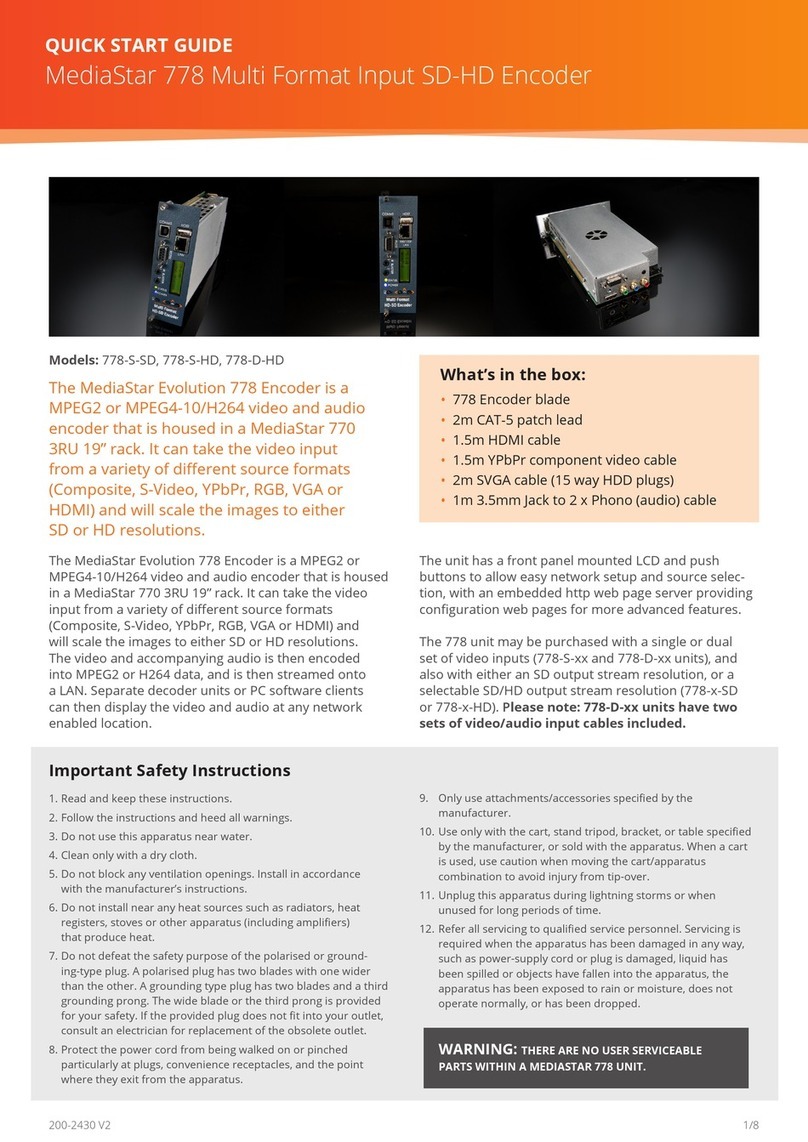

A RS-485 connector

B CN105/CN92 connection lead

1

[Fig. 1]

