Procon MelCOMMS MINI User manual

Procon

MelCOMMS MINI

FOR INSTALLERS

INSTALLATION MANUAL

Manual version 1.0.0

Firmware version 1.0.0

For safe and correct use, please read this installation manual thoroughly before installing the PROCON

MelCOMMS MINI.

• i •

Preface

Safety warnings

Caution:

Do not expose to rain or moisture.

Operating Temperature:

The product has been designed to operate between -20° C and +60° C

Shielded Signal Cables:

Use only shielded cables for connecting peripherals to any Procon MelCOMMS MINI device to

reduce the possibility of interference with radio communications services. Using shielded cables

ensures that you maintain the appropriate EMC classification for the intended environment.

CE Notice:

This product has been determined to be in compliance with the following European Safety and

EMC Directives:

2014/30/EU (EMC Directive)

2014/35/EU (Low Voltage Directive)

2011/65/EU (RoHS Directive).

European Union, Class A:

Class A products are intended for use in non-residential/non-domestic environments. Class A

products may also be utilized in residential/domestic environments but may cause interference

and require the user to take adequate corrective measures.

This is a Class A product. In a domestic environment this product may cause radio frequency

interference in which case the user may be required to take adequate measures.

A “Declaration of Conformity” in accordance with the preceding directives and standards has

been made and is available on request.

If this equipment does cause interference with radio communications services, which can be

determined by turning the equipment off and on, you are encouraged to try to correct the

interference by one or more of the following measures:

Reorient the receiving antenna.

Relocate the Procon MelCOMMS MINI with respect to the receiver.

Move the Procon MelCOMMS MINI away from the receiver.

If necessary, consult a Procon MelCOMMS MINI technical support representative or an

experienced radio/television or EMC technician for additional suggestions.

• ii •

Disclaimer

Warranty:

All products manufactured on behalf of Mitsubishi Electric UK are warranted against defective

materials for a period of three years from the date of delivery to the original purchaser.

Warning:

Mitsubishi Electric UK assumes no liability for damages consequent to the user of this product.

We reserve the right to change this manual at any time without notice. The information furnished

by us is believed to be accurate and reliable. However, no responsibility is assumed by us for its

use, nor for any infringements of patents or other rights of third parties resulting from its use.

If the equipment is used in a manor not specified by the manufacturer, the protection provided by

the equipment may be impaired.

• iii •

Amendment Register

Document

Version

Latest

Firmware

Version Date Author Notes

1.0.0

1.0.0 12/07/17 GD Initial version.

Any additional notes since printing will be appended to the rear of this document on separate

sheets of paper.

1 [Fig. 1]

