Production Basics 8539 User manual

Production Basics, Inc. Massachusetts, USA 800.318.2770 617-926-8100 Fax: 617-926-8010 www.pbasics.com

Note: For correct installation of Uprights, ensure•

theworksurfaceispositionedushwithbackof

the Easy-Lift workstation.

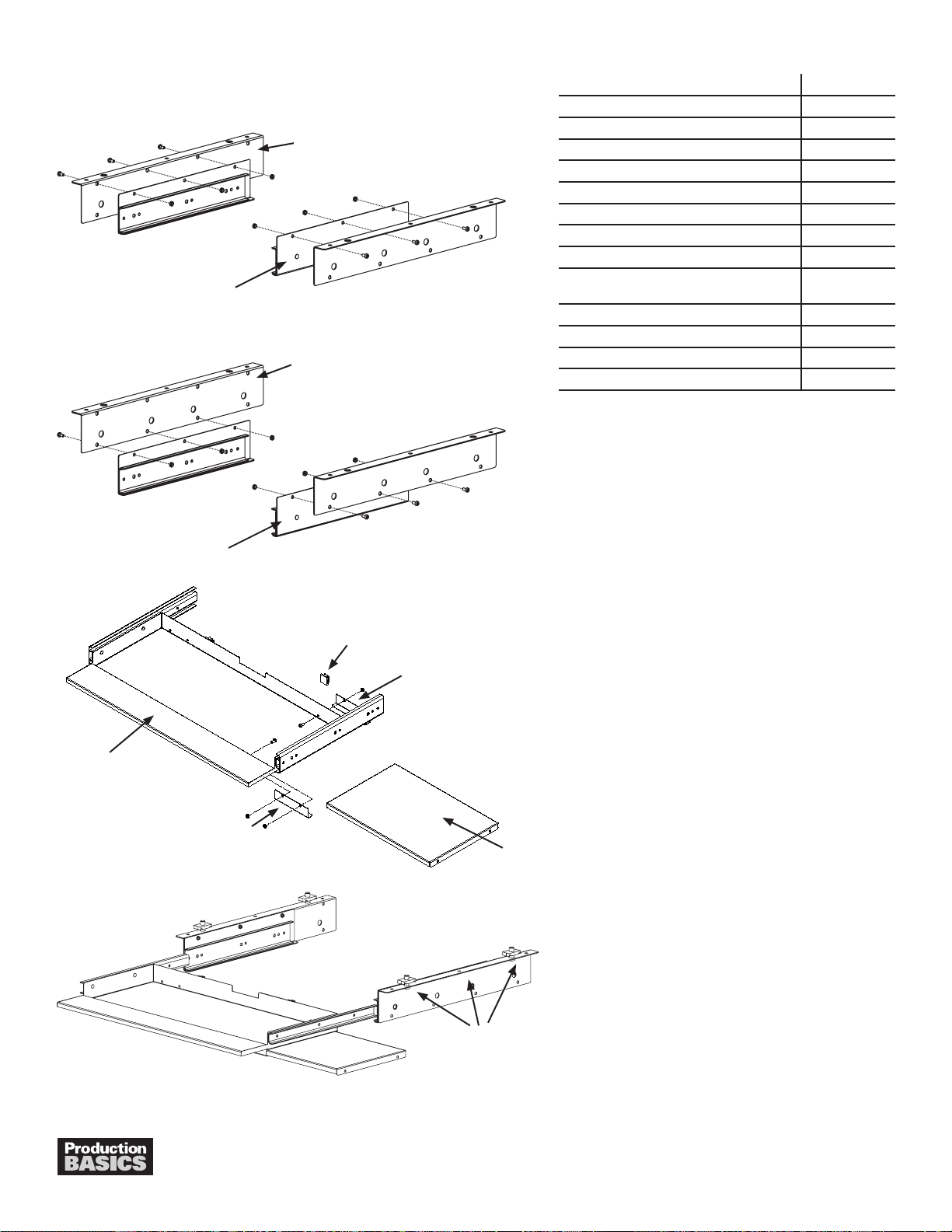

Insert a Basic Bolt and washer into each hole on the1. front of the integrated mounting plate. Secure with Basic

Nut. Turn only one revolution. Repeat for other mounting

plate.

Position Uprights against the two (2) Basic Nuts on each2. mounting plate. Turn Basic Bolts 90 degrees clockwise to

grip. Tighten the Bolts. Repeat for other Upright. Ensure

Uprights make contact with both Basic Nuts.

PARTS AND HARDWARE QUANTITY

Uprights 2

3” Bolts 4

Basic Nuts 4

Washers 4

Allen Wrench 1

UPRIGHTS: EASY LIFT, DUAL-LEG

Item Numbers 8539, 8540

Integrated Mounting Plate

1

Production Basics, Inc. Massachusetts, USA 800.318.2770 617-926-8100 Fax: 617-926-8010 www.pbasics.com

