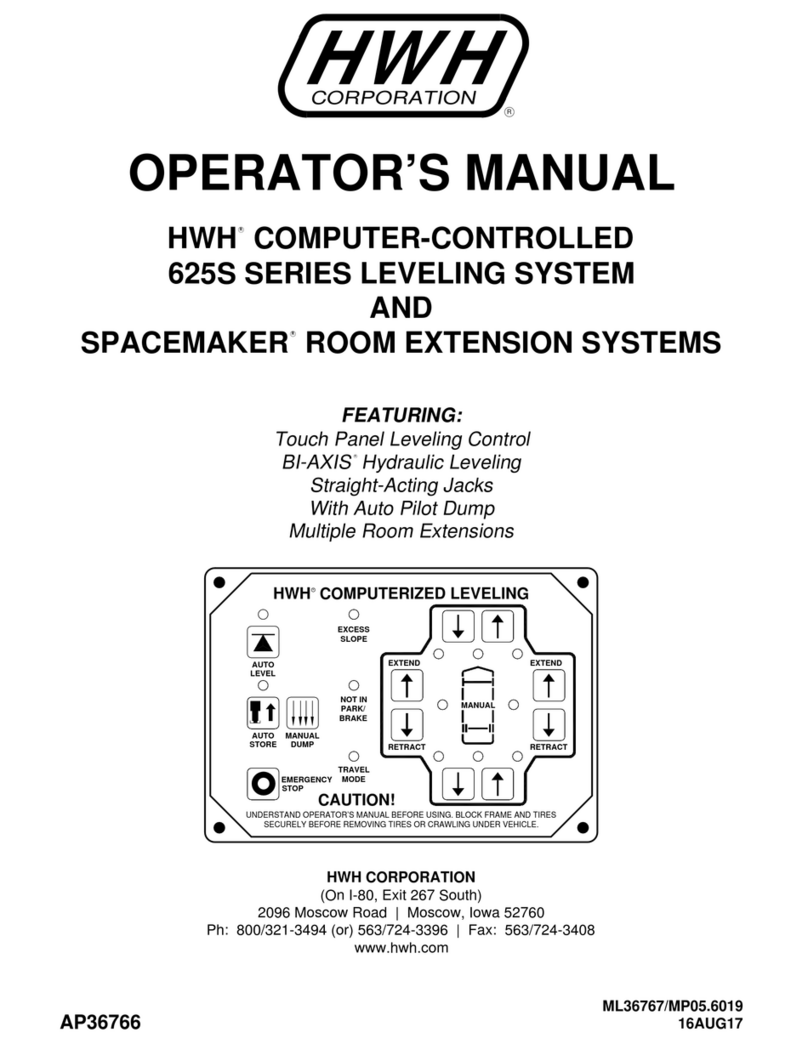

Profire Energy PF3100 Series User manual

PF3100 MANUAL

with UI, BMS Controller, Network Expansion,

Modbus RS-485, Ion Pilot, and Thermocouple Cards

REV: 1.0

IMPORTANT SAFETY INFORMATION

Ambient Operating Temperature Range-40°C to +60°C

GENERAL WARNINGS

Installation & use must conform to the directions in this guide.

System must be properly connected to earth-ground for effective operation of flame detection circuitry.

Electrical devices connected to the controller must meet certain electrical standards and be within voltage limits.

Replacement fuses must be ceramic and of correct rating.

Avoid unauthorized replacement of the fuse.

MODELS: PF3100-00A/C, PF3101-00A

Warnings

1. This equipment is suitable for use in Class I, Div 2, Groups A, B, C, and D hazardous locations or non-hazardous

locations only.

2. WARNING – EXPLOSION HAZARD – Do not disconnect equipment while the circuit is live or unless the area is

known to be free of ignitable concentrations.

3. WARNING – EXPLOSION HAZARD – Substitution of components may impair suitability for Class I, Div 1

hazardous locations.

MODELS: PF3102-00A

Warnings

1. This equipment is suitable for use in Class I, Div 1, Groups A, B, C, and D hazardous locations or non-hazardous

locations only.

2. WARNING – EXPLOSION HAZARD – Do not disconnect equipment while the circuit is live or unless the area is

known to be free of ignitable concentrations.

3. WARNING – EXPLOSION HAZARD – Substitution of components may impair suitability for Class I, Div 1

hazardous locations.

4. The flame rods are not intended to be installed and mounted in a Class I, Division 1 or Division 2 hazardous

location. Routing and installation of the flame rods shall be in accordance with the Canadian Electrical Code or

National Electrical Code as per local requirements.

5. CAUTION – Conduit seal required within 18” of enclosure. Div 2 seal not required.

MODELS: PF3103-00B

Warnings

1. This equipment is suitable for use in Class I, Div 1, Groups A, B, C, and D hazardous locations or non-hazardous

locations only.

