Prodigit 3350F Series User manual

3350F Series

High power

Electronic Load

Operation manual

S/N:9003350F04 REV: I

SAFETY SYMBOLS

Direct current (DC)

Alternating current (AC)

Both direct and alternating

Three

-

phase altern

ating

Off (Supply)

On (Supply)

Protective earth

Caution

!

Refer to this anual before using the eter.

Caution, risk of electric shock

CAT IV – Is for measurements performed at the source of the low-voltage

installation.

CAT III – Is for measurements performed in the building installation.

CAT II – Is for measurements performed on circuits directly connected to the

low-voltage installation.

CAT I – Is for measurements performed on circuits not directly connected to

Fuse

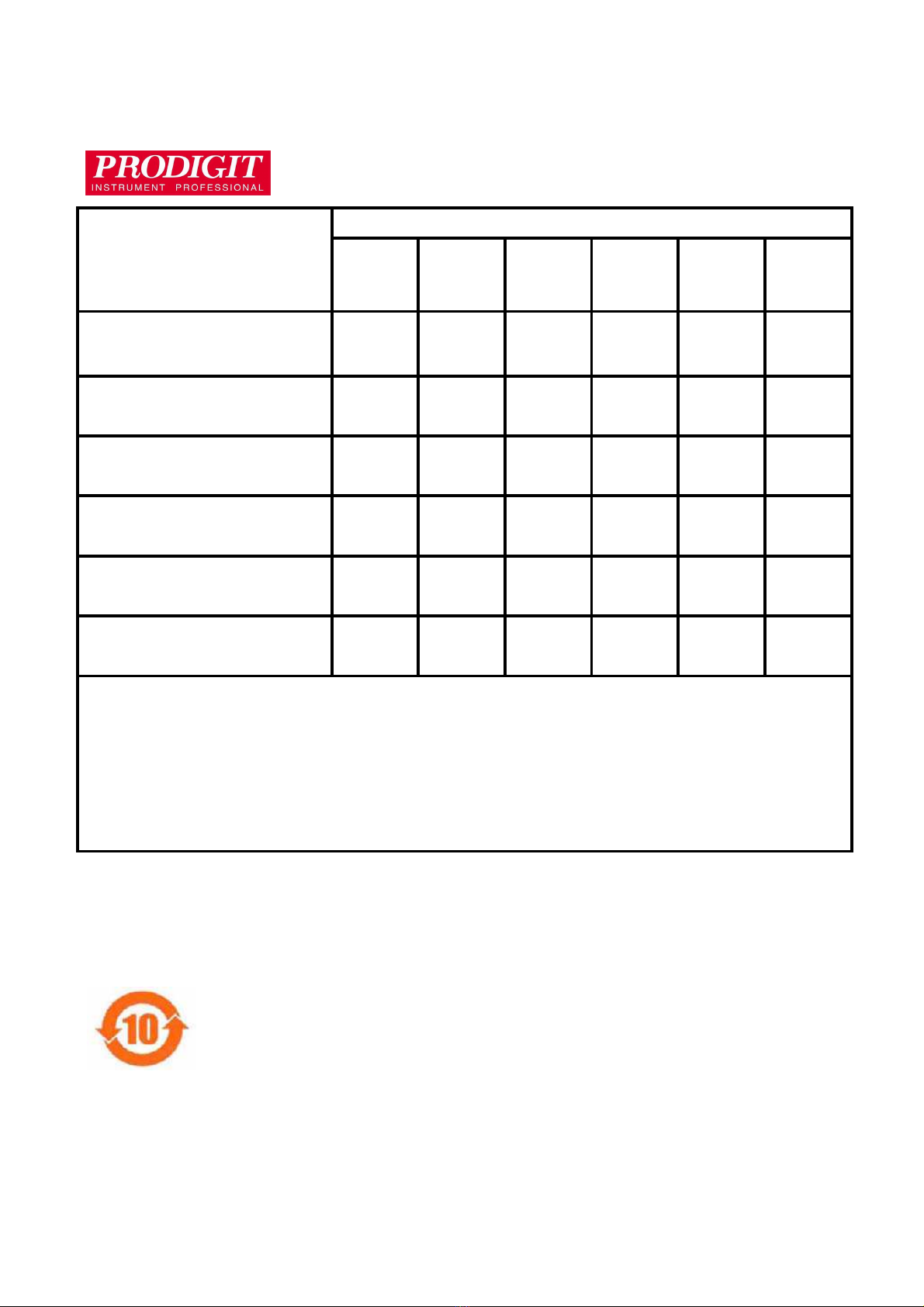

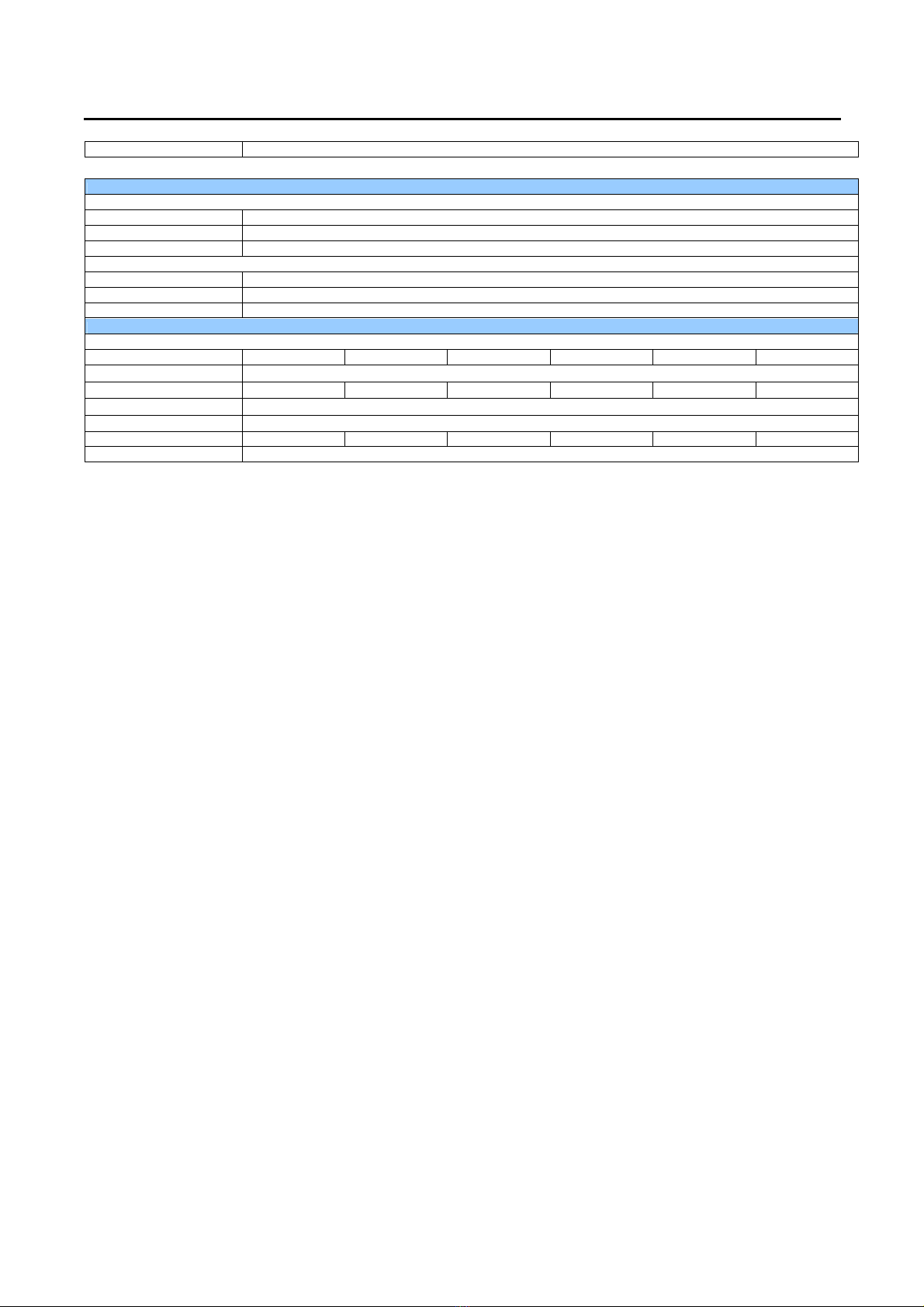

Material Contents Declaration

(材料含量宣称)

Hazardo s S bstance (有毒有害物质或元素)

(Part Name)

零件名称 铅

(Pb)

汞

(Hg)

镉

(Cd)

六价铬

(Cr6+)

多溴

联苯

(PBB)

多溴

二苯醚

(PBDE)

PCBA

(印刷电路装配件) X O X O O O

Electrical part not on PCBA’s

未在PCBA上的电子零件 X O X O O O

Metal parts

金属零件 O O O X O O

Plastic parts

塑料零件 O O O O X X

Wiring

电线 X O O O O O

Package

封装 X O O O O O

对销售之日的所售产品,本表显示, PRODIGIT 供应链的电子信息产品可能包含这些物质。注意:所售产品中可能

会也可能不会含有所有所列的部件。This table shows where these substances may be found in the supply chain

of Prodigit electronic information products, as of the date of sale of the enclosed product. ote that some of the

component types listed above may or may not be a part of the enclosed product. ○:表示该有毒有害物质 该部

件所有均质材料中的含量均 SJ/T 11363-2006 标准规定的限量要求以下。○:Indicates that the concentration of

the hazardous substance in all homogeneous materials in the parts is below the relevant threshold of the SJ/T

113632006 standard. ×:表示该有毒有害物质至少 该部件的某一均质材料中的含量超出SJ/T 11363-2006 标准

规定的限量要求。×: Indicates that the concentration of the hazardous substance of at least one of all

homogeneous materials in the parts is above the relevant threshold of the SJ/T 11363-2006 standard.

ote(注释):

1.Prodigit has not fully transitioned to lead-free solder assembly at this moment;However, most of the

components used are RoHS compliant.

(此刻,Prodigit 并非完全过渡到无铅焊料组装;但是大部份的元器件一至于RoHS的规定。)

2. The product is labeled with an environment-friendly usage period in years.

The marked period is assumed under the operating environment specified in the product specifications.

(产品标注了环境友好的使用期限制(年)。所标注的环境使用期限假定是在此产品定义的使用环境之下。)

Example of a marking for a 10 year period:

(例如此标制环境使用期限为10年)

SAFETY SUMMARY

The following general safety precautions must be observed during all phases of operation, service,

and repair of this instrument. Failure to comply with these precautions or with specific warnings

elsewhere in this manual violates safety standards of design, manufacture, and intended use of

the instrument. PRODIGIT assumes no liability for the customer's failure to comply with these

requirements.

GENERAL

This product is a Safety Class 1 instrument (provided with a protective earth terminal). The

protective features of this product may be impaired if it is used in a manner not specified in the

operation instructions.

ENVIRONMENTAL CONDITIONS

This instrument is intended for indoor use in an installation category I, pollution degree

environments. It is designed to operate at a maximum relative humidity of 80% and at altitudes of