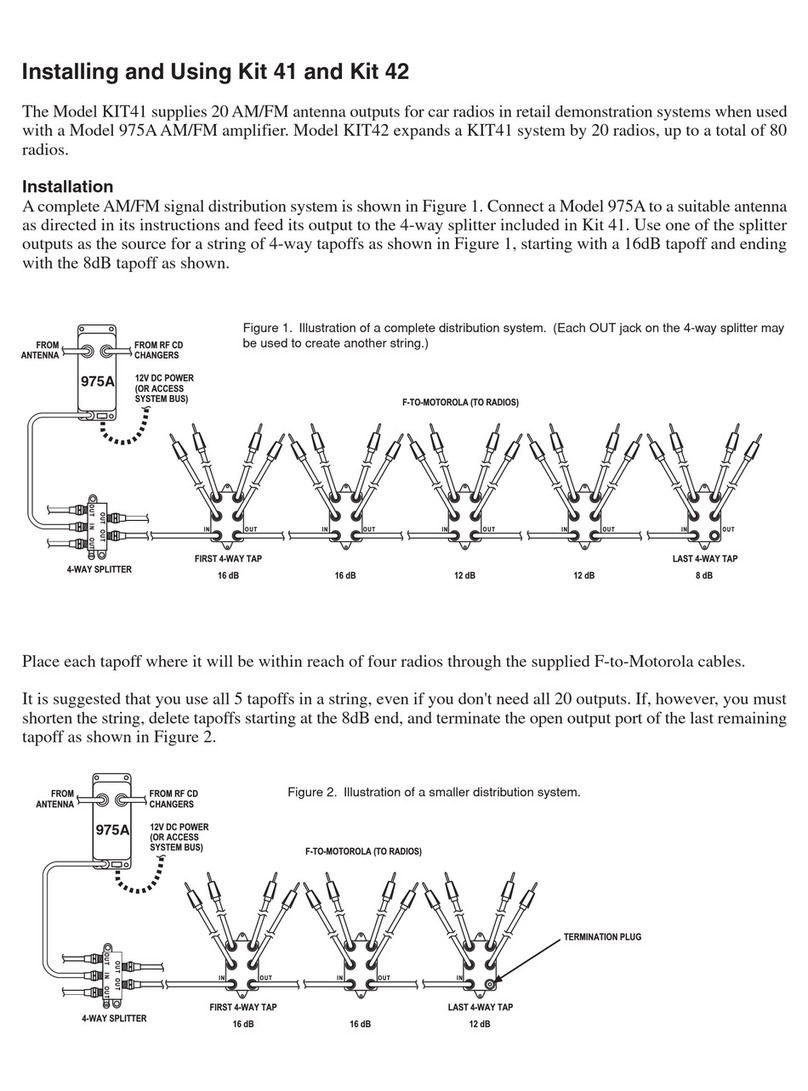

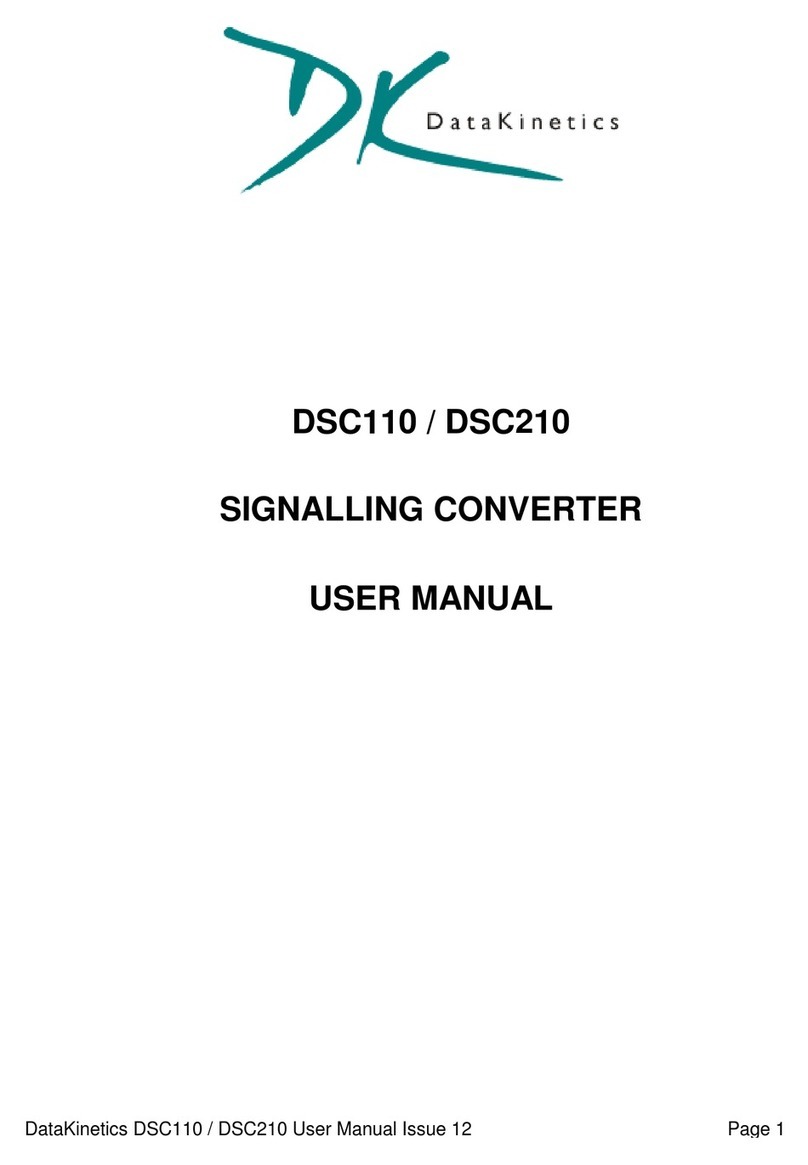

2 [Fig. 2] Wiring Diagram

LK1 = Line A pull-up resistor

LK2 = A-B termination resistor