2. WARNING – EXPLOSION HAZARD – Do not disconnect equipment while the circuit is live or unless the area is

known to be free of ignitable concentrations.

3. WARNING – EXPLOSION HAZARD – Substitution of components may impair suitability for Class I, Div 1

hazardous locations.

4. This assembly must be used with approved Profire probes and thermowells to maintain hazardous locations

certification.

PRIMARY SAFETY CONTROL

FOR USE IN HAZARDOUS LOCATIONS

CAMERA-READY LOGOTYPE FOR TYPE L AND TYPE R LISTING MARKS FOR CANADA AND THE U.S.

These Marks are registered by Underwriters Laboratories Inc.

The minimum height of the registered trademark symbol ® shall be 3/64 of an inch. When the overall diameter of the

UL Mark is less than 3/8 of an inch, the trademark symbol may be omitted if it is not legible to the naked eye.

The font for all letter forms is Helvetica Condensed Black, except for the trademark symbol ®, which is

Helvetica Condensed Medium. No other fonts are acceptable.

Please Note:

The word "MARINE" should only be used for UL Classified marine products.

200-195F 20M/11/97

E474004

TABLE OF CONTENTS

Introduction 1

Modules 1

Features 2

Specifications 2

Mounting Considerations 3

Installation Warnings 4

Wiring Pinouts 4

Wiring 5

PFRN Power and Communication 7

Display User Interface 8

Menu Map 9

Operation 15

Troubleshooting 16

System Errors 17

Resetting to Defaults 17

1

PF3100 MODULE FAMILY

INTRODUCTION

The PF3100 burner management system consists of individual building blocks called modules which can

be mixed and matched to form a complete solution. Each module performs a specific function and is

intended to be installed close to the device they are measuring or controlling. This simplifies wiring and

reduces issues with noise and signal loss compared to centralized control systems. This also allows the

user to purchase only the modules which are necessary for a given application. The modules interact with

one another using a network based communication method to perform a given task safely.

MODULES

UI Module

UI Network Module

UI BMS Module

UI BMS Network Module

UI Modbus Module

UI Modbus BMS Module

BMS Module

BMS Network Module

Ion Pilot Module

Type K Temperature Module

2

FEATURES

• Can view the status of other modules through the PFRN network from the UI Module

• Multiple UIs can show the same info on each screen

• Able to mount the UI away from the burner

• Simple indication of overall status through LEDs allowing end-users to check statuses from afar

• UI’s LCD screen shows statuses of overall system, individual modules, and groups of modules

• Numeric keypad is on the UIX enclosure for easy data entry

• Data logging and field firmware updates

• BMS modules in BMS enclosures can be placed near the burner housing away from the UI interface

• BMS Controller cards provide power to other modules through PFRN ports

• Network cards allow for connections to many other modules to form a single communication network

SPECIFICATIONS

Card Specs

Specs UI Card Network Card BMS Card Modbus Card Ion Pilot Card Thermocouple

Card

Card Type Interface Network Controller IO IO IO

Power Method Power

Consumer

Power Producer Power Producer Power Producer Power

Consumer

Power

Consumer

Voltage Input 36 VDC through

PFRN

12/24 VDC 12/24 VDC 12/24 VDC 36 VDC through

PFRN

36 VDC through

PFRN

Number of Ports 1 PFRN Port 5 PFRN Ports 5 PFRN Ports 4 PFRN Ports 1 PFRN Port 1 PFRN Port

Fuse Rating N/A 6.3 A 10 A 500 mA N/A N/A

Fuse Part

Number

N/A 3412.0113.22 1.2514 3412.0113.22 N/A N/A

Fuse MFG N/A Schurter Schurter Schurter N/A N/A

Enclosure Specs

Specs UIX Enclosure BMS Enclosure AUX Enclosure EPX Enclosure TLX Enclosure

Dimensions Width 30.9 cm

(12.15 in)

Height 23.4 cm

(9.23 in)

Depth 13.4 cm

(5.28 in)

Width 30.9 cm

(12.15 in)

Height 23.4 cm

(9.23 in)

Depth 13.4 cm

(5.28 in)

Width 30.9 cm

(12.15 in)

Height 23.4 cm

(9.23 in)

Depth 13.4 cm

(5.28 in)

Top Width 11.7 cm

(4.61 in)

Base Width 16.8

cm (6.63 in)

Height 21.7 cm

(8.53 in)

Depth 13.3 cm

(5.25 in)

(Body Type)

Standard ½” NPT

Head Connection

Hazloc Rating Class I Div 2 Class I Div 2 Class I Div 2 Class I Div 1 Class I Div 1

Operating

Temperature

-40°C to 60°C -40°C to 60°C -40°C to 60°C -40°C to 60°C -40°C to 60°C

Storage

Temperature

-40°C to 60°C -40°C to 60°C -40°C to 60°C -40°C to 60°C -40°C to 60°C

3

MOUNTING CONSIDERATIONS

Orientation

The UIX, CTX, and AUX enclosures should be mounted upright.

