Procopi Wooden Pools Rectangular Pro User manual

Installation instructions

To be read carefully and kept for future reference

Wooden Pools

WOODEN POOLS

RECTANGULAR PRO

PROCOPI

Les Landes d’Apigné

B.P.45328

35650 LE RHEU Cedex

FRANCE

Notice Piscine bois rectangle pro GF6/2012

FR-GB - Indice de révision : B - Code : 97289999

46

>> RECTANGULAR POOLS

>>

RESIN BEADS

When resinous wood species

are autoclaved, the alternating

pressure and vacuum can cause

sticky resin residues to rise to the

surface. To remove them, scrape

them carefully with an appropriate

tool, being careful not to touch the

wood. Turpentine spirits could also

be effective, but could stain the

wood if too much is applied.

>>

SALT STAINS

Small green stains are frequently

found on the surface of autoclaved

wood. These can be removed

with light sanding. Otherwise, this

colour will disappear over time.

>> GREYING

Wood exposed to sunlight is

susceptible to greying. Some

people like the silvery sheen of

this natural patina. If, however, you

would prefer the wood to keep its

original colour with brown tones,

apply a protective coating (lazure,

oil) when the product is assembled.

>>

SPLITTING AND

CRACKING

Wood expands and contracts when

exposed to variations in humidity

and temperature. As it dries, wood

contracts unevenly resulting in

the appearance of cracks. While

these can seem to be cause for

concern, they have no impact on

the mechanical properties of the

product and therefore do not fall

within the scope of the guarantee.

>>

KNOTS

Knots mark the places where

branches were attached. The

quantity and size depends on

the species of wood and the

sorting process. For outdoor

installations, small adherent knots

are acceptable. The more stringent

the sorting process to limit the

number and size of knots, the more

expensive the wood will be.

>>

JOINED WOOD

To ensure the highest quality in the selection of our

wood, it is sorted meticulously before planing. Planks

that feature defects on both sides are taken out. Defects

(knots, cracks, flashes) are removed and the planks are

joined together (see the image above).

This is why it is not unusual to find joined elements in

a wooden pool, it in no way penalises the mechanical

properties of the wood. For the same reason, imperfections

on the interior surface of the pool (knots, cracks, flashes)

are entirely acceptable.

>>

SURFACE MOULD

Mould, caused by microscopic fungi, can grow on wood,

particularly on resinous species, on which the growth

can appear as «blueing». It is a surface phenomenon,

exacerbated by heat, humidity and inadequate aeration

and is characterised by stains raging from light to dark blue.

They can be removed by wiping the surface. Remember

that class IV treated wood is protected against attack

by fungi that could destroy the physical and mechanical

properties of the wood. For further information, please

refer to Procopi’s guarantees concerning the types of

wood and their treatment.

>>

COLOUR

VARIATIONS

Colour variations are common to

every species of wood. Treatment

brings them our because the depth

of penetration of the product will

depend on the wood density

and grain. Weathering of wood

outdoors will significantly attenuate

these colour variations.

WOOD,

A NATURAL MATERIAL.

Being a natural material, wood will have some imperfections. These are

normal and have no impact on the service life of the product.

A certain number are superficial and are not covered within the scope of

the guarantee.

CAUTION

storage. If you do not intend to assemble your pool immediately, you should store it without opening it in a well-

ventilated room, or failing this, in an area protected from humidity and sunlight. If, however, you were obliged to

unpack your pool, redo and restrap the pallet. Once the pallets are undone, the kit must be assembled within 24 to

48 hours.

47

>> TABLE OF CONTENTS

Foreword ................................................................................................................ P. 48, 49

Excavation and the rebar mesh .................................................... P. 50, 51

The metallic structure..................................................................... P. 52, 53, 54

Pouring the concrete slab .............................................................................. P. 55

Assembling the structure

.......................................................... P.

56-57-58-59

Mounting the support brackets...................................................... P. 60-61

Mounting the coping support fittings.................................... P. 62, 63

Liner locking track................................................................................................... P. 64

Finishing & wall piercings .............................................................................. P. 65

Mounting the pool fittings................................................................... P. 66, 67

Counter-swim prefitting & underlay................................................... P. 68

Fitting the liner & starting to fill the pool.................................... P. 69

Installation of the filtration system ............................................ P. 70, 75

Filling the pool and cutting out the liner...................................... P. 76

UW lights and coping................................................................................ P. 77, 78

Ladders................................................................................................................................. P. 79

Commissioning & operating tips ................................................ P. 80, 83

Guarantees ........................................................................................................... P. 84, 85

PEFC chain of custody certificate ....................................................... P. 86

Don’t play with safety ..................................................................................... P. 87

48

>> RECTANGULAR POOLS

Storage:

If you do not intend to assemble your pool immediately, you should store it

properly.

You should:

wLeave the pallet intact (or redo the pallet if it has been opened for

handling).

wStore the pool in an area protected from water and sunlight.

The aim is to avoid any warping of the wooden elements that could impede

correct assembly. If the pool is to be stored, we also recommend that you

insert little wooden wedges between each layer of wood to allow air to

circulate freely.

An above-ground kit

The kit delivered is intended for installation above-ground. If the pool is to

be installed partially or entirely in-ground, additional measures will need to

be taken:

w If the ground is not level, dig into the slope, never backfill under the pool.

w Take care to ensure sufficient drainage adapted to the terrain around the

periphery of the concrete slab.

w Cover the portion of the wall that is underground with a protective layer of

foundation grade plastic film.

w For backfilling around the pool use stabilised sand (mortar 150 kg/m3).

(Supplies necessary to implement these measures are not included in the kit)

Safety:

wYour installation should comply with the standard C15-100. Notably, the

electrical supply of the pump should be protected by a 30mA differential

circuit breaker. (Wiring should be carried out by a qualified professional).

wThe kit provided will allow installation of the filtration system 3.5 m from the

pool, this is in line with pool safety standards.

We recommend that you secure access to the pool using one of the

protective measures set out in the pool safety standards NF P 90-306,

307, 308 & 309 that is: Barriers - Alarms - Safety covers - Shelters.

wChildren should only use the pool under the supervision of an adult.

wRemember to remove the exterior wooden ladder while the pool is not in

use to prevent unsupervised access to the pool.

wThis pool is intended for private use only.

wDo not install the pool beneath electrical wires.

>> FOREWORD

Congratulations on your purchase. We have taken great care with the design and

manufacture of your pool, nevertheless, some precautions should be taken to ensure

that it is used correctly. Please read these instructions very carefully before beginning

assembly of your pool and keep it for future reference.

This document applies to all 3 pool sizes.

A detailed nomenclature of the various components specific to your pool is enclosed

in the liner package.

Wood is a natural

material, cracks

may appear but

these do not alter

the technical

characteristics of the

wood.

Similarly, wood

exposed to sunlight

can change colour

over time.

