Prology DVD-557 User manual

S P E C IF IC ATION

S E R VIC E MANUAL

C AR DVD P LAY E R

P R OL OG Y DVD-557

P ower requirement 12 V DC car battery

(negative earth)

oo

Operating temperature -10 C to +70 C

Dimens ions Approx 50mm x178mm

x165mm

(W/h/d)

oo

S torage temperature: -30 C ~ +80 C

Operational humidity: 45% ~80%R H

Atmos phere pressure: 860mbar~1060mbar

TAB LE OF C ONT E NT S

1. G E NE R AL ___________________________________________ 2-3

2. B L OC K DIAG R AM_____________________________________ 4-5

3. E LE C T R IC AL T R O UB LE S HOOT ING G UIDE ________________ 6-21

4. P R INTE D C IR C UIT _____________________________________ 22-28

5. E LE C T R IC AL P AR TS LIS T____________________________ 29-40

1

PRODUCT SAFETY SERVICING GUIDELINES FOR VIDEO PRODUCTS

CAUTION: DO NOT ATTEMPT TO MODIFY THIS PRODUCT IN ANY WAY AND NEVER SUBJECT: X-RADIATION

PERFORM CUSTOMIZED INSTALLATIONS WITHOUT MANUFACTURER'S APPROVAL.

NAUTHORIZED MODIFICATIONS WILL NOT ONLY VOID THE WARRANTY, BUT MAY LEAD TO 1.BE SURE PROCEDURES AND INSTRUCTIONS TO ALL SERVICE PERSONNEL COVER THE

YOUR BEING LIABLE FOR ANY RESULTING PROPERTY DAMAGE OR USER INJURY. SUBJECT OF X-RADIATION. THE ONLY POTENTIAL SOURCE OF X-RAYS IN CURRENT T.V.

RECEIVERS IS THE PICTURE TUBE. HOWEVER, THIS TUBE DOES NOT EMIT X-RYS WHEN THE

SERVICE WORK SHOULD BE PERFORMED ONLY AFTER YOU ARE THOROUGHLY FAMILIAR HIGH VOLTAGE IS AT THE FACTORY SPECIFIED LEVEL. THE PROPER VALUE IS GIVEN IN THE

WITH ALL OF THE FOLLOWING SAFETY CHECKS AND SERVICING GUIDELINES. TO DO APPLICABLE SCHEMATIC. OPERATION AT HIGHER VOLTAGES MAY CAUSE A FAILURE OF

OTHERWISE, INCREASES THE RISK OF POTENTIAL HAZARDS AND INJURY TO THE USER. THE PICTURE TUBE OR HIGH VOLTAGE SUPPLY AND, UNDER CERTAIN CIRCUMSTANCES,

MAY PRODUCE RADIATION IN EXCESS OF DESIRABLE LEVELS.

.WHILE SERVICING, USE AN ISOLATION TRANSFORMER FOR PROTECTION FROM A.C. LINE

SHOCK. 2. ONLY FACTORY SPECIFIED C.R.T ANODE CONNECTORS MUST BE USED

DEGAUSSING SHIELDS ALSO SERVE AS AN X-RAY SHIELD IN COLOR SETS,

SAFETY CHECKS ALWAYS RE-INSTALL THEM.

AFTER THE ORIGINAL SERVICE PROBLEM HAS BEEN CORRECTED, A CHECK SHOULD BE 3. IT IS ESSENTIAL THAT SERVICE PERSONNEL HAVE AVAILABLE AN ACCURATE AND

MADE OF THE FOLLOWING. RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF THE METER SHOULD BE CHECKED

PERIODICALLY AGAINST A REFERENCE STANDARD, SUCH AS THE ONE AVAILABLE AT YOUR

DISTRIBUTOR.

SUBJECT: FIRE & SHOCK HAZARD

4. WHEN THE HIGH VOLTAGE CIRCUITRY IS OPERATING PROPERLY, THERE IS NO

1. BE SURE THAT ALL COMPONENTS ARE POSITIONED IN SUCH A WAY AS TO AVOID POSSIBILITY OF AN ACCURATE AND RELIABLE HIGH VOLTAGE METER. THE CALIBRATION OF

POSSIBILITY OF ADJACENT COMPONENT SHORTS. THIS IS ESPECIALLY IMPORTANT ON THE METER SHOULD BE CHECKED PERIODICALLY AGAINST A REFERENCE STANDARD,

THOSE MODULES WITCH ARE TRANSPORTED TO AND FROM THE REPAIR SHOP. SUCH AS THE ONE AVAILABLE AT YOUR DISTRIBUTOR.

2. NEVER RELEASE A REPAIR UNLESS ALL PROTECTIVE DEVICES SUCH AS INSULATORS, 5. WHEN TROUBLESHOOTING AND MAKING TEST MEASUREMENTS IN A PRODUCT WITH A

BARRIERS, COVERS, SHIELDS, STRAIN RELIEFS, POWER SUPPLY CORDS, AND OTHER PROBLEM OF EXCESSIVE HIGH VOLTAGE AVOID BEING UNNECESSARILY CLOSE TO THE

HARDWARE HAVE BEEN REINSTALLED PER ORIGINAL DESIGN. BE SURE THAT THE SAFETY PICTURE TUBE AND THE HIGH VOLTAGE SUPPLY DO NOT OPERATE THE PRODUCT LONGER

PURPOSE OF THE POLARIZED LINE PLUG HAS NOT BEEN DEFEATED. THAN IT IS NECESSARY TO LOCATE THE CAUSE OF EXCESSIVE VOLTAGE.