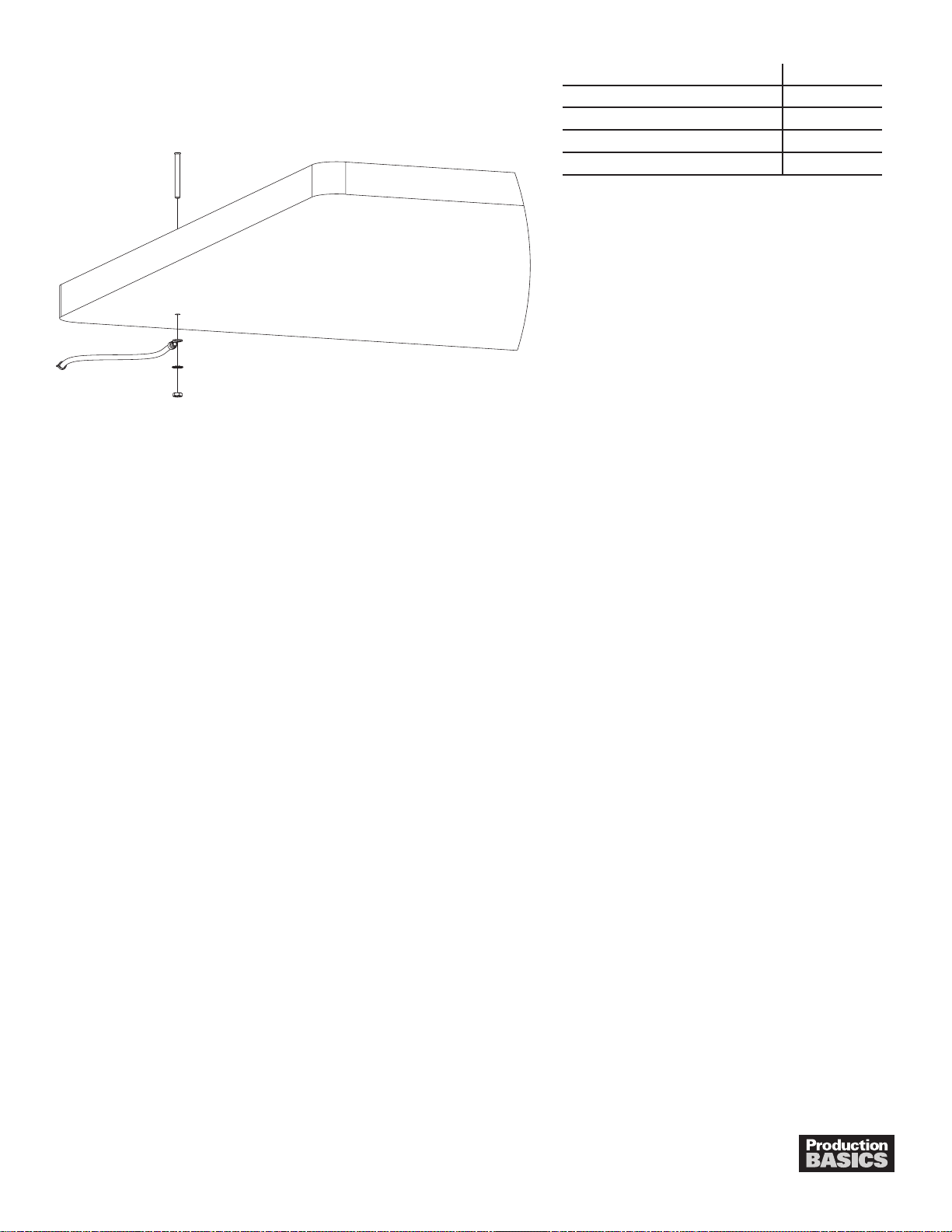

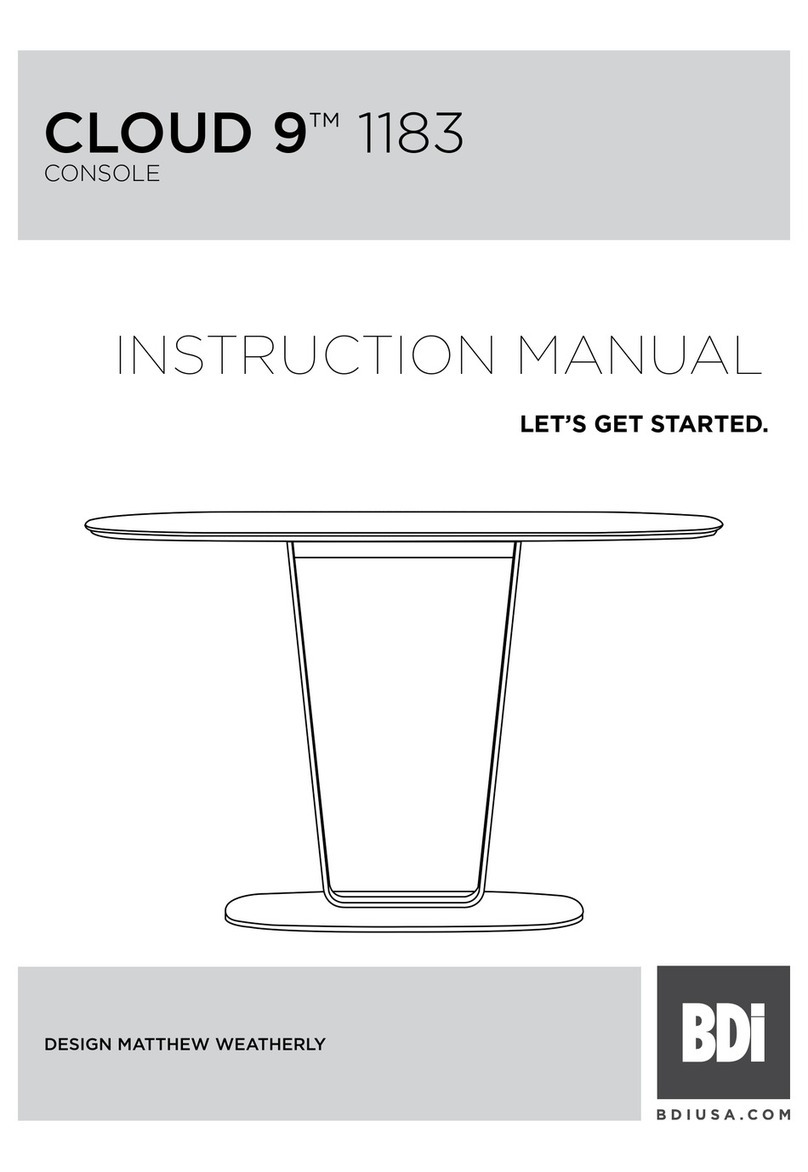

Insert Ground Bolt through top of worksurface through1. pre-drilled hole.

Slip ground wire over bolt underneath the worksurface.2. Add the nut and tighten.

Ground other end of wire to electrical ground.3.

For additional information on grounding, contact your4. company’s ESD manager or the ESD Association at

315.339.6937, www.esda.org.

GROUND BOLT

For ESD Laminate Worksurfaces and Shelving PARTS AND HARDWARE QUANTITY

Ground Bolt 1

Ground Wire 1

Washer 2

Nut 1

2

Production Basics, Inc. Massachusetts, USA 800.318.2770 617-926-8100 Fax: 617-926-8010 www.pbasics.com

ASSEMBLY MANUAL

Note: To install Overhead Arms• only, perform

steps 3 & 4.

Unscrew security screws on face of light unit. Remove1. plastic diffuser.

InsertT8lightbulbsintoxture.Pluglightintotest2. correct installation of bulbs. Replace diffuser and security

screws.

Insert two (2) Basic Bolts into mounting plate on3. Overhead Arm. Secure with Basic Nut. Turn only one

revolution. Repeat for other Overhead Arm.

Insert Basic Nuts attached to Overhead Arm mounting4. plate into frame channel of workstation and turn Basic

Bolt 90 degrees clockwise to grip. Top of mounting plate

shouldbeushwithtopofframecrossmember.Tighten

the bolts. Repeat for other Overhead Arm.

Insert a Basic Bolt from bottom into light mounting plate.5. Secure with Basic Nut. Turn only one revolution.

Position light unit with cord facing the frame. Insert Basic6. Nuts attached to light unit into Overhead Arm channel

and turn Basic Bolt 90 degrees clockwise to grip.

Slide the light unit to the desired position. Tighten the7. bolts. Slide End Caps onto front ends of Overhead Arms.

OVERHEAD LIGHT & OVERHEAD ARMS

Item Numbers 8500, 8504, 8505, 8510, 8538

A C C E S S O R I E S

PARTS AND HARDWARE QUANTITY

Overhead Arms 2

End Caps 2

Basic Bolts 4 (Arms only)

8 (With light)

Basic Nuts 4 (Arms only)

8 (With light)

Light Unit 1

Allen Wrench 1

Other Items Needed (not included)

24” T8 bulb for 36” 3

36” T8 bulb for 48” 3

48” T8 bulb for 60” & 72” 3

Phillips head screwdriver

Tape Measure

Diffuser

Overhead Arm

mounting plate

Security Screws

Light Mounting Plate

3

Note: Install Overhead Arms before Tool Trolley•

System.