LK3 = Line B Pull-down resistor

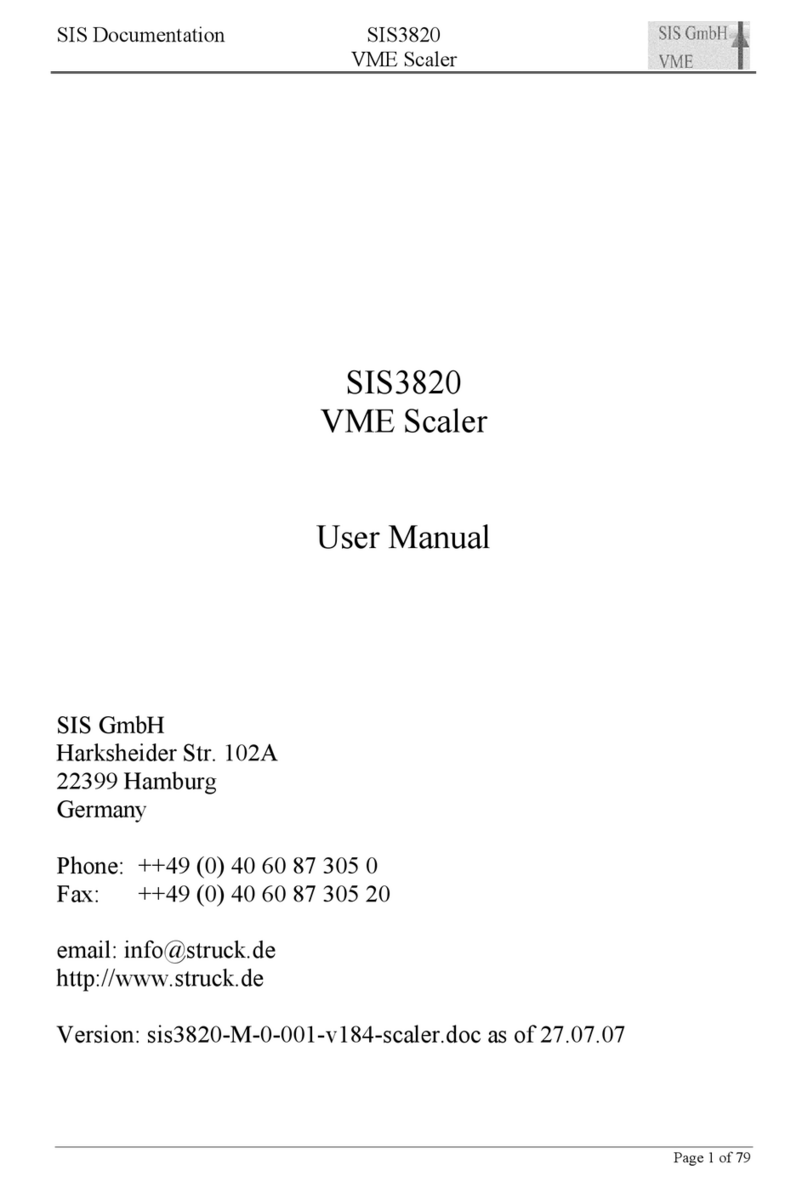

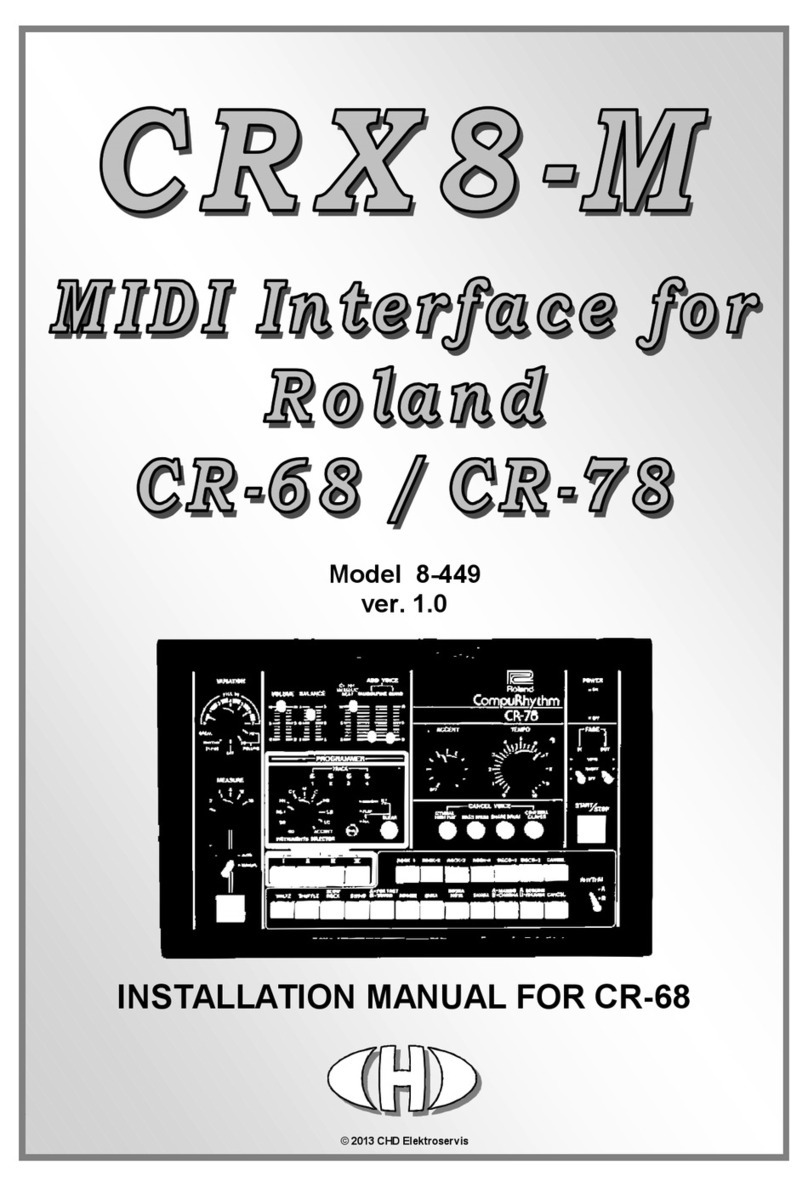

[Fig. 3]

3

MelcoBEMS MINI (A1M)

DIP switch configuration MelcoBEMS MINI (A1M)

RS-485 resistors

Each MelcoBEMS MINI (A1M) unit must have a

unique address on the RS-485 bus.

The baud rate must be set to 9600.

