Cod. +050003515 - rel. 1.4 - 29.09.2015

DPWL*: sensore rilevatore perdite gas refrigerante / refrigerant gas leak sensor

La presente guida ha lo scopo di fornire le operazioni minime da eseguire per una veloce configurazione e messa in

funzione del sensore rivelatore di gas refrigerante DPWL alimentato con trasformatore 24Vac. Eseguire la configura-

zione delle operazioni riportate nell’elenco contraddistinte dal segno (quelle evidenziate con il segno – non sono

da fare) seguendo la colonna del“tipo di configurazione da eseguire”in accordo al controllo o tipo di collegamento.

Per maggiori informazioni consultare il foglio istruzioni +050003510 o manuale tecnico +0300035EN.

Conf. Elenco delle azioni da fare

Tipo di configurazione da eseguire

pRACK /pCO3

(collegamento

ingresso analogico

4…20mA)

pCO5/PVPRO/

PWPRO (collega-

mento seriale

RS485 Modbus)

IR33 Univ.

(collegamento

ingresso analogico)

Vedi nota 1

Funz.

autonomo

J1-J2

Configura il tipo di alimentazione Vac

J1=PRESENTE - J2=NON PRESENTE

Configura il tipo di alimentazione Vdc

J1= NON PRESENTE - J2= PRESENTE

J3

Configura il segnalatore acustico

J3= PRESENTE = attivo

J3= NON PRESENTE = disattivo

J5-J6

Impostazione del ritardo allarme selezionando il

jumper seguendo la tabella sotto riportata. Se si ha

un collegamento seriale RS485 selezionare J5=Off

e J6=Off, impostando il ritardo da parametro via

seriale.

Delay jumper Sounder and Relay Delay

J5 J6

OFF OFF 0 (no delay)

ON OFF 1 minute

OFF ON 5 minutes

ON ON 10 minutes

Legenda:

On=Presente Off=Non Presente

-

SW1-

SW2

Configura indirizzo seriale: SW1 seleziona gli indi-

rizzi da 1 a 15. SW2 moltiplica il valore impostato su

SW1 per un valore 16. Vedi tabella 2

Formula: ID = SW1+(SW2 x 16)

Esempio: ID = 17 SW1=1; SW2=1

---

CN4

Collegare il cavo seriale RS485 prestando attenzio-

ne ai collegamenti Defaul Baud rate 9600. Verificare

che il software preveda la gestione del sensore.

---

CN3 Collegamenti uscita digitale N/O – COM

(max 1A/24V) -- -

CN2 Collegare uscita corrente tra 0V e I (vedi Nota 3) --

CN1

Alimentare il sensore con trasformatore esterno

12…24 Vac 3 VA (Se si alimenta solo sensore si

possono usare i seguenti trasformatori:

TRA12VDE00 – pannello,

TRADR4W012 – guida omega,

TRASP3E120 – a spina);

Vedi nota 2

Tab. 1

Legenda da fare - non fare

Note: Usato con controllo IR33 Universale il valore espresso a display in ppm per la versione semiconduttore è x 10, per la

versione infrared x100; È possibile alimentare in DC anche prelevando l’alimentazione da pRACK dai terminali +VTerm e

GND (J24) In questo caso DPWL - J1 non presente, J2 presente; J7 – J8 – J9 – J10 si configurano solo se si desidera l’uscita in

tensione (vedi manuale tecnico).

Cambio del baud rate da 9600 (default) a 19.200

1. Posizionare i commutatori rotativi SW1=F e SW2=F;

2. Cortocircuitare per un breve attimo il jumper J4;

3. Rimpostare l’indirizzo desiderato di SW1 e SW2;

4. Per verificare se è stato cambiato, togliere l’alimentazione e verificare se alla riaccensione il led rosso esegue un lampeg-

gio (conferma dell’avvenuto cambiamento del parametro);

Per cambiare il livello di soglia allarme ppm

1. Collegare il multimetro in volts DC tra TP3 (0V–GND) e TP1 (alarm).

2. Ruotare il trimmer P1 nella scala da 0 a 5Vdc selezionando il valore ( scala lineare). Per il calcolo applicare la seguente formula:

V(TP1-TP3) = ppm (set point desiderato) x 5V

max valore fondo scala ppm

Es. sensore ver. semiconduttore

con set point a 500 ppm V(TP1-TP3) = 500 x 5

1000

= 2,5 V

max valore fondo scala ppm: Semiconduttore = 1000; Infrared = 10000.