Insert Basic Bolts into hole on Tool Track and secure1. with Basic Nut.

Position Track spanning the width of the Overhead Arms.2. Insert the Basic Nut into the Overhead Arm channel, turn

bolt 90 degrees and tighten.

Ensure an end cap is secure on each end of the Track

3. and there is a green ‘brake’ positioned on each end of

the track.

Remove security screws, plastic diffuser and light bulb.

1.

Position light unit with cord facing the frame. Attach light2. unit to laminate shelf using wood screws. Pre-drilled

holes are located behind bulb.

If attaching to Universal Shelf, insert bolt througha. shelf and into light. Secure with nut.

If attaching to Storage Cabinet, insert wood screwsb. through inside of light into Cabinet with drill.

Replace light bulbs, diffuser and security screws.

3.

Need Help? Call Assembly Support at 800.318.2770

TOOL TROLLEY SYSTEM

item Numbers 8339, 8340, 8343, 8346

UNDER SHELF LIGHT: LAMINATE AND UNIVERSAL SHELVES

Item Numbers 8523, 8524

Laminate Shelf

Universal Shelf

PARTS AND HARDWARE QUANTITY

Tool Track 1

Trolley with clip 1

Trolley Brake 2

Basic Bolts 4

Basic Nuts 4

End Caps 2

Allen Wrench 1

PARTS AND HARDWARE QUANTITY

Light Unit 1

Wood Screws 2

Bolts 2

Nuts 2

T8 Light Bulbs 1

Other Items Needed (not included)

Phillips head screwdriver or drill

4

Production Basics, Inc. Massachusetts, USA 800.318.2770 617-926-8100 Fax: 617-926-8010 www.pbasics.com

ASSEMBLY MANUAL

Note: Surface Mount method is not compatible•

with C-Leg Series workstations.

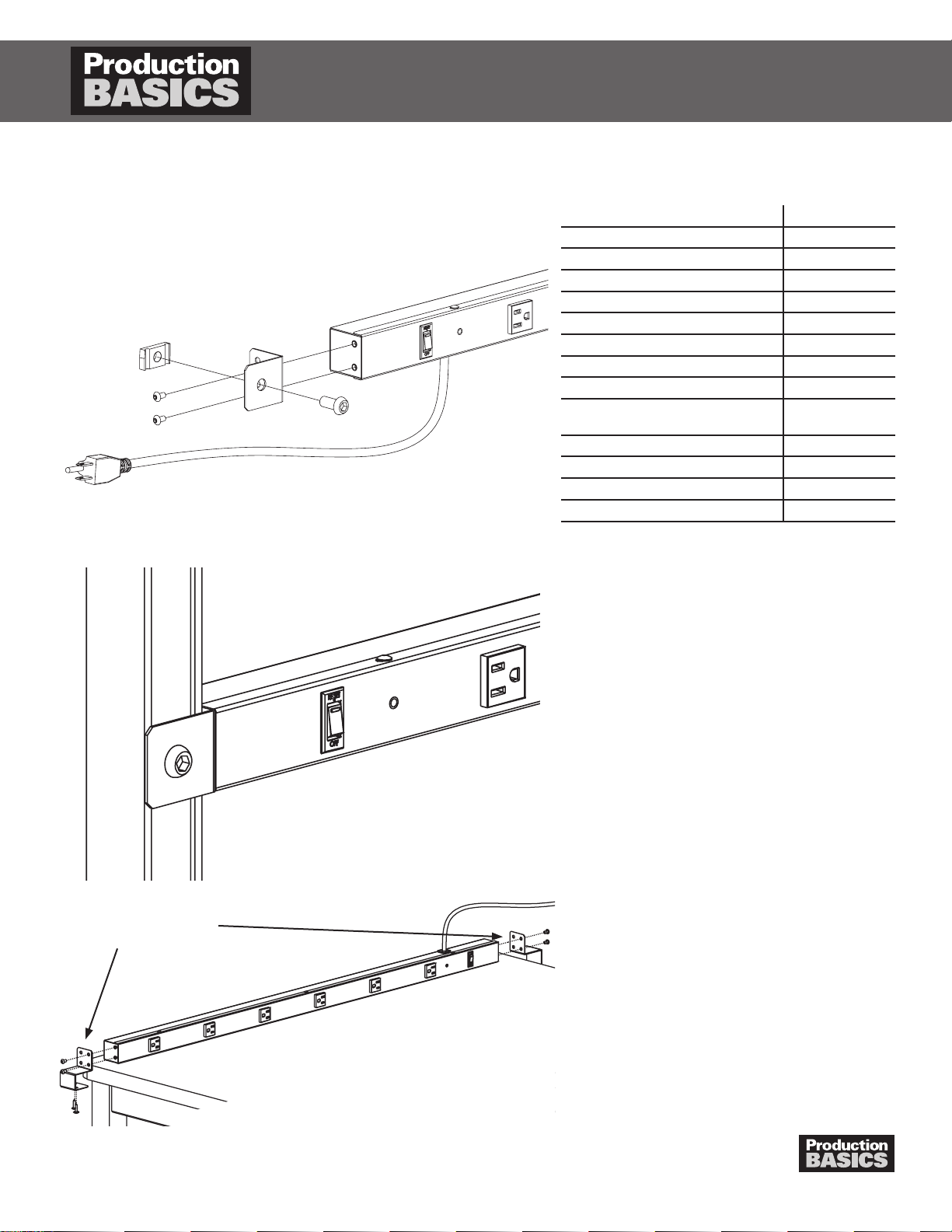

To install Power Rail to an Upright or Frame, attach1. brackets to Power Rail as shown.

Insert a Basic Bolt into bracket. Add a Basic Nut and turn2. one revolution.

Install Power Rail at any height on your Uprights, Frame3. or Overhead Arms.

Alternate mounting to RTW, Easy-Lift or existing work4. table: use enclosed bracket shown below to mount

Power Rail to your worksurface. Secure under the

worksurface with wood screws.

POWER RAIL

Item Numbers 8319-8322, 8324, 8326, 8327

ACCESSORIES

PARTS AND HARDWARE QUANTITY

Power Rail 1

Basic Bolt 2

Basic Nuts 2

Wood Screws 4

Bracket- frame mount 2

Bracket-table mount 2

Bracket bolts 4

Allen Wrench 1

Medium Allen Wrench for bracket

bolts 1

Other Items Needed (not included)

Phillips head screwdriver or drill

Tape measure

Level

Bracket attachment for

surface mount Power Rail

5

Production Basics, Inc. Massachusetts, USA 800.318.2770 617-926-8100 Fax: 617-926-8010 www.pbasics.com

ASSEMBLY MANUAL

Insert a Basic Bolt into the holes on the product’s1. mounting plate. Secure with a Basic Bolt by turning one

revolution.

