ProFire PF3100 Series User manual

PF3100 Modbus Card Product Manual R 1.0

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 1 of 10

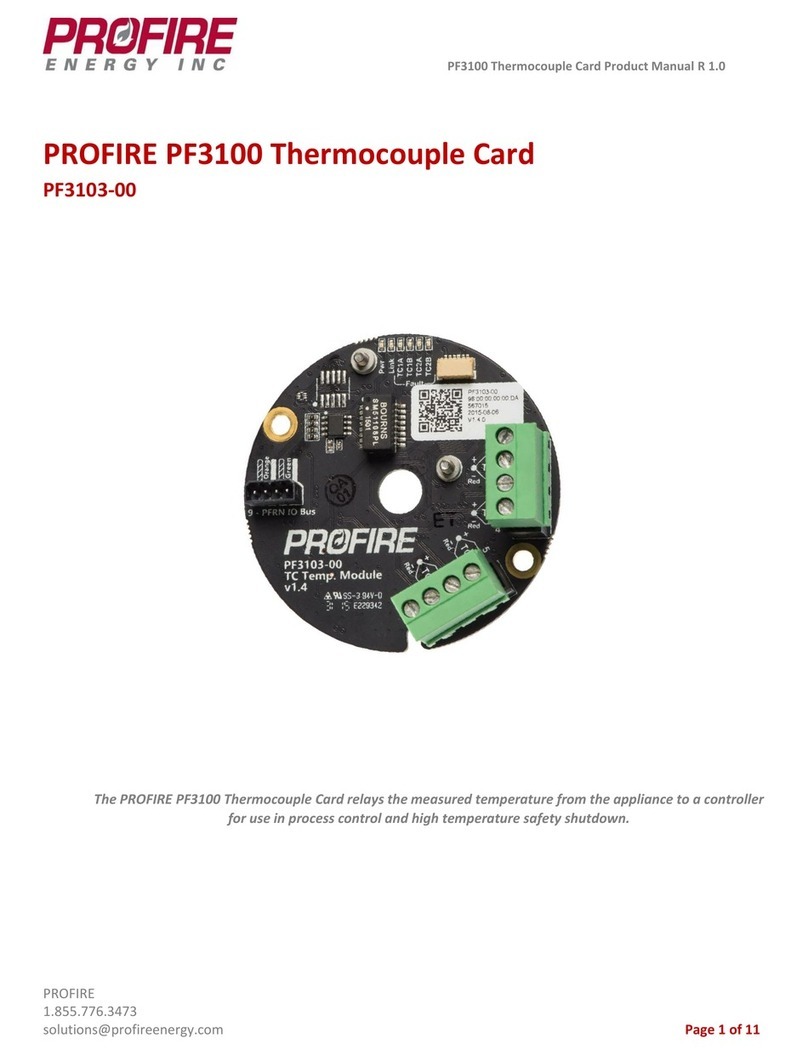

PROFIRE PF3100 Modbus Card

PF3107-00

The PROFIRE PF3100 IO Modbus RS-485 card allows a PF3100 system to interact with other devices.

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 2 of 10

1. Introduction............................................................................................................................................... 3

2. Certifications..............................................................................................................................................3

3. Card Information........................................................................................................................................4

4. Wiring Diagram .......................................................................................................................................... 6

5. Mounting Instructions ................................................................................................................................7

6. Enclosure Specifications ............................................................................................................................. 8

7. Instructions for Use .................................................................................................................................... 8

8. Preventative Maintenance & Inspection .....................................................................................................8

9. Important Safety Information.....................................................................................................................9

10. PROFIRE Contact Information ................................................................................................................... 10

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 3 of 10

1. Introduction

Functional Description

The PROFIRE PF3100 Modbus RS-485 card allows the PF3100 system to interact with other devices, such as PLCs

and SCADA networks that support RS-485 two wire (half-duplex) communication via Modbus RTU Protocol. This

card is always a Modbus slave device. Separate Modbus master devices can start/stop the system, read system

status and process values, and modify settings.

Model Types

Model Number

Name

Description

PF3107-00A

Modbus TCP and Modbus RTU

Standalone - polyester painted steel enclosure.

2. Certifications

PROFIRE strives to ensure that certifications are updated as quickly as they become available for all of our products.

Modbus Card - Hazardous Location Rating

Certification: Class I, Div 2, Grp ABCD; T4; Type 4

CSA 22.2 No. 60730-2-5, UL 60730-2-5.