Contents

Preface............................................................................................................................................................................. i

Safety warnings............................................................................................................................................................ i

Disclaimer.....................................................................................................................................................................ii

Amendment Register.................................................................................................................................................... iii

1.Safety precautions................................................................................................................................................ 5

2.Connecting Mains Power..................................................................................................................................... 6

3.Overview................................................................................................................................................................ 7

4.Getting Started...................................................................................................................................................... 8

4.1.Unpacking ...................................................................................................................................................... 8

4.2.Before switching ON....................................................................................................................................... 8

5.Installation............................................................................................................................................................. 9

5.1.Physical connection........................................................................................................................................ 9

5.2.Power supply.................................................................................................................................................. 9

5.3.Modbus RS-485 connection........................................................................................................................... 9

5.4.Configuration................................................................................................................................................ 10

5.5.Initial Power ON ........................................................................................................................................... 12

5.6.Status Indicators........................................................................................................................................... 12

5.6.1.Fault LED.............................................................................................................................................. 12

5.6.2.Buzzer................................................................................................................................................... 12

5.6.3.Relay Status LEDs................................................................................................................................ 12

5.6.4.RS-485 Comms Status LED.................................................................................................................. 13

6.Control Functionality.......................................................................................................................................... 14

6.1.Automatic Mode ........................................................................................................................................... 14

6.1.1.Backup & Rotate................................................................................................................................... 14

6.1.2.Example................................................................................................................................................ 14

6.2.Manual Mode................................................................................................................................................ 15

6.3.Rotation Test Mode...................................................................................................................................... 15

6.4.Modbus Slave Test Mode............................................................................................................................. 15

6.4.1.Modbus registers................................................................................................................................... 15

7.Troubleshooting ................................................................................................................................................. 17

Appendix A – Compatible Air-To-Air units................................................................................................................. 18

1. Safety precautions

Symbols used in the text

Warning:

Describes precautions that should be observed to prevent danger of injury or death to the user.

Caution:

Describes precautions that should be observed to prevent damage to the unit.

Warning:

•Ask the dealer or an authorised technician to install the unit

-Improper installation by the user may result in electric shock, or fire

•Use the specified cables for wiring. Make the connections securely so that any outside forces acting on the cables are

not applied to the terminals

-Inadequate connection and fastening may generate heat and cause a fire

•Never repair the unit. If the controller must be repaired, consult the dealer

- If the unit is repaired improperly, electric shock, or fire may result

•Have all electric work done by a licensed electrician according to "Electric Facility Engineering Standard", "Interior Wire

Regulations" and the instructions given in this manual and always use a special circuit

- If the power source capacity is inadequate or electric work is performed improperly, electric shock and fire may result

•Keep the electric parts away from any water - washing water etc…

- Contact may result in electric shock, fire or smoke

•To dispose of this product, consult your dealer

Caution:

•Safely dispose of the packing materials

- Packing materials, such as nails and other metal or wooden parts, may cause stabs or other injuries

- Tear apart and throw away plastic packaging bags so that children will not play with them - If children play with a plastic bag

which has not been torn apart, they face the risk of suffocation

¾Before installing the unit, make sure you read all the

“Safety precautions”

¾The “Safety precautions” provide very important points

re

g

ardin

g

safet

y

. Make sure

y

ou follow them

2. Connecting Mains Power

The power requirements of the MelCOMMS MINI are 100-240VAC, 0.7A, 50/60Hz.

A 6A single gang fused switch must be provided in-line with the mains supply and be in close proximity to the

MelCOMMS MINI enclosure. It must be clearly marked as the disconnecting device. The supply should also be fed via

a 6amp type B circuit breaker in the distribution box.

The construction of the connections of the conductors should be such that, if the cord were to slip in its anchorage,

the protective earth conductor would be the last to take the strain.

Ensure that the mains cable supplying the MelCOMMS MINI is rated to the following specification:

- 1.5mm2- 3 core flexible flex blue, brown, yellow/green

- External diameter 8.0mm

- BS EN 50525

Recommended cable: CEF Part Code: 3183B1.5W050

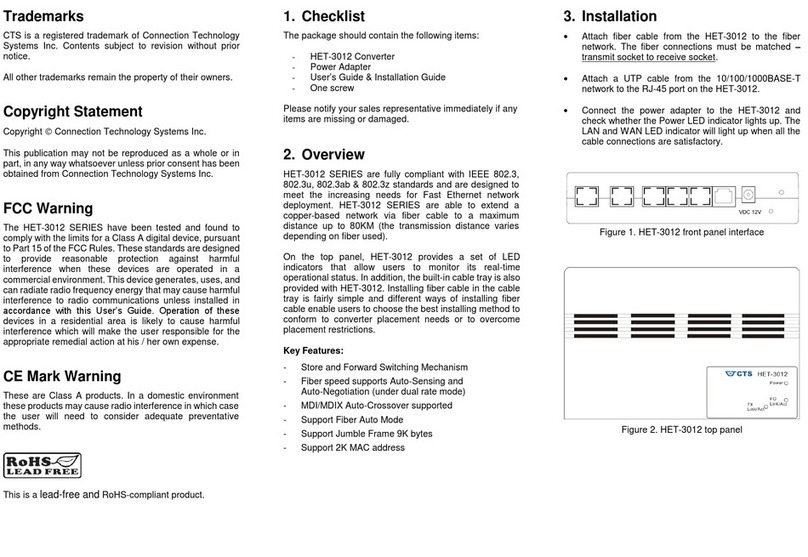

This apparatus must be earthed via the 3 way mains terminal block shown in Figure 6 below.

Connect Live (L), Neutral (N) and Earth (E) to the 3 way terminal block located on the right side of the enclosure, as

indicated below.

Figure 6: Mains terminal block connection

The mains cable should be secured to the metal enclosure using the supplied M20 locking gland.

F1

Live (L)

F1 – Fuse

T3.15AH250V

Pre-installed 3.15A

20mm ceramic fuse

Neutral (N)

Earth (E)

3. Overview

The Procon MelCOMMS MINI is a standalone controller for run/standby (backup and rotate) functionality for between 2

and 8 indoor units, connected via MelcoBEMS MINI (A1M) interfaces.

Compatible Air-To-Air model numbers can be found in Appendix A of this document.

Figure 1 shows the MelCOMMS MINI dimensions.

Figure 2 shows the MelCOMMS MINI wiring diagram for connections to an external fault relay, high temperature alarm

relay and multiple MelcoBEMS MINI (A1M) units.

Figure 3 gives information on how to configure the MelcoBEMS MINI (A1M) units.

4. Getting Started

4.1.Unpacking

The MelCOMMS MINI is supplied with the following components:

- Procon MelCOMMS MINI unit.

- 2x Procon MelcoBEMS MINI (A1M) units.

- This installation instruction manual.

Please contact your supplier if any of these components are missing.

4.2.Before switching ON

Please carefully read the Installation section before switching the unit ON. Check all connections are secure.

5. Installation

5.1.Physical connection

The MelCOMMS MINI has four screw holes on the base plate of the panel. These can be used to attach the unit in

place. Please secure the MelCOMMS MINI before powering the unit on.

5.2. Power supply

A double pole (Live and Neutral) 5A switch or circuit breaker must be provided in line with the supply to the

MelCOMMS MINI power supply and be in close proximity to it. It must be clearly marked as the disconnecting device

for the MelCOMMS MINI.

Ensure the mains cable supplying the power to the MelCOMMS MINI power supply is suitably rated for the intended

environment and current draw of the MelCOMMS MINI.

Warning:

Electrical work should be done by qualified electrical engineers / electrician in accordance with "Engineering

Standards for Electrical Installation" and supplied installation manuals. Dedicated circuits should also be

used. If the power circuit lacks capacity or has an installation failure, it may cause a risk of electric shock or

fire.

Caution:

Do not use anything other than the correct capacity breaker and fuse. Using fuse, wire or copper wire with too

large capacity may cause a risk of malfunction or fire.

−Be sure to take power from the special branch circuit

−Install the unit to prevent any of the control circuit cables coming into direct contact with power

cables

−Ensure that there is no slack on all wire connections

−Never connect the power cable to leads for the transmission cables. This will damage the

transmission cables

.

