PRODEM DCS Series User manual

Operating- and maintenance manual

Service manual

Spare parts lists

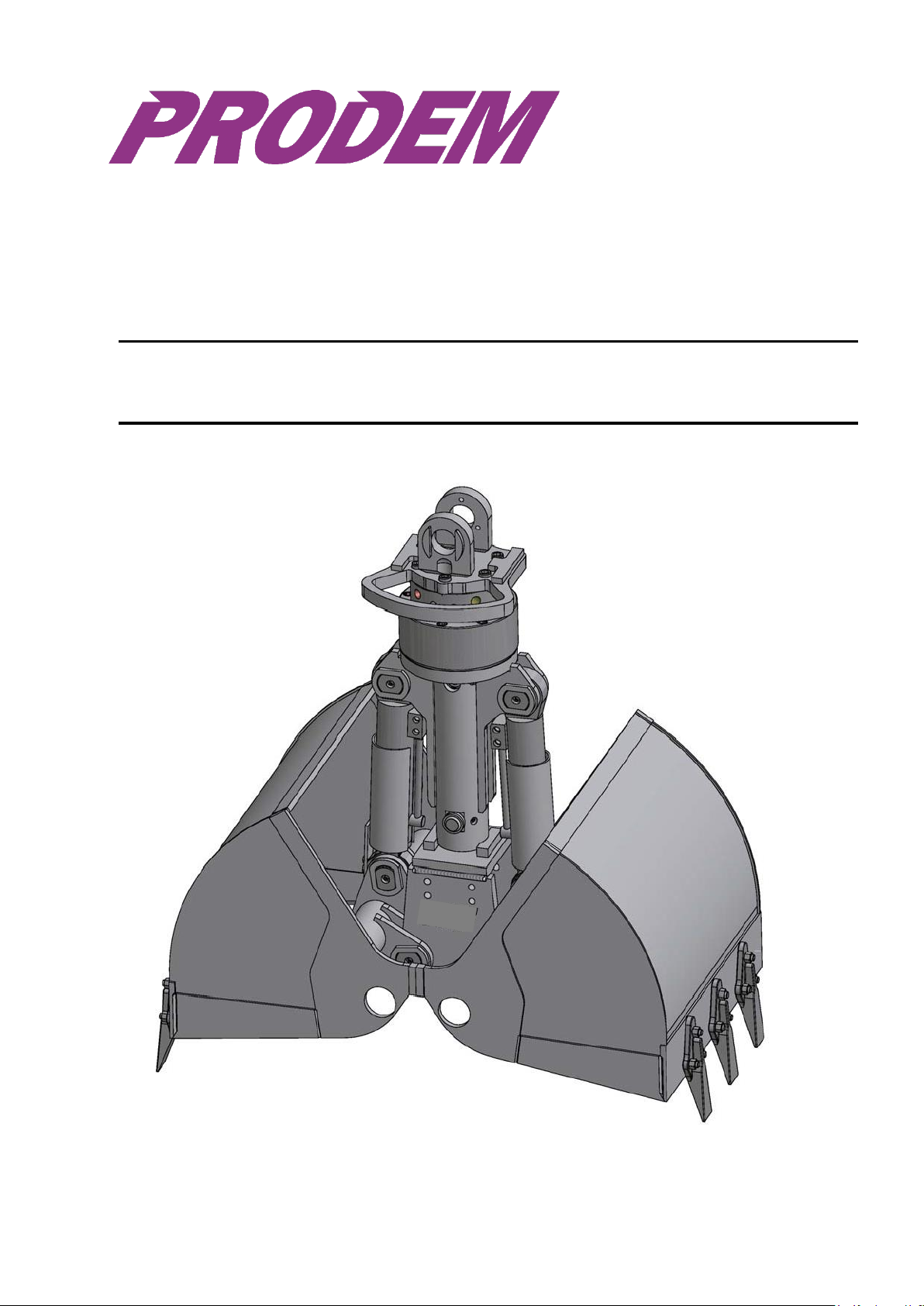

Clamshell grab –Model line DCS

Clamshell grab

2

Table of contents:

Part 1. Operating manual.....................................................................................................3

1.1

Product identification:.................................................................................................3

1.2

Terms of guarantee:...................................................................................................4

1.3

General safety instructions:........................................................................................5

1.4

Product information:...................................................................................................6

1.4.1

Assembly:............................................................................................................6

1.4.2

Product description:.............................................................................................6

1.4.3

Design features: ..................................................................................................6

1.4.4

Plug system:........................................................................................................6

1.4.5

Measures / Technical data:..................................................................................7

1.4.6

Recommended Hydraulic fluids:..........................................................................7

1.4.7

Employment:........................................................................................................8

1.5

Transport / Storage: ...................................................................................................9

1.6

Installation and initiation:..........................................................................................10

1.6.1

Positions of the hydraulic connectors at the rotator:..........................................11

Part 2. Service manual ......................................................................................................12

2.1

Inspection:...............................................................................................................12

2.1.1

Items of daily inspection: ...................................................................................12

2.1.2

Items of weekly inspection:................................................................................12

2.2

Maintenance.............................................................................................................13

2.2.1

Items of daily maintenance / after 8 operating hours:........................................13

Part 3. Spare parts lists: ....................................................................................................14

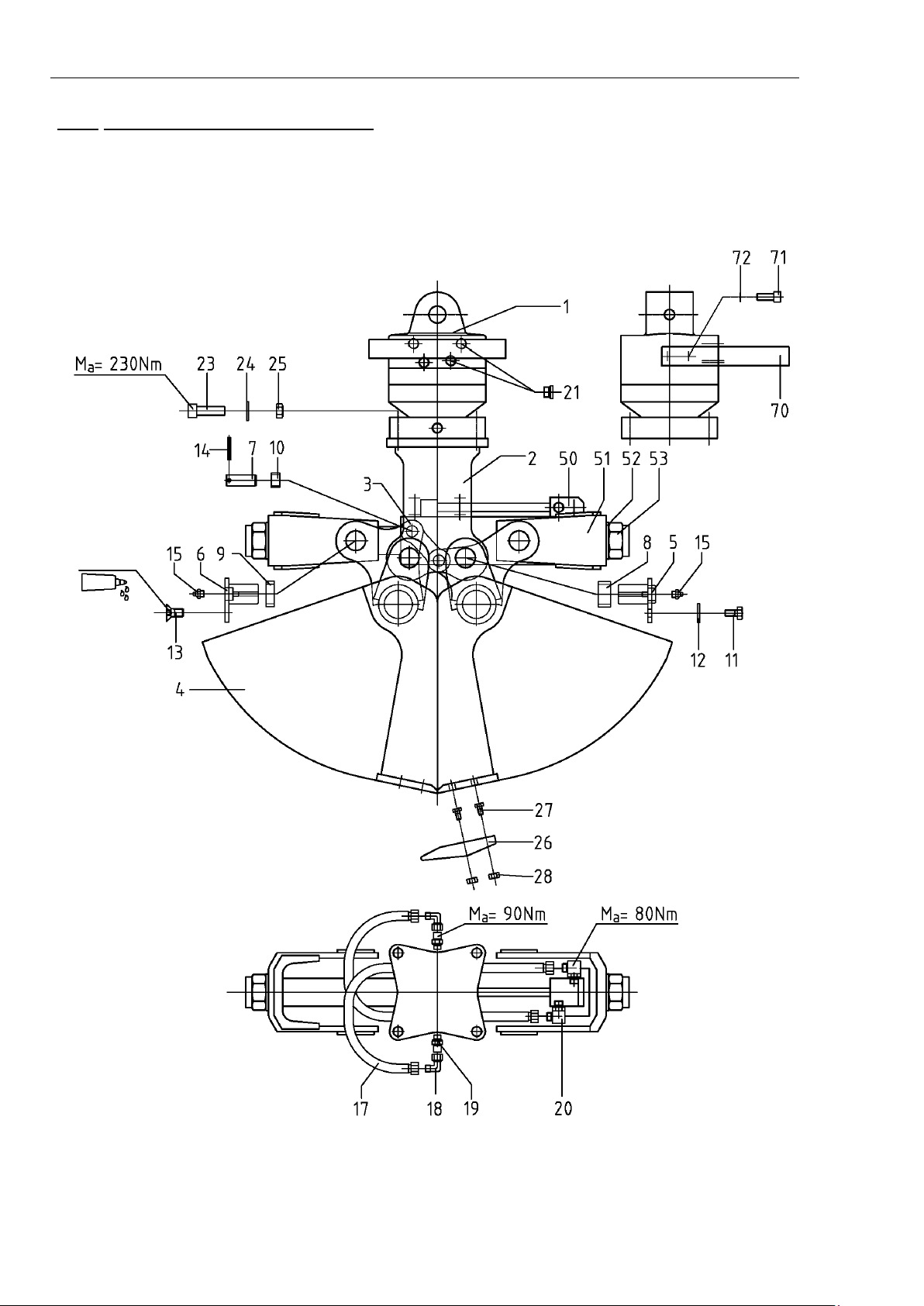

3.1 DCS05 / Z-Z05 with AG 5-2 .....................................................................................14

3.1.1

DCS05 / Z-Z05 - Grab cpl. - Spare parts ...........................................................14