The EPX and TLX enclosures can be mounted in whichever direction makes sense for

the application.

Location

1. The UI Module is typically mounted in an operator-safe, easily accessible area. The

recommended mounting height is 1.5m (5ft) above where the operator will be standing

for ease of use. If there is a BMS card in the UIX enclosure with the UI card, then you

will need to adjust the location accordingly.

2. Mount any BMS enclosures near the corresponding valve train.

3. The Thermocouple card is included inside of a head connection (TLX enclosure) with a

thermocouple probe. The Type K Temperature module comes ready to install into the

thermowells of each tank. Install in a Div 1 rated thermowell.

4. The Ion Pilot module should be located within 50 feet of the pilot it is igniting.

5. The Network and Modbus cards will typically be mounted inside of a UIX, CTX, and AUX

enclosure. Must be within max PFRN run length of 250 ft.

HAZARDOUS LOCATION MOUNTING

In order to maintain the hazardous location rating for the EPX Enclosure, the following conditions must be

met.

The EPX Enclosure lid must be tightened down until it is flush with the base. The locking

screw must be installed into the base.

Each unused base port must be sealed with pipe plugs. Use our plugs or figure out

appropriately rated plugs that are equivalent.

Any base ports in use must be sealed within 18 inches of the EPX Enclosure. All fittings must

have at least 5 threads of engagement.

4

INSTALLATION WARNINGS

Before installing the PF3100, please review the following list of warnings.

Failure to observe the following may result in death, electrocution,

property damage, product damage, and/or government fines.

1. For burners greater than 12.5 MMBtuh, additional modules may be required for use with

the PF3100 system.

2. It is recommended that the low fire feature be used with anything above 1 MMBtuh. To

use the PF3100 on burners greater than 5 MMBtuh, the Proof of Closure feature must

be used.

3. Failure to properly ground the pilot assembly back to the PF3100’s Ion terminal may

result in accidental electrocution, product damage, or failure to ignite the pilot.

4. The PF3100 generates 20kV- 40kV at its high voltage output terminal which can cause

cardiac arrest. Do not touch or place any object near the ignition coil’s high voltage

terminal or connected ignition wire while the product is operating. Even without making

physical contact with the terminal, it is possible to draw a spark from several inches

away, especially if the pilot bracket is not properly grounded.

5. Make sure that the PF3100 enclosures are securely closed each time after opening

the enclosure. This protects the internal circuitry from moisture damage and other

environmental concerns. Moisture damage is not covered by the product warranty if the

door has been left open.

WIRING PINOUTS

/ VDC

COMMON

EARTH GND

Power

Input

Relay

Output

4-20mA /

Dry Contact

Inputs

Powered Outputs Dry Contact Inputs

STATUS

HFV

HFV +

SSV

SSV +

SSV

SSV +

Pilot -

Pilot +

Aux Out - (4-20mA)

Aux Out + (4-20mA)

START

START +

POC

POC +

AUX IN

AUX IN +

ESD

ESD +

PRESSURE

PRESSURE +

LEVEL

LEVEL +

/ VDC

COMMON

EARTH GND

Power

Input

Relay

Output

4-20mA /

Dry Contact

Inputs

Powered Outputs Dry Contact Inputs

STATUS

HFV

HFV +

SSV

SSV +

SSV

SSV +

Pilot -

Pilot +

Aux Out - (4-20mA)

Aux Out + (4-20mA)

START

START +

POC

POC +

AUX IN

AUX IN +

ESD

ESD +

PRESSURE

PRESSURE +

LEVEL

LEVEL +

*Output terminals are limited to 4A max current draw. 4-20 mA output terminals are limited to 20mA.

5

WIRING

Modules

The wiring in this section of the document is required for all PF3100 installations. Skipping or performing

any steps in this section incorrectly can result in the PF3100 not working properly.

6. Run appropriately zoned conduits between the modules. The UIX and CTX enclosures

have pre-drilled conduit holes in two different sizes – 0.5 in (1.27 cm) and 0.75 in (1.91

cm). There are 4 of each size available. Remove the hole seals as needed and install the

conduit.

7. Run a Cat5e or higher rated Ethernet cable through each conduit (between the BMS

Controller Card and each other card). Make sure that the UI Card is plugged into the port

on the BMS Controller Card labelled “UI Port”.

8. Make sure that all other cards are plugged into one of the other ports on the BMS

Controller Card.

9. Connect power wires according to specifications from the BMS Controller to an

appropriately rated power supply running at 12 or 24VDC.

10. Connect power wires according to specifications from each Ethernet switch to an

appropriately rated power supply running at 12 or 24VDC.

11. Wire valves (including PoC, PoLF, and Temperature Control Valve) to the BMS Controller

Card.