A

B

Page 2 of 47

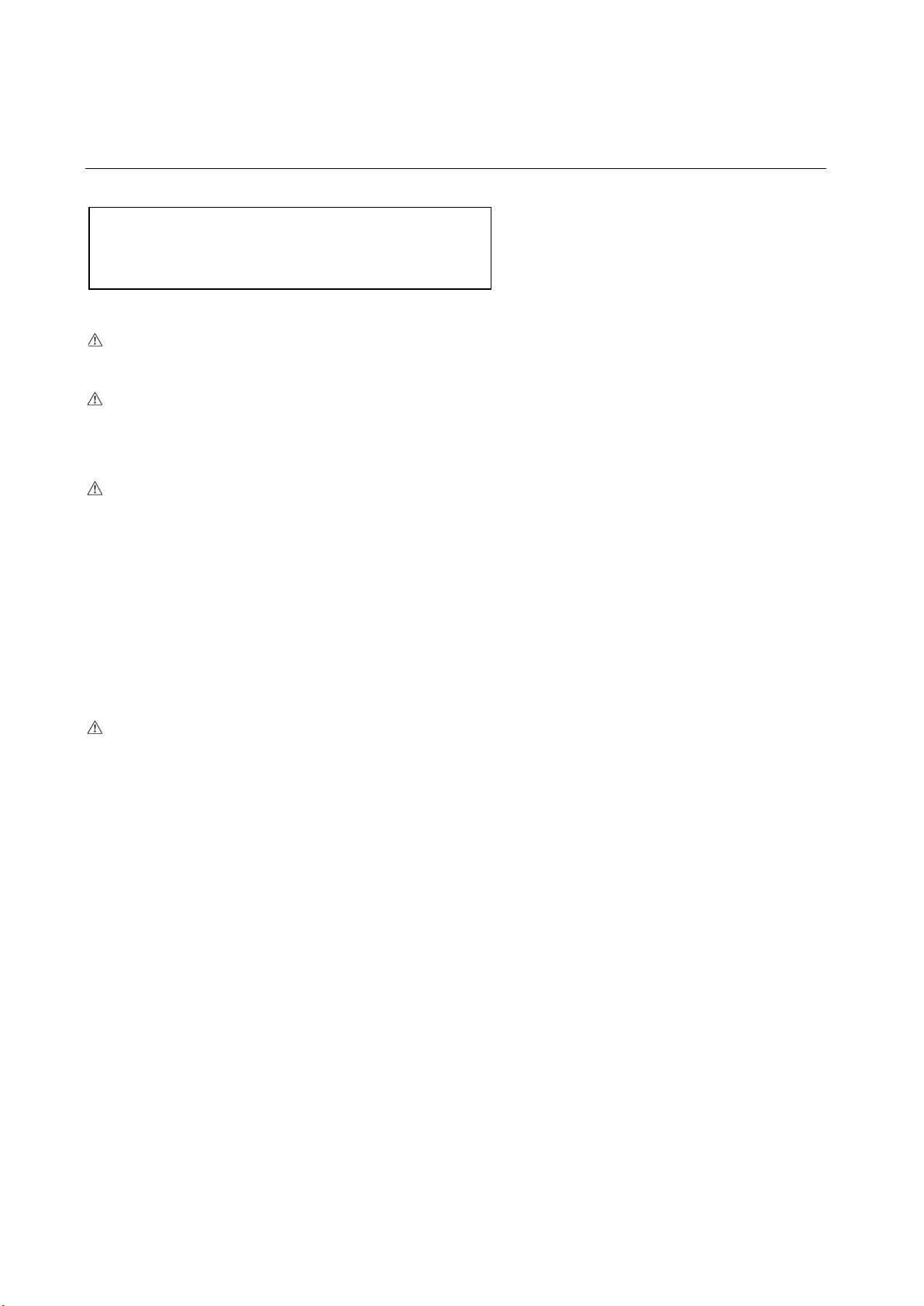

2

[Fig. 2]

Air to air unit

Air to water unit

Page 3 of 47

Contents

Preface ............................................................................................................................................................................. i

Safety warnings............................................................................................................................................................ i

Disclaimer..................................................................................................................................................................... i

Amendment Register ..................................................................................................................................................... ii

1. Safety precautions................................................................................................................................................ 4

2. Overview................................................................................................................................................................ 5

3. DIP switch settings............................................................................................................................................... 6

3.1. RS-485 Node address.................................................................................................................................... 6

3.2. RS-485 communication settings..................................................................................................................... 6

3.3. Protocol selection ........................................................................................................................................... 7

3.4.Deadband mode............................................................................................................................................. 7