up to 000 meters. Refer to the specifications tables for the ac mains voltage requirements and

ambient operating temperature range.

BEFORE APPLYING POWER

Verify that the product is set to match the available line voltage and the correct fuse is installed.

GROUND THE INSTRUMENT

This product is a Safety Class 1 instrument (provided with a protective earth terminal). To

minimize shock hazard, the instrument chassis and cabinet must be connected to an electrical

ground. The instrument must be connected to the ac power supply mains through a three

conductor

power cable, with the third wire firmly connected to an electrical ground (safety ground) at the

power outlet. Any interruption of the protective (grounding) conductor or disconnection of the

protective earth terminal will cause a potential shock hazard that could result in personal injury.

FUSES

Only fuses with the required rated current, voltage, and specified type (normal blow, time delay,

etc.) should be used. Do not use repaired

Fuses or short circuited fuse holder. To do so could cause a shock or fire hazard.

DO NOT OPERATE IN AN EXPLOSIVE ATMOSPHERE.

Do not operate the instrument in the presence of flammable gases or fumes.

KEEP AWAY FROM LIVE CIRCUITS.

Operating personnel must not remove instrument covers. Component replacement and internal

adjustments must be made by qualified service personnel. Do not replace components with power

cable connected. Under certain conditions, dangerous voltages may exist even with the power

cable removed. To avoid injuries, always disconnect power, discharge circuits and remove

external voltage sources before touching components.

DO NOT SERVICE OR ADJUST ALONE.

Do not attempt internal service or adjustment unless another person, capable of rendering first aid

and resuscitation, is present.

DO NOT EXCEED INPUT RATINGS.

This instrument may be equipped with a line filter to reduce electromagnetic interference and must

be connected to a properly grounded receptacle to minimize electric shock hazard. Operation at

line voltages or frequencies in excess of those stated on the data plate may cause leakage

currents in excess of 5.0 mA peak.

DO NOT SUBSTITUTE PARTS OR MODIFY INSTRUMENT.

Because of the danger of introducing additional hazards, do not install substitute parts or perform

any unauthorized modification to the instrument. Return the instrument to a PRODIGIT

ELECTRONICS Sales and Service Office for service and repair to ensure that safety features are

maintained.

Instruments which appear damaged or defective should be made inoperative and secured against

unintended operation until they can be repaired by qualified service personnel.

DECLARATION OF CONFORMITY

Co pany Na e: PRODIGIT ELECTRONICS CO., LTD

Address: 8F, No.88, Baojhong Rd., Sindian City, Taipei County,Taiwan, R.O.C.

Declares under sole responsibility that the product as originally delivered

Product Na es: DC Electronic Loads

Model Nu bers: 3350F、3351F、335 F、3353F、3354F、3356F

(And other customized products based upon the above)

Safety and EMC Infor ation:

This declaration covers all options and customized products based on the above products.

Complies with the essential requirements of the Low Voltage Directive 006/95/EC and the EMC

Directive 004/108/EC and carries the CE Marking accordingly.