12. Wire the Pilot valve to the Pilot +/- terminals.

13. Wire the Main valve to the High Fire / Main +/- terminals.

14. If the Safety Shutoff Valves (SSV) are required in your application, wire one valve to the

SSV1 +/- terminals and the other valve to the SSV2 +/- terminals.

15. Make sure that each valve has a separate return wire. Multiple valves sharing common

return wires will not function properly.

16. Connect valve EGND wires to Earth Ground.

1 7. Note that the PF2100 valve output called “Low Fire” has been replaced by two new

valve outputs called Safety Shutoff Valve 1(SSV1) and Safety Shutoff Valve 2 (SSV2).

This is for applications that require two valves for safety. These two contacts always

follow each other but are provided separately for improved current handling and also for

improved troubleshooting.

18. Wire dry contact inputs to the BMS Controller Card as required.

19. There are 5 dry contact inputs on the PF3100. The expected connection to each of these

is a switch. These contacts must all be closed (shorted) in order for the system to start.

Jumpers are provided for each of these by default. If you need to use a particular contact

for your application, simply remove the associated jumper and connect a switch in its

place.

20. Wire the start contact to the BMS Controller Card as required.

21. The Start Contact can be used to attach a remote start/stop switch. This is typically

connected to a PLC dry contact output.

22. When the contact is open, the system is stopped. For safety reasons, a double action is

required to start the system remotely via this contact. This is accomplished by closing

the switch, opening it, and then closing it again. Once the system is running, simply

open the switch again to stop it.

23. Wire the 4-20 inputs or Pressure/Level Switches to the BMS Controller Card if required.

24. The Level Contact can be connected to a Level Switch installed right above the fire tube.

This is used to signal when the tank level drops below a certain minimum. This is often

the point at which the fluid in the tank is no longer covering the fire tube. Running the

burner with an empty tank can damage both the fire tube and the tank.

25. The Level Contact is time averaged to help reject brief fluctuations in tank level which

6

might be a result of vibration. The contact must be open continuously for 2 or 20

seconds (depending on the “Pressure/Level Delay” setting) before the system will

shutdown. If “Level Restart” is enabled, the system will restart automatically when the

Level Contact recloses.

26. Note that the PF2100 has level and pressure contact inputs on the Terminal Card and

corresponding 4-20 inputs on an expansion card. The PF3100 has contacts and 4-20

inputs overloaded on the same inputs. The behavior is selectable in software. Also note

that there is not a separate low and high pressure contact. If both switches are desired,

they need to be wired in series and connected to the pressure contact.

27. Wire thermocouples to the Thermocouple Card as required. The TC1A thermocouple

inputs are mandatory and must be connected to a Dual Element thermocouple. The

other thermocouples are only required when a second process temperature (such as the

outlet temperature on a line heater) must be monitored.

28. Connect a dual element, Type K thermocouple to the TC1A inputs.

29. Note that TC1A, TC1B, TC2A, and TC2B require dual element Type-k thermocouples. This

is different from the PF2100 which only supported a single TC for the auxiliary input.

30. Wire the ignition coil and flame rod to the Ion Pilot Card.

Flame Rod/Ignition Coil

This section provides some tips to set up the system for reliable ignition and flame detection.

Wire Lengths

When wiring the ignition and flame detection circuits, the wire length between the ignition coil and pilot

should be no more than 5m (15ft). If the wire lengths are too long, the PF3100 may not be able to deliver

enough energy to the ignition rod to ignite the pilot. The PF3100 may also fail to receive a signal from the

flame rod for detecting flame.

Grounding

Properly grounding the pilot assembly back to the PF3100 Ion Pilot module is critical for proper ignition

and flame detection. The Earth Ground wire should run from the EGND terminal of the Ion Pilot card to

the pilot assembly. This wire should be connected to the burner housing. Use a multimeter to verify that

the burner housing has electrical continuity with the pilot assembly.

Ignition

Coil Straight

Silicone

Boot

PF3100 Ion Pilot

Card Header

Ferrule Single

Rod

EGND

+Ion

{

Coil

+

7

PFRN POWER AND COMMUNICATION

Below is a small sample network describing module communication through Profire’s propriety

communication network, PFRN.

UI CARD

(Interface Class)

BMS CARD

(Controller Class)

ION PILOT CARD

(IO Class)

THERMOCOUPLE

CARD

(IO Class)

NETWORK

EXPANSION CARD

(Network Class)

MODBUS CARD

(Network/Controller Class)

BMS CARD

(Controller Class)

ION PILOT CARD

(IO Class)

THERMOCOUPLE

CARD

(IO Class)

BMS CARD

(Controller Class)

ION PILOT CARD

(IO Class)

THERMOCOUPLE

CARD

(IO Class)

BMS CARD

(Controller Class)

ION PILOT CARD

(IO Class)

THERMOCOUPLE

CARD

(IO Class)