The board includes the following symbols:

Caution: possibility of electric shock.

Caution: documentation must be consulted in all cases where this symbol is marked.

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 4 of 10

3. Card Information

Card Specifications

The ambient temperature rating for the Modbus Card is -40°C (-40°F) to +60°C (+140°F).

Card Diagram

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 5 of 10

Terminal Specifications

Terminal

Number

Terminal Name

Expected Connections

Input/Output

Safety

Rated

Electrical Ratings

Voltage

Current

1

Power 12-24 VDC

Vin -

Input power from a DC source

12/24 VDC Power

Input

N/A

Nominal:

12 VDC or

24 VDC

Max: 30V

Max: 6A

2

Common 12-24

VDC Vin +

Ground back to DC source

Ground

N/A

N/A

N/A

3

EGND

Earth Ground

Ground

N/A

N/A

N/A

6 + 7

Status Out

Not implemented.

Not

implemented.

No

120VAC

50/60Hz or

12/24 VDC

80mA

4

Start Signal In

Not implemented.

Not

implemented.

No

30 VDC

5mA

5

Start PWR Out

Not implemented.

Not

implemented.

No

12 VDC or

24VDC

(same as

voltage

supply

150mA

8

RS-485 D+

Connect to a RS-485 Bus

connected to a PLC or similar

device.

RS-485

Input/Ouput

No

+/-6V

250mA

9

RS-485 D-

Connect to a RS-485 Bus

connected to a PLC or similar

device.

RS-485

Input/Ouput

No

+/-6V

250mA

10

RS-485 Reference

(Terminal 10)

Connect to a RS-485 Bus

connected to a PLC or similar

device.

Ground

N/A

N/A

N/A

Port

Number

Port Name

Expected Connections

Input/Output

Safety

Rated

Electrical Ratings

Voltage

Current

1

PFRN Port 1

The PFRN IO connect ports are

used for IO modules to

communicate with the BMS

card.

I/O

N/A

36 VDC

500mA

2

PFRN Port 2

The PFRN IO connect ports are

used for IO modules to

communicate with the BMS

card.

I/O

N/A

3

PFRN Port 3

The PFRN IO connect ports are

used for IO modules to

communicate with the BMS

card.

I/O

N/A

4

PFRN Port 4

The PFRN IO connect ports are

used for IO modules to

communicate with the BMS

card.

I/O

N/A

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 6 of 10

Terminal Descriptions

Power, Common

Input power 12/24 VDC, 6.3A max.

EGND

Internally connected to Common; must be wired to a nearby Earth Ground.

RS-485 D+/D-

-7V to 12V absolute.

+/- 3VDC differential recommended.

The baud rates supported are from 9600 baud to 19200.

RS-485 Reference (Terminal 10)

Shared common ground with customer PLC. Must be wired in.

Terminator Selector Switch

The termination selector switch is used to apply a 120ohm resistance to the signal. By applying this resistance,

it in turn “terminates” the signal. It should only be used when you want to terminate the signal.

4. Wiring Diagram

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 7 of 10

Wiring Specifications

12-30 AWG can be used for all connections. External fuses must be installed according to the local electrical code.

Wire gauge size must also be selected in accordance with local electrical codes.

5. Mounting Instructions

Mounting the Card in the Enclosure

1. Install four (4) #10-32 screws through the Modbus card (as indicated in the image below) and attach them to

the upper set of enclosure stand-offs. Please note the board orientation.

2. Torque to 26 in*lb.

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 8 of 10

6. Enclosure Specifications

The Modbus card can be mounted in a fire-proof enclosure that is safe for the area of operation (e.g. –

hazardous/non-hazardous.) The UIX, CTX, and AUX enclosures described below are examples:

Enclosure Type

Specifications

UIX

CTX

AUX

Dimensions

Height 30.9cm (12.15 inches)

Width 23.4cm (9.23 inches)

Depth 13.4cm (5.28 inches)

Height 30.9cm (12.15 inches)

Width 23.4cm (9.23 inches)

Depth 13.4cm (5.28 inches)

Height 30.9cm (12.15 inches)

Width 23.4cm (9.23 inches)

Depth 13.4cm (5.28 inches)

Hazloc Rating

Class I Div 2, IP66

Class I Div 2, IP66

Class I Div 2, IP66

Mounting

Channel Bar or Direct Mount

Channel Bar or Direct Mount

Channel Bar or Direct Mount

Enclosure Construction

Poly Painted Steel

Poly Painted Steel

Poly Painted Steel

Operating Temperature

-40°C (-40°F) to 60°C (140°F)

-40°C (-40°F) to 60°C (140°F)

-40°C (-40°F) to 60°C (140°F)

Storage Temperature

-40°C (-40°F) to 60°C (140°F)

-40°C (-40°F) to 60°C (140°F)

-40°C (-40°F) to 60°C (140°F)

7. Instructions for Use

The Modbus card is designed to be used with a certified BMS controller as part of the PF3100 platform.