Safety standard:

Safety standards following:

IEC 61010-1: 010 / EN 61010-1: 010

EMC standard:

EN 613 6-1: 006

EN 613 6- -1: 006

EN 55011: 009+A1: 010

EN 61000-3- : 006+A1: 009+A : 009

EN 61000-3-3: 008

EN 61000-4- : 009

EN 61000-4-3: 006+A1: 008+A : 010

EN 61000-4-4: 004+A1: 010

EN 61000-4-5: 006

EN 61000-4-6: 009

EN 61000-4-8: 010

EN 61000-4-11: 004

Oct 7, 01

Date

Larsson Tsou / R&D Assistant Manager

The holder of the verification is authorized to use this verification in connection with the EC

declaration Of conformity according to the Directives. The CE marking may only be used if all

releveant and effective EC Directives are complied with. Together with the manufacturer’s own

documented production control, The manufacturer (or his European authorized representative)

can in his EC Declaration of Conformity Verify compliance with the directives.

3350F Series High Power Electronic load operation manual

Table of Contents

CHAPTER 1 INTRODUCTION........................................................................................................................... 1

1-1. GENERAL DESCRIPTION ......................................................................................................................... 1

1-2. FEATURES ........................................................................................................................................... 9

1-3. ACCESSORIES ...................................................................................................................................... 9

1-4. OPTION ............................................................................................................................................... 9

1-5. SPECIFICATIONS ................................................................................................................................... 9

CHAPTER 2 INSTALLATION.......................................................................................................................... 12

2-1. INSPECTION ....................................................................................................................................... 12

2-2. CHECK LINE VOLTAGE ......................................................................................................................... 12

2-3. FUSE EXCHANGE ................................................................................................................................ 13

2-4. GROUNDING REQUIREMENTS................................................................................................................ 14

2-5. ADJUST THE FEET ............................................................................................................................... 14

2-6. RACK MOUNT ..................................................................................................................................... 14

2-7. ENVIRONMENTAL REQUIREMENTS ......................................................................................................... 14

2-8. OBSERVE THE INTERNATIONAL ELECTRICAL SYMBOL LISTED BELOW......................................................... 14

2-9. CLEANING .......................................................................................................................................... 15

2-10. POWER UP........................................................................................................................................ 15

2-11. CONNECTION TO THE LOAD INPUT TERMINAL ON THE REAR PANEL ........................................................... 15

2-12. REPAIR.............................................................................................................................................. 15

2-13. GPIB CONNECTION OPTION ................................................................................................................. 15

2-14. RS-232C CONNECTION OPTION .......................................................................................................... 16

2-15. USB CONNECTION OPTION.................................................................................................................. 16

2-16. LA CONNECTION OPTION .................................................................................................................. 17

2-17. GPIB & RS232 CONNECTION .............................................................................................................. 17

2-18. ANALOG PROGRAMMING TERMINAL INPUT .............................................................................................. 18

2-19. LOAD CURRENT SLEW RATE SETTING..................................................................................................... 18

2-20. EMERGENCY STOP AND ALARM ............................................................................................................ 20

2-21. LOAD WIRE INDUCTANCE...................................................................................................................... 21

CHAPTER 3 OPERATION............................................................................................................................... 24

3-1. FRONT PANEL DESCRIPTION (1) ............................................................................................................ 24

3-2. OPERATING INSTRUCTIONS .................................................................................................................. 25

3-3. FRONT PANEL DESCRIPTION (2) ............................................................................................................ 54

3-4. FRONT PANEL DESCRIPTION (3) ............................................................................................................ 56

3-5. OPERATING INSTRUCTIONS .................................................................................................................. 57

3-6. INITIAL SETTING OF 3350F SERIES LOAD MODULE ................................................................................... 65

3-7. INPUT BINDING POST AND WIRE CONSIDERATION..................................................................................... 68

3-8. LOAD CURRENT COURSE/FINE INCREASE/DECREASE ADJUSTMENT KNOB ................................................... 69

3-9. PROTECTION FEATURES ...................................................................................................................... 72

CHAPTER 4 REMOTE CONTROL PROGRAMMING OPERATION ................................................................ 73

4-1. INTRODUCTION ................................................................................................................................... 73

4-2. THE SUMMARY OF RS-232 INTERFACE AND COMMAND............................................................................ 73

4-3. 3350F REMOTE CO TROL COMMA D LIST1 ................................................................................ 74

4-4. THE DESCRIPTION OF ABBREVIATION ..................................................................................................... 83

4-5. REMOTE CONTROL COMMAND LANGUAGE DESCRIPTION ......................................................................... 83

4-6. REMOTE CONTROL COMMAND DESCRIPTION........................................................................................... 84

CHAPTER 5 APPLICATIONS ......................................................................................................................... 5

5-1. LOCAL SENSE CONNECTIONS................................................................................................................ 95

5-2. REMOTE SENSE CONNECTIONS............................................................................................................. 96

5-3. CONSTANT CURRENT MODE APPLICATION.............................................................................................. 97

5-4. CONSTANT VOLTAGE MODE APPLICATION ............................................................................................ 100

5-5. CONSTANT RESISTANCE MODE APPLICATION........................................................................................ 103

5-6. CONSTANT POWER MODE APPLICATION ............................................................................................... 105

5-7. CONSTANT CURRENT SOURCE OPERATION........................................................................................... 107

5-8. ZERO-VOLT LOADING APPLICATION ..................................................................................................... 108

5-9. PARALLEL OPERATION ....................................................................................................................... 108

5-10. POWER SUPPLY OCP TESTING .......................................................................................................... 109

5-11. POWER SUPPLY OPP TESTING .......................................................................................................... 111

5-12. POWER SUPPLY SHORT TESTING...................................................................................................... 113

APPENDIX A GPIB PROGRAMMING EXAMPLE ......................................................................................... 115

APPENDIX B 3350F USB INSTRUCTION ..................................................................................................... 118

APPENDIX C 3350F LAN INSTRUCTION ..................................................................................................... 120

APPENDIX D 3350F MAINFRAME AUTO. SEQU FUNCTION PROVIDE EDIT, ENTER, EXIT, TEST AND

STORE 5 KEYS OPERATION. ...................................................................................................................... 122

Figures

Fig 1-1 3350F Power Contour................................................................................................

Fig 1- 3351F Power Contour................................................................................................

Fig 1-3 335 F Power Contour................................................................................................ 3

Fig 1-4 3353F Power Contour................................................................................................ 3

Fig 1-5 3354F Power Contour................................................................................................ 3

Fig 1-6 3356F Power Contour................................................................................................ 4

Fig 1-7 Constant Current mode.............................................................................................. 4

Fig 1-8 Constant Resistance mode........................................................................................ 5

Fig 1-9 Constant Voltage mode ............................................................................................. 5

Fig 1-10 Constant Power mode ............................................................................................. 6

Fig 1-11 Dynamic Wave form................................................................................................. 6

Fig 1-1 Rise Time Transition Limitation................................................................................ 8

Fig -1 SET OF SWITCH..................................................................................................... 1

Fig - FUSE RECEPTACLE .............................................................................................. 13

Fig -3 3350F series GPIB Rear panel ................................................................................ 16

Fig -4 3350F Series Rs- 3 Rear panel............................................................................. 16

Fig -5 3350F USB Connection ........................................................................................... 16

Fig -6 3350F LAN Connection............................................................................................ 17

Fig -7 3350F GPIB & RS 3 Connection........................................................................... 17

Fig -8 Analog programming load current in CC mode operation......................................... 18

Fig -9 The relationship of load current load ON/OFF, load level and output voltage of DC

power............................................................................................................................ 19

Supply at turn ON ................................................................................................................ 19

Fig -10 Emergency stop controller Connection................................................................... 0

Fig -11 3350F series Rear panel........................................................................................ 0

Fig -1 Waveform example: Generate unstable oscillation.................................................