5.3. Modbus RS-485 connection

The MelCOMMS MINI has a 3-way screw terminal to provide Modbus RTU communication via RS-485 for up to 8x

MelcoBEMS MINI (A1M) adapters.

Caution:

All notes below should be carefully followed to ensure the Modbus network communicates correctly.

−For communication over RS-485 all 3 connections are needed. These are labelled A, B and GND.

−The RS-485 cable must be a shielded data cable. Mains flex or other unshielded cable must not be used. The

cable shield should be connected to GND at one end only.

−RS-485 has polarised data connections. It is crucial that all ‘A’s are connected together, all ‘B’s are connected

together and all ‘GND’s are connected together.

−The RS-485 cable must be a daisy-chained network. T-junctions (e.g. star network) are not permitted

−Please see Procon MelcoBEMS MINI (A1M) Installation and Operation manual for more details.

5.4. Configuration

Note:

The MelCOMMS MINI unit must be restarted if any changes are made to the following configuration settings.

The configuration is done using the 12x DIP switches, 4x digital inputs and 4x configurable inputs (which are fixed as

digital inputs).

To help installers who are already familiar with the PANEL_RS product the 4x digital inputs on the MelCOMMS MINI

will be used as follows:

Digital

Input 03 Digital

Input 04 Settings

name Units

connected Units

running Days

between

rotation

High

temperature

alarm (ºC)

Setpoint

(ºC) /

Mode

No link No link RS1 2 1 7 26 20 COOL

Link No link RS2 3 2 7 26 20 COOL

No link Link RS3 4 3 7 26 20 COOL

Link Link Custom - - - - -

If links are fitted to both digital input IN03 and IN04 then custom settings will be applied. These custom settings are

determined by the 12x DIP switches and 4x configurable inputs.

The following shows the custom configuration options (Note: Value 0 = DIP switch OFF, Value 1 = DIP switch ON):

DIP Switch Usage

1-1

Number of units connected

[1-1 | 1-2 | 1-3]

0 0 0 = 2

0 0 1 = 2

0 1 0 = 3

0 1 1 = 4

1 0 0 = 5

1 0 1 = 6

1 1 0 = 7

1 1 1 = 8

1-2

1-3

1-4

Number of units running

[1-4 | 1-5 | 1-6]

0 0 0 = 1

0 0 1 = 2

0 1 0 = 3

0 1 1 = 4

1 0 0 = 5

1 0 1 = 6

1 1 0 = 7

1 1 1 = 8

1-5

1-6

1-7

Days between rotation

[1-7 | 1-8]

0 0 = 1 day

0 1 = 3 days

1 0 = 5 days

1 1 = 7 days

1-8

2-1

Temperature setpoint (ºC)

[2-1 | 2-2 | 2-3]

0 0 0 = 18ºC

0 0 1 = 19ºC

0 1 0 = 20ºC

0 1 1 = 21ºC

1 0 0 = 22ºC

1 0 1 = 23ºC

1 1 0 = 24ºC

1 1 1 = 25ºC

2-2

2-3

2-4 Mode

0 = COOL

1 = AUTO

For the 4x configurable inputs (which will be set to be digital inputs)

Input Label Usage

IN01

Temp Alarm

High temperature alarm (ºC)

[IN01 | IN02 | IN03]

0 0 0 = No high temp alarm

0 0 1 = 23

0 1 0 = 24

0 1 1 = 25

1 0 0 = 26

1 0 1 = 27

1 1 0 = 28

1 1 1 = Rotation test mode (1 min rotation)

IN02

IN03

IN04 E.R. Error response

0 = Bring next unit ON

1 = Bring all units ON

0 = No wire link applied to the input,

1 = Link applied to the input.

5.5. Initial Power ON

When the wiring and configuration is complete power can be applied to the unit. The power indicator on the front panel

will light up to indicate the unit is powered.

5.6.Status Indicators

5.6.1. Fault LED

On the front panel below the power LED there is a Fault LED which will illuminate whilst a fault is present. The

conditions which cause the unit to go into fault are:

- A communication fault between MelCOMMS MINI and one or more MelcoBEMS MINI (A1M) units.