3.1.2

DCS05 / Z-Z05 - Grab cpl. - Picture...................................................................15

3.1.3

DCS05 / Z-Z05 - Cylinder - Picture/spare parts.................................................16

3.2 DCS1 / Z-Z1 with AG 5-2 .........................................................................................17

3.2.1

DCS1 / Z-Z1 - Grab cpl. - Spare parts...............................................................17

3.2.2

DCS1 / Z-Z1 - Grab cpl. - Picture.......................................................................18

3.2.3

DCS1 / Z-Z1 - Cylinder - Picture/spare parts.....................................................19

3.3 DCS2 / Z-Z2 with AG 5-2 .........................................................................................20

3.3.1

DCS2 / Z-Z2 - Grab cpl. - Spare parts...............................................................20

3.3.2

DCS2 / Z-Z2 - Grab cpl. - Picture.......................................................................21

3.3.3

DCS2 / Z-Z2 - Cylinder - Picture/spare parts.....................................................22

3.4 DCS3 / Z-Z3 with TH609H-2-G3/4” ..........................................................................23

3.4.1

DCS3 / Z-Z3 - Grab cpl. - Spare parts...............................................................23

3.4.2

DCS3 / Z-Z3 - Grab cpl. - Picture.......................................................................24

3.4.3

DCS3 / Z-Z3 - Cylinder - Picture/spare parts.....................................................25

3.5 DCS4 / Z-Z4 with AB1000-30-PV.............................................................................26

3.5.1

DCS4 / Z-Z4 - Grab cpl. - Spare parts...............................................................26

3.5.2

DCS4 / Z-Z4 - Grab cpl. - Picture.......................................................................28

3.5.3

DCS4 / Z-Z4 - Cylinder - Spare parts.................................................................29

3.5.4

DCS4 / Z-Z4 - Cylinder - Picture.......................................................................30

3.6 DCS5 / Z-Z5 with AB1500-31-PV.............................................................................31

3.6.1

DCS5 / Z-Z5 - Grab cpl. - Spare parts...............................................................31

3.6.2

DCS5 / Z-Z5 - Grab cpl. - Picture.......................................................................32

3.6.3

DCS5 / Z-Z5 - Cylinder - Spare parts.................................................................33

3.6.4

DCS5 / Z-Z5 - Cylinder - Picture.......................................................................34

Clamshell grab

3

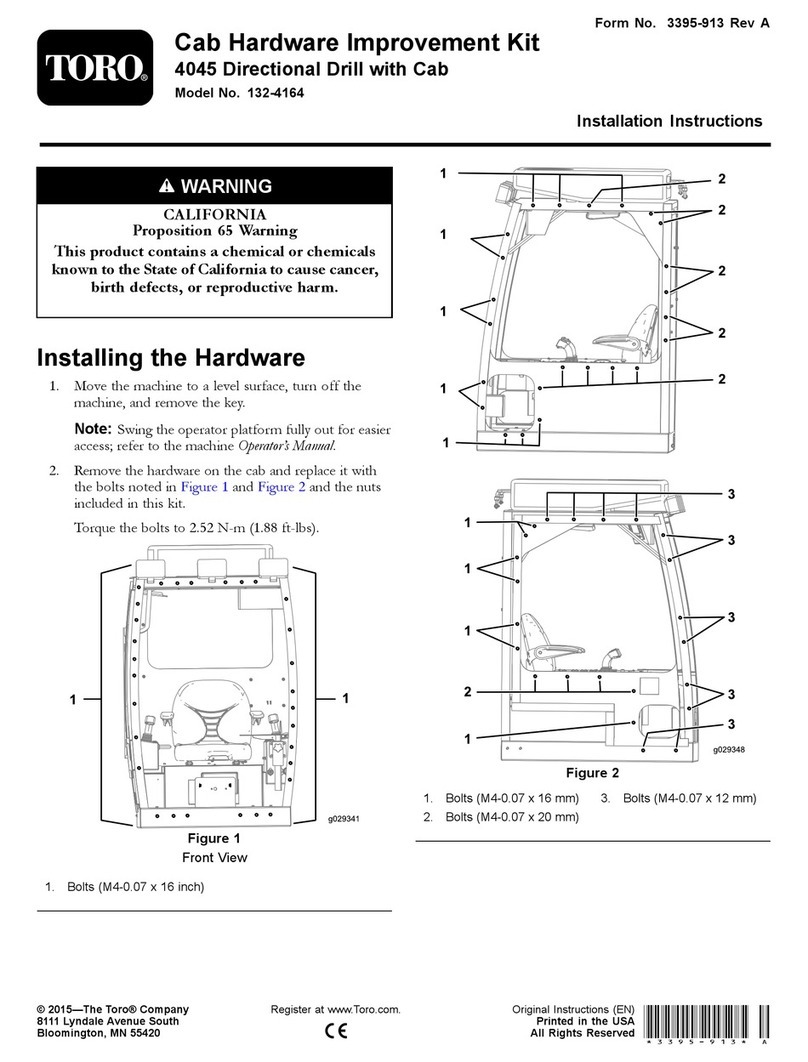

Part 1. Operating manual

1.1

Product identification:

Position of identification data

1

1. Serial number –rotator

(on identification plate –rotator) 2

2. Serial number –grab

(stamped onto frame) 3

3. Identification plate -grab

Explanation of identification plate

Contact postal address

Max. lifting capacity –grab

Max. working pressure - turning

Max. oil amount - turning

Max. working pressure –griffin

Max. oil amount –griffin

Max. weight of carrier machine

Identification information: Trader- / customer number

Type designation –grab:

Serial number –grab:

Serial number –rotator:

Type designation –carrier machine:

Day of delivery:

Trader information:

Name: Branch:

Address:

Customer number:

Phone: Fax:

E-Mail: Contact person:

Clamshell grab

4

1.2

Terms of guarantee:

A) Guarantee period

Prodem offers a guarantee period of 12 months after delivery of the product.

B) Guarantee extent

The guarantee shall include all parts showing defects which are traceable to material or production faults.

C) Guarantee completion

a)

Guarantee claims must be submitted to Prodem in writing (see D Guarantee notification).

b)

Defective parts, replaced within the scope of the guarantee, shall remain the property of the HGT. Upon request they

must be delivered immediately to the manufacturer for the purpose of guarantee claim settlement (see E Allocation).

c)

Spare/replacement parts must be ordered from Prodem on account.

d)

After the investigation by Prodem, an evaluation and a written statement are made and if necessary a credit note of

the resultedcosts.

D) Guarantee notification

Guarantee claims must be submitted to PRODEM in writing within 4 weeks after the damage or fault has occurred and

must include the following information:

Type identification number of PRODEM product

Factory and, where necessary, rotator IDnumber

Denotation of the defective part ( if possible with PRODEM - spare part number )

Date and kind of thedamage

Possible cause of damage (photographs asrequired)

Information about deployment and carrier machine ( digger / crane)

E) Allocation

Defective parts must be made available free of charge for PRODEM min. 6 weeks after guarantee notification for

investigation of the defect. Defective parts which are not returned to PRODEM/and/or are not made available for the

investigation are excluded from the guarantee.