Fig -13 Length of wiring ..................................................................................................... 3

Fig 3-1 3350F-Series High Power Front Panel..................................................................... 4

Fig 3- 3350F Series High Power electronic load ................................................................ 5

Fig 3-3 Remote sense connection on front panel................................................................. 51

Fig 3-4 an equivalent circuit in terms of the current monitor ................................................. 5

Fig 3-5 (Correct) Connections to an oscilloscope................................................................. 5

Fig 3-6 (Wrong) Connections to an oscilloscope.................................................................. 53

Fig 3-7 EDIT MODE OPERATION FLOW CHART............................................................... 6

Fig 3-8 TEST MODE OPERATION FLOW-CHART ............................................................. 64

Fig 4-1 RS- 3 C INTERFACE CONNECTION OF REAR PANEL....................................... 73

Fig 5-1 Local voltage sense connections ............................................................................. 95

Fig 5- Remote voltage sense connections ......................................................................... 96

Fig 5-3 constant mode application ....................................................................................... 97

Fig 5-4 Dynamic load current with independent programmed Rise/Fall slew rate................. 98

Fig 5-5 Constant Voltage mode application........................................................................ 101

Fig 5-6 Constant Resistance mode Application.................................................................. 103

Fig 5-7 CONSTANT POWER MODE APPLICATION......................................................... 106

Fig 5-8 Constant current source connection....................................................................... 107

Fig 5-9 Zero-Volt loading connection ................................................................................. 108

Fig 5-10 Parallel operation connection............................................................................... 108

Tables

Table 1-1A 3350F Series Specifications ................................................................................ 9

Table 1-1B 3350F Series Specifications .............................................................................. 11

Table 3-1 3350F initialize..................................................................................................... 65

Table 3- 3351F initialize..................................................................................................... 65

Table 3-3 335 F initialize..................................................................................................... 66

Table 3-4 3353F initialize..................................................................................................... 66

Table 3-5 3354F initialize..................................................................................................... 67

Table 3-6 3356F initialize..................................................................................................... 67

Table 3-7 the resolution of range I/II vs. Course/Fine load setting Key................................. 71

Table 4-1 REMOTE CONTROL SETTING COMMAND SUMMARY .................................... 74

Table 4- REMOTE CONTROL QUERY COMMAND SUMMARY....................................... 75

Table 4-3 REMOTE CONTROL LIMIT COMMAND SUMMARY .......................................... 75

Table 4-4 STAGE COMMAND SUMMARY.......................................................................... 76

Table 4-5 SYSTEM COMMAND SUMMARY ....................................................................... 77

Table 4-6 MEASURE COMMAND SUMMARY .................................................................... 77

Table 4-7 Auto sequence command list ............................................................................... 78

Table 4-1B REMOTE CONTROL SETTING COMMAND SUMMARY.................................. 79

Table 4- B REMOTE CONTROL QUERY COMMAND SUMMARY..................................... 80

Table 4-3B REMOTE CONTROL LIMIT COMMAND SUMMARY........................................ 80

Table 4-4B STAGE COMMAND SUMMARY ....................................................................... 81

Table 4-5B SYSTEM COMMAND SUMMARY..................................................................... 81

Table 4-6B MEASURE COMMAND SUMMARY.................................................................. 8

Table 4-8B Auto sequence command list............................................................................. 8

Table 4-8 GPIB COMMAND TERMINATOR........................................................................ 83

Table 4-9 module for each series......................................................................................... 89

Table 4-10 register of PROT status...................................................................................... 91

Table 4-11 MODEL NUMBER.............................................................................................. 93

3350F Series Operation Manual 1

Chapter 1 Introduction

1-1. General description

The 3350F Series Electronic Load is designed to test, evaluation and burn-in of DC power

supplies and batteries.

The 3350F Series electronic load can be operated for manual and GPIB operation. The

power contour of 3350F 1 00 Watts Electronic Load is shown in Fig 1-1~1-6, it has an input

from 0-1 0A, and 0 -60V current and voltage operating range respectively. The power

contour of 3350F series. The prodigit 3350F Series high power electronic Load can be

controlled locally at the front panel or remotely via computer over the GPIB/RS-

3 C/USB/LAN. Current (CC) mode, Constant Resistance (CR) mode, and Constant Voltage

(CV) mode. and Constant Power ( CP ) mode. The wide range dynamic load with

independent rise and fall current slew rate and analog programming input with arbitrary

wave-form input is available in Constant Current mode.