CAUTION

wAfter installing

your pool, keep

these documents

(installation

instructions and

invoice) in a safe

place. You will

need them for

future exchanges

with our various

departments.

49

QUICK OVERVIEW

>> Excavation

>> Assembly of the metal structure

>> Pouring the concrete slab

>> The wooden structure

>> The filtration group

Tools :

(excluding concrete works and excavation)

a decameter,

a rope, tube wrench (13 and 17), a mallet,

a screw gun (with a torx, pozi bit), a stanley knife, a metal saw, a big spirit

level, a flat head screw driver, a cross head screw driver, bolt cutters, sand

paper, a file, excavation equipment.

Time required :

w Excavation:

1 to 2 days (depending on the materials used)

w Metallic structure

1 day (with 2 people)

w Pouring the slab:

1 to 2 days (with 2 people and depending on the materials used)

w Wooden structure and filtration :

2 to 3 days (with 2 people). The time indicated does not include the

concrete curing time.

w Curing of the concrete slab before filling the pool with water : 2 to 3

weeks

50

>> RECTANGULAR POOLS

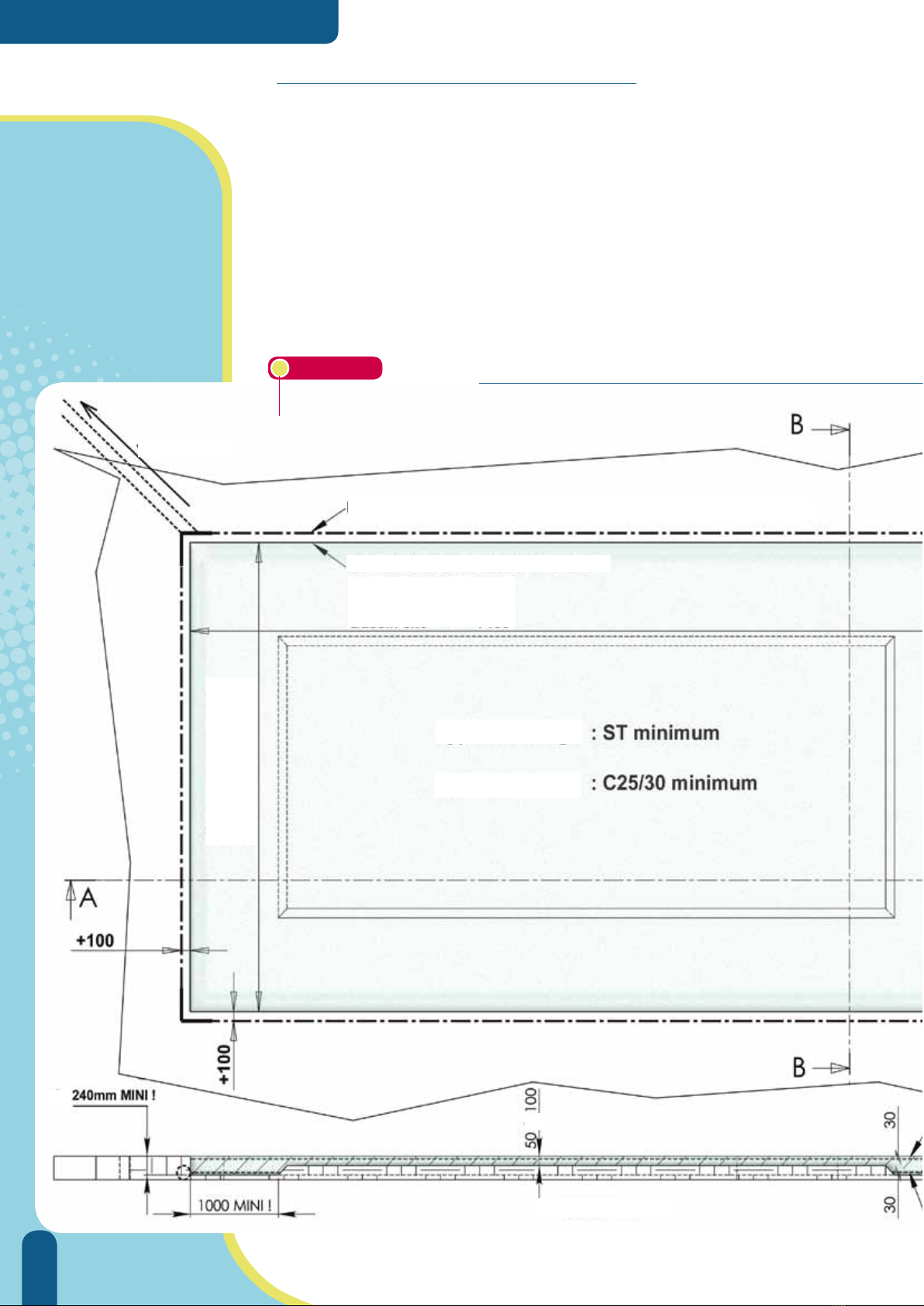

>> EXCAVATION & REBAR MESH

w After determining the ideal position for your pool, start with the

excavation required to accomodate the concrete slab that will form

the base of your pool. On fig. 1, identify those dimensions that

correspond to your pool.

w Never backfill under the pool to achieve a level surface, always dig

down so that your pool rests on a stable, level surface.

w Ensure that there is adequate peripheral drainage, especially if the

pool is to be installed in-ground.

w Seek the assistance of a professional if necessary.