Insert the nuts into the Frame or Uprights and tighten2. bolts.

Repeat for other side3.

Insert a Basic Bolt into the holes on the product’s1. mounting plate. Secure with a Basic Bolt by turning one

revolution.

Insert the nuts into the Frame or Uprights and tighten2. bolts.

Repeat for other side.3.

GLOBAL INSTALLATION: These instructions apply to the following accessories:

Peg Board Item Numbers 8721-8724

Bin Panel Enclosure Item Numbers 8312-8315

Tack Board Item Numbers 8729, 8730, 8733, 8735

Modesty Panel Item Numbers 8705, 8709, 8712, 8715

Magnetic Dry Erase Board Item Numbers 8716-8719

Multi- Panel Enclosures Item Numbers 8776-8797

GLOBAL INSTALLATION: These instructions apply to the following accessories:

Tool Shelf and Bin Rail Item Numbers 8492-8494

Universal Mount Item Numbers 8640, 8643

Cable Trough Item Numbers 8620-8623

Binder Holder Item Numbers 8352

Peg Board Panel Item Numbers 8626, 8649

Parts Bin Panel Item Numbers 8627, 8639

CRT MonitorTray Item Numbers 8630, 8631

Flat Screen MonitorArm Item Numbers 8632

Air Rail Item Numbers 8330, 8331, 8333, 8336

Bin Rail Item Numbers 8300, 8301, 8303, 8306

ACCESSORIES

PARTS AND HARDWARE QUANTITY

Basic Bolts 4

Basic Nuts 4

Allen Wrench 1

Other Items Needed (not included)

Tape Measure

Level

PARTS AND

HARDWARE QUANTITY

BASIC BOLTS BASIC NUTS

Tool Shelf and Bin Rail 2 2

Universal Mount 2 2

Cable Trough 2 2

Binder Holder 2 2

Parts Bin Panel 2 2

Air Rail 2 2

Bin Rail 2 2

Allen Wrench 1

Other Items Needed

(not included)

Tape Measure

Level

6

Need Help? Call Assembly Support at 800.318.2770

Attach extension to back of Parts Bin Rail by inserting1. a Basic Bolt through hole on the Bin Rail and into

Extension. Repeat for other side. Tighten bolts.

Insert Basic Bolt through mounting plate on Extension,2. secure with a Basic Nut, turning one revolution.

Insert the nuts into the Frame or Uprights and tighten3. bolts.

Insert Basic Bolt into holes on bracket. Secure with a

1. Basic Nut turning one revolution.

Insert Nuts into Frame or Upright and tighten bolts.2. Notches on brackets face inward, as shown. Repeat for

other bracket. Measure or use a level to ensure brackets

are at the same height.

Insert the bar clip into one of 3 positions on the bracket.3. Repeat for other bar clip in the same position.

Add labels, foam or paper rolls to rod and nest rod into4. each bar clip.

Insert Basic Bolt into holes on bracket. Secure with a Basic

1. Nut turning one revolution.

Position brackets on the left and right, as shown. Insert2. Nuts through bracket and into Frame or Upright as shown

in diagram and tighten bolts. Repeat for other bracket.

Measure or use a level to ensure brackets are at the same

height.

Position rail supports as shown. Line up holes on rail3. supports with bracket holes. Insert a handle into the hole

from the inside (recommended) and secure with a kep nut.

To install slide rails, position rails to accommodate your4. circuit boards and insert a threaded stud through the

bottom of the rail support and slide rail. Secure with silver

knob.

BIN RAIL EXTENSION

Item Numbers 8308, 8310

ENCLOSURES: PAPER ROLL HOLDER

Item Numbers 8740-8743

ENCLOSURES: SLIDE LINE

Item Numbers 8770- 8773

Bin Rail Extension

Bar Clip

Rail Support

Slide Rails

Threaded Stud

Bracket

PARTS AND HARDWARE QUANTITY

Basic Bolts 2

Basic Nuts 2

Bin Rail Extension 2

Allen Wrench 1

PARTS AND HARDWARE QUANTITY

Paper Roll Bar 1

Brackets 2

Bar Clip 2

Basic Bolts 4

Basic Nuts 4

Allen Wrench 1

PARTS AND HARDWARE QUANTITY

Slide Rails 2

Brackets 2

Rail Support 2

Basic Bolts 2

Basic Nuts 2

Handles 2

Kep Nut 2

Threaded Stud and Knob 4

Allen Wrench 1

Paper Roll Bar

Brackets

7

Production Basics, Inc. Massachusetts, USA 800.318.2770 617-926-8100 Fax: 617-926-8010 www.pbasics.com