2 PRODIGIT

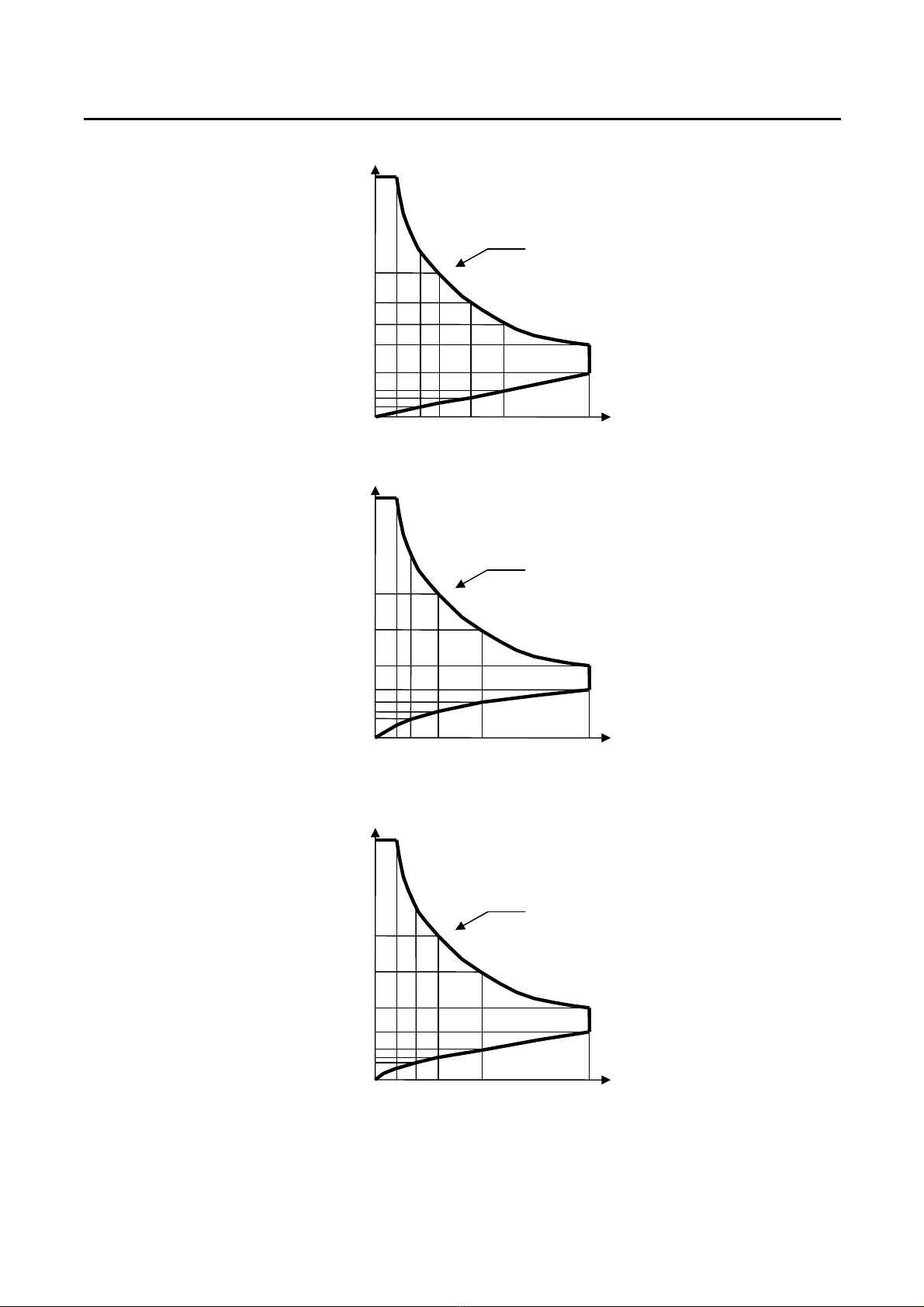

Fig 1-1 3350F Power Contour

Fig 1- 3351F Power Contour

1800W CONTOUR

120 A 30 40 60 90

60

30

20

0.4

Current

Voltage

0.1

15

0

0.15

0.225

1200W CONTOUR

120 A

20 30 60 80

60

20

15

0.

6

Current 0.1

10

0.3

0

0.4

Voltage

3350F Series Operation Manual 3

Fig 1-3 335 F Power Contour

Fig 1-4 3353F Power Contour

Fig 1-5 3354F Power Contour

1800W CONTOUR

360 A

30 60 90 180

60

20

10

0.

7

Current

0.1

5

0

0.3

Voltage

0.15

1800W CONTOUR

240 A 30 34.38 60 120

60

30

15

0.

7

Current

0.1

7.5

0

0.

3

5

0.175

Voltage

1200W CONTOUR

240 A

20 34.38 60 80 120

60

20

15

0.7

Current

0.1

5

0

10

0.23

0.35

Voltage

4 PRODIGIT

Fig 1-6 3356F Power Contour

CC Mode:

With the operating mode of constant current, the 3350F Series Electronic load will sink a

current in accordance with the programmed value regardless of the input voltage (see Fig.1-

7).

Fig 1-7 Constant Current mode

600W CONTOUR

120 A

10 30 60 90

60

1

0

6.66

0.

6

Current

0.1

5

0

0.225

Voltage

0.15

3350F Series Operation Manual 5

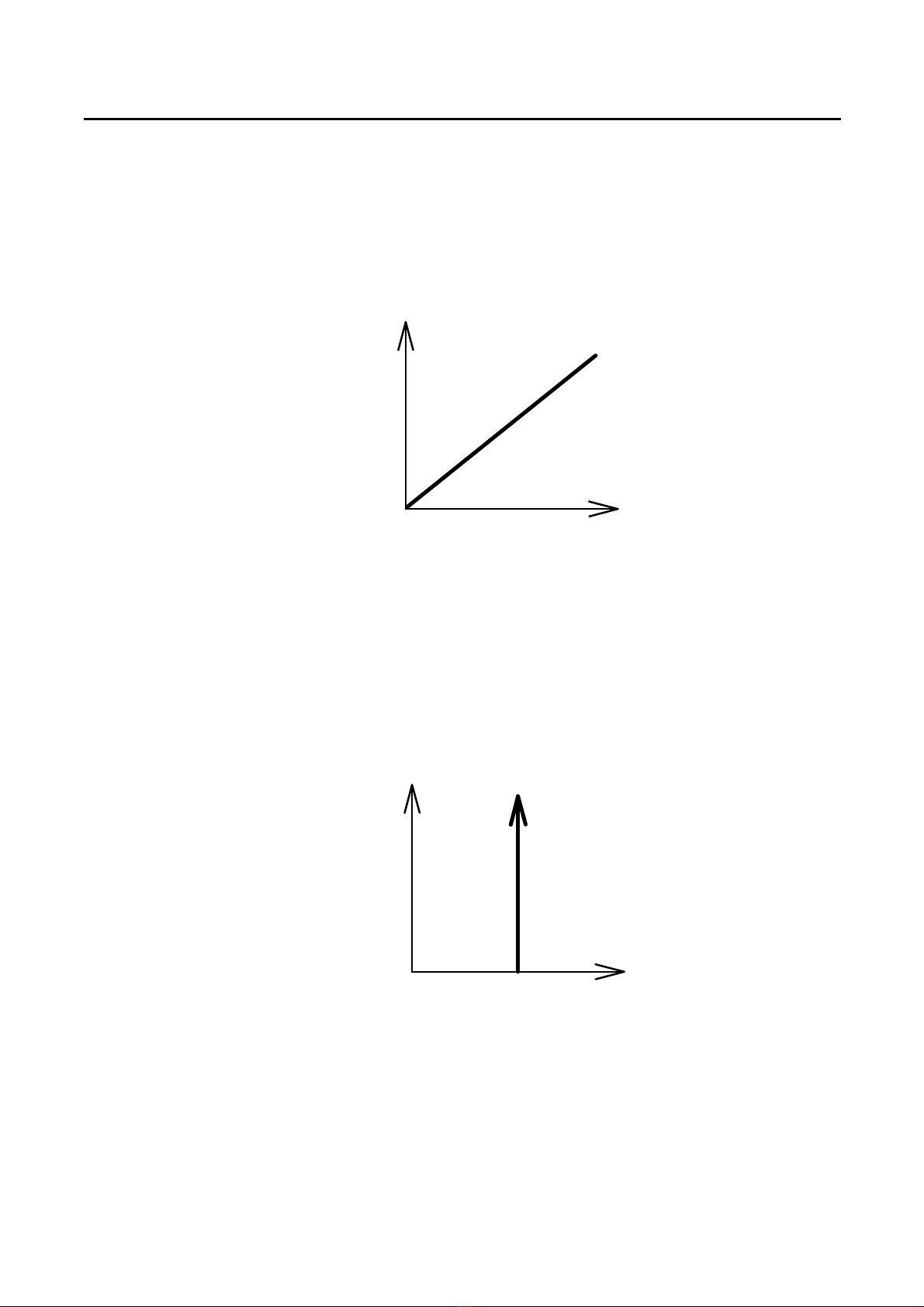

CR Mode:

At constant resistance mode, The 3350F Series Electronic Load will sink a current linearly

proportional to the load input voltage in accordance with the programmed resistance setting

(see Fig 1-8).