4. Deadband Mode.................................................................................................................................................... 8

4.1. Settings .......................................................................................................................................................... 8

4.2. Operation........................................................................................................................................................ 8

4.3. Initialisation..................................................................................................................................................... 9

5. Setpoint Offset.................................................................................................................................................... 10

5.1. Settings ........................................................................................................................................................ 10

5.2. Operation...................................................................................................................................................... 10

6. RS-485 termination............................................................................................................................................. 12

7. Installation........................................................................................................................................................... 13

7.1. Physical connection...................................................................................................................................... 13

7.2. Power supply................................................................................................................................................ 13

7.3. Modbus connections .................................................................................................................................... 13

7.4. Unit type selection ........................................................................................................................................ 13

8. Status LEDs ........................................................................................................................................................ 14

8.1. AC ACK........................................................................................................................................................ 14

8.2. RS-485 ACK................................................................................................................................................. 14

9. BACnet ................................................................................................................................................................ 15

9.1. BACnet MS/TP ............................................................................................................................................. 15

9.2. Object types supported ................................................................................................................................ 15

9.3. Object list...................................................................................................................................................... 16

10. Modbus connection............................................................................................................................................ 17

10.1. Modbus background..................................................................................................................................... 17

10.2. Modbus registers.......................................................................................................................................... 17

10.3. Modbus connections .................................................................................................................................... 17

11. Modbus tables – Air-To-Air systems................................................................................................................. 19

11.1. Holding registers .......................................................................................................................................... 19

11.2. Input registers............................................................................................................................................... 21

11.3. Discrete Inputs ............................................................................................................................................. 21

11.4. Coils ............................................................................................................................................................. 21

Modbus tables – Air-To-Water systems ..................................................................................................................... 22

11.5. Holding registers .......................................................................................................................................... 22

11.6. Input registers............................................................................................................................................... 34

11.7. Coils ............................................................................................................................................................. 40

11.8. Discrete Inputs ............................................................................................................................................. 41

Appendix A – Compatible Air-To-Air units................................................................................................................. 44

Appendix B – Compatible Air-To-Water units............................................................................................................ 45

Page 4 of 47

1. Safety precautions

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Warning:

•Ask the dealer or an authorised technician to install the unit

-Improper installation by the user may result in electric shock, or fire

•Use the specified cables for wiring. Make the connections securely so that any outside forces acting on the cables are

not applied to the terminals

-Inadequate connection and fastening may generate heat and cause a fire

•Never repair the unit. If the controller must be repaired, consult the dealer

- If the unit is repaired improperly, electric shock, or fire may result

•Have all electric work done by a licensed electrician according to "Electric Facility Engineering Standard", "Interior Wire

Regulations" and the instructions given in this manual and always use a special circuit

- If the power source capacity is inadequate or electric work is performed improperly, electric shock and fire may result

•Keep the electric parts away from any water - washing water etc…

- Contact may result in electric shock, fire or smoke

•To dispose of this product, consult your dealer

Caution:

•Safely dispose of the packing materials

- Packing materials, such as nails and other metal or wooden parts, may cause stabs or other injuries

- Tear apart and throw away plastic packaging bags so that children will not play with them - If children play with a plastic bag

which has not been torn apart, they face the risk of suffocation

Before installing the unit, make sure you read all the

“Safety precautions”

The “Safety precautions” provide very important points

regarding safety. Make sure you follow them

Page 5 of 47

2. Overview

The Procon MelcoBEMS MINI (A1M) Protocol Converter is used for remote monitoring and control of both Air-to-Air

products (M-, S- and P-series split air conditioning systems) and Air-to-Water products (CAHV, CRHV, PWFY). It acts

as a gateway between the system and external third party equipment.

The MelcoBEMS MINI (A1M) continuously reads data from the system and changes configuration when necessary.