ASSEMBLY MANUAL

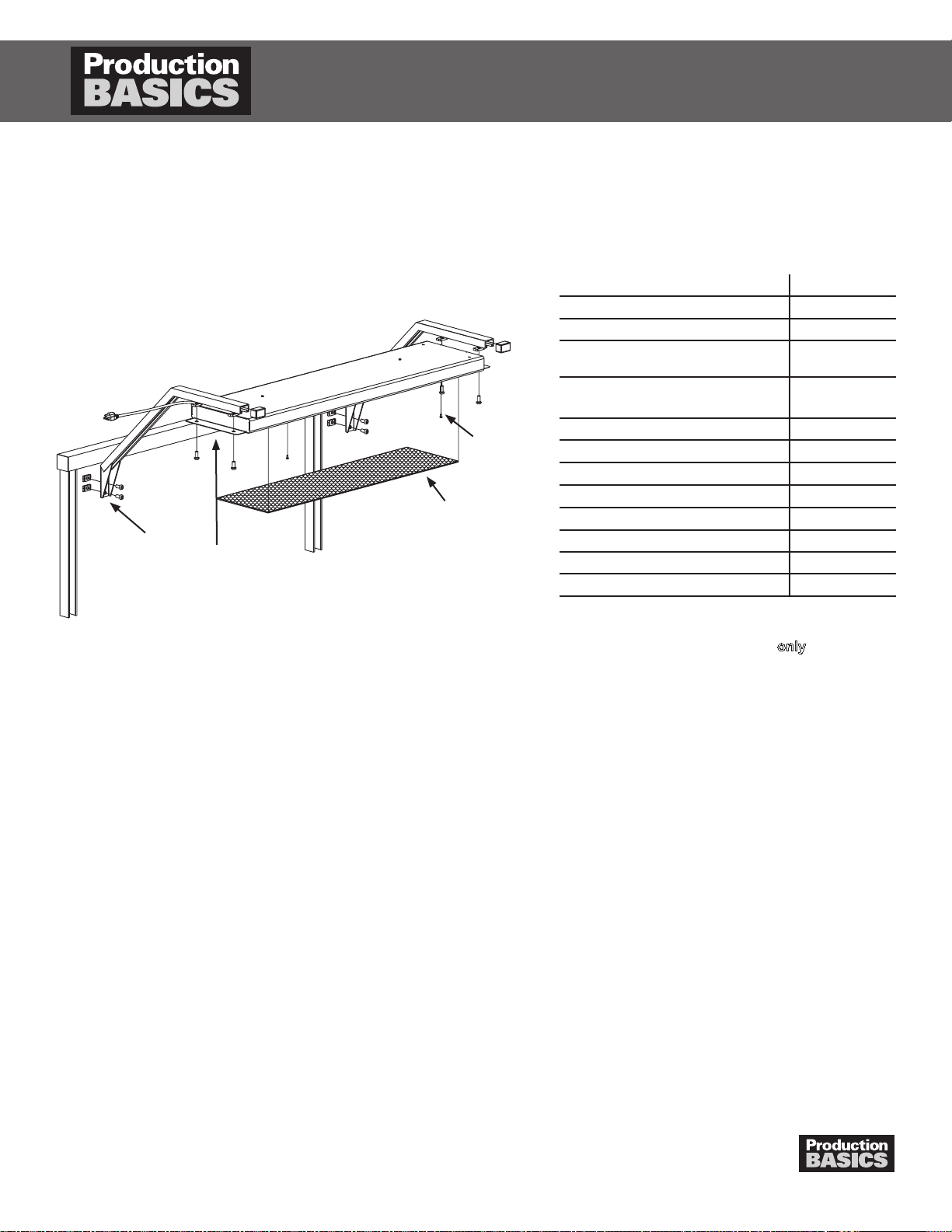

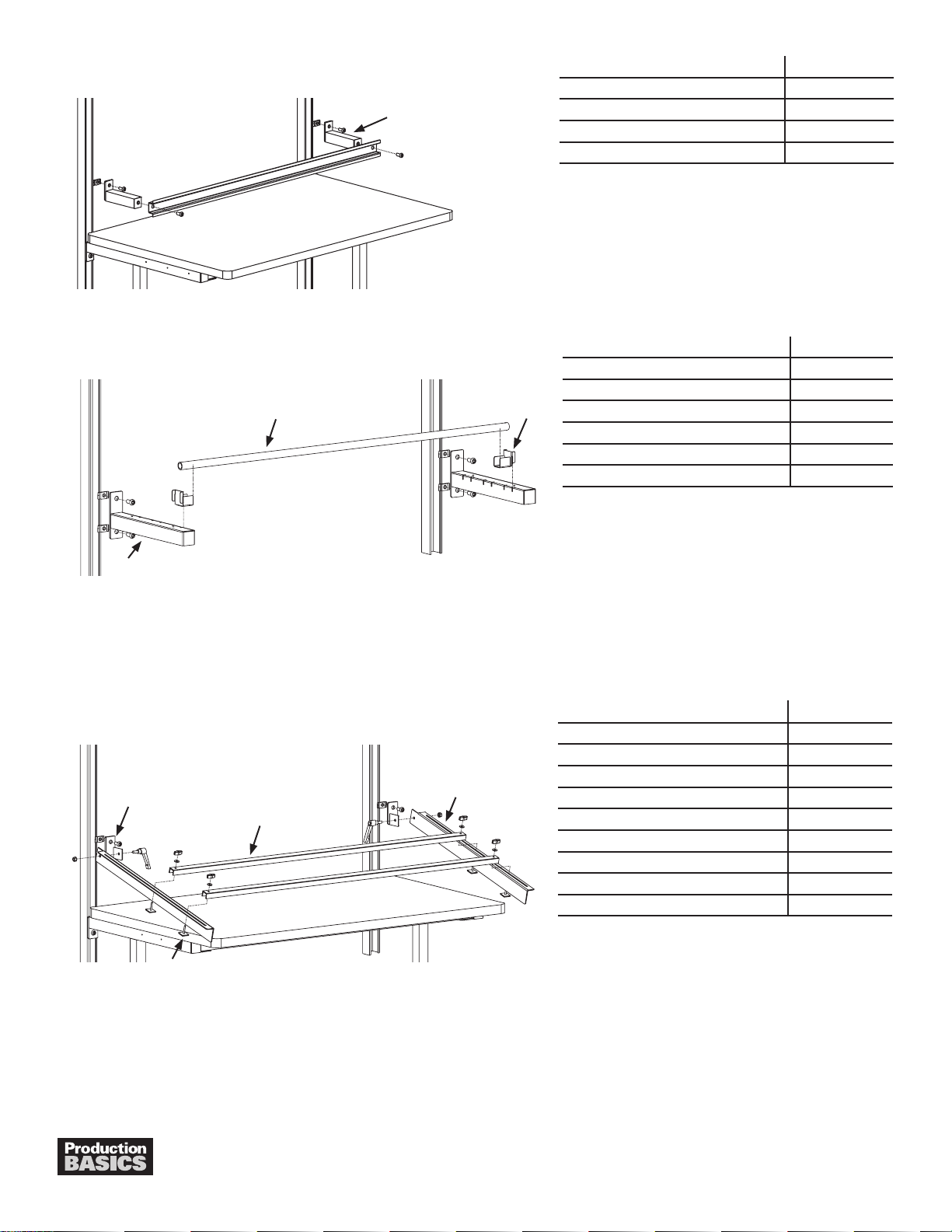

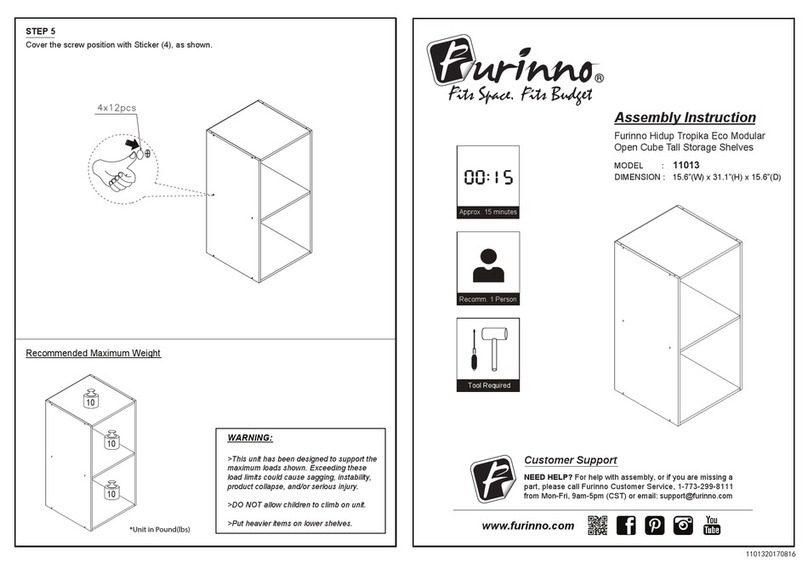

Insert Basic Bolt into holes on bracket. Secure with a1. Basic Nut turning one revolution.

Insert Nuts into Frame or Upright and tighten bolts.2. Notches on brackets face inward. Repeat for other

bracket. Measure or use a level to ensure brackets are

at the same height.