F) Guarantee exclusion

The following shall be excluded from the guarantee:

Damage incurred by improper assembly of machine parts and/or hydraulic components, as a result of improper

use or maintenance or damage incurred duringtransport.

Defects which are traceable to repairs carried out by a non-authorised third party.

Defects incurred by the use of foreign spareparts.

Damage to parts subject to normal wear, such as e.g.: sleeve bearings, hoses, bolts etc.

Secondary damage traceable to the delayed replacement of wearable parts.

If repairs are carried out independently by the owner on machine parts during the guarantee period without the prior

consent of the manufacturer (PRODEM), guarantee and/or liability claims shall become void.

G) Guarantee claims

Guarantee claims shall only relate to the possible cost-free delivery of replacement parts. Travel and wage costs shall be

subject to negotiation.

We reserve ourselves to adapt assembly/disassembly hours in individual cases on a necessary measure. To customer

service expenditures the following, firm sentences apply:

Assembly/disassembly by mechanic

Travel expenses of mechanic, vehicle included

H) Special arrangements

Special arrangements according to the specified points 1-5 are to be submitted in writing before conclusion of the sales

contract and be confirmed by PRODEM in writing. Later special arrangements cannot be considered.

I) Contact –guarantee: PRODEM

Clamshell grab

5

1.3

General safety instructions:

Please observe the following items before assembling or operating this machine component:

1. First read this operating manual thoroughly!

Should unclear points or questions arise when reading through this operating manual, please

consult you supplier in the first instance.

2. Check whether your carrier machine if suitable for this product!

3. Acquaint yourself with the safety regulations applicable at your place of

Work!

4. If you do not comply with the information and instructions given in this operating manual, all

guarantee and/or liability claims shall beexcluded.

The grab is constructed according to the present state of technology and complies with the currently

applicable safety regulations. Unforeseeable factors may, however, affect the safety of the grab.

It is therefore extremely important to precisely adhere to the safety regulations.

Safety rules:

1. Any damage to the grab must be repaired immediately by a qualified technician.

If necessary, the assistance of the supplier or manufacturer must be called upon.

2. The grab must only be deployed for carrying out tasks for which it is intended.

3. Unauthorised persons must keep clear of the working area of the carrier machine and

the grab.

4. Observe all safety regulations applicable at your place of work.

5. Protection or safety devices must not be removed. In the event of damage or loss these must be replaced

immediately.

6. When assembling or disassembling the grab, ensure that all connections and attachments are secured in

accordance with the regulations.

7. When repositioning the machine, ensure that the grab is in a safe position. Secure the grab e.g. with

chains in order to prevent all uncontrolled movements.

8. When carrying out repairs, only use original replacement parts. If foreign parts are used, the safety of

the grab can no longer be guaranteed.

9. Also observe the additional safety regulations given in this operating manual.

Safety regulations are only effective provided these are known and understood.

Please consult your supplier if questions arise.

Clamshell grab

6

1.4

Product information:

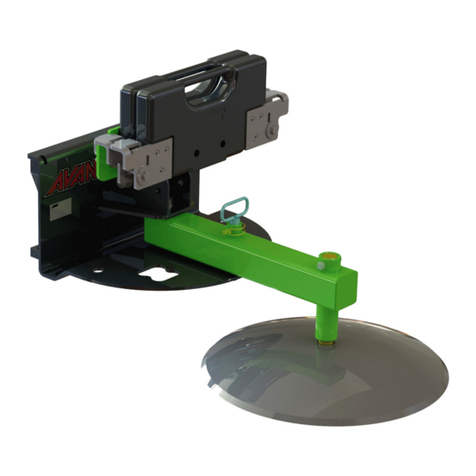

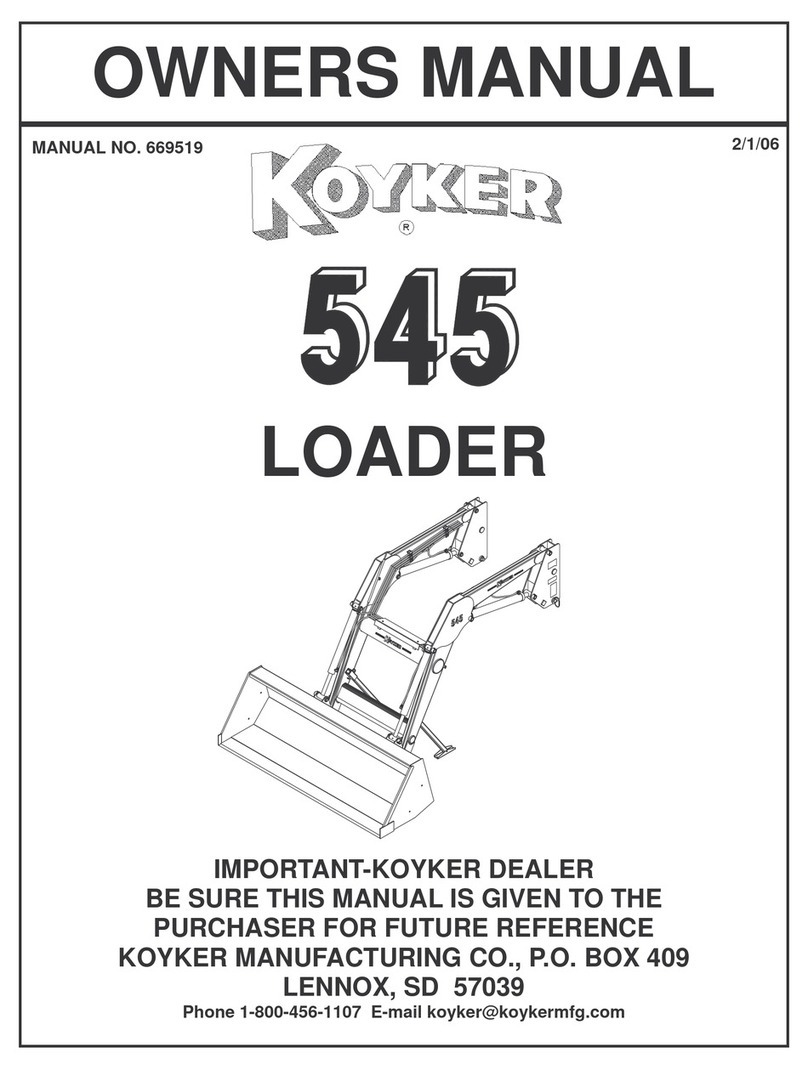

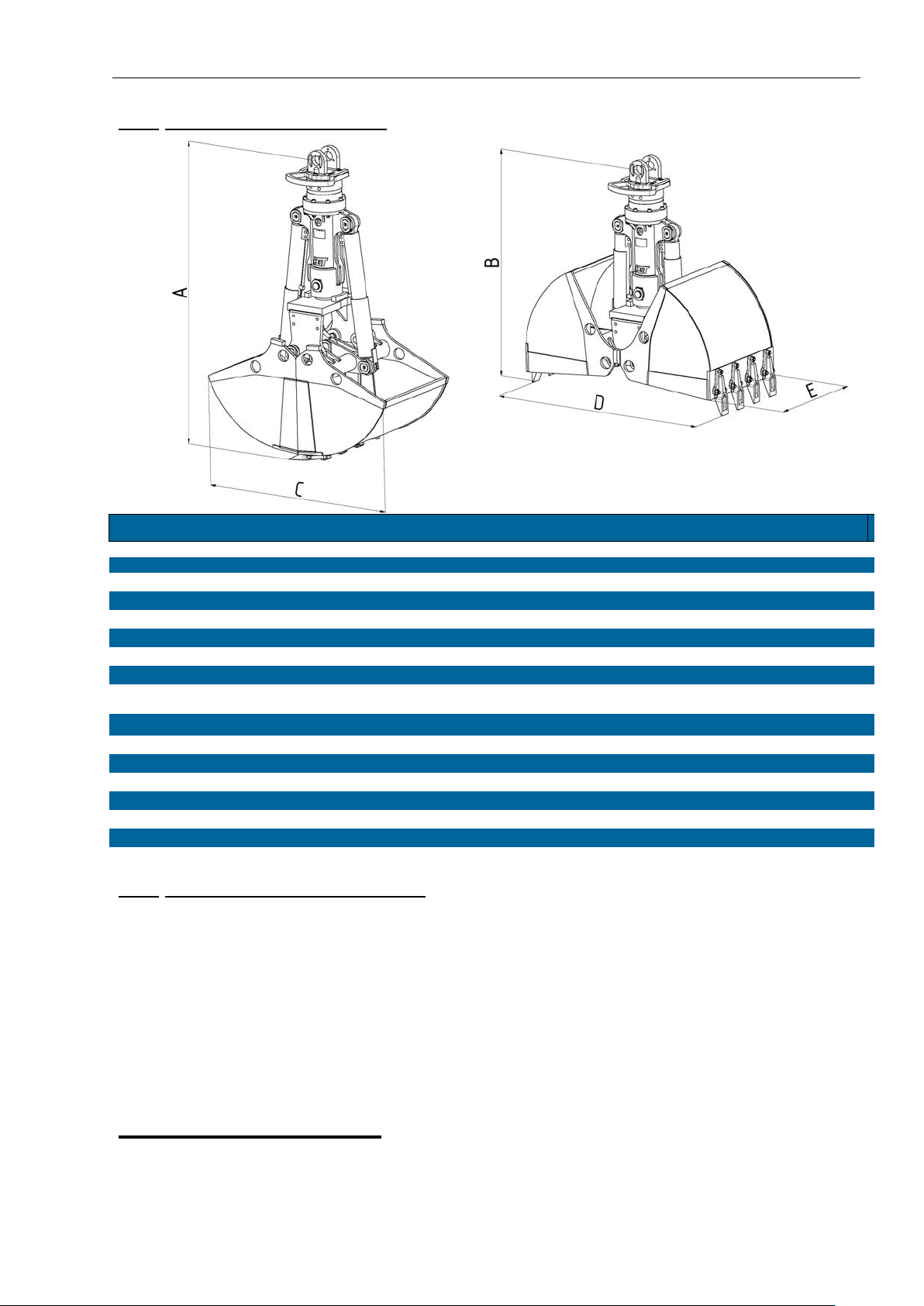

1.4.1

Assembly:

Suspension

Rotator

Frame

Cylinder

Clamshell carrier

Clamshell

Exchange teeth

1.4.2

Productdescription:

Special clamshell grabs for hydraulic excavator use as excavating and dredging of grown soil, pulling ditches

and cable pits, shipping bulk materials.

1.4.3

Design features:

-

Multi-functional clamshell grab for oscillatinguse

-

Clamshell with clamshell carrier exchangeable within the entire line of products

-

Rotator with endless hydraulicrotation

-

Hose protection for rotatorconnection

-

Exchange teeth out of high density resistant steel 400HB

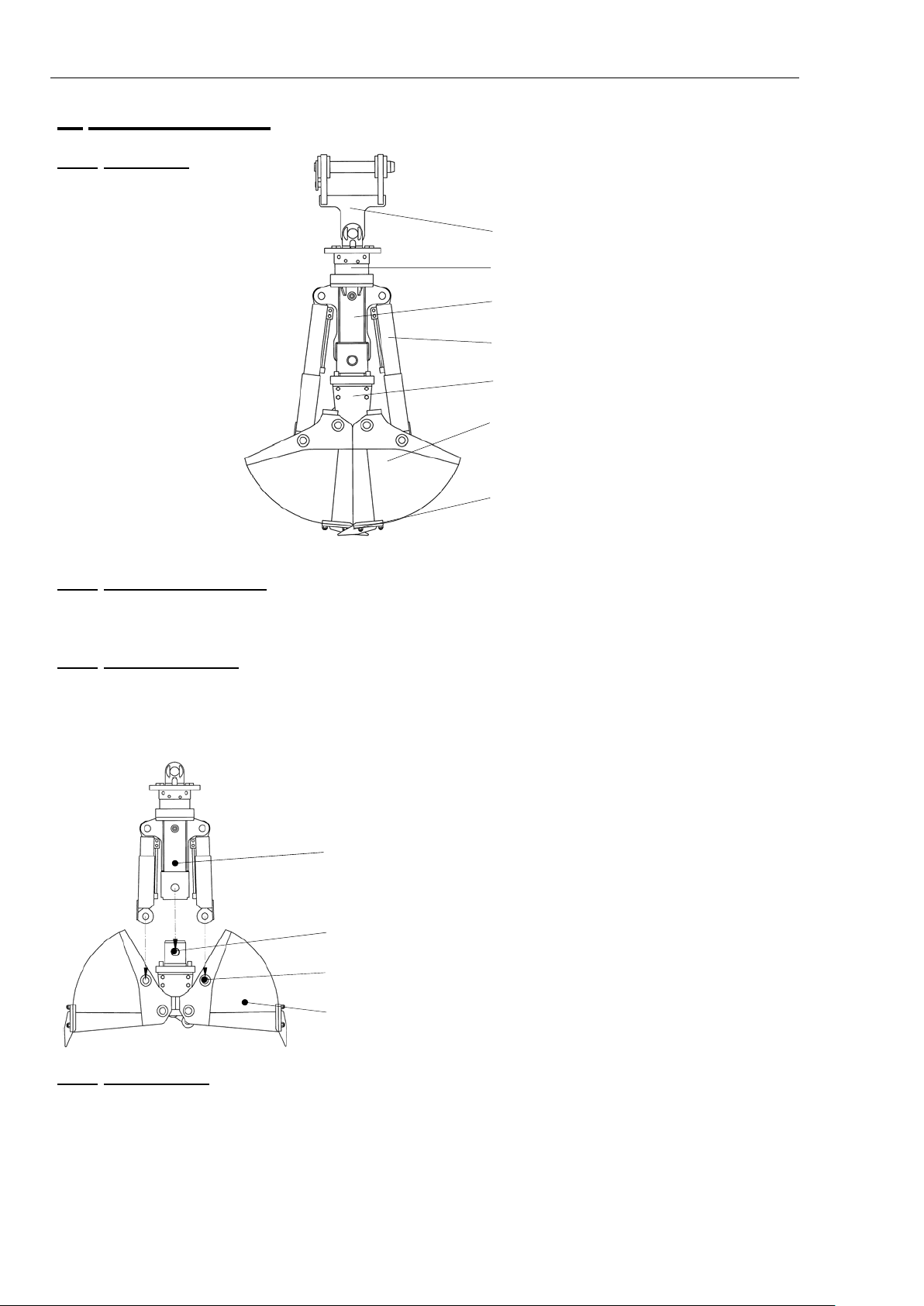

Control unit

(Frame with connector and hydraulic unit)

Socket pin - frame

Socket pin - cylinder

Clamshell carrier with clamshell

1.4.4

Plug system:

The Clamshell grabs of the series DCS2 –DCS5 are equipped with a plug system, which makes it possible to quick

change the clamshell with clamshell carrier and synchronisation steering element.

Only the two lower cylinder socket pins and the frame socket pin are to be detached in order to change the clamshell.

This economical solution makes a versatile employment, with only one control unit and with the most different clamshell

sizes and clamshell forms, possible for the customer.