- A fault code read from any MelcoBEMS MINI (A1M) unit which is not 8000 (8000 = OK).

5.6.2. Buzzer

The buzzer will activate at the same time as the Fault LED. However, the buzzer can be muted by pressing the ‘Mute’

pushbutton. The buzzer will stay muted until a new fault is present after all faults have been cleared.

5.6.3. Relay Status LEDs

Inside the enclosure on the PCB there are four LEDs which provide the status of each of the four relays. When the LED

is OFF the relay is de-energised, when the LED is ON the relay is energised.

The LED labelled ‘Relay 3’ is for the Fault Relay and the LED labelled ‘Relay 4’ is for the High Temp Relay.

5.6.4. RS-485 Comms Status LED

Next to the DIP switches are two LEDs, one of these will constantly be ON and the other will flash to indicate

successful Modbus communication with the MelcoBEMS MINI (A1M) units. If both are permanently ON then this

indicates no communication with the MelcoBEMS MINI (A1M) units.

6. Control Functionality

6.1.Automatic Mode

When the switch on the front panel is set to ‘Automatic’ the MelCOMMS MINI will perform Backup & Rotate

functionality.

6.1.1. Backup & Rotate

A common installation scenario is a number of split systems that operate on a cyclical basis, with one unit on backup to

operate in case of failure. MelCOMMS MINI can handle Backup and Rotate functionality for between 2 and 8 indoor

units. On a periodic basis, typically every week, the operational units can be cycled to share the cooling load.

If the high temperature is exceeded by any unit while backup and rotate is active, all units are brought into operation. If

a fault is detected the next available unit will be brought into action or all available units will be switched ON depending

on the E.R. (Error Response) setting. The unit(s) will remain on until the next changeover cycle.

6.1.2. Example

Consider the following setup:

- Number of units = 4

- Number of units running = 2

- Max Temperature setpoint = 28ºC

- Rotation period = 1 day

- Error Response = Bring all units ON.

The following sequence of events show how the units are controlled when firstly a unit goes into fault and secondly

when a high temperature is detected:

6.2. Manual Mode

When the switch on the front panel is set to ‘Manual’ the MelCOMMS MINI will not perform any control of the indoor

units. The Fault Relay and High Temp Relay will still operate in Manual mode.

6.3. Rotation Test Mode

MelCOMMS MINI can be put into rotation test mode by powering up the unit with a wire link placed across inputs IN01,

IN02 and IN03 (see section 5.4 – Configuration).

In this mode the rotation period for automatic control will be set to 1 minute. If using custom settings the high

temperature alarm will be disabled.

6.4. Modbus Slave Test Mode

MelCOMMS MINI can be put into Modbus slave test mode by powering the unit up with the 8 DIP switches 1-1 to 1-8

all in the OFF position. In this mode the MelCOMMS MINI unit will not attempt to communicate with any MelcoBEMS

MINI (A1M) devices, the RS-485 port will instead be used to provide Modbus RTU Slave functionality.

In this mode the MelCOMMS MINI will have the following fixed communications settings:

- Slave ID 1

- Baud rate 9600

- Data bits 8

- Parity None

6.4.1. Modbus registers

Using a Modbus Master PC utility the current state of all MelCOMMS inputs can be monitored and the relay outputs

can be temporarily switched for testing purposes.

The tables below show the Modbus registers supported:

Coil Status Registers (Digital Outputs)

Register Name Address Modicon

Address Details

Fault Relay Output

0 00001

0 = Relay OFF (de-energised)

1 = Relay ON (energised)

High Temp Relay Output 1 00002

Coil Status Registers can be read using function code 1, they can be written using either function code 5 or 15.

Function code 5 is used when writing to a single Coil register, function code 15 is used for writing to multiple coil

registers in the same command.

Table of contents

Other Procon Media Converter manuals