Insert the shelf cross bar into frontmost position3. (recommended).

Place shelf on top of bracket installation and secure with

4. wood screws underneath the shelf.

SHELVING: LAMINATE SHELF

Item Numbers 8417-8439, 8449-8461

ACCESSORIES

PARTS AND HARDWARE QUANTITY

Laminate Shelf 1

Brackets 2

Cross Bar 1

Basic Bolts 4

Basic Nuts 4

Wood Screws 8

Allen Wrench 1

Other Items Needed (not included)

Phillips head screwdriver or drill

Tape Measure

Level

Bracket

Shelf Cross Bar

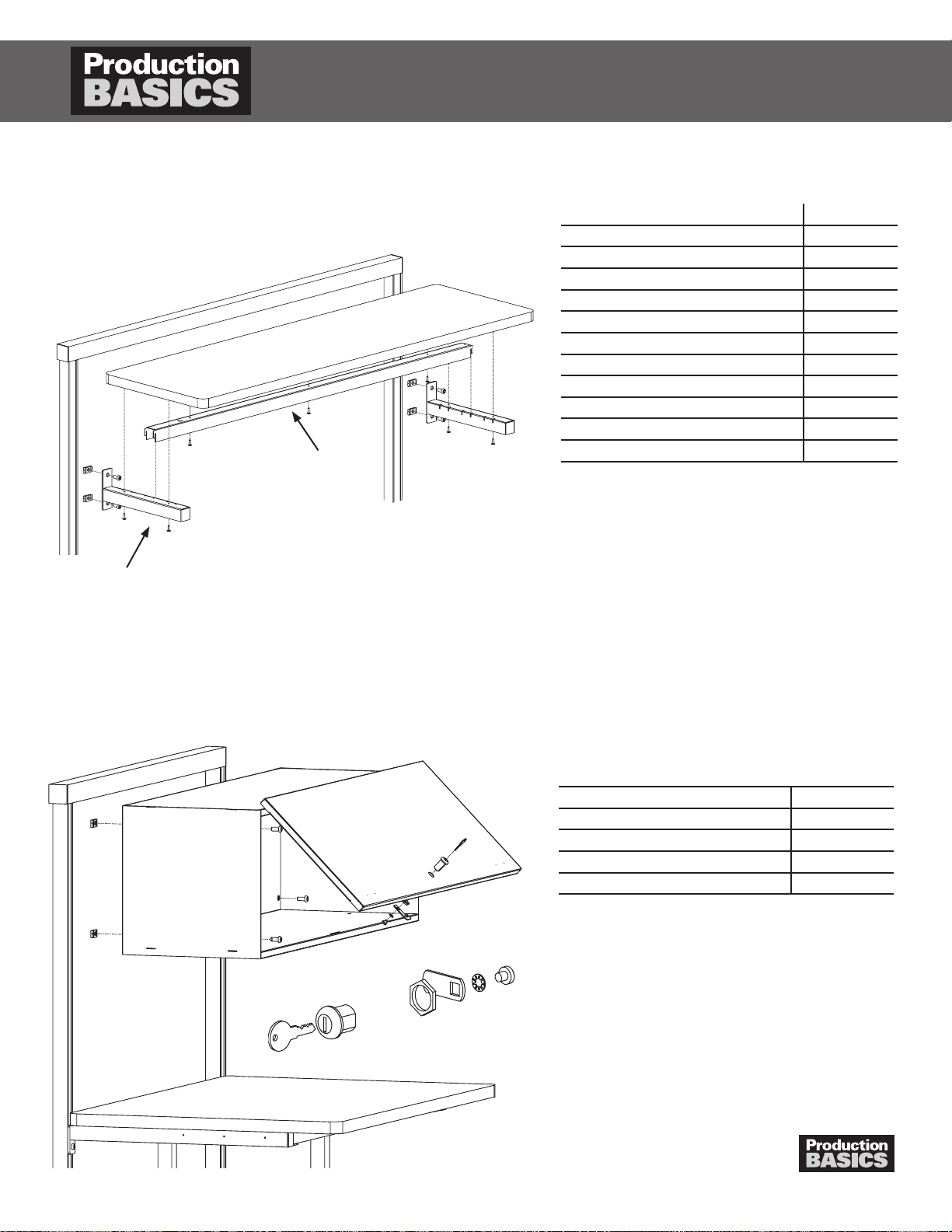

Open Storage Cabinet and slide door back.1.

Insert Basic Bolts into the holes on the inside corners2. of the Cabinet. Secure with a Basic Nuts and turn one

revolution.

Position Storage Cabinet on frame and turn bolts 903. clockwise to grip channel. Tighten bolts.

To install the lock, push the lock mechanism through4. the hole in front right side of the drawer. Assemble as

shown. Ensure the unthreaded part of the lock and the

key teeth face upwards.

PARTS AND HARDWARE QUANTITY

Storage Cabinet

Lock mechanism

Basic Bolts

Basic Nuts

Allen Wrench

STORAGE CABINET

Item Numbers 8551-8553

Lock Detail

1

1

4

4

1

8

Production Basics, Inc. Massachusetts, USA 800.318.2770 617-926-8100 Fax: 617-926-8010 www.pbasics.com