Se possibile, cambiare la soglia allarme da supervisore o parametri modbus.

Esempio selezione indirizzo ID (SW1-SW2)

Address SW1 SW2 Selection Address SW1 SW2 Selection Address SW1 SW2 Selection

0 0 0 Reserve 11 B 0 Address 11 ……… …. …… ………….

1 1 0 Address 1 12 C 0 Address 12 246 6 F Address 246

2 2 0 Address 2 13 D 0 Address 13 247 7 F Address 247

3 3 0 Address 3 14 E 0 Address 14 248 8 F Reserve

4 4 0 Address 4 15 F 0 Address 15 249 9 F Reserve

5 5 0 Address 5 16 0 1 Address 16 250 A F Reserve

6 6 0 Address 6 17 1 1 Address 17 251 B F Reserve

7 7 0 Address 7 18 2 1 Address 18 252 C F Reserve

8 8 0 Address 8 19 3 1 Address 19 253 D F Reserve

9 9 0 Address 9 20 4 1 Address 20 254 E F 9600 Baud rate

10 A 0 Address 10 21 5 1 Address 21 255 F F 19200 Baud rate

Tab. 2

The purpose of this guide is to describe the minimum operations required for quick configuration and setup of the

DPWL refrigerant gas sensor supplied with 24 Vac transformer. Perform the configuration operations shown in the list

marked (those marked – should be skipped) under the “Type of configuration required”column, depending on the

controller used or type of connection. For further information see instruction sheet +050003510 or technical manual

+0300035EN.

Conf. List of operations

Type of configuration required

pRack /pCO3

(4 to 20 mA

analogue input

connection)

pCO5/PVPRO /

PWPRO (RS485

Modbus serial

connection)

IR33 Univ. (analogue

input connection)

See note 1

Stand-alone

operation

J1-J2

Set the type of power supply Vac

J1=PRESENT - J2=NOT PRESENT

Set the type of power supply Vdc

J1= PRESENT - J2= NOT PRESENT

J3

Enable audible signal

J3= PRESENT = enabled

J3= NOT PRESENT = disabled

J5-J6

Set the alarm delay by setting the jumpers shown

in the table below. If an RS485 serial connection is

used, select J5=Off and J6=Off, setting the delay by

parameter via the serial connection.

Delay jumper Sounder and Relay Delay

J5 J6

OFF OFF 0 (no delay)

ON OFF 1 minute

OFF ON 5 minutes

ON ON 10 minutes

Key:

On=Present Off=Not present

-

SW1-

SW2

Set serial address: SW1 selects addresses from 1 to

15. SW2 multiplies the value set on SW1 by value

16. See table 2

Formula: ID = SW1+(SW2 x 16)

Example: ID = 17 SW1=1; SW2=1

---

CN4

Carefully connect the RS485 serial cable. Default

baud rate 9600. Make sure the software allows

management of the sensor.

---

CN3 N/O – COM digital output connections

(max 1A/24V) -- -

CN2 Connect current output between

0V and I (see Note 3) --

CN1

Power up the sensor with 12-24 Vac 3 VA external

transformer (if only powering the sensor the

following transformers can be used:

TRA12VDE00 – panel,

TRADR4W012 – DIN rail,

TRASP3E120 – plug-in);

See note 2

Tab. 1

Key to do - not to do

Note: When used with the IR33 Universal controller the value on the display in ppm for the semiconductor version is x 10, for the

infrared version is x100; DC power is also available from the pRack via the +VTerm and GND (J24) terminals. In this case,

DPWL - J1 is not present, J2 is present; J7 – J8 – J9 – J10 are only configured for voltage output (see the technical manual).