Clamshell grab

7

1.4.5

Measures / Technicaldata:

Model

DCS05

DCS1

DCS2

DCS3

DCS4

DCS5

Excavator weight class

t 1 –2

1 –4

4,5 –8

9 –12

13 –21

22 –30

Max. lifting capacity clamshell

t 1

1

2

2

4

6

Max. lifting capacity rotator

t 2

4

4

10

10

15

Measure A

mm 865

885

1230

1695

2100

2380

Measure B

mm 670

630

890

1340

1610

1790

Measure C

mm 700

840

1180

1295

1490

1730

Measure D

mm 790

950

1305

1410

1700

2000

Cut width E

mm 280-400

300-500

270-600

300-800

300-1000

400-1200

Max. bulk density

t/m32

2

2

2

3

3

Max. closing pressure

kN 20

24

27

40

67

95

Max. working pressure griffin

bar 250

250

300

350

350

350

Max. working pressure turning

bar 250

250

300

320

320

320

Hydraulic connection griffin

M18x1,5

M18x1,5

M18x1,5

G3/4

G3/4

G3/4

Hydraulic connection turning

M18x1,5

M18x1,5

M18x1,5

G1/2

G1/2

G1/2

Max. oil consumption griffin

l/min 25

25

50

60

90

120

Max. oil consumption turning

l/min 20

20

20

20

25

25

1.4.6

Recommended Hydraulicfluids:

Hydraulic fluid H-LP e.g.: Mineral oilHLP46

Hydraulic fluid HE ES e.g.: Panolin HLP Synth32/46/68

Synthetic ester oils Ukabiol HE46

DEA ECONA E46

Agip Arnica S46

Hydraulic fluid HE TG e.g.:

Plant oils Ukabiol HY 32

Brennrag HV32

Hydraulic fluids HFC, HFD, HFA, and HFB are not recommended!

Filter designs for min. oil purity according to DIN ISO 4406. Class 18/16/13

Recommended lubricating greases:

Lubricating grease e.g.: ESSO - MULTI-PURPOSE GREASE (Moly)

ESSO - Joint grease 2-083

Lubricating grease e.g.: AVIA - AVIALITH 2 F(water-resistant)

Clamshell grab

8

1.4.7

Employment:

Operating regulations:

1.

Take care to comply with the regulations for operating the carrier machine and the functions necessary for working

with the grab.

2.

Ensure that all persons keep well clear of the working area of the carrier machine and the grab.

3.

Only use the grab to carry out work for which it isdesigned:

Excavating andshipping

4.

Do not use the clamshell grabfor:

Hammering

Striking

Tamping

Crushing –The rotary function is not a crushingdevice!

Coiling –Rotation device is for positioning thegrab!

Moving of containers andwaggons!

! In the event of improper use all guarantee and / or liability claims shall become void.

Grab is designed for free oscillating

employment!

Load admission only in vertical grab

axle!

Do not pull loads with

the grab!

Clamshell grab

9

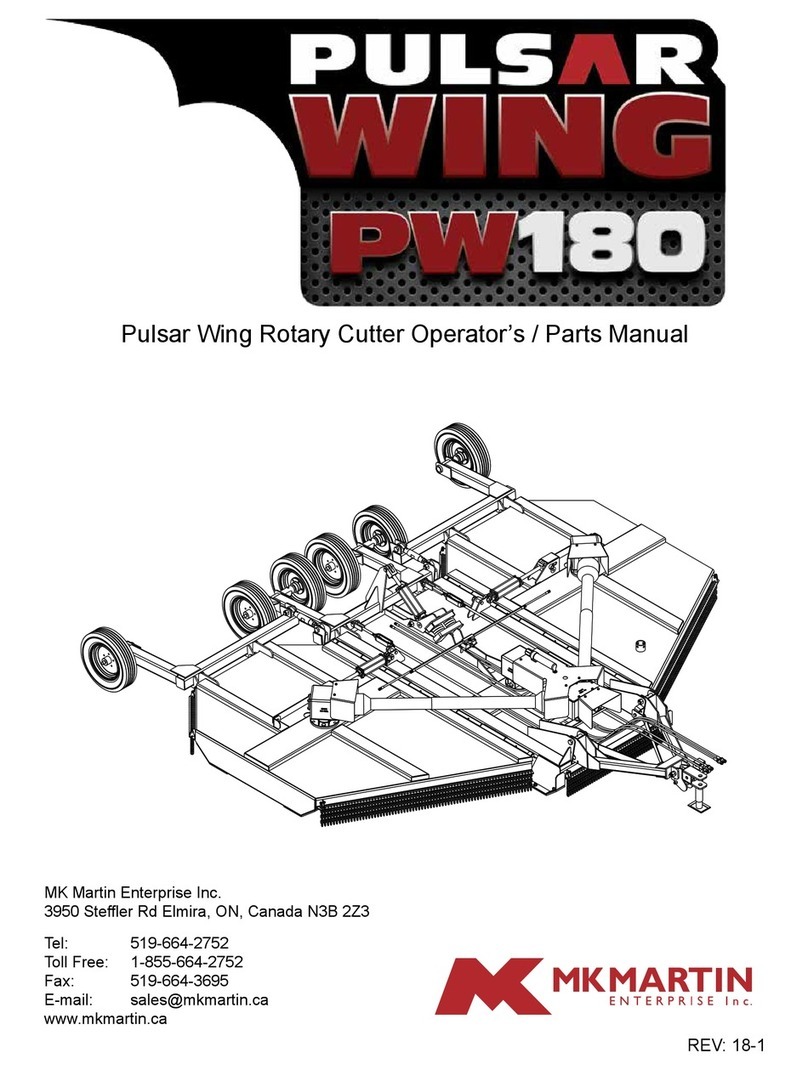

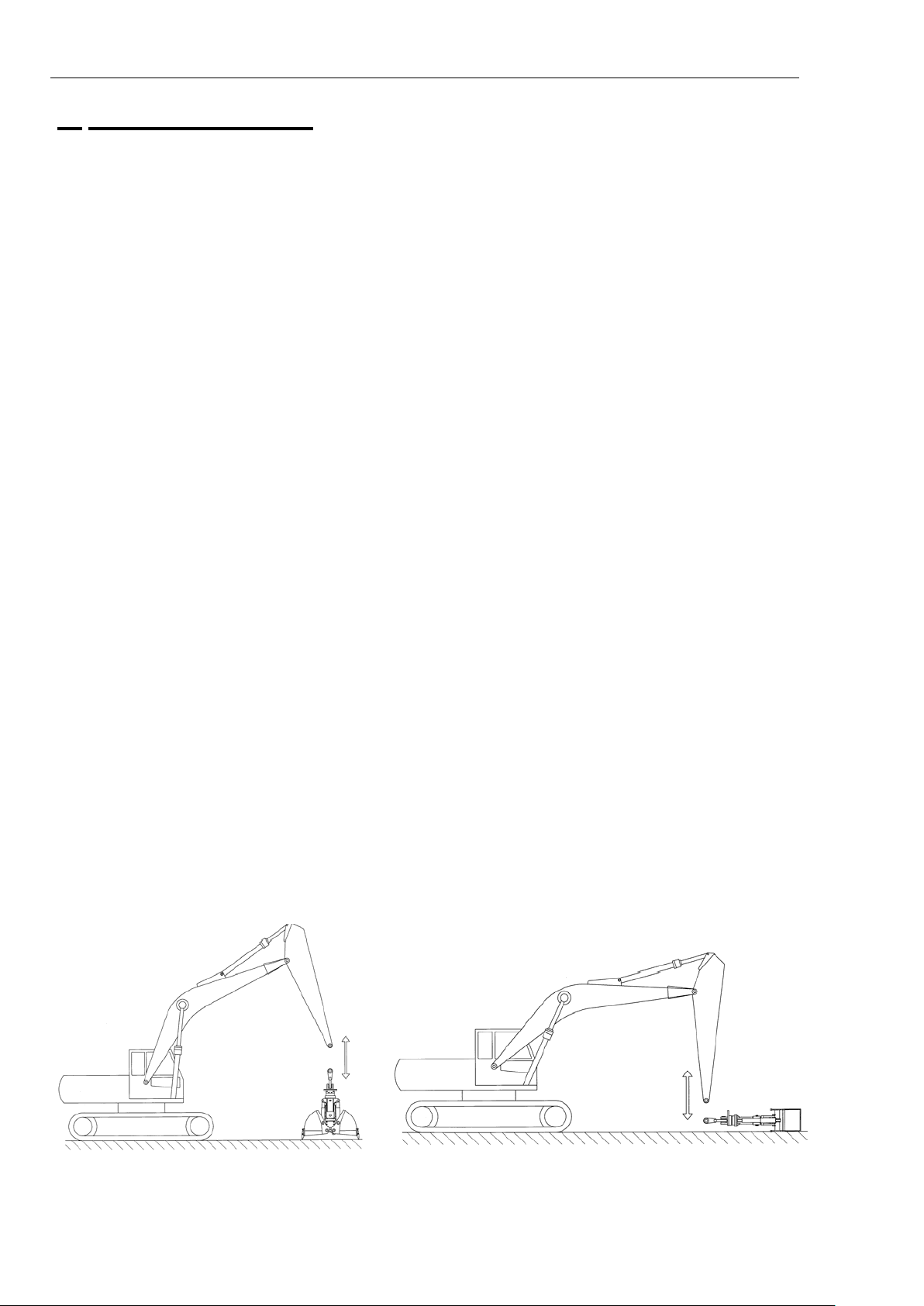

1.5

Transport / Storage:

The transportation and lifting or lowering of the grab must be carried out using the tools provided for this

purpose.