ASSEMBLY MANUAL

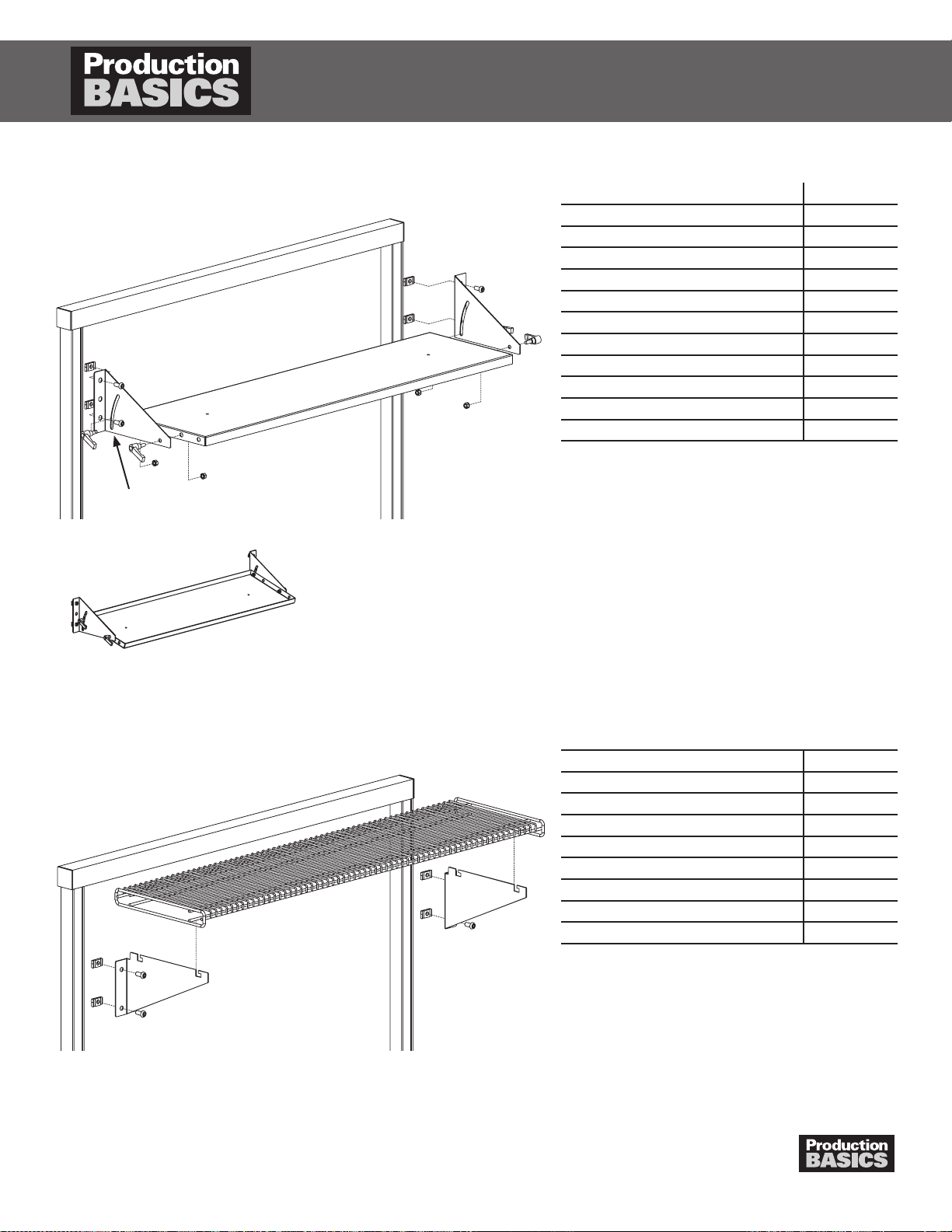

Insert Basic Bolt into holes on shelf bracket. Secure with1. Basic Nut and turn only one revolution. Repeat for other

side of bracket.

Position brackets as shown. Insert Basic Nuts attached2. to shelf bracket tabs into frame channel. Turn Basic Bolt

90 degrees clockwise to grip.

Slide brackets to desired height. Measure or use a level3. to ensure brackets are at the same height.

Position shelf to line up with adjustment slots on bracket.4. Insert handle from outside into adjustment slots and

secure with star washer and nut. Repeat for all four

handles.

Insert Basic Bolt into holes on shelf bracket. Secure with

1. Basic Nut and turn only one revolution. Repeat for other

bracket.

Position brackets as shown. Insert Basic Nuts attached2. to shelf bracket tabs into frame channel. Notches

indicate top of bracket. Turn Basic Bolt 90 degrees

clockwise to grip. Measure or use a level to ensure

brackets are at the same height.

Attach the shelf to the bracket. Nest shelf in notches and3. pull forward to lock in place.

ACCESSORIES

PARTS AND HARDWARE QUANTITY

Laminate Shelf 1

Brackets 2

Basic Bolts 4

Basic Nuts 4

Handles 4

Kep Nuts 4

Allen Wrench 1

Other Items Needed (not included)

Phillips head screwdriver or drill

Tape Measure

Level

Universal Shelf- inverted with a 1” lip.

Adjustment Slot

SHELVING: WIRE

Item Numbers 8400, 8401, 8403, 8406 PARTS AND HARDWARE QUANTITY

Wire Shelf 1

Brackets 2

Cross Bar 1

Basic Bolts 4

Basic Nuts 4

Allen Wrench 1

Other Items Needed (not included)

Tape Measure

Level

Note:UniversalShelfcanbeinstalledasat•

surface or sloped with a 1-inch lip.

SHELVING: UNIVERSAL

Item Numbers 8390-8397, 8410-8416

Bracket

9

Need Help? Call Assembly Support at 800.318.2770

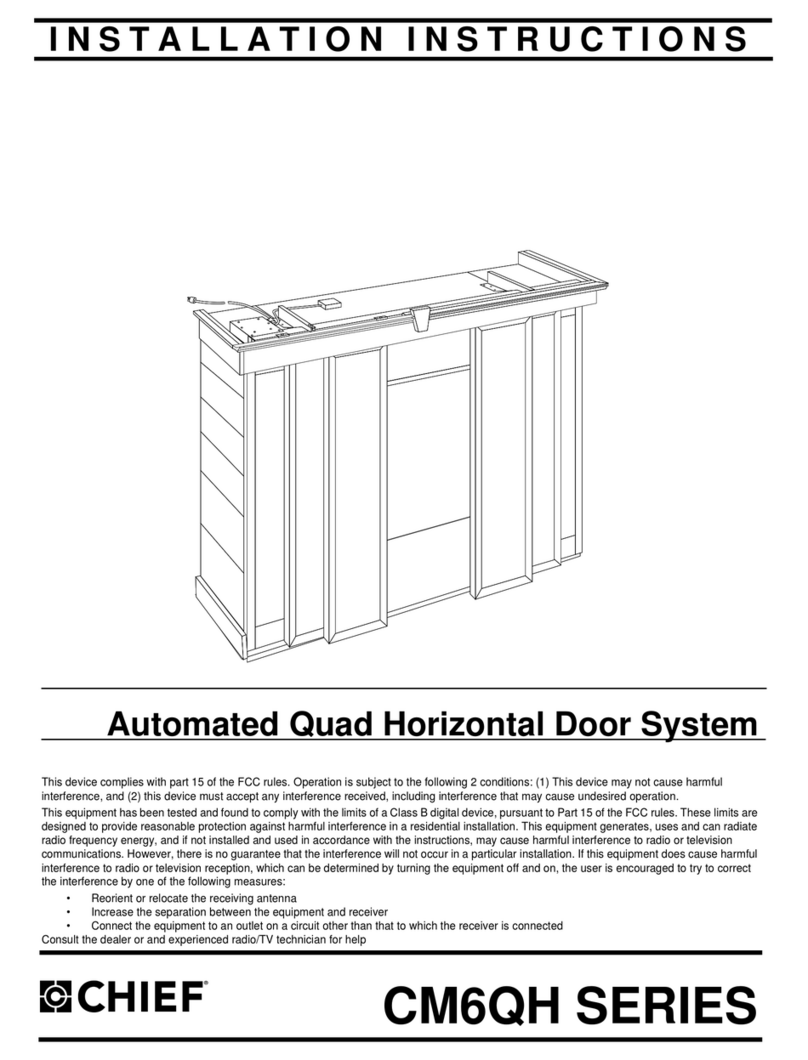

Remove the drawer from the chassis by pushing down1. on the black tabs on both sides of the drawer and pull

the drawer forward. If installing cabinet, start with Step 2.