Because the reading is continuous the MelcoBEMS MINI (A1M) always stores up-to-date data. This data is then

available to external devices through the RS-485 port using the Modbus RTU software protocol. Values can be read

and changed via this connection. Please refer to the Modbus section for further information.

The MelcoBEMS MINI (A1M) is powered via the CN105/CN92 connector, hence no external power supply is needed.

Compatible Air-To-Air model numbers can be found in Appendix A of this document.

Caution:

MAC-397IF and MAC-399IF units cannot be connected when the MelcoBEMS MINI (A1M) is connected, as the same

CN105/CN92 connector is used.

Appendix A lists the compatible Air-To-Air indoor units.

Appendix B lists the compatible Air-To-Water indoor units.

Figure 1 shows the MelcoBEMS MINI (A1M) converter.

Figure 2 shows the CN105/CN92 connector on the indoor unit PCB that the MelcoBEMS MINI (A1M) connects to, for

both Air-to-Air and Air-To-Water type units.

Page 6 of 47

3. DIP switch settings

There is a bank of 8 DIP switches on the MelcoBEMS MINI (A1M) labeled ‘CONFIGURATION’. These switches are

used to configure communication settings and to enable some features.

3.1. RS-485 Node address

When BACnet MS/TP protocol has been selected (see section 3.3) the node address is used as the Station ID.

When Modbus RTU protocol has been selected (see section 3.3) The node address is used as the Slave ID.

Any node address in the range 1 – 30 can be chosen using switches 1 – 5. The address is set in binary, where the

switch positions have the following values:

Switch number

Value when switch is set to ON

1

1

2

2

3

4

4

8

5

16

To get the node address, add together the value for each switch set ON. For example, to set address 13, set switches

1, 3 and 4 ON (1 + 4 + 8 = address 13).

When all switches 1 – 5 are set to the ON position the node address is set in software by writing to a Modbus register

(see Modbus Holding Registers section).

Note: When all switches are set to the OFF position a node address of 1 is assumed.

Note: Each MelcoBEMS MINI (A1M) connected on the same RS-485 network must be set to a unique node address.

3.2. RS-485 communication settings

The RS-485 settings are set using DIP switch 6.

When the switch is in the OFF position the Baud Rate and Parity settings are set in software by writing to Modbus

registers (see Modbus Holding Register section).

Switch 6

RS-485 communication settings

OFF

Baud Rate and Parity set in software

ON

9600 baud, no parity

The number of data bits is fixed at 8 and the number of stop bits is fixed at 1.

Page 7 of 47

3.3. Protocol selection

The RS485 protocol is set using DIP switch 7.

When the switch is in the ON position the Modbus RTU protocol is selected.

Switch 7

Protocol selection

OFF

BACnet MS/TP

ON

Modbus RTU

3.4. Deadband mode

The Deadband feature can be enabled using DIP switch 8.

When the switch is in the OFF position the Deadband feature is disabled.

When the switch is in the ON position the Deadband feature is enabled.

Switch 8

Deadband feature

OFF

Disabled

ON

Enabled

Page 8 of 47

4. Deadband Mode

The deadband mode is enabled by setting DIP switch 8 ON. It is only applicable to Air-To-Air type units.

4.1. Settings

There are two settings, the Heating Setpoint (default 19º) and Cooling Setpoint (default 23ºC). These values can be

changed via Modbus, refer to the Air-To-Air Modbus tables for more information.

The Cooling Setpoint must be at least 2ºC greater than the Heating Setpoint, otherwise the default values given above

will be assumed.