Operation

Operating controls and their uses are described under “Terminal Descriptions” above. For an outline of all registers

supported through Modbus, please see the link below for the document “Modbus Register Map”:

http://3100.profireenergy.com/pf3100-documentation/

8. Preventative Maintenance & Inspection

In order to ensure that the Modbus card works correctly and efficiently, the following maintenance and inspection

procedures should be followed:

➢Ensure that all wires are connected correctly.

➢Minimize copper wire exposure.

➢Check for corrosion and ensure that no wires are frayed or worn out, and all insulation is intact.

➢Confirm no moisture or condensation is apparent on the board or in the enclosure.

➢Ensure that the board does not show any sign of mechanical damage (e.g. –damage from an impact such as

dropping an item).

➢Ensure that the board does not show any sign of electrical damage (components should not be burnt or

damaged in any way).

➢Check that the device is not subject to excessive vibration.

➢Confirm that the temperature of the board is within ambient temperature operating limits.

➢Check that the enclosure is secured and that the device is not subject to excessive vibration.

➢Routine inspections of all equipment should be performed. If any abnormality is found, corrective actions should

be taken. If the abnormality cannot be corrected, contact PROFIRE.

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 9 of 10

➢A qualified technician should perform any tests necessary to confirm that the equipment is still in a safe

condition.

Cleaning

If the card becomes dirty it can be cleaned with compressed air. Do NOT use solvents, cleaners, or liquids to clean

the board. Caution must be exercised when cleaning the board in order to prevent damage from ESD (electrostatic

discharge).

Replacement Parts

Please contact PROFIRE should any replacement parts be required.

9. Important Safety Information

Before installing the PF3100 Modbus card, please review the list of warnings below. Product use in a manner not

specified by PROFIRE is not recommended. Failure to observe the following warnings may result in death,

electrocution, property damage, product damage, product damage, government fines, or malfunction of the

product itself.

WARNING: Explosion Hazard

➢Do not disconnect while circuit is live unless area is known to be non-hazardous or equivalent.

➢Substitution of components may impair suitability for specified zones.

➢Do not service unless the area is known to be non-hazardous.

➢Do not open when energized.

➢Installation and use must conform to the directions in this guide.

➢System must be properly connected to earth-ground for effective operation of flame detection circuitry.

Installation Warnings

➢Ensure that the PF3100 enclosures are securely closed each time after opening the enclosure. This protects

the internal circuitry from moisture damage and other environmental concerns. Moisture damage is not

covered by the product warranty.

➢Do not connect wires or handle the device when powered.

➢Properly fuse the board according to local codes.

➢Do not disassemble or modify the board in any way. The board is not field repairable and must be sent back to

PROFIRE for replacement if damaged.

PF3100 IO Modbus Card Product Manual

PROFIRE

1.855.776.3473

solutions@profireenergy.com Page 10 of 10

10. PROFIRE Contact Information

If you have any concerns or questions about this product, please contact PROFIRE as follows:

U.S.

1.801.796.5127

321 South, 1250 West Suite 1

Lindon, UT

84042, USA

solutions@profireenergy.com

CANADA

1.780.960.5278

Box 3313, Bay 12, 55 Alberta Ave

Spruce Grove, AB

T7X 3A6, Canada

solutions@profireenergy.com

http://www.profireenergy.com/

Other manuals for PF3100 Series

6

This manual suits for next models

1

Table of contents

Other ProFire Control Unit manuals

Popular Control Unit manuals by other brands

National Instruments

National Instruments NI 9870 Getting started guide

National Instruments

National Instruments FlexRIO PXIe-79 R Series installation guide

National Instruments

National Instruments CompactRIO cRIO-FRC Operating instructions and specifications

Lutron Electronics

Lutron Electronics QSGRK-6D Quick installation and operation guide

Arduino

Arduino MKR1000 Getting started

EBS

EBS CPX200NW user manual