Using the allen wrench, punch out the lock knock-out on2. the front side of the drawer or cabinet. Assemble lock

mechanism as shown. Ensure the unthreaded part of the

lock and key teeth face upward.

Insert a Basic Bolt from the inside of the drawer or3. cabinet chassis and secure with Basic Nut, turning one

revolution. Repeat for all four corners.

Insert attached Basic Nuts into Worksurface Support4. Rail channel and turn Basic Bolt 90 degrees clockwise to

grip. Position chassis under worksurface as desired and

tighten bolts.

If stacking items, insert small bolt from above intoa. the pre-drilled hole in bottom back of chassis and

lightly secure with nut and washer.

Align second chassis’ back keyhole slot with nutsb. and pull forward. This will help you support the

drawer while securing other nuts and bolts for

stacking drawers.

Give all nuts and bolts a final tightening.c.

Push in drawer slides on chassis and insert complete5. drawer into chassis.

DRAWERS & SUSPENDED CABINET:

C-LEG AND EASY-LIFT, DUAL LEG UNITS

Item Numbers 8600, 8605, 8607, 8610, 8613, 8615, 8617 PARTS AND HARDWARE QUANTITY

Drawer 1

Drawer or Cabinet Chassis 1

Lock Mechanism 1

Keys 2

Basic Bolts 4

Basic Nuts 4

Bolts (used for stacking drawers) 4

Kep Nuts (used for stacking drawers) 4

Washers (used for stacking drawers) 4

Allen Wrench 1

Other Items Needed (not included)

Phillips head screwdriver

Open end wrench

Black tabs- push in to release drawer

Keyhole details for

stacking drawers

Use hole set for hanging

first drawer -step 3

10

Production Basics, Inc. Massachusetts, USA 800.318.2770 617-926-8100 Fax: 617-926-8010 www.pbasics.com

ASSEMBLY MANUAL

Keyboard tray is positioned between monitor and1. mounting plate. Use provided screws to secure all 3 items

in order shown.

To adjust tension and swivel of Flat Screen Monitor Arm,2. remove plastic end caps and use included T-handle

wrench to adjust.

Before assembling the keyboard support with the

1. enclosed instructions, attach mounting plate to adapter

using button head bolts and nuts provided. See diagram

at left.

Insert a Basic Bolt into the corner holes of the adapter2. and secure with a Basic Nut. See diagram at left. For

RTW Tables, proceed to step 4a.

Insert nuts attached to adapter into Worksurface Support3. Rails on your workstation, as shown. Turn Basic Bolt 90

degrees clockwise to grip. Tighten the bolts.

Proceed with enclosed instructions for your keyboard.4.

For RTW Tables, insert wood screws through holesa. on tabs to attach Keyboard Support to underside of

worksurface.

Secure the wrist support by inserting plastic screws from

5. the bottom and tighten.

FLAT SCREEN MONITOR ARM WITH ADD-ON KEYBOARD TRAY

Item Numbers 8632 + 8633

ADJUSTABLE KEYBOARD SUPPORT

Item Numbers 8680

PARTS AND HARDWARE QUANTITY

Keyboard Tray 1

Phillips head screws 4

Other Items Needed (not included)

Phillips Head Screwdriver

ACCESSORIES

PARTS AND HARDWARE QUANTITY

Adapter Plate 1

Mounting Plate 1

8/32 Button head bolt 6

Nuts 6

Washers 6

Wood screws 4

Basic Bolts 4

Basic Nuts 4

Allen Wrench 1

Small Allen Wrench 1

See Step 1

Adapter Plate

See Step 4a for RTW Tables,

Easy-Lift 4-Post

See Step 2 for C-Leg,

Easy-Lift Dual-Leg

Mounting Plate

Adapter Plate

11

Need Help? Call Assembly Support at 800.318.2770

Using three (3) 3/8” nuts and bolts, assemble Upper and1. Lower Side Brackets as shown for right and left brackets,

according to your style of workstation (C-Leg, Easy-Lift,

RTW or PedSys). Set aside until step 4.

Choose right or left side for mouse tray. Using two (2)2. 3/8” bolts, hex nuts and washers, install the mouse pad

bracket onto the keyboard tray under the back lip of the

wrist rest. Slide the tray onto the bracket and repeat

for the rear mouse pad bracket with tray in place. The

mouse tray should slide freely. A lip on the tray acts as

a stop.

Attach adhesive backed cable clip to back of keyboard3. tray. These hold your mouse and keyboard wires in

place.

For C-Leg and Easy-Lift workstations insert a Basic4. Bolt through the two (2) large holes on top of each

bracket from step 1. Secure with a Basic Nut. Turn one

revolution.

For RTW, use wood screws to attach to underside ofa. worksurface. Go to Step 6.

Position the keyboard under the workstation. Insert the

5. Basic Nuts attached to the bracket into the Worksurface

Support Rail and tighten the bolts.

Slide keyboard onto left and right side brackets as6. shown.

PARTS AND HARDWARE QUANTITY

Upper Side Bracket 2

Lower Side Bracket 2

Basic Bolts 4

Basic Nuts 4

Keyboard Drawer 1

Cable Clip 2

Mouse Pad Bracket 2

Mouse Tray 1

Nuts & 3/8” Bolts for Upper and Lower

Side Brackets, Mouse Pad Bracket 10

Wood Screws 6

Small Allen Wrench 1

Other Items Needed (not included)

Phillips head drill

KEYBOARD DRAWER

item Number 8681

Upper side Bracket- C-leg/Easy-Lift Dual Leg, left side

Lower Side Bracket C-Leg/EasyLift Dual Leg, right side

Upper side Bracket- RTW/Easy-Lift 4-Post, left side

Lower Side Bracket RTW/Easy-Lift 4-Post, PedSys, left side

Cable Clip

Mouse Tray

Completed Keyboard Drawer for

C-Leg/Easy Lift Dual Leg

See Step 4a for RTW Table,

Easy-Lift 4-post, PedSys

Wrist Rest

Rear Mouse Pad Bracket

Mouse Pad Bracket

12

This manual suits for next models

1

Table of contents

Other Production Basics Indoor Furnishing manuals

Popular Indoor Furnishing manuals by other brands

Wisteria Lane

Wisteria Lane KX-AL01-1 instruction manual

BDI

BDI CLOUD 9 1183 instruction manual

VONDOM

VONDOM SUAVE 44310 Assembling instructions

Bestway

Bestway P3073 owner's manual

Home Decorators Collection

Home Decorators Collection Ellia HDC30MFV Use and care guide

Furinno

Furinno 11013 Assembly instruction

Furniture of America

Furniture of America YNJ-15409 Assembly instructions

CHIEF

CHIEF CM6QH SERIES installation instructions

Keter

Keter PIU-TALL Assembly instructions

Richard Lampert

Richard Lampert EIERMANN 1 Assembly instruction

John Lewis

John Lewis 836 78003 manual

Badger Basket

Badger Basket 09130 Assembly instructions