Transport: -Grab installed at the carrier machine (Pict.1):

The grab is determined to the transportation claw of the excavator and secured (see

operating manual of the excavator)

-The grab is transported in open position (Pict.2):

Place the grab on an even, stable surface (! sharp knives) and take precautions to prevent it

from tipping over and slipping. The same is valid during the storage of the grab.

-The grab is transported/stored in horizontal position (Pict. 3):

Stabilize the grab under the rotator while storing. Take precautions to prevent it from tipping

over and slipping during the transport.

Pict. 1 Pict. 2

Pict. 3

! Before longer storage the grab must be cleaned and maintenance

completely first. An oil exchange is recommended before any further

employment! Seals and hoses age, become useless and have to be

exchanged in time.

Lifting / moving

Always lift the grab at the connection point provided(Pict. 4). Pict. 4

! The following checks must be carried out after each transport:

Visual check for transport damages

Check grab for missing parts (see spare parts list)

Check firm seat of screws, bolts and safetydevices

Check for leaks in the hydraulic system

If any defects are detected the grab must be repaired immediately by a qualified technician before

employment.

Clamshell grab

10

1.6

Installation and initiation:

The carrier machine must fulfil the following requirements:

1. The carrier machine must be fitted with a safe hydraulic unit.

In order to realise the two basic functions (rotation and opening/closing) of the grab,

two separate hydraulic circuits are necessary.

2. Make yourself acquainted with the hydraulic connection layout for the carrier machine.

Errors in the operating logistics must not endanger the safety of thefunctions.

4. The adapter unit (adapter/suspension/connector) between the carrier machine and the grab must be

designed for the working load of the grab.

! Only use original parts.

5. The working load of the excavator must match the grab type (see 1.4.5 Excavator weight class).

6. Connection values (pressures, delivery volumes) must be checked in advance for compliance with the

correct specifications (see 1.4.5 Technical data)

! Never change the pressure and volume settings of safety valves without the permission of the

manufacturer.

-Check whether the connection hoses (excavator - grab) have the correct length and are appropriate

for the grab operatingpressure.

-Ensure that the correct hoses and connectors are used (Table 1). Take care to follow the supplier’s

specifications.

! Improper connectors and/or incorrect hose connections may lead to malfunctioning and damage

to the grab.

Attachment:

-Attach the adapter/suspension to the admission on the excavator arm using the stud bolt (Pict. 1/2).

Follow thereby the instructions of the supplier of the carriermachine.

-Attach the hoses to the rotator according to their respectivefunctions.

Consider thereby the connection symbols next to the screw threads on the rotator (Pict. 3).

! Ensure absolute cleanliness when attaching all hydraulic hoses. Dirt will damage your hydraulic

system.

Pict. ½

Clamshell grab

11

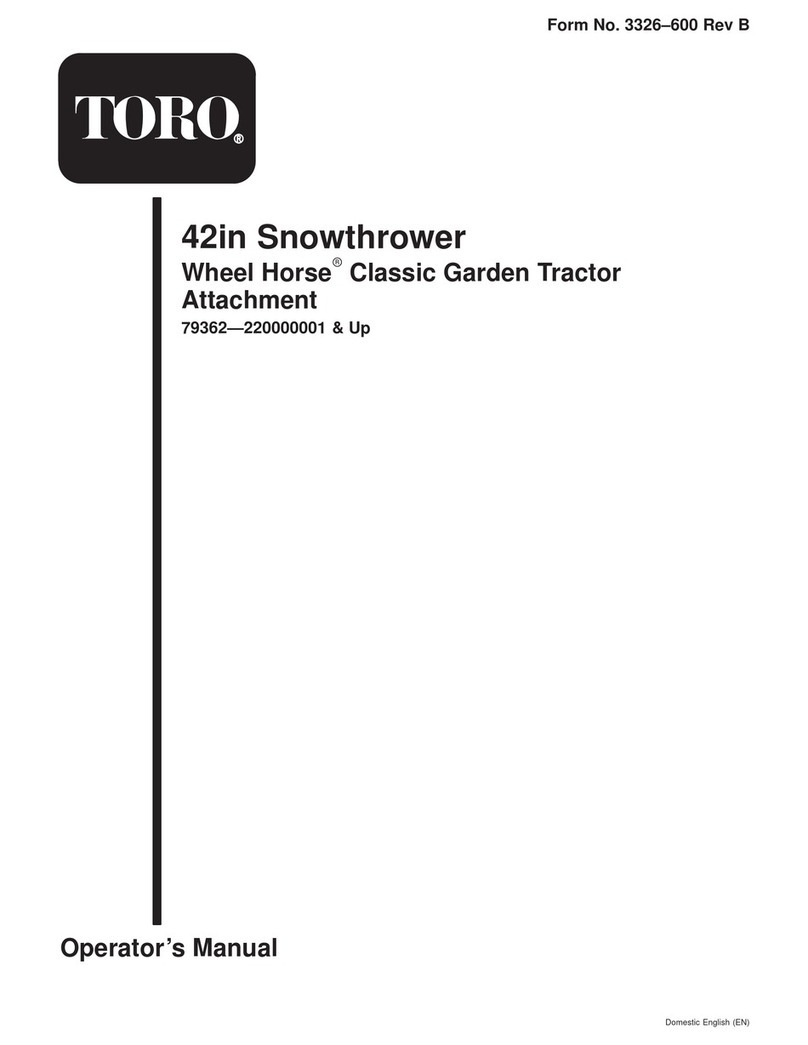

1.6.1 Positions of the hydraulic connectors at the rotator:

DCS05 –DCS2 DCS3 –DCS4 DCS5

Pict. 3

Thread sizes (Internal threads in the rotator)

Connecting thread

DCS05

DCS1

DCS2

DCS3-S

DCS4

DCS5

R1 rotate left

M18x1,5

M18x1,5

M18x1,5

G1/2

G1/2

G1/2

R2 rotate right

M18x1,5

M18x1,5

M18x1,5

G1/2

G1/2

G1/2

GS close grab

M18x1,5

M18x1,5

M18x1,5

G3/4

G3/4

G3/4

GO open grab

M18x1,5

M18x1,5

M18x1,5

G3/4

G3/4

G3/4

Table 1

Clamshell grab

12

Part 2. Service manual

2.1

Inspection:

Acquaint yourself with the safety regulations applicable at your place of work first.

Inspection

During maintenance and inspection work the grab must be placed on a stable and even surface.

a) Place the grab on the ground

b) Switch off the motor of the carriermachine

c) Remove the starter key from the carrier machine

d) Block the machine

e) Ensure that the hydraulic system is depressurized

f) During inspection/maintenance work place a sign in the machine cabin reading

“Do not start / operate”

2.1.1

Items of dailyinspection:

- Visual check whether any parts are missing

- Visual check whether any parts are loose (screws, bolts and safety devicesetc.)

- Visual check for leaks in the hydraulic system (connectors, hoses, cylindersetc.)

- Visual check for signs of mechanical damage (cracks, deformationsetc.)

2.1.2

Items of weeklyinspection:

Check the grab for signs of wear

- Play in the bearings (steering element, clamshell, cylinder, adapter)

- Exchange teeth

- Stops opening limit - opening min. lifting cylinder assembly dimension (Table 1 - measure E)

- Exchange teeth limit - closing max. lifting cylinder assembly dimension (Table 1 - measureE)

In case of noticeable wear or other defects contact your supplier immediately and arrange for parts to be

replaced or repaired.

Assembly

dimensions

Opening / E min.