I

V

LOAD

CURRENT

INPUT VOLTAGE

RESISTANCE

SETTING

Fig 1-8 Constant Resistance mode

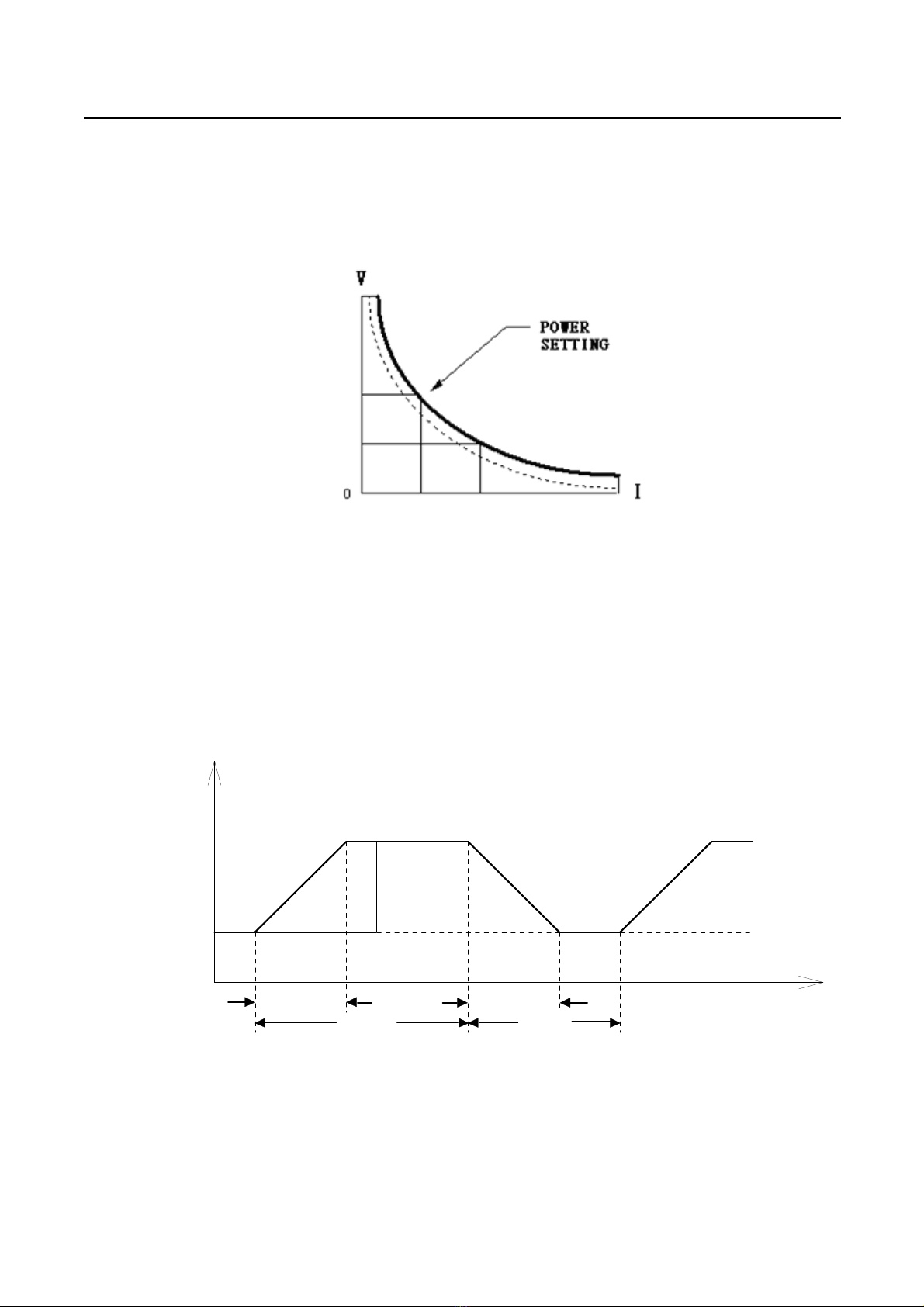

CV Mode:

At constant voltage mode, the 3350F Series Electronic Load will attempt to sink enough

current until the load input voltage is equaled to the programmed value (see Fig 1-9).

I

V

LOAD

CURRENT

INPUT VOLTAGE

VOLTAGE

SETTING

Fig 1-9 Constant Voltage mode

6 PRODIGIT

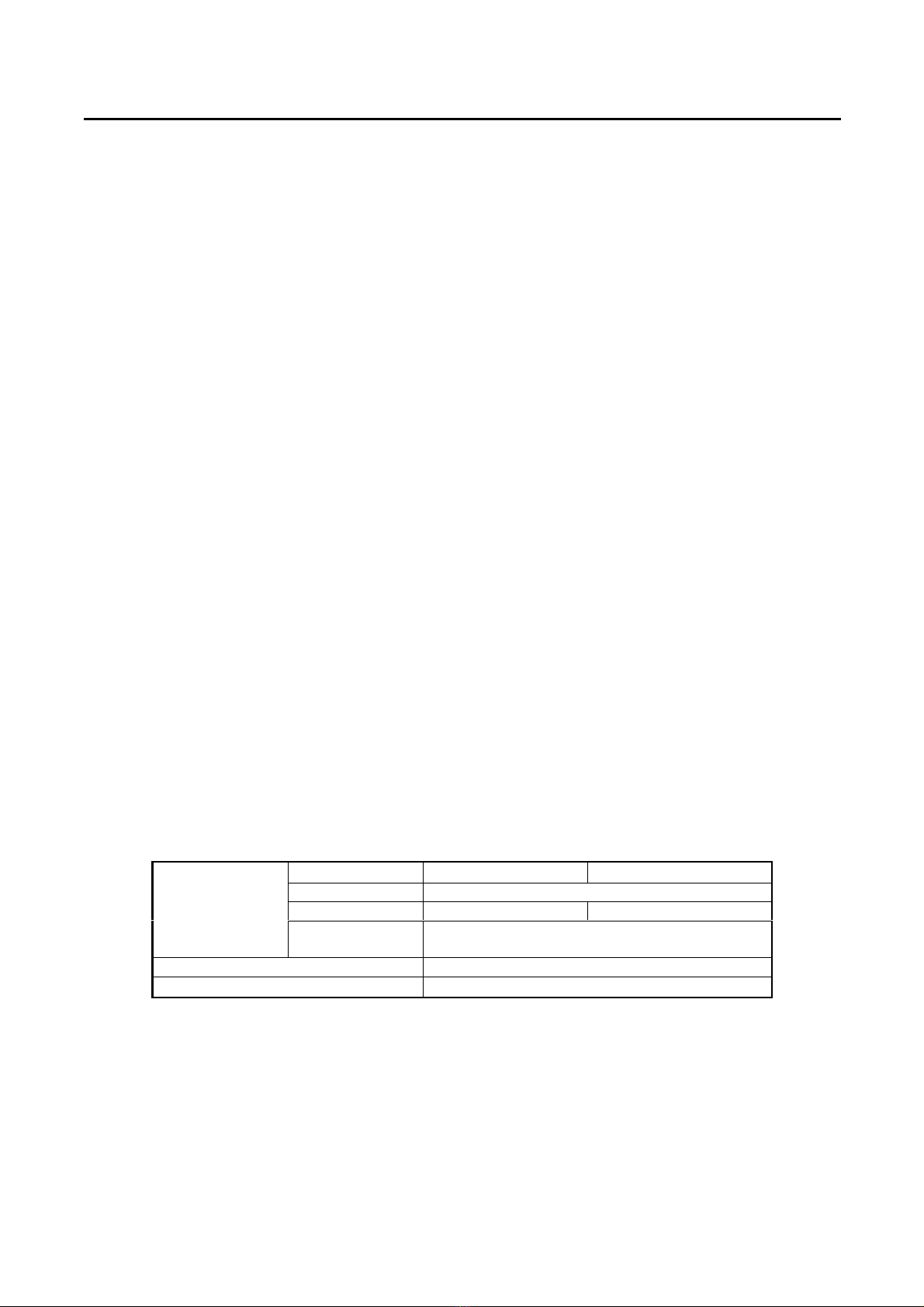

CP Mode:

At Constant Power mode, the 3350F Series Electronic Load will attempt to sink load power

(load voltage x load current) in accordance with the programmed power. (See Fig 1-10).