8

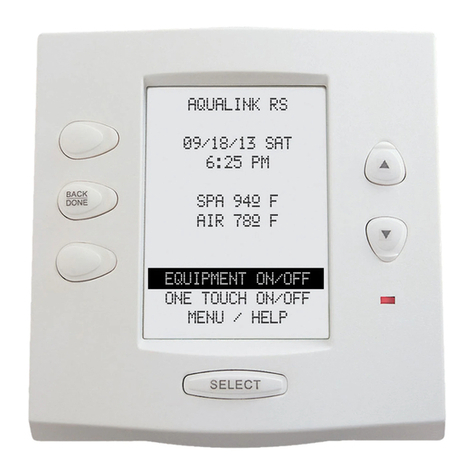

DISPLAY USER INTERFACE

POWER LED

Off: UI is not powered

On: UI is powered

STATUS LED

Off: UI is not powered

Flashing Green: Startup sequence

Green: System is running

Red: System is stopped

Amber: Warning or alarm is present

LCD SCREEN

Displays diagnostics, current settings, and options

when navigating through menus.

STOP KEY

Used to stop the system which immediately turns

off the burner.

BACK KEY

Used to go back one screen and cancel out of

dialog boxes.

ARROW KEYS

Used to navigate through menus.

TRIPLE BAR KEY

Menu key that opens a menu of global options.

OK KEY

Used to enter a menu, acknowledge a prompt,

save an edited setting or return to the home

screen.

? (HELP) KEY

Allows access to system help. One button press

brings up tooltips for items on the current screen.

Two button presses opens the integrated user

manual for the selected item.

+/- KEYS

Used to adjust settings up or down.

START KEY

Used to start the system.

NUMBER PAD

Used to key in changes in settings.

DELETE KEY

Used to delete the last character entered when

using the number pad.

ENCLOSURE DOOR LOCK

Mechanism for securing the door. A flat-head

screwdriver is needed to open and close the enclo-

sure.

9

MENU MAP

The following sections include brief descriptions of each PF3100 menu, including the valid settings range

and default setting. Any entries highlighted in gray are hidden in the menu by default.

Settings: Temperature Setpoints

This menu is used to adjust the Temperature Setpoints.

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

HighTempSetpoint High Temp Setpoint for

Process TC

0 to 1350˚C

32 to 2462˚F

90˚C

194˚F

PilotOffSetpoint Pilot Off Setpointfor

Process TC

0 to 1350˚C

32 to 2462˚F

85˚C

185˚F

LowFireSetpoint Low Fire Setpoint for

Process TC

0 to 1350˚C

32 to 2462˚F

85˚C

185˚F

ProcessTempSetpoint Process Temp Setpoint for

Process TC

0 to 1350˚C

32 to 2462˚F

80˚C

176˚F

LowTempAlarmSetpoint Low Alarm Setpoint for

Process TC

0 to 1350˚C

32 to 2462˚F

50˚C

122˚F

AuxHighTempSetpoint High Temp Setpoint for Aux

TC

0 to 1350˚C

32 to 2462˚F

90˚C

194˚F

AuxProcessTempSetpoint Process Setpoint for Aux TC 0 to 1350˚C

32 to 2462˚F

20˚C

68˚F

Settings: Deadband

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

TemperatureDeadband Deadband setting used

for various temperature

setpoints

0 to 13˚C 2˚C

AuxTempDeadband Deadband setting used for

Aux temperature setpoints

0 to 13˚C 2˚C

420AuxIn1Deadband Deadband setting used for

various 4-20mA Aux In 1

setpoints

0-16 mA 2 mA

LELDeadband Deadband setting used for

LEL setpoint

0-16 mA 2 mA

FuelPressureDeadband Deadband setting used

for various fuel pressure

setpoints

0-16 mA 2 mA

TankLevelDeadband Deadband setting used for

various tank level setpoints

0-16 mA 2 mA

VoltageDeadband Deadband setting used for

various voltage setpoints

0 to 5V 2 V

Settings: 4-20 Input Setpoints

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

420AuxIn1HighSetpoint 4-20mA Aux In 1 High

Setpoint

4-20 mA 14 mA

420AuxIn1LowSetpoint 4-20mA Aux In 1 Low

Setpoint

4-20 mA 9 mA

10

420LELSetpoint 4-20mA Lower Explosive

Limit Setpoint

4-20 mA 14 mA

420FuelPressureHighSetpoint 4-20mA Fuel Pressure High

Setpoint

4-20 mA 17.33 mA

420FuelPressureLowSetpoint 4-20mA Fuel Pressure Low

Setpoint

4-20 mA 5.6 mA

420TankLevelHighSetpoint 4-20mA Tank Level High

Setpoint

4-20 mA 19.6 mA

420TankLevelLowSetpoint 4-20mA Tank Level Low

Setpoint

4-20 mA 12 mA

Settings: Commissioning

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

ControllerCommissionDate Controller Commissioning

Date, YYYY-MM-DD

0 - 0xFFFFFFFF 0

ControllerLocation Controller Location 0 to 64 chars "Test Location"