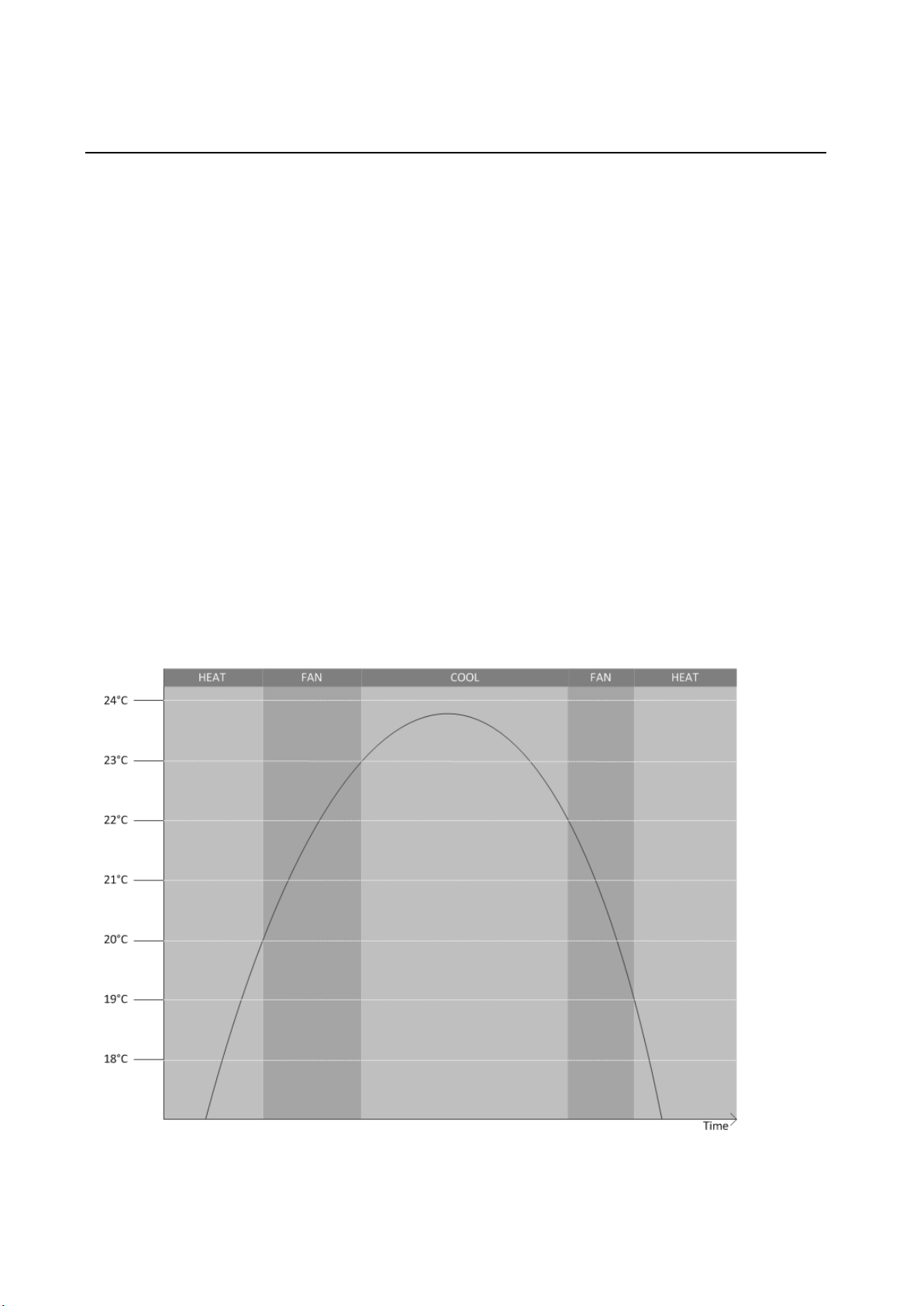

4.2. Operation

When enabled, the MelcoBEMS MINI (A1M) controls the Mode and Temperature Setpoint based on the Room (return

air) Temperature.

While the room temperature is less than the Heating Setpoint the unit will be set to HEAT mode with a setpoint of 28ºC.

Whilst in HEAT mode, if the room temperature rises above the Heating Setpoint + 1ºC the unit will be set to FAN mode.