Changing the baud rate from 9600 (default) to 19200

1. Switch rotary selectors SW1=F and SW2=F;

2. Jumper terminal J4 for a brief moment;

3. Reset the desired address on SW1 and SW2;

4. To make sure that the setting has been changed, power down and when restarting check that the red LED flashes (confir-

ming the parameter has been changed);

Changing the alarm threshold in ppm

1. Connect the multimeter with DC voltage setting between TP3 (0V–GND) and TP1 (alarm).

2. Turn trimmer P1 on the scale from 0 to 5 Vdc to select the value (linear scale). For the calculation apply the following formula:

V(TP1-TP3) = ppm (set point desiderato) x 5V

max valore fondo scala ppm

E.g. semiconductor ver. sensor

with set point 500 ppm V(TP1-TP3) = 500 x 5

1000

= 2,5 V

max. full scale ppm value: Semiconduttore = 1000; Infrared = 10000.

It is possible change the threshold alarm by supervisor or modbus parameter.

Example address ID settings (SW1-SW2)

Address SW1 SW2 Selection Address SW1 SW2 Selection Address SW1 SW2 Selection

0 0 0 Reserve 11 B 0 Address 11 ……… …. …… ………….

1 1 0 Address 1 12 C 0 Address 12 246 6 F Address 246

2 2 0 Address 2 13 D 0 Address 13 247 7 F Address 247

3 3 0 Address 3 14 E 0 Address 14 248 8 F Reserve

4 4 0 Address 4 15 F 0 Address 15 249 9 F Reserve

5 5 0 Address 5 16 0 1 Address 16 250 A F Reserve

6 6 0 Address 6 17 1 1 Address 17 251 B F Reserve

7 7 0 Address 7 18 2 1 Address 18 252 C F Reserve

8 8 0 Address 8 19 3 1 Address 19 253 D F Reserve

9 9 0 Address 9 20 4 1 Address 20 254 E F 9600 Baud rate

10 A 0 Address 10 21 5 1 Address 21 255 F F 19200 Baud rate

Tab. 2

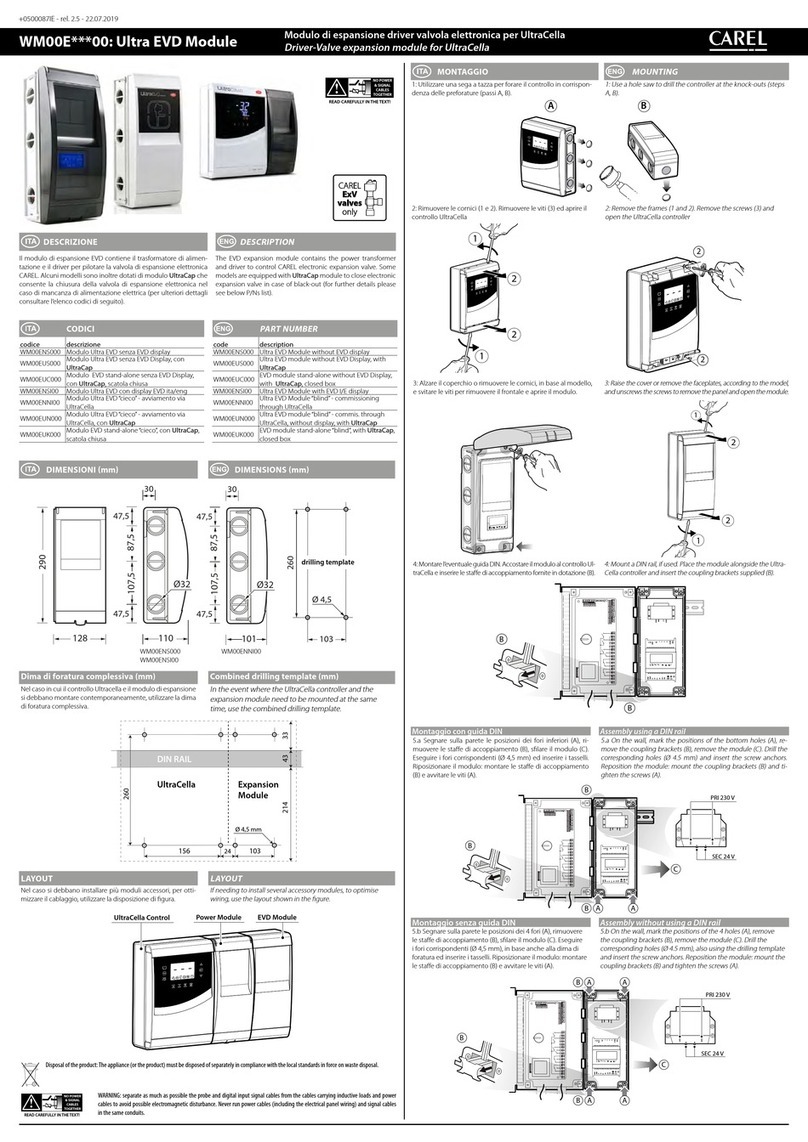

Semiconductor sensor R22-R134a-R404a-R407a-

R407c-R407f-R410a-R507a-R290-CO2 version

Infrared sensor

CO2version

Semiconductor

(SC) Sensor

PC board

GREEN

LED

RED

LED

TP2

(Vs)

TP

(Alarm)

Reset

J4

Addressing

SW1 SW2

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

0

1

2

3

4

5

6

7

8

9

A

B

C

D

E

F

Alarm

P1

P4

4-20mA

J3

J2

J1

AC Select

DC

Select

0 0 1 2

5 10 5 10

CN4

CN2