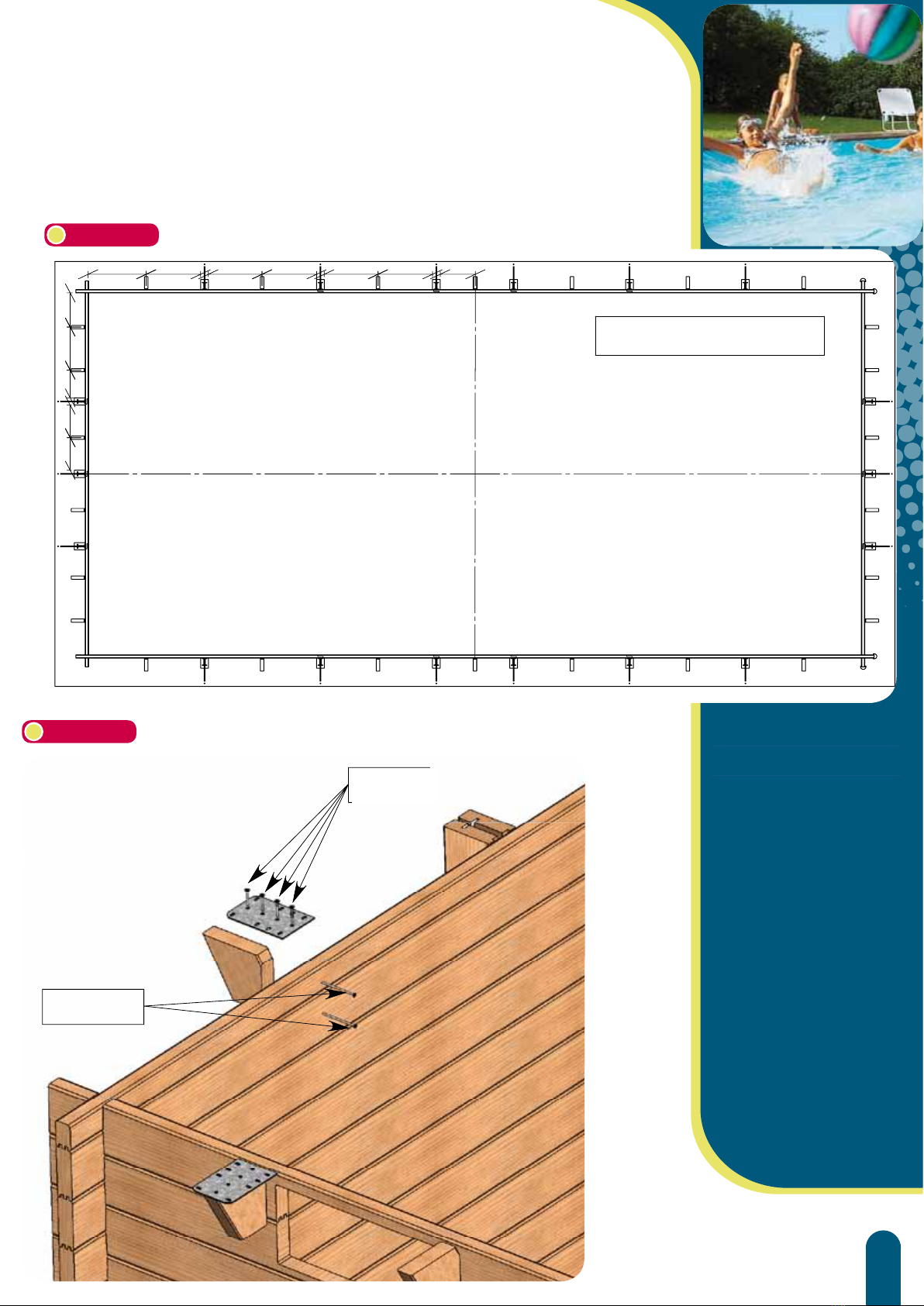

Figure 1 DIMENSIONS OF THE EXCAVATION & THE CONCRETE SLAB

th

to

SECTION A-A

Rebar

Concrete

Pool 5x10 = 11100

Pool 4.8 = 9100

Pool 3x6 = 7100

Pool 5x10 = 6100

Pool 4.8 = 5100

Pool 3x6 = 4100

Outfall

EXCAVATION LIMIT (include a drain pipe, diameter 80mm)

SLAB LIMITS

51

Avoid siting your

pool beneath trees or

electrical lines.

Orient the pool such

that skimmers face

into prevailing winds.

>> EXCAVATION & REBAR MESH

w Note that the excavation is deeper around

the periphery in order to accommodate the

reinforcing metallic structure. (fig. 2)

By deepening the excavation around the edges

only, you minimise the total volume of concrete

required to pour the slab.

Figure 2

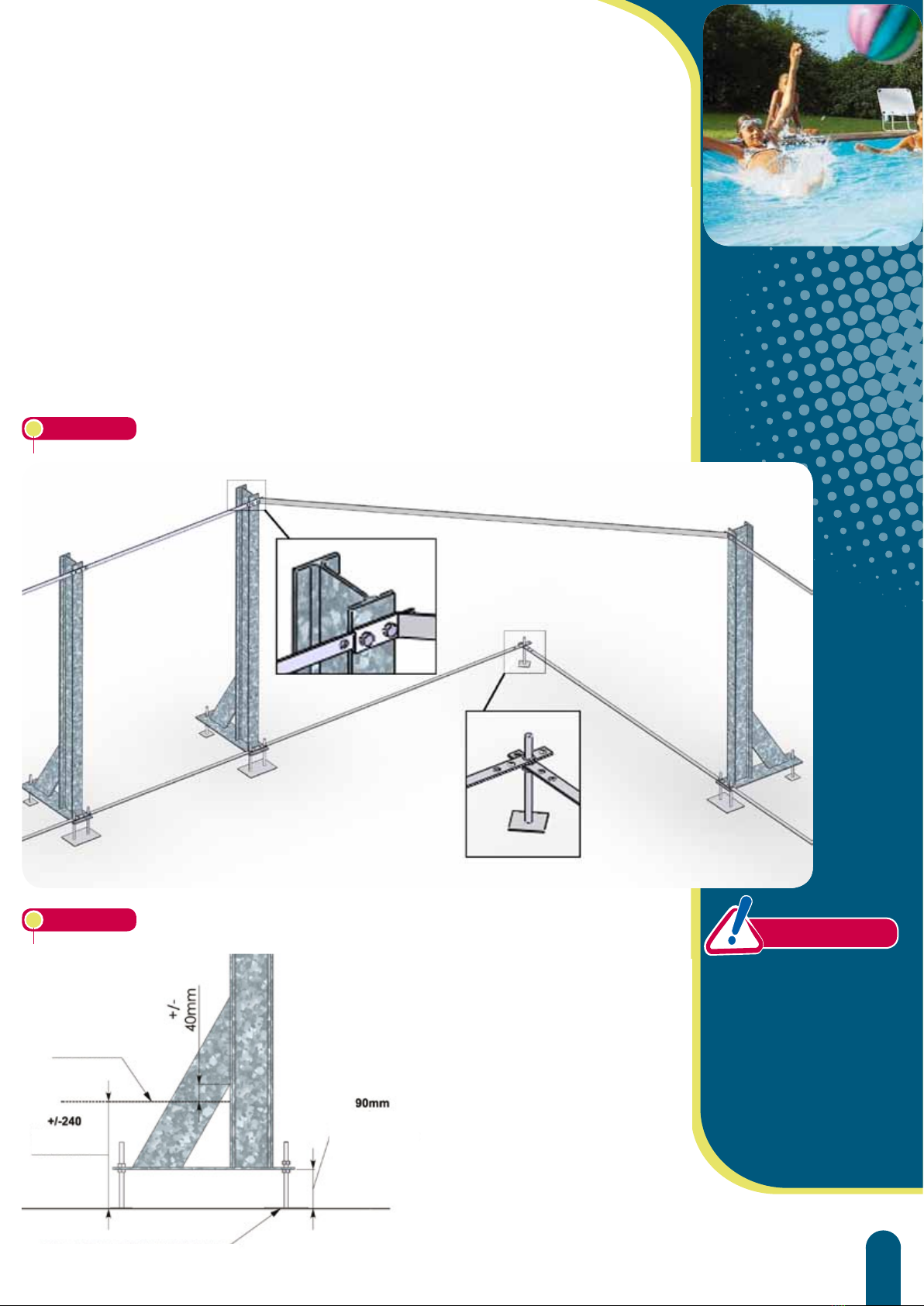

w The bottom of the excavation should be perfectly level

to facilitate installation of the metallic structure. (fig. 3)

(either add a layer of compacted gravel or pour a rough

layer of concrete).

w Lay a rebar mesh over this section (fig 3) .