Whilst in FAN mode, if the temperature rises above the Cooling Setpoint the unit will be set to COOL mode with a

setpoint of 19ºC.

Whilst in COOL mode, if the room temperature falls below the Cooling Setpoint – 1ºC the unit will be set to FAN mode.

Whilst in FAN mode, if the room temperature falls below the Heating Setpoint the unit will be set to HEAT mode with a

setpoint of 28ºC.

The following image shows this graphically (assuming a Heating Setpoint of 19ºC and a Cooling Setpoint of 23ºC):

Page 9 of 47

4.3. Initialisation

When the MelcoBEMS MINI (A1M) powers up it will set the mode, which will be determined by the room temperature.

If less than the Heating Setpoint the unit will be set to HEAT mode with a setpoint of 28ºC.

If greater than or equal to the Cooling Setpoint the unit will be set to COOL mode with a setpoint of 19ºC.

If between the Heating and Cooling Setpoints the unit will be set to FAN mode.

Page 10 of 47

5. Setpoint Offset

The Setpoint Offset feature is only applicable to, and will only be enabled for, Air-To-Air type units.

5.1. Settings

There are two settings which are applicable to the Setpoint Offset feature, BMS Room Temperature and BMS Virtual

Setpoint.

The BMS Virtual Setpoint can be changed using Modbus and is stored in non-volatile memory so the value is retained

if the MelcoBEMS MINI (A1M) loses power.

The BMS Room Temperature can be changed using Modbus but is not stored in non-volatile memory, so the value is

lost and reset to zero upon the MelcoBEMS MINI (A1M) losing power.

5.2. Operation

In some situations a 3rd party room temperature sensor connected to a BMS or other controller may provide a more

accurate temperature reading than the return air temperature of the indoor unit. The A1M can calculate the difference

between these two temperature readings and compensate by adjusting the indoor unit’s temperature setpoint.

The new temperature setpoint is calculated using the following equation:

Temperature Setpoint = Return Air Temperature – (BMS Room Temperature – BMS Virtual Temperature)

As a hypothetical example, consider the BMS Virtual Setpoint being set to 21ºC and the indoor unit return air

temperature remaining constant at 22ºC. As the BMS Room Temperature decreases the MelcoBEMS MINI (A1M)

increases the indoor unit’s temperature setpoint.

When the BMS Room Temperature reaches 18ºC the Temperature Setpoint = 22 – (18 – 21) = 25ºC.

Hysteresis has been built in to prevent the temperature setpoint from rapidly changing.

Page 11 of 47

The setpoint offset will only operate correctly if the BMS Room Temperature is periodically updated via Modbus, to

ensure the MelcoBEMS MINI (A1M) always has an up to date reading.

If the BMS Room Temperature is set to 0ºC (which it will be on power up) the setpoint offset feature will be disabled. It

will only activate when the BMS Room Temperature is not 0ºC.

To disable the feature without removing the MelcoBEMS MINI (A1M) power, simply set the BMS Room Temperature to

0ºC.

Page 12 of 47

6. RS-485 termination

An RS-485 termination resistor can be enabled on the MelcoBEMS MINI (A1M) PCB using the single jumper labeled

J1.

The jumper setting is summarised below:

Jumper Setting

Description

Not fitted

Termination resistor not enabled

Fitted

Termination resistor enabled

Page 13 of 47

7. Installation

7.1. Physical connection

The MelcoBEMS MINI (A1M) has a 1 metre flying lead to connect directly into the CN105/CN92 connector on the

controller PCB. As an example, Figure 2 shows this connection on a Mr Slim indoor unit and a CRHV unit.

7.2. Power supply

The MelcoBEMS MINI (A1M) is powered from the CN105/CN92 connector and hence does not require an external

power supply.