ControllerName Controller Name (User

Assigned)

0 to 64 chars "Test Name"

ControllerVoltageSetting The Voltage Setting of the

Controller Module

0 = 12V

1 = 24V

1

L1PasswordEnable Enable Level 1 Password Enable, Disable Disable

L1Password Level 1 Password 1 to 8 chars 1397

L2Password Level 2 Password 1 to 8 chars 2684

DeviceConfig[0] Ignition Module MAC

address

6 hex bytes -

DeviceConfig[1] Temperature Module MAC

address

6 hex bytes -

Settings: Process Control

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

RestartOptions Restart Options Bit Vector:

b0 = Low Voltage Restart

Enable

b1 = High Voltage Restart

Enable

b2 = Low Fuel Pressure

Restart Enable

b3 = Low Tank Level Restart

Enable

Defined Bits 0

StatusContactMode Status Contact Mode:

0 = Default

1 = Alarm when Remote

Stop

2 = Process Control

3 = Follow Flame

4 = Low Temp Alarm

In List 0

11

420AuxOutMode 4-20mA Aux Output Mode:

0 = Disabled

1 = Proportional Valve

Control

2 = Process Temperature

Echo

3 = Aux Temperature Echo

4 = Fuel Gas Pressure Echo

5 = Tank Level Echo

In List 0

PilotOffEnable Pilot Off Enabled:

0 = Disabled

1 = Enabled

In List 1

LowFireEnable Low Fire Enabled:

0 = Disabled

1 = On at Process Setpoint

2 = On at Low Fire Setpoint

In List 0

AuxTempEnable Aux Temp Enabled:

0 = Disabled

1 = Secondary Process

Control

2 = Secondary High Temp

ESD

3 = Display Only

In List 0

ProcessControl Process Control Enabled:

0 = Disabled

1 = On/Off Control

In List 1

RelightAttempts The number of times that

the controller will attempt

to relight the pilot in the

event of a flame fail

0-3 3

Settings: Valves

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

PilotValvePWM Pilot Valve PWM Duty Cycle 20-100% 60%

SSV1PWM SSV1 PWM Duty Cycle 20-100% 60%

SSV2PWM SSV2 PWM Duty Cycle 20-100% 60%

HighFirePWM High Fire PWM Duty Cycle 20-100% 60%

ProportionalValveMinOpening Proportional Valve (TCV)

Minimum Opening (Also

used as the Low Fire

Setting)

0-70% 40%

Settings: IO

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

ProofOfClosureEnable Used to enable the Proof Of

Closure Dry Contact Input.

0-1 0

AuxInContact Function of the AuxIn

Contact:

0 = Disabled

1 = PoLF (Wire to HFV)

2 = PoC2 (Wire to SSV2)

3 = PoP (Wire to Pilot Valve)

In List 0

12

TankLevelInputMode Tank Level Input Mode:

0 = Disabled

1 = Dry Contact

2 = 4-20mA Input

In List 0

420TankLevelMax The 4-20mA Tank Level

Maximum value which is

the value that is associated

with a 20mA loop current.

0-65535L 120L

420TankLevelMin The 4-20mA Tank Level

Minimum value which is

the value that is associated

with a 4mA loop current.

0-65535L 0L

FuelPressureInputMode Fuel Pressure Input Mode:

0 = Disabled

1 = Dry Contact

2 = 4-20mA Input

In List 0

420FuelPressureMax 4-20mA Fuel Pressure Max 0-65535 kPa 30 kPa

Settings: Ignition

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

CoilDriveMode Coil Drive Mode:

0 = Default Spark Pattern

In List 0

FlameDetectionGain Flame Detection Gain 1-7 3

Settings: Timing

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

PurgeTime Purge Time 10-900 s 30 s

PilotToMainDelay Pilot to Main delay 5-600 s 15 s

LowToHighFireDelay Low fire to High fire delay 30-600 s 30 s

Settings: Temp Module Field Calibration

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

ProcTemp1SpanCal Span Calibration Factor for

TC1A

-32768 to 32767 1

ProcTemp1ZeroCal Zero Calibration Factor for

TC1A

-32768 to 32767 0

ProcTemp2SpanCal Span Calibration Factor for

TC1A_Check -32768 to 32767 1

ProcTemp2ZeroCal Zero Calibration Factor for

TC1A_Check

-32768 to 32767 0

ProcTemp3SpanCal Span Calibration Factor for

TC1B

-32768 to 32767 1

ProcTemp3ZeroCal Zero Calibration Factor for

TC1B

-32768 to 32767 0

AuxTemp1SpanCal Span Calibration Factor

for TC2A

-32768 to 32767 1

AuxTemp1ZeroCal Zero Calibration Factor

for TC2A

-32768 to 32767 0

AuxTemp2SpanCal Span Calibration Factor

for TC2A_Check

-32768 to 32767 1

13

AuxTemp2ZeroCal Zero Calibration Factor

for TC2A_Check

-32768 to 32767 0

AuxTemp3SpanCal Span Calibration Factor

for TC2B

-32768 to 32767 1

AuxTemp3ZeroCal Zero Calibration Factor

for TC2B

-32768 to 32767 0

Settings: Ignition Module Field Calibration

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

FlameTemp1SpanCal Span Calibration Factor for

TCA

-32768 to 32767 1

FlameTemp1ZeroCal Zero Calibration Factor for

TCA

-32768 to 32767 0

FlameTemp2SpanCal Span Calibration Factor for

TCA_Check -32768 to 32767 1

FlameTemp2ZeroCal Zero Calibration Factor for

TCA_Check

-32768 to 32767 0

FlameTemp3SpanCal Span Calibration Factor for

TCB

-32768 to 32767 1

FlameTemp3ZeroCal Zero Calibration Factor for

TCB

-32768 to 32767 0

Settings: Controller Configuration

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

DeviceConfig[0]

DeviceConfig[30]

MAC_Address[n] The Ethernet MAC Address 0x000000000000 to

0xFFFFFFFFFFFF

0

ModelNumber[n] The model number: 3100,

3101, 3102, etc.

3100-3199 0

Role[n] 0 = No Assigned Role

1 = Default Role

2-255=Secondary Function

(not implemented)

In List 0

Settings: Appliance Configuration

MENU MAP BRIEF DESCRIPTION RANGE DEFAULT SETTING CUSTOM SETTINGS

ControllerConfig[0] Configuration info for the

first expected controller

within this appliance

ControllerConfig[11] Configuration info for the

last expected controller

within this appliance

MAC_Address[n] The Ethernet MAC Address 0x000000000000 to

0xFFFFFFFFFFFF

0

ModelNumber[n] The model number: 3100,

3101, 3102, etc.

3100-3199 0

14

Role[n] 0 = No Assigned Role

1 = Independent

Temperature

2 = Primary Temperature

Source

3 = Secondary Temperature

Source

4 = Temperature Sink

5-255 = Not Implemented

In List 0

MinControllersRunning The minimum number of

controllers that must be

running in order for the

appliance to keep running.

0-12 0

MaxAdjacentShutdown The maximum number of

adjacent controllers that can

shutdown before and the

appliance keep running.

0-12 0

EndsAreAdjacent Treat the controller at

the beginning of the list

as being adjacent to the

controller at the end of the

list.

0-1 0

RunningDefinition This setting determines

how the appliance decides

if a given controller is

running or not:

0 = Communicating

1 = Green State

2 = Blue or Green State

In List 1

ShutdownTimeout One or more rules must be

broken continuously for this

amount of time before the

appliance will shutdown.

The counter will only stop

counting down if no rules

are being violated. The

counter will keep counting

down if the particular rules

being violated change

during this time so long

as one or more rules are

always being violated.

1-600 10

15

OPERATION

STARTING THE SYSTEM

From any screen on the UI, press the Start Key on the keypad. If there are alarms present, you will be

notified.

If no alarms are present, you will be prompted to confirm that you want to start. Press the OK key to

confirm or the Back key to cancel.

If you are on the Status Tab, the system will show a count down of 5 seconds (or more if the purge cycle

has not been completed). At the end of the countdown, the system will open the pilot valve, and ignite

the pilot with the ignition coil. The flame quality should go to 100% on the screen. Then the system will

begin its process control trying to maintain the process setpoint.

STOPPING THE SYSTEM

From any screen on the UI, press the Stop Key on the keypad.

You will be prompted to confirm that you want to stop. Press the OK key to confirm or the Back key to

cancel.

Note that the Stop function on the UI is not safety rated! It is provided as a convenience. This function

may be unavailable if the UI is offline, disconnected from the network, or otherwise incapacitated. If a

safety rated stop button is required, connect an appropriately rated mushroom switch to the ESD contact

on the BMS controller.

16

TROUBLESHOOTING

ETHERNET COMMUNICATIONS

BLUE POWER LEDS NEXT TO THE ETHERNET PORTS OF THE MODULES ARE OFF

1. Verify that the Ethernet cable is plugged in on both ends.

2. Check that the port supplying power has a Blue LED illuminated indicating that it is

currently supplying power.

3. Check that the Ethernet cable is wired correctly to the T568B standard. (use a standard

Ethernet cable tester)

4. Verify that the Ethernet cable is not cut or otherwise damaged.

5. Check all user replaceable fuses on the module.

GREEN LINK LEDS NEXT TO THE ETHERNET PORTS OF THE MODULES ARE OFF

1. Verify that the Ethernet cable is plugged in on both ends.

2. Check that the Ethernet cable is wired correctly to the T568B standard. (use a standard

Ethernet cable tester)

3. Verify that the Ethernet cable is not cut or otherwise damaged.

4. Ensure that all Ethernet switches in the system are wired correctly and receiving power

5. Ensure that there are no more than 4 cascaded Ethernet switches between any two

modules in the system

FLAME DETECTION

SYSTEM HAS VISIBLE FLAME BUT CANNOT DETECT IT

1. The flame rod, pilot assembly and the gap between them should be fully engulfed in

flame. If not, adjust the rod positioning.