Closing / E max.

DCS05

80 mm

290 mm

DCS1

80 mm

290 mm

DCS2

365 mm

520 mm

DCS3

565 mm

815 mm

DCS4

670 mm

1015 mm

DCS5

780 mm

1195 mm

Clamshell grab

13

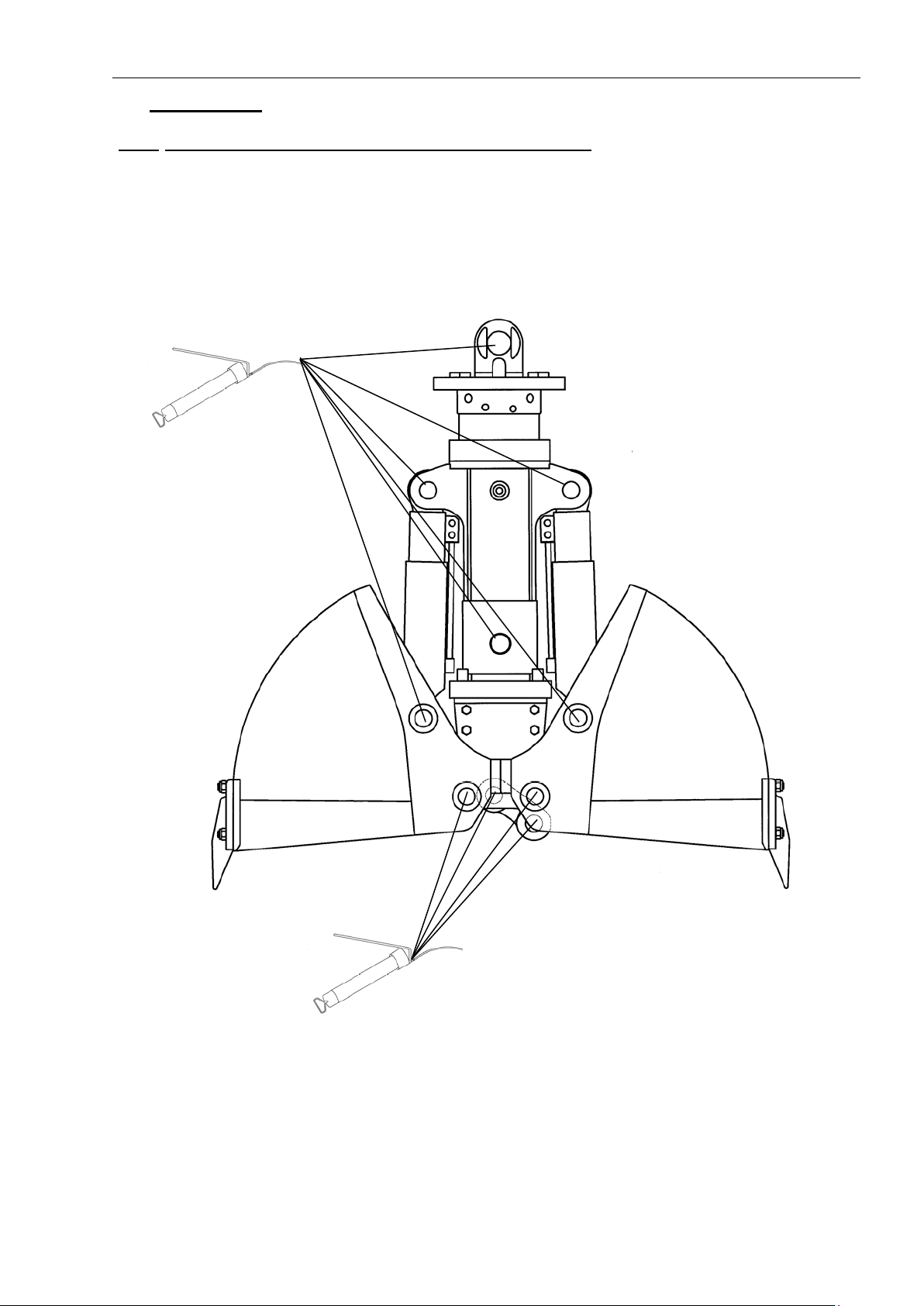

2.2 Maintenance

2.2.1

Items of daily maintenance / after 8 operatinghours:

- All bearings (Pict. 2) should be lubricated at least 1x daily and/or after 8 operating hours with multi-

purpose grease

Clamshell grab

14

Part 3. Spare parts lists:

A –Replacement part / E –Spare part / S –Set / V –Wearing part

Ma= Torque

= Description of adhesive:

Secured with medium strength screw adhesive

(e.g. Loctite 638)

3.1

DCS05 / Z-Z05 with AG 5-2

3.1.1

DCS05 / Z-Z05 - Grab cpl. - Spareparts

Item

Pc.

Designation

Group

Order-No.

1

1

rotator

E

3007000119

2

1

frame

E

2002001001

3

2

steering

E

2004001001

4

1

clamshell with steering –280

E

2006001010

clamshell with steering –300

E

2006001011

clamshell with steering –400

E

2006001012

5

4

pin –frame/clamshell

V

3009035005

6

4

pin –cylinder/clamshell

V

3009035004

7

4

pin –steering

V

3009020001

8

4

bush –frame/clamshell

V

5003002103

9

4

bush –cylinder retainer

V

5003002108

10

4

bush –steering

V

5003002001

11

4

bolt

A

5001001014

12

4

washer

A

5001002084

13

4

bolt

A

5001001008

14

4

spring pin

A

5001005005

15

8

grease nipple

A

5003001001

16

1

bush set ( items 5 –15 )

S

2013001001

17

2

hose

A

5002010238

18

2

threaded adapter ( W )

A

5002001041

19

2

threaded adapter ( E )

A

5002001015

20

2

threaded adapter ( SW )

A

5002001089

21

4

threaded adapter ( VSTI )

A

5002001217

22

1

hydraulic set ( items 17 –20 )