Figure 3

DIMENSIONS OF THE EXCAVATION & THE CONCRETE SLAB

Upper rebar mesh

Lower rebar mesh

Drain pipe

SECTION B-B

52

>> RECTANGULAR POOLS

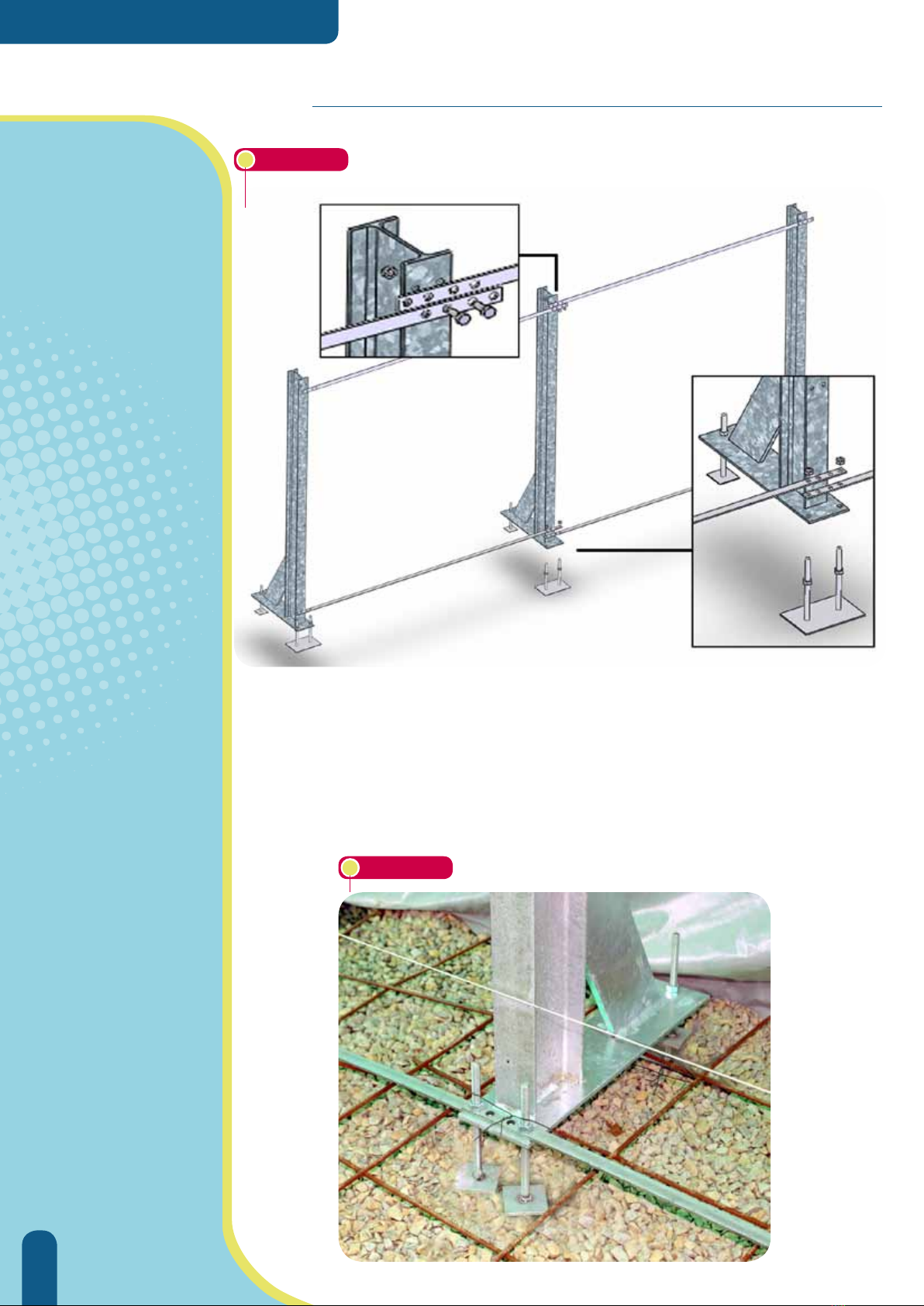

>> ASSEMBLY OF THE METALLIC STRUCTURE

wThe metallic structure comprises posts joined together by flat bars at the top and

bottom (fig. 4). Observe how these parts overlap to ensure correct positioning of

the structure. The top links should be dismantled once the slab has been poured.

Figure 4

wAfter correctly positioning the first layer of rebar (fig 3), set out the metallic posts required

to assemble your pool (fig 8). Make sure that you fit them with jacks first (fig. 4). These posts

are joined together at the bottom with flat bars fastened by two screws (bag of screws A

and B fig. 4).

w

The distance between the each post is determined by the length of the flat bars.

w

The flat bars features 4 holes at each end.

w

The upper and lower connection bars are identical.

w

Around the base, the outer holes are used while the inner holes are used on bars

around the top of the structure. (fig 6).

Figure 5

53

>> ASSEMBLY OF THE METALLIC STRUCTURE

wAfter correctly positioning the first layer of rebar (fig 3), set out the metallic posts required

to assemble your pool (fig 8). Make sure that you fit them with jacks first (fig. 4). These posts

are joined together at the bottom with flat bars fastened by two screws (bag of screws A

and B fig. 4).

w

The distance between the each post is determined by the length of the flat bars.

w

The flat bars features 4 holes at each end.

w

The upper and lower connection bars are identical.

w

Around the base, the outer holes are used while the inner holes are used on bars

around the top of the structure. (fig 6).