2. Check that the flame detection wiring does not exceed the recommended maximum

length.

3. Check that the Ion+ wire is securely connected as per the appropriate wiring diagram.

4. Check that the ground connection between the PF3100 and the pilot assembly is

present and secure.

5. Put the PF3100 into Manual Mode and use the Review Menu to check the flame quality

level.

6. The PF3102-00C Ignition Module is designed to be mounted in the burner housing to

minimize the length of flame ionization wire required. Generally speaking, the shorter

the wire, the less problems you will experience.

7. Ensure that the ground wire from the pilot nozzle is connected to the ground terminal on

the ignition module.

8. If you need to use a long length of ignition wire, try increasing the flame detection gain

setting under the “Ignition” settings on the UI

17

SYSTEM ERRORS

The UI screen will display any shutdown messages, alarm codes, or warning messages that the system

is currently experiencing. For each of these entries, an explanation will accompany the system error.

Shutdown messages

These indicate the reason that the system last shutdown. In the event of a safety shutdown (ESD), the

system will shutdown in 1 second or less. The flame failure response time (FFRT) spans 2 seconds, after

which the system will initiate shutdown.

Alarm codes

These indicate a persistent problem that must be cleared before the system can be restarted.

Warning messages

These indicate a problem that may be developing or a condition from which the system may

automatically restart once cleared.

RESETTING TO DEFAULTS

The system settings can all be reset to factory defaults by following these instructions:

1. Make sure that the system is stopped.

2. Navigate to the “Reset to Factory Defaults” menu item.

3. Use the Arrow Keys to change the setting to “Yes” and then press the OK Key. The

system will display “Parameter Saved” and will reboot.

4. After rebooting, the system will display the message “CONFIGURATION RESET TO

DEFAULT” alternating with “Check Settings and Setpoints.”

5. Press the OK Key to acknowledge this warning.

This process only resets the user settings back to factory defaults and does not affect the calibration

settings.

Other manuals for PF3100 Series

5

This manual suits for next models

2

Table of contents

Popular Control System manuals by other brands

Next Wave CNC

Next Wave CNC SHARK SD110 owner's manual

BECKWITH ELECTRIC

BECKWITH ELECTRIC Syncrocloser M-5625 manual

Pilz

Pilz PSSu E F 2DOR 8 operating manual

HEIDENHAIN

HEIDENHAIN TNC 370 D technical information

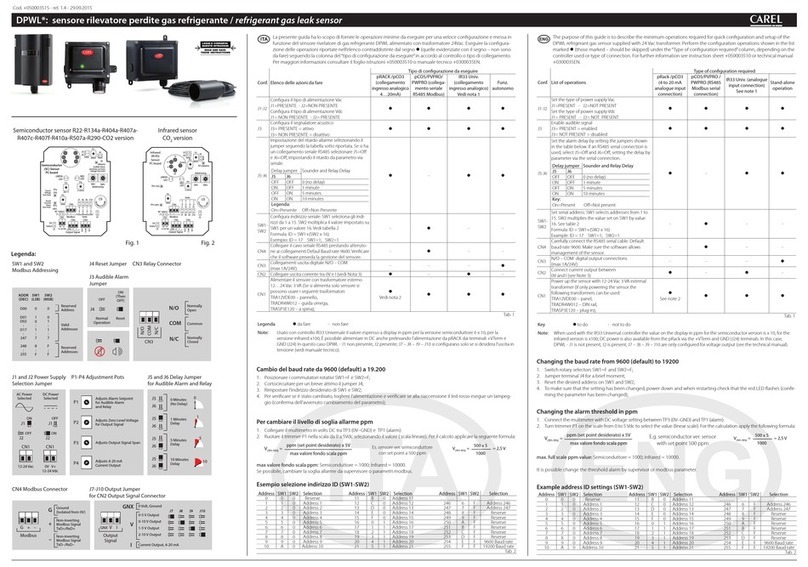

Carel

Carel DPWL Series quick start guide

Mitsubishi Heavy Industries

Mitsubishi Heavy Industries SC-SL4-AE Technical manual

RKC INSTRUMENT

RKC INSTRUMENT SR Mini System Supplementary information

LEGRAND

LEGRAND 035 86 installation manual

Key Digital

Key Digital FATCAT Series Setup guide

MachMotion

MachMotion 2000 Series General installation manual

Teagle

Teagle Tomahawk C12 Instruction book / parts list

Sony

Sony Dream Machine ICF-C900HS operating instructions