S

2010001001

23

4

bolt –rotator/frame

A

5001001211

24

4

washer

A

5001002083

25

4

nut

A

5001006002

26

3

tooth

V

5004001002

27

6

bolt

V

5001001003

28

6

nut

V

5001006004

50

1

cylinder

E

2011001000

51

2

retainer

E

2001001001

52

2

washer

A

5001002021

53

2

nut

A

5001006005

70

1

hose protection

E

3005000001

71

4

bolt

A

5001001102

72

4

washer

A

5001002060

Clamshell grab

15

3.1.2

DCS05 / Z-Z05 - Grab cpl. -Picture

Clamshell grab

16

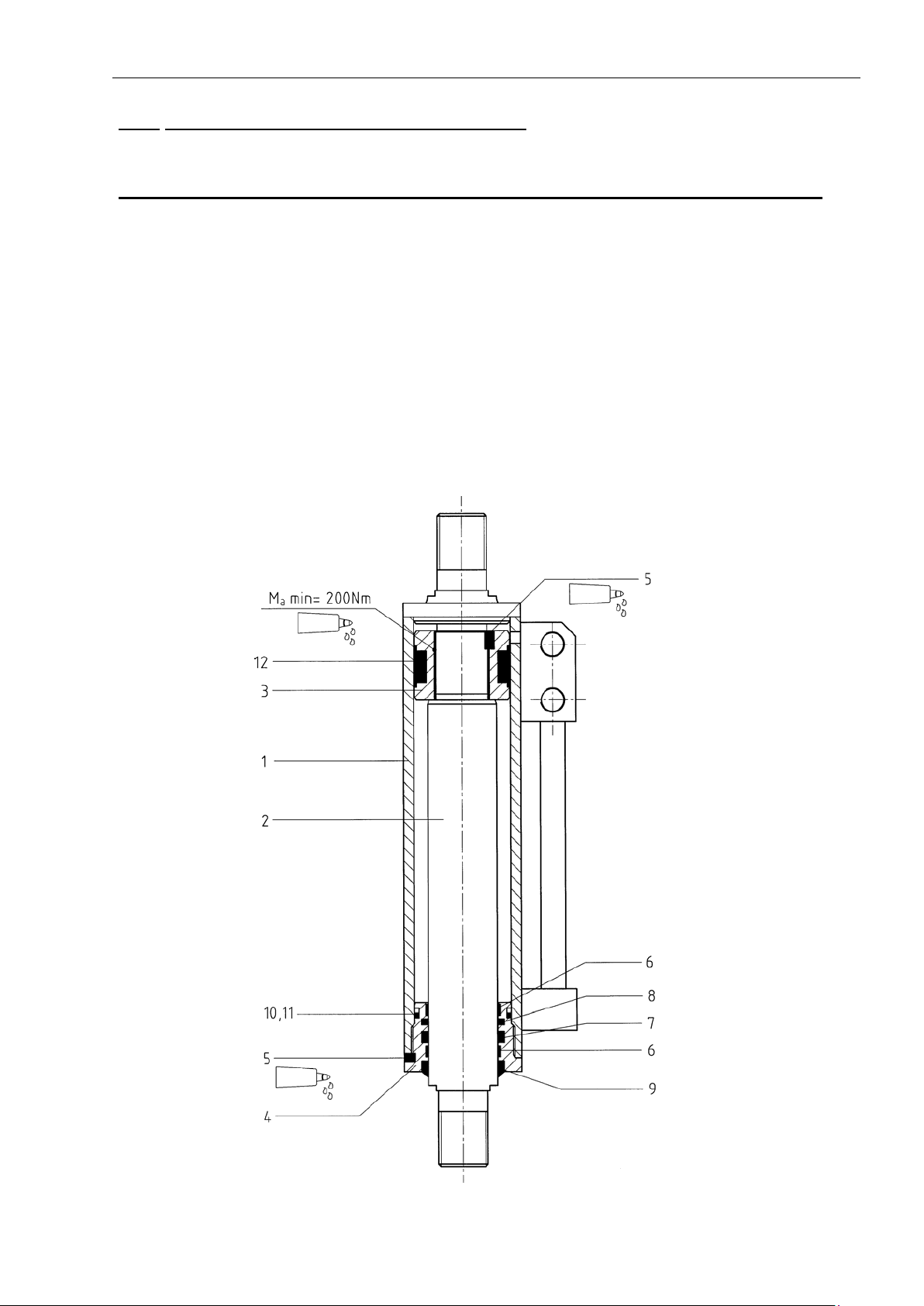

3.1.3

DCS05 / Z-Z05 - Cylinder - Picture/spare parts

Item

Pc.

Designation

Group

Order-No.

50

1

cylinder

E

2011001000

1

1

cylinder barrel

E

2011001001

2

1

piston rod

E

2011001002

3

1

piston

E

2011001003

4

1

guide nut

E

2011001004

5

2

set screw (! secured with screw adhesive)

A

5001007001

6

2

guide band

V

5002006002

7

1

rod seal

V

5002005002

8

1

rod seal

V

5002005001

9

1

scraper

V

5002007003

10

1

o-ring

V

5002004004

11

1

support ring

V

5002014002

12

1

piston seal

V

5002003006

13

1

seal set ( items 6 –12 )

S

2011001005

Clamshell grab

17

3.2

DCS1 / Z-Z1 with AG 5-2

3.2.1

DCS1 / Z-Z1 - Grab cpl. - Spareparts

Item

Pc.

Designation

Group

Order-No.

1

1

rotator

E

3007000119

2

1

frame

E

2002001001

3

2

steering

E

2004001001

4

1

clamshell with steering –300

E

2006001001

clamshell with steering –400

E

2006001002

clamshell with steering –500

E

2006001003

5

4

pin –frame/clamshell

V

3009035005

6

4

pin –cylinder/clamshell

V

3009035004

7

4

pin –steering

V

3009020001

8

4

bush –frame/clamshell

V

5003002103

9

4

bush –cylinder retainer

V

5003002108

10

4

bush –steering

V

5003002001

11

4

bolt

A

5001001014

12

4

washer

A

5001002084

13

4

bolt

A

5001001008

14

4

spring pin

A

5001005005

15

8

grease nipple

A

5003001001

16

1

bush set ( items 5 –15 )

S

2013001001

17

2

hose

A

5002010238

18

2

threaded adapter ( W )

A

5002001041

19

2

threaded adapter ( E )

A

5002001015

20

2

threaded adapter ( SW )

A

5002001089

21

4

threaded adapter ( VSTI )

A

5002001217

22

1

hydraulic set ( items 17 –20 )

S

2010001001

23

4

bolt –rotator/frame

A

5001001211

24

4

washer

A

5001002083

25

4

nut

A

5001006002

26

tooth

V

5004001002

27

bolt ( 2 pc./tooth )

V

5001001003

28

nut ( 2 pc./tooth )

V

5001006004

50

1

cylinder

E

2011001000

51

2

retainer

E

2001001001

52

2

washer

A

5001002021

53

2

nut

A

5001006005

70

1

hose protection

E

3005000001

71

4

bolt

A

5001001102

72

4

washer

A

5001002060

Clamshell grab

18

3.2.2

DCS1 / Z-Z1 - Grab cpl. -Picture

Clamshell grab

19

3.2.3

DCS1 / Z-Z1 - Cylinder - Picture/spare parts

A –Replacement part / E –Spare part / S –Set / V –Wearing part

Item

Pc.

Designation

Group

Order-No.

50

1

cylinder

E

2011001000

1

1

cylinder barrel

E

2011001001

2

1

piston rod

E

2011001002

3

1

piston

E

2011001003

4

1

guide nut

E

2011001004

5

2

set screw (! secured with screw adhesive)

A

5001007001

6

2

guide band

V

5002006002

7

1

rod seal

V

5002005002

8

1

rod seal

V

5002005001

9

1

scraper

V

5002007003

10

1

o-ring

V

5002004004

11

1

support ring

V

5002014002

12

1

piston seal

V

5002003006

13

1

seal set ( items 6 –12 )

S

2011001005

Clamshell grab

20

3.3

DCS2 / Z-Z2 with AG 5-2

3.3.1

DCS2 / Z-Z2 - Grab cpl. - Spareparts

A –Replacement part / E –Spare part / S –Set / V –Wearing part

Item

Pc.

Designation

Group

Order-No.

1

1

hose protection

E

3005000001

2

1

rotator

E

3007000119

3

1

frame

E

2002002001

4

1

clamshell carrier

E

2003002001

5

1

steering

E

2004002001

6

1

clamshell with teeth and clamshell carrier –

270

S

2007002001

clamshell with teeth and clamshell carrier –

300

S

2007002002

clamshell with teeth and clamshell carrier –

400

S

2007002003

clamshell with teeth and clamshell carrier –

500

S

2007002004

clamshell with teeth and clamshell carrier –

600

S

2007002005

7

2

pin –cylinder/frame

V

3009035003

8

6

pin - clamshell pivot/cylinder/clamshell

V

3009035002

9

2

pin –steering

V

3009035001

10

1

pin –frame/clamshell carrier

V

3009040001

11

2

bush –steering

V

5003002102

12

4

bush - frame/clamshell carrier

V

5003002101

13

1

folding split pin

A

5001004103

14

8

split pin

V

5001004003

15

12

grease nipple

A

5003001001

16

2

folding split pin

A

5001004104

17

1

bush set ( items 7 –16 )

S

2013002001

18

4

hose

A

5002010201

19

6

threaded adapter ( E )

A

5002001015

20

2

threaded adapter ( T )

A

5002001048

21

4

threaded adapter ( W )

A

5002001041

22

4

threaded adapter ( plug )

A

5002001217

23

1

hydraulic set ( items 18 –22 )

S

2010002001

24

tooth

V

5004001003

25

bolt ( 2 pc./tooth )

V

5001001203

26

nut ( 2 pc./tooth )

V

5001006006

27

4

bolt –rotator/frame

A

5001001206

28

4

washer

A

5001002083

29

4

washer

A

5001002060

30

4

bolt –hose protection

A

5001001102

31

4

threaded adapter ( plug )

A

5002001217

50

2

cylinder

E

2011002000

70

2

piston rod protection

E

2012002001

71

4

bolt –piston rod protection / cylinder

A

5001001007

72

4

washer

A

5001002085

This manual suits for next models

7

Table of contents