w

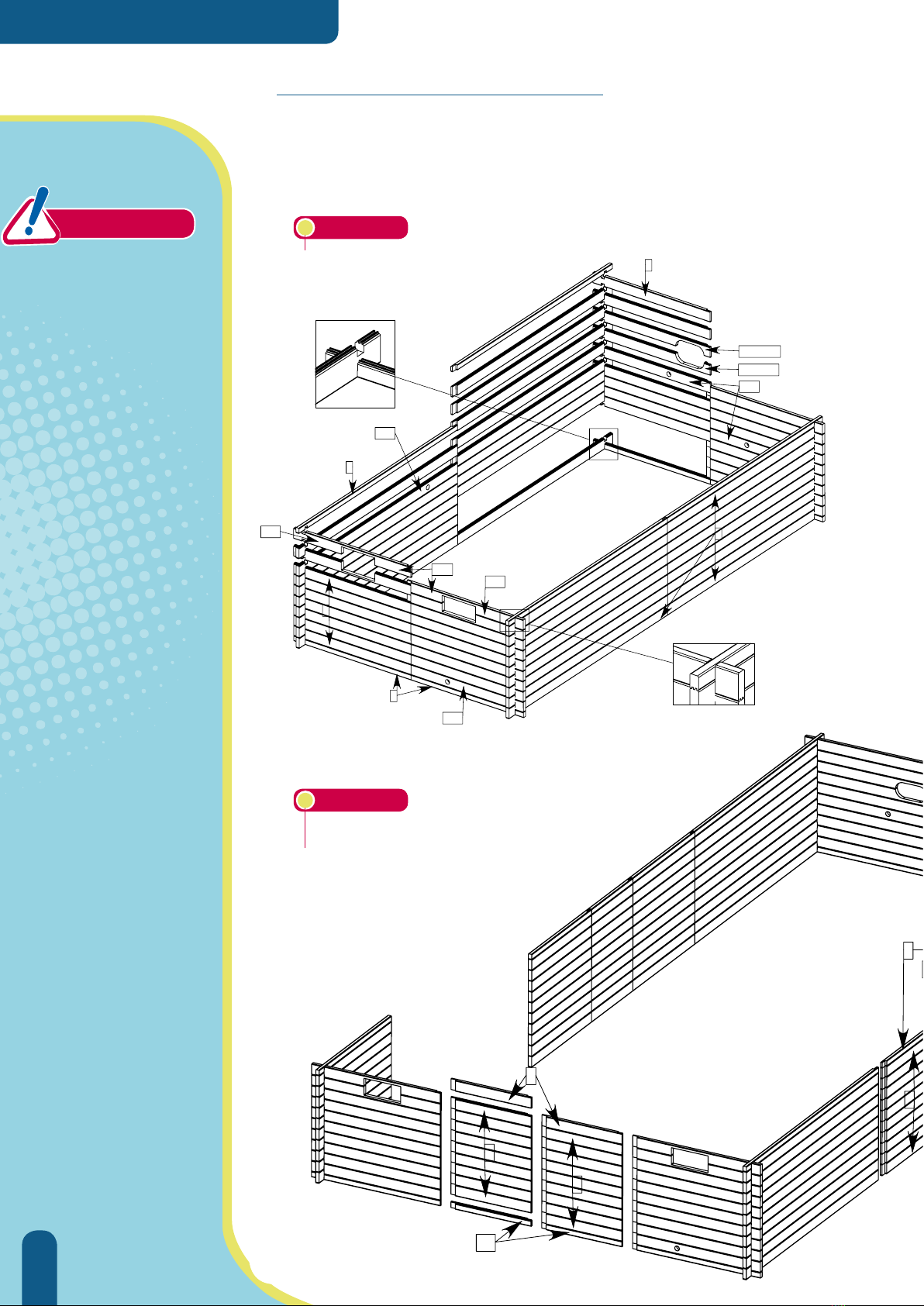

Once the metallic structure has

been assembled, adjust the

position of the posts carefully

and check :

• that the posts are level, straight

and perfectly aligned.

• that the pool diagonals

measured at the axis of the

corner jacks are equal. (fig 8)

Figure 6

Take particular care

during this stage of

the assembly, it will

impact subsequent

phases and

determine the quality

of the pool finish.

CAUTION

FB

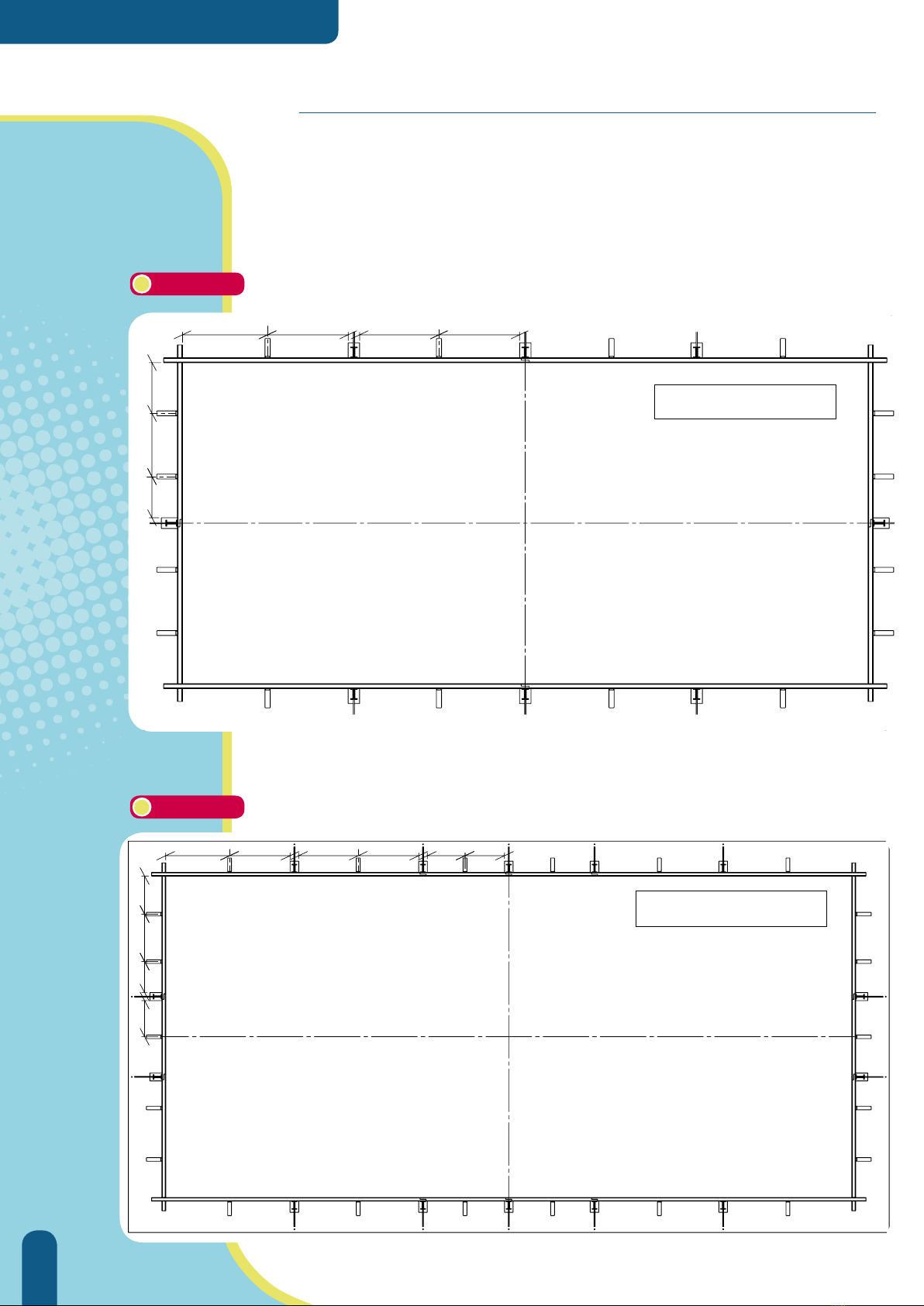

Figure 7

Level of the

finished slab

GROUND - BOTTOM OF THE EXCAVATION

Slab

thickness

Height before

resurfacing

54

>> RECTANGULAR POOLS

wLay the top layer of rebar (second layer) over the entire surface of the excavation

before pouring the concrete.

wOnce laid, the metal trellis should cover the whole surface (lay the trellis such that it is

set 3 to 5 cm back from the edge around the entire periphery

). Some cutting around

the posts will be necessary (fig 9a.)