3. SOLDERING MUST BE INSPECTED TO DISCOVER POSSIBLE COLD SOLDER JOINTS, 6. REFER TO HV. B+ AND SHUTDOWN ADJUSTMENT PROCEDURES DESCRIBED IN THE

SOLDER SPLASHES OR SHARP SOLDER POINTS. BE CERTAIN TO REMOVE ALL LOOSE APPROPRIATE SCHEMATIC AND DIAGRAMS(WHERE USED).

FOREIGN PARTICLES.

4. CHECK FOR PHYSICAL EVIDENCE DF DAMAGE OR DETERIORATION TO PARTS AND SUBJECT: IMPLOSION

COMPONENTS, FOR FRAYED LEADS AND DAMAGED INSULATION (INCLUDING A.C.

CORD), AND REPLACE IF NECESSARY FOLLOW ORIGINAL LAYOUT, LEAD LENGTH AND 1. ALL DIRECT VIEWED PICTURE TUBES ARE EQUIPPED WITH AN INTEGRAL IMPLOSION

DRESS. PROTECTION SYSTEM, BUT CARE SHOULD BE TAKEN TO AVOID DAMAGE DURING

INSTALLATION, AVOID SCRATCHING THE TUBE. IF SCRATCHED REPLACE IT.

5. NO LEAD OR COMPONENT SHOULD TOUCH A RECEIVING TUBE OR A RESISTOR RATED

AT 1 WATT OR MORE. LEAD TENSION AROUND PROTRUDING METAL SURFACES MUST BE 2. USE ONLY RECOMMENDED FACTORY REPLACEMENT TUBES.

AVOIDED.

SUBJECT: TIPS ON PROPER INSTALLATION

6. ALL CRITICAL COMPONENTS SUCH AS FUSES. FLAMEPROOF RESISTORS, CAPACITORS,

ETC. MUST BE REPLACED WITH EXACT FACTORY TYPES, DO NOT USE REPLACEMENT

COMPONENTS OTHER THAN THOSE SPECIFIED OR MAKE UNRECOMMENDED CIRCUIT 1. NEVER INSTALL ANY PRODUCT IN A CLOSED-IN RECESS. CUBBYHOLE OR CLOSELY

MODIFICATIONS. FITTING SHELF SPACE, OVER OR CLOSE TO HEAT DUCT, OR IN THE PATH OF HEATED AIR

FLOW.

7. AFTER RE-ASSEMBLY OF THE SET, ALWAYS PERFORM AN A.C. LEAKAGE TEST ON ALL

EXPOSED METALLIC PARTS OF THE CABINET, (THE CHANNEL SELECTOR KNOB, ANTENNA 2. AVOID CONDITIONS OF HIGH HUMIDITY SUCH AS: OUTDOOR PATIO INSTALLATIONS

TERMINALS. HANDLE AND SCREWS) TO BE SURE THE SET IS SAFE TO OPERATE WITHOUT WHERE DEW IS A FACTOR, NEAR STEAM RADIATORS WHERE STEAM LEAKAGE IS A FACTOR,

DANGER OF ELECTRICAL SHOCK. DO NOT USE A LINE ISOLATION TRANSFORMER DURING ETC.

THIS TEST, MAKE SURE TO USE AN A.C. VOLTMETER. HAVING 5000 OHMS PER VOLT OR

MORE SENSITIVITY, IN THE FOLLOWING MANNER; CONNECT A 1500 OHMS 10 WATT 3. AVOID PLACEMENT WHERE DRAPERIES MAY OBSTRUCT REAR VENTING. THE CUSTOMER

RESISTOR, PARALLELED BY A.15 MFD. 150V A.C. TYPE CAPACITOR BETWEEN A KNOWN SHOULD ALSO AVOID THE USE OF DECORATIVE. SCARVES OR OTHER COVERINGS WHICH

GOOD EARTH GROUND (WATER PIPE, CONDUIT, ETC.) AND THE EXPOSED METALLIC PARTS, MIGHT OBSTRUCT VENTILATION.

ONE AT A TIME. MEASURE THE A.C. VOLTAGE ACROSS THE COMBINATION OF 1500 OHM 4. WALL AND SHELF MOUNTED INSTALLATIONS USING A COMMERCIAL MOUNTING KIT,

RESISTOR AND 15 MFD CAPACITOR. REVERSE THE A.C. PLUG AND REPEAT A.C. ANY MUST FOLLOW THE FACTORY APPROVED MOUNTING INSTRUCTIONS. A PRODUCT

VOLTAGE MEASUREMENTS FOR EACH EXPOSED METALLIC PART. VOLTAGE MEASURED MOUNTED TO A SHELF OR PLATFORM MUST RETAIN ITS ORIGINAL FEET (OR THE

MUST NOT EXCEED 75 VOLTS R.M.S. THIS CORRESPONDS TO 0.5 MILLIAMP A.C. ANY EQUIVALENT THICKNESS IN SPACERS). TO PROVIDE ADEQUATE AIR FLOW ACROSS THE

VALUE EXCEEDING THIS LIMIT CONSTITUTES A POTENTIAL SHOCK HAZARD AND MUST BE BOTTOM. BOLTS OR SCREWS USED FOR FASTENERS MUST NOT TOUCH ANY PARTS OR

CORRECTED IMMEDIATELY. WIRING. PERFORM LEAKAGE TEST ON CUSTOMIZED INSTALLATIONS.

5. CAUTION CUSTOMERS AGAINST THE MOUNTING OF A PRODUCT ON SLOPING SHELF