Fig 1-10 Constant Power mode

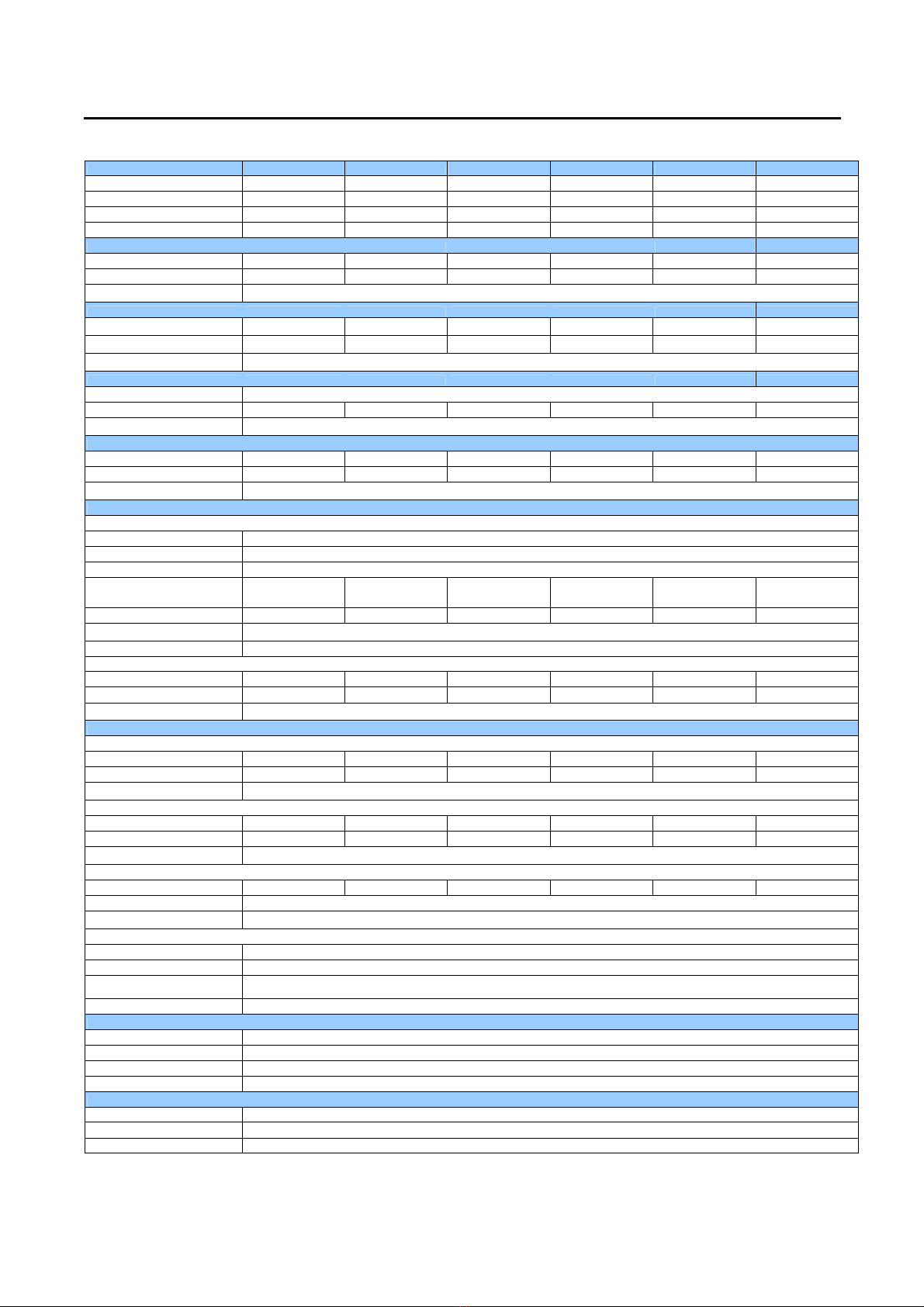

Dyna ic wave for definition:

There are six parameters to generate dynamic wave form or pulse wave form, the 3350F

Series Electronic Load will sink current from power source proportional to the dynamic wave

form, the dynamic wave form definition is shown in Fig 1-11. The period of dynamic wave form

is Thigh + Tlow, dynamic frequency = 1 / (Thigh + Tlow), the Duty cycle = Thigh / (Thigh + Tlow)

I

V

LOAD

CURRENT

RISE

SLEW RATE

HIGH LOAD

LOAD

LOW LOAD

LEVEL

THIGH TLOW

FALL SLEW RATE

Fig 1-11 Dynamic Wave form

3350F Series Operation Manual 7

The load current level and load status are can be set with Front panel on each module, GPIB

command. It is called manual operation and GPIB operation respectively, the load input

voltage and load current can be read back to computer through GPIB.

The GPIB operation is described in Chapter 4 GPIB operation.

Slew Rate:

Slew rate is defined as the change in current or voltage over time. A programmable slew rate

allows a controlled transition from one load setting to another to minimize induced voltage

drops on inductive power wiring, or to control induced transients on a test device (such as

would occur during power supply transient response testing).

In cases where the transition from one setting to another is large, the actual transition time can

be Calculated by dividing the voltage or current transition by the slew rate. The actual transition

time is Defined as the time required for the input to change from 10% to 90% or from 90% to

10% of the Programmed excursion. In cases where the transition from one setting to another is

small, the small Signal bandwidth of the load limits the minimum transition time for all

programmable slew rates. Because Of this limitation, the actual transition time is longer than

the expected time based on the slew rate, as Shown in Figure 1-1

Therefore, both minimum transition time and slew rate must be considered when determining

the actual transition time.

The minimum transition time for a given slew rate as about a 30% or greater load change, the

slew rate increases from the minimum transition time to the Maximum transition time at a 100%

load change. The actual transition time will be either the minimum transition time, or the total

slew time (transition divided by slew rate), whichever is longer.

Use the following formula to calculate the minimum transition time for a given slew rate

Min transition time = 36/slew rate (in amps/second)(7. us(36/5)*0.8(10%~90%)=5.76uS)

Use the following formula to calculate the maximum transition time for a given slew rate

Max transition time = 1 0/slew rate (in amps/second) ( 4us(1 0/5)*0.8(10%~90%)=19. uS)

EX. CCH= 4A, CCL=0A Slew Rate = 5A, The expected time is 3.84uS but the actual transition

time will be limited to 5.76uS((36/5)x0.8 )

8 PRODIGIT

Fig 1-1 Rise Time Transition Limitation

3350F Series Operation Manual 9

1-2. Features

1. .1. Flexible configuration of high power Electronic Load.

1. . . Fully GPIB control of Load condition setting and meter read back.

1. .3. Dual high accuracy & resolution 5 digit voltage and current meter.