. Bars should be allowed to overlap and should be

connected together.

>> STRUCTURE

CAUTION

wOnce the

structure has

been assembled,

make sure that the

diagonals are equal

in length.

wCheck that the

posts are level and

straight.

wCheck that the

height is correct.

Diagram:

A represents a flat bar with an interaxial distance of 1m.

B represents a flat bar with an interaxial distance of 1.5m

C represents a flat bar for top corners

At the bottom corners, these flat bars are joined together by an AR type jack

(Detail fig.6)

Figure 8b

Figure 8c

Figure 8a

POOL

3X6

POOL

4X8

POOL

5X10

55

wLay the top layer of rebar (second layer) over the entire surface of the excavation

before pouring the concrete.

wOnce laid, the metal trellis should cover the whole surface (lay the trellis such that it is

set 3 to 5 cm back from the edge around the entire periphery

). Some cutting around

the posts will be necessary (fig 9a.)

. Bars should be allowed to overlap and should be

connected together.

Encase the base of

the metal posts with

a small amount of

concrete before

pouring the rest of

the slab, this will help

prevent deformation of

the metallic structure.

(fig. 9a).

See figures 7 and 9’ to

determine the correct

height of the concrete

slab with respect to the

posts.

The finish of the

concrete slab will

determine the correct

seating of the walls as

well as the quality of the

pool floor.

Figure 9

>> POURING THE CONCRETE SLAB

wWhile pouring the slab, make sure that the

upper rebar mesh is encased to a correct

depth in the concrete.

(minimum 3 cm)

wLevel the surface and smooth it as carefully

as possible in order to minimise protrusions

and asperities that will have to be corrected

later.

Figure 9b

Figure 9a

CAUTION

56

>> RECTANGULAR POOLS

wYour pool comprises several types of wooden slat, the position of the various types

of slat are indicated in the various exploded views.

>> ASSEMBLING THE WALLS

Figure 10

CAUTION

wThe finish of the

concrete slab will

determine the

correct seating of

the walls as well as

the quality of the

pool floor.

wBefore starting to

assemble the wooden

walls, make sure

that the finish of

the concrete slab is

perfectly smooth and

level. Any uneveness

will be accentuated

and more noticeable

once the pool has

been filled with water.

If necessary, correct

defects by sanding or

resurfacing.

w

The slats comprising the pool corners are common to pools of all sizes. For the 4x8

and 5x10 pools, refer to the exploded view of the 3x6 pool.

6

4

4

3

9

11

4

10

3

POOL 5X10

11 rows of slats

Figure 11

wAssembly of the

wooden structure

may begin 2 to 3

days after the slab

is poured, it is not

necessary to wait for

the concrete to cure

completely.

However, you must

wait 2 to 3 weeks

before filling the

pool with water.

7

5SH

2SB

2PR

8

5

2

2SB

1

2Ncc H

2Ncc B

1BP

2PR

POOL 3X6

10 rows of slats

57

>> ASSEMBLING THE WALLS

6

4

11

10

4

Figure 12

1/2 FEMALE

SLAT

FEMALE

SLAT

MALE-FEMALE

SLAT

1/2 MALE

SLAT

POOL 4X8

11 rows of slats

w

The slats comprising the pool corners are common to pools of all sizes. For the 4x8

and 5x10 pools, refer to the exploded view of the 3x6 pool.

6

4

4

3

9

11

4

10

3

58

>> RECTANGULAR POOLS

w

Use a hammer and a clamp to gently tap the slats into position if necessary. Do not

strike the wooden slats directly, use the protective brace (supplied). Be careful to

ensure that each row of slats is fully engaged before starting with the next.

>>THE WOODEN WALLS (CONT)

wWhile assembling

the slats, make sure

as of the beginning

that the tongues

are fully engaged in

the grooves.

CAUTION

w

Start by unrolling the strips of asphalt (fig.

13) that will insulate the wooden structure

from the concrete slab.

w

Lay out the ½ slats ‘8’ that make up the

pool widths, then at the corners fit them

into the slats marked ‘1’ that make up the

lengths (fig. 14).

wThe slats should be fixed to the metallic

posts as they are slotted into position

(these are predrilled) with screws 6x30 from

bag D.

w

After positioning the 1st layer of slats,

check that the diagonals are equal.

w

Screw the slats together using screws from

bag C as shown in fig 14.

w

Be careful to remove any splinters as you

go.

81

5x40

sachet C

Figure 15

Figure 13

Figure 14

w

Fit together the remaining slats taking care that the slats machined to receive the

pool fittings are in their correct positions.

•The slats with the openings for the return fittings should be in the 6th row.

•

The slats machined to take the skimmers should be placed in rows 9 and 10 for the

3x6 pools and rows 10 and 11 for 4x8 and 5x10 pools.

•

The slat that will hold the vacuum point should be in row 8 of the 3x6 pool or row 9

of the 4x8 and 5x10 pools.

bag C

59

w

Use a hammer and a clamp to gently tap the slats into position if necessary. Do not

strike the wooden slats directly, use the protective brace (supplied). Be careful to

ensure that each row of slats is fully engaged before starting with the next.

Figure 16

5x100

w

Put the decorative profiles in

position covering the metallic posts.

They should be flush with the top of

the wooden wall.

w

Screw them in place from the inside

of the pool as shown opposite. (SS

screw 5x80 bag O). The top of the

profiles will be screwed together

when the coping support fittings

are mounted on top of the posts

(fig 22).

w

Eliminate any splinters raised by

screwing.

w

Should it be necessary to trim the

profiles to size (for example, if the

pool is partially in-ground) orient

the cut surface facing upwards.

wThe 2 profiles do not meet, the

metallic post remains visible.

5x80

w

Fit together the remaining slats taking care that the slats machined to receive the

pool fittings are in their correct positions.

•The slats with the openings for the return fittings should be in the 6th row.

•

The slats machined to take the skimmers should be placed in rows 9 and 10 for the

3x6 pools and rows 10 and 11 for 4x8 and 5x10 pools.

•

The slat that will hold the vacuum point should be in row 8 of the 3x6 pool or row 9

of the 4x8 and 5x10 pools.