SPAN

Volts

TP3

(0V)

Board

Ground

Plane

Test Point

Sensor

Voltage

Test Point

Audible Alarm

and Relay Set Point

Voltage Test Point

J7 J8 J9 J10

A

U

D

I

B

L

E

A

L

A

R

M

N/O

N/C

COM

CN3

G

Modbus

+–

GNX

Output Signal

VI

12-24 Vdc

CN1

0V V+

P3

J5

J6

Delay

ADJ V

P2

TP1(Alarm)

Addressing

Alarm

Reset

J5

J6 J4

J3

SW1 SW2

Infrared

(IR-RS)

Sensor

PC board

J2

TP2 (Vs)

GREEN

LED

RED

LED

J1

AC Select

DC

Select

0 0 1 2

5 10 5 10

P4

P1

Zero

P2

CN4

CN2

SPAN

Volts

TP3 (0V)

J7 J8 J9 J10

0

1

2

3

4

5

6

7

8

9

A

B

0

1

2

3

4

5

6

7

8

9

A

B

A

U

D

I

B

L

E

A

L

A

R

M

N/O

N/C

COM

CN3

G

Modbus

+–

GNX

Output Signal

VI

12-24 Vdc

CN1

0V V+

4-20mA

P3

Delay

SIGNAL

TX

+V

–V

RX

Fig. 1 Fig. 2

Legenda:

SW1 and SW2

Modbus Addressing

J4 Reset Jumper

J3 Audible Alarm

Jumper

CN3 Relay Connector

N/O

N/C

COM

CN3

N/ONormally

Open

COMCommon

N/C Normally

Closed

Reserved

Address

0

F

:

F

0

1

:

1

:

7

D00

248

:

255

D01

D02

:

D17

:

247

0

SW2

(MSB)

ADDR

(DEC)

SW1

(LSB)

8

:

F

1

0

:

1

:

7

Valid

Addresses

Reserved

Addresses

OFF

Normal

Operation

J4

Reset

ON

(Then

OFF)

J1 and J2 Power Supply

Selection Jumper

P1-P4 Adjustment Pots J5 and J6 Delay Jumper

for Audible Alarm and Relay

AC Power

Selected

DC Power

Selected

OFF

J1

J2

ONOFF

ON

J1

P1

P2

P3

P4

J2

CN1

12-24 Vac

12-24 Vdc

CN1

0V V+

10

5

1

0

J5

J6

J5

J6

J5

J6

J5

J6

0Minutes

(No Delay)

Adjusts Alarm Setpoint

for AudibleAlarm

and Relay

Adjusts Zero Level Voltage

for Output Signal

Adjusts Output Signal Span

Adjusts 4-20 mA

Current Output

1 Minutes

Delay

5Minutes

Delay

10Minutes

Delay

CN4 Modbus Connector J7-J10 Output Jumper

for CN2 Output Signal Connector

G

Modbus

+–

GGround

(Isolated from 0V)

+Non-inverting

Modbus Signal

TxD+/RxD+

–Non-inverting

Modbus Signal

TxD–/RxD–

GNX

Output

Signal

VI

GNX J7 J8 J9J10

0Volt, Ground

V

0-5 VOutput

0-10VOutput

1-5 VOutput

2-10VOutput

ICurrent Output, 4-20 mA