1. .4. Built-in pulse generator includes wide Thigh/Tlow dynamic load range, independent

Rise/Fall load current slew rate control, and High/Low Load level.

1. .5. Controllable load current slew rate of load level change, load ON/OFF switch

change, and power supply turn ON.

1. .6. Short circuit test and current measure capability.

1. .7. Automatic voltage sense capability.

1. .8. Full protection from over power, over temperature, over voltage, and reverse polarity.

1. .9. Analog programming input capability at rear panel.

1-3. Accessories

1.3.1. 3350F series operation manual 1 PC

1.3. . M8 ROUND SCREW PCs

1.3.3. Vsense - Alligator Clip(red、black) Cable 1 PC

1.3.4. I-monitor - BNC Cable 1 PC

1.3.5. Power Cord 1 PC

1-4. Option

1.4.1. IEEE-488 cable (1 Meter)

1.4. . IEEE-488 cable ( Meter)

1.4.3. RS 3 interface

1.4.4. GPIB interface

1.4.5. USB interface + USB DRIVER CD

1.4.6. LAN interface + LAN DRIVER CD

1-5. Specifications

Table 1-1A 3350F Series Specifications

LI E 115V ± 10﹪ 230V ± 10﹪

FREQUE CY 50/60 Hz

FUSE T2A/250V(5×20 mm)

T1A/250V(5×20 mm)

AC I PUT

MAX. POWER

CO SUMPTIO

100 VA

DIME SIO S (W * H * D) 483 mm × 177 mm × 445Dmm/EA

WEIGHT ET:23.6 Kg

10 PRODIGIT

Model 3350F 3351F 3352F 3353F 3354F 3356F

Power 1200W 1800W 1200W 1800W 1800W 600W

Current 0~120A 0~120A 0~240A 0~240A 0~360A 0~120A

Voltage 0~60V 0~60V 0~60V 0~60V 0~60V 0~60V

Min. Operating Voltage 0.6V @ 120A 0.4V @ 120A 0.7V @ 240A 0.7V @ 240A 0.7V @ 360A 0.6V @ 120A

Constant Current Mode

ange *1 0~12A/120A 0~12A/120A 0~24A/240A 0~24A/240A 0~36A/360A 0~12A/120A

esolution 0.2mA/2mA 0.2mA/2mA 0.4mA/4mA 0.4mA/4mA 0.6mA/6mA 0.2mA/2mA

Accuracy ± 0.1% OF (Setting + ange)

Constant Resistance Mode

ange 0.0083~0.5~30KΩ

0.0083~0.5~30KΩ

0.0041~0.25~15KΩ

0.0041~0.25~15KΩ

0.0027~0.167~10KΩ

0.0083~0.5~30KΩ

esolution 0.0083mΩ/0.033mS

0.0083mΩ/0.033mS

0.0041mΩ/0.066mS

0.0041mΩ/0.066mS

0.0027mΩ/0.1mS 0.0083mΩ/0.033mS

Accuracy ± 0.2% OF (Setting + ange)

Constant Voltage Mode

ange 6V/60V

esolution 0.1mV/1mV 0.1mV/1mV 0.1mV/1mV 0.1mV/1mV 0.1mV/1mV 0.1mV/1mV

Accuracy ± 0.05% OF (Setting + ange)

Constant Power Mode

ange 120W/1200W 180W/1800W 120W/1200W 180W/1800W 180W/1800W 60W/600W

esolution 2mW/20mW 3mW/30mW 2mW/20mW 3mW/30mW 3mW/30mW 1mW/10mW

Accuracy ± 0.5% OF (Setting + ange)

Dynamic Mode CC

Timing

Thigh & Tlow 0.050~9.999 / 99.99 / 999.9 / 9999mS

esolution 0.001 / 0.01 / 0.1 / 1mS

Accuracy 1uS/10uS/100uS/1mS + 50ppm

Slew rate 8mA~500mA/uS

80mA~5000mA/uS

8mA~500mA/uS

80mA~5000mA/uS

0.016A~1A/uS

0.16A~10A/uS

0.016A~1A/uS

0.16A~10A/uS

0.024A~1.5A/uS

0.24A~15A/uS

8mA~500mA/uS

80mA~5000mA/uS

esolution 2/20mA/uS 2/20mA/uS 0.004/0.04A/uS 0.004/0.04A/uS 0.006/0.06A/uS 2m/20mA/uS

Accuracy (5% of setting) ± 10 uS

Min. ise Time 24uS(typical)

Current

ange *2 12A/120A 12A/120A 24A/240A 24A/240A 36A/360A 12A/120A

esolution 0.2mA/2mA 0.2mA/2mA 0.4mA/4mA 0.4mA/4mA 0.6mA/6mA 0.2mA/2mA

Accuracy ± 0.1% OF (Setting + ange)

Measurement

Voltage Read Back

ange (5 Digital) 0~6V/60V 0~6V/60V 0~6V/60V 0~6V/60V 0~6V/60V 0~6V/60V

esolution 0.1mV/1mV 0.1mV/1mV 0.1mV/1mV 0.1mV/1mV 0.1mV/1mV 0.1mV/1mV

Accuracy ± 0.025% OF ( eading + ange)

Current Read Back

ange (5 Digital) 0~12A/120A 0~12A/120A 0~24A/240A 0~24A/240A 0~36A/360A 0~12A/120A

esolution 0.2mA/2mA 0.2mA/2mA 0.4mA/4mA 0.4mA/4mA 0.6mA/6mA 0.2mA/2mA

Accuracy ± 0.1% OF ( eading + ange)

Power Read Back

ange (5 Digital) 0~1200W 0~1800W 0~1200W 0~1800W 0~1800W 0~600W

esolution 0.01W

Accuracy ± 0.125% OF ( eading + ange)

Program mode(Mainframe)

Sequence No. F1~9/16 Steps

T1/T2 (Dwell) 0.1S~9.9S/ epeat 9999

Load Setting(External

Programming) 0~10V for CC mode F.S.

GO/NG Check Voltage/Current/Power

Protections

Over Power 105% of ated Power

Over Current 105% of ated Current

Over Voltage 105% of ated Voltage

Over Temp. Yes

Interface(Mainframe)

S-232 Optional

GPIB Optional

USB Optional

3350F Series Operation Manual 11

Ethernet Optional

Others

Load ON Voltage

ange 0.1~25.0V

esolution 0.1V

Accuracy 1% of Setting + 0.25V

Load OFF Voltage

ange 0~25V

esolution Same as Voltage Meter

Accuracy Same as Voltage Meter

General

Short Circuit

Current 120A 120A 240A 240A 360A 120A

Temperature Coefficient 100ppm/℃(typical)

Power 100Wmax 100Wmax 100Wmax 100Wmax 100Wmax 100Wmax

Operating Temperature *2 0~40℃

Dimension(HxWxD) 177 x 440 x 445 mm/6.97x17.3x17.5 inch

Weight 19.4 kg / 42.77 lbs

23.6 Kg/52.03 lbs 19.4 kg / 42.77 lbs

23.6 Kg/52.03 lbs 23.6 Kg/52.03 lbs 15.2 Kg/33.51 lbs

Safety & EMC CE

Table 1-1B 3350F Series Specifications

This manual suits for next models

6

Table of contents

Other Prodigit Power Supply manuals