Figure 17

>>THE WALLS (CONT) & DECORATIVE PROFILES

60

>> RECTANGULAR POOLS

>>

MOUNTING THE COPING SUPPORT BRACKETS

700725 700

385 590

725

475

bassin 3x6

475475700700725 725

475590385

450

bassin 4x8

Figure 18

Figure 19

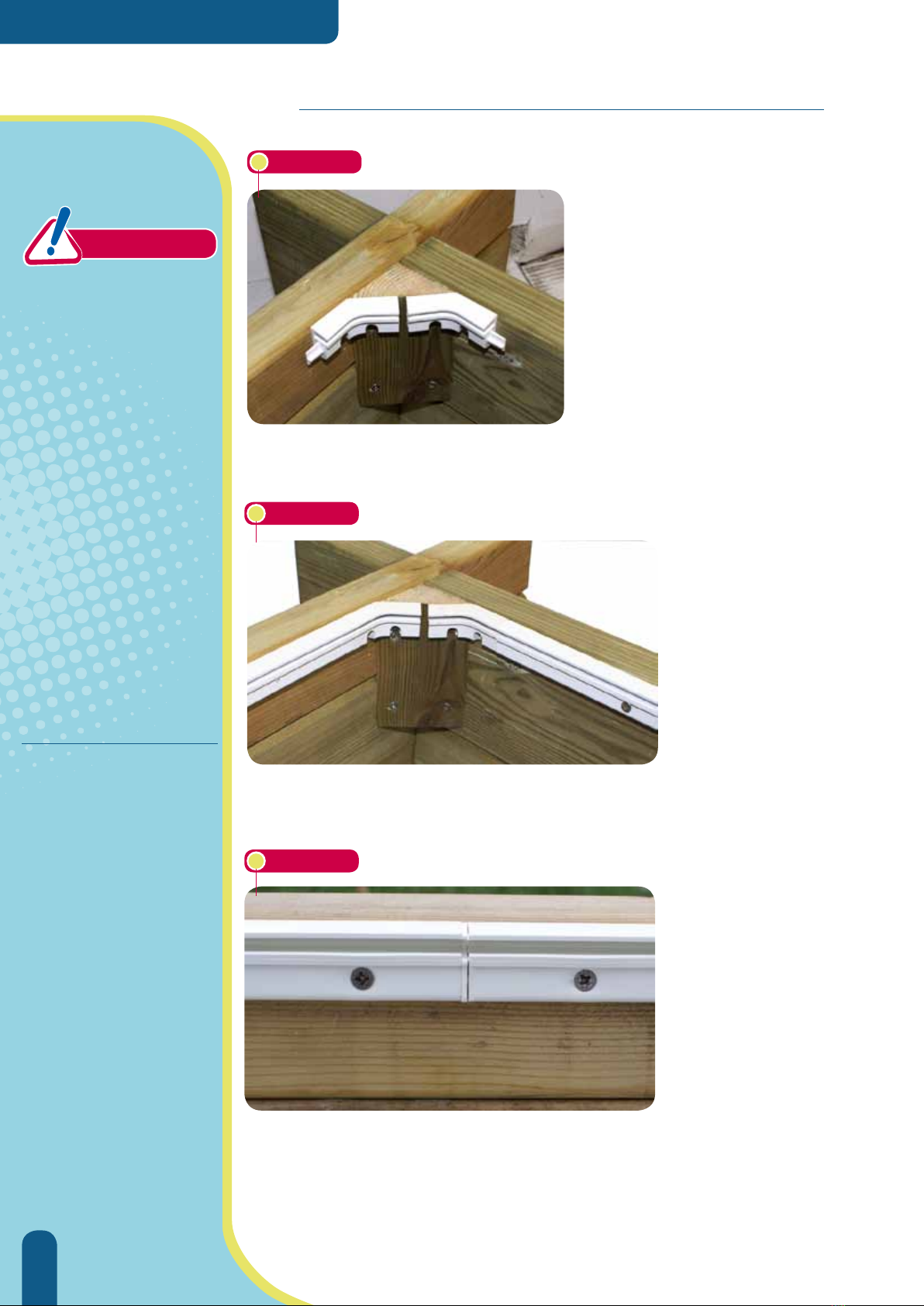

w

Refer to the diagram that corresponds to your pool before mounting the wooden

support brackets. Use the 5x100 SS screws from bag L to fasten them in position. The

brackets should be installed 3mm down from the top of the wall (fig. 21). To ensure that

the brackets are correctly positioned use the support bracket plates that will be fastened

to the brackets, these should be flush with the top of the wall. Before screwing the

plates into position, lightly mill the central holes through which the screws (5x40) will be

inserted.

Pool 4x8

Pool 3x6

61

725 725 700 700 700 700 450

475385450450 590

bassin 5x10

5x100

4x40

Figure 20

Figure 21

5x40 TIP :

Chamfer the edge of

the central holes in the

support bracket plates

so that they can be

correctly screwed into

position.

Make sure that the

plates are level to

facilitate subsequent

laying of the coping.

Pool 5x10

62

>> RECTANGULAR POOLS

The coping

support fittings are

designed to hold

the coping modules

and fix them in

position.