7.3. Modbus connections

The MelcoBEMS MINI (A1M) has a 3-way screw terminal to provide Modbus RTU communication via RS-485. Figure 1

shows the RS-485 connections. The Modbus section contains further detail of the Modbus communications.

7.4. Unit type selection

The MelcoBEMS MINI (A1M) software will automatically detect whether an Air-To-Air or Air-To-Water unit is connected.

It will then only send commands applicable to that unit type.

Page 14 of 47

8. Status LEDs

There are two status LEDs on the MelcoBEMS MINI (A1M). The LED indications are as follows:

LED Name

Colour

Functionality

AC ACK Green Lit when A1M is powered, flashing indicates valid communication

with the indoor unit.

RS-485 ACK Green Lit when A1M is powered, flashing indicates valid Modbus

communication.

8.1. AC ACK

If this LED is permanently lit and does not flash, check the CN105/CN92 connection is secure.

8.2. RS-485 ACK

If this LED is permanently lit and does not flash it could be due to a physical RS-485 connection problem, or incorrect

Modbus/RS-485 configuration.

Page 15 of 47

9. BACnet

9.1. BACnet MS/TP

The MelcoBEMS MINI (A1M) can be connected to a BACnet MS/TP network using RS-485.

BACnet protocol can be selected using DIP switch 7 (see section 3.3).

9.2. Object types supported

Property

Object Type

Analogue Input

Analogue

Output

Binary Input Binary Output

Multi State

Output

Object Identifier

R

R

R

R

R

Object Name

R

R

R

R

R

Object Type

R

R

R

R

R

Present Value

R

R/W

R

R/W

R/W

Status Flags

R

R

R

R

R

Event State

R

R

R

R

R

Out Of Service

R

R

R

R

R

Number Of States

R

State Text

R

Units

R

R

Polarity

R

R

Priority Array

R

R

Relinquish Default

R

R

R

R = Read accessible only

R/W = Read and write accessible

Page 16 of 47

9.3. Object list

The MelcoBEMS MINI (A1M) currently has objects for certain ATA protocol data points, detailed in the following table.

Object type

Object ID

Object name

Notes

Binary Output BO01 Drive OFF/ON

0 = Drive OFF

1 = Drive ON

Analog Output AO1 Setpoint

Value in either ºC or ºF, depending on the

Temperature Units setting

Analog Output AO2* Heating Setpoint

Value in either ºC or ºF, depending on the

Temperature Units setting

Analog Output AO3* Cooling Setpoint

Value in either ºC or ºF, depending on the

Temperature Units setting

Multistate Output MS4 Mode

1 = Heating

2 = Humidity reduction

3 = Cooling

4 = Ventilation, clean air operation

5 = Auto Operation

Multistate Output MS5 Fan Speed

1 = Auto

2 = Quiet

3 = Weak

4 = Strong

5 = Very strong (SH i)

Multistate Output MS6 Air Direction

1 = Auto

2 = Position 1

3 = Position 2

4 = Position 3

5 = Position 4

6 = Position 5

7 = Swing

Multistate Output MS7** Temperature Units

1 = ºC

2 = ºF

Analog Input AI8 Return Air Temperature

Value in either ºC or ºF, depending on the

Temperature Units setting

Analog Input

AI9

Fault Code

4-digit fault code

* Deadband mode must be enabled for these objects to have any effect (see section 4).

** Please power cycle the MelcoBEMS MINI after changing the Present Value object property.

This manual suits for next models

1

Table of contents

Other Procon Media Converter manuals

Popular Media Converter manuals by other brands

Altronix

Altronix NetWaySP1P installation guide

IMC Networks

IMC Networks MediaChassis/I-AC installation guide

RDL

RDL TX-LC2 Installation and operation

Axis

Axis M7014 installation guide

Runco

Runco ViViX PIXEL FOR PIXEL PFP-7 Owner's operating manual

Omnitron Systems Technology

Omnitron Systems Technology XM5-1G quick start guide