CAUTION

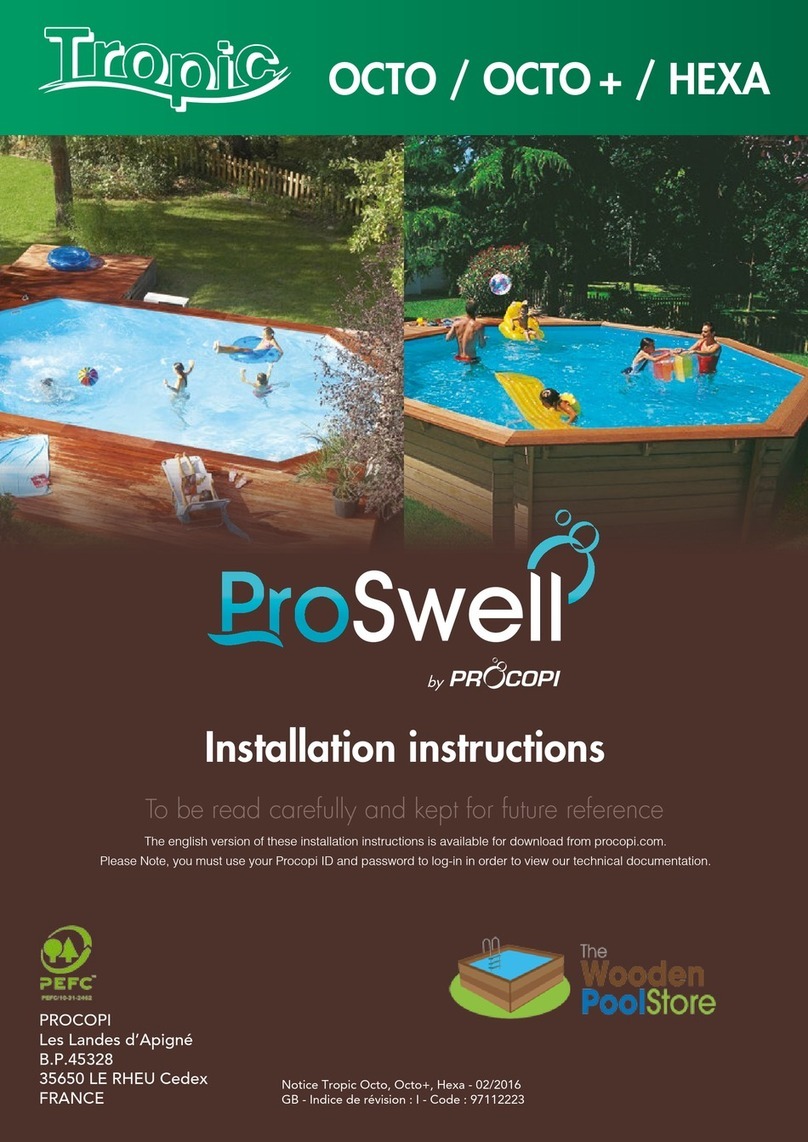

w

Place the metal fittings that will hold the coping on top of the posts. Make sure that

they are flush with the top slat and that they are aligned with each other and with the

support bracket plates along the lengths of the wall. Use the 6x30 Torx screws from

bag E.

>>

MOUNTING THE METAL FITTINGS

Figure 22

Figure 24

wIn the corners, use the remaining left and right fittings and 4 corner

brackets.

63

w

Attach decorative profiles to the ends of each

wall using 3 evenly spaced nails from bag I.

The decorative profiles should be predrilled

along their axis.

If you need to trim the profiles, orient the cut

side so that it is facing upwards.

Figure 23

Figure 25

w

In each corner, mount a wooden triangle to support the liner locking track

corner elements. (stainless steel screw 5x40 bag C)

64

>> RECTANGULAR POOLS

>> MOUNTING THE LINER LOCKING TRACK

Before beginning

to mount the liner

locking track,

make sure that the

structure has been

correctly assembled.

To do this:

wuse a spirit level

to verify that the

structure is level

around the entire

periphery,

w

check that the

diagonals are equal

in length,

wcorrect any

imperfections

before continuing.

CAUTION

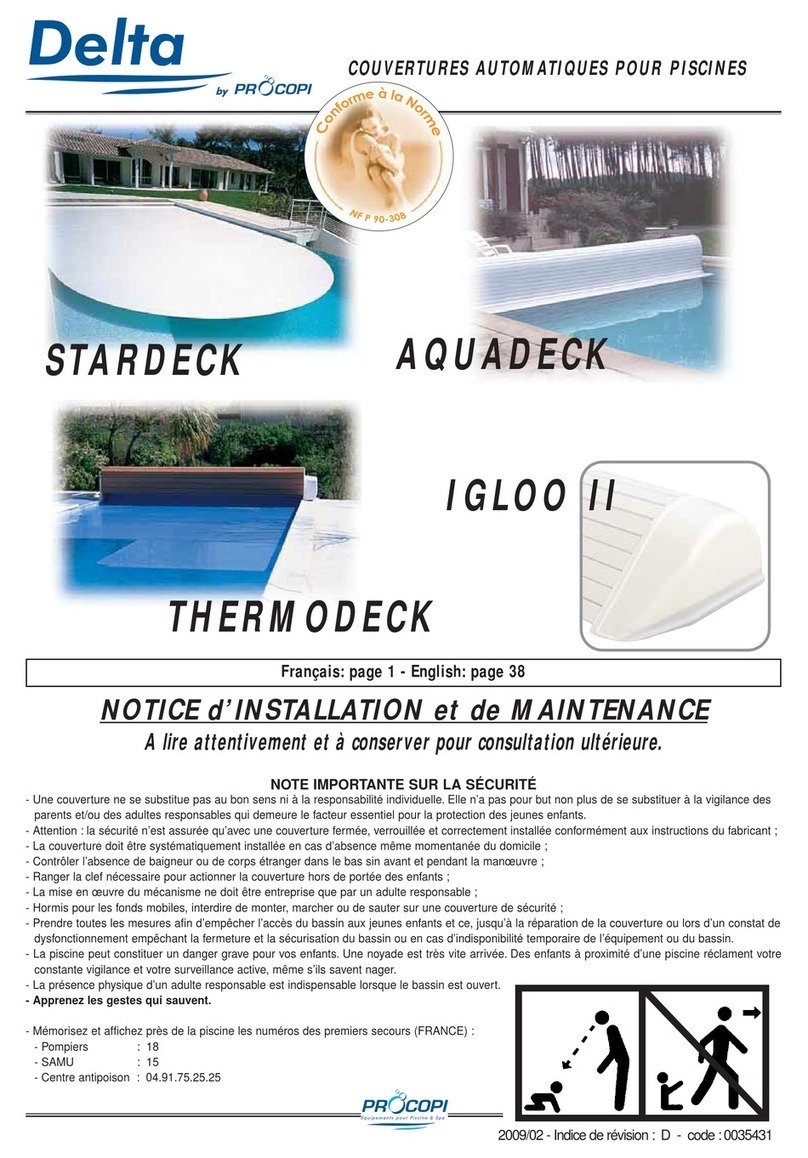

wPosition 2 liner locking track corner

pieces in each corner. (You will find

the parts in the liner/ waterproofing

kit). You will need to trim an

interlocking pin off each corner piece.

Make sure that the 2 corner parts are

level with each other and flush with

the top of the wall. A gap of a few

mm between the two parts is not

problematic. Use 4x35 stainless steel

screws from bag H.

TIPS:

w

The track should be

perfectly flush with the

top of the wall.

w

Before fixing the track

in position, pre-drill

the holes using the Ø

4mm drill bit provided.

(bag J)

w Remember to deburr

the track after making

the cuts.

w Take care not to

overtighten to ensure

that the screws do not

break through the track.

Figure 27

Figure 26

wContinue to mount the

locking track using the

lengths provided, these

should abut the locking

track junctions (fig 28).

Insert a screw (stainless

steel 4x35 from bag H) at

20cm intervals. Locking

track junctions do not

necessarily line up with the

post interaxial distance.

Towards the end, it will

be necessary to trim the

lengths. Cut the length

to size between two liner

locking junctions then

bend the track to allow

the junction pins to fit into

place.

Figure 28

Table of contents

Other Procopi Swimming Pool manuals

Procopi

Procopi ODYSSEA RECTANGLE User manual

Procopi

Procopi Proswell Tropic OCTO User manual

Procopi

Procopi Piscines Bois ODYSSEA OCTO User manual

Procopi

Procopi Delta STARDECK User manual

Procopi

Procopi ProSwell TROPIC JUNIOR User manual

Procopi

Procopi ProSwell Weva octo 440 User manual

Procopi

Procopi OCTO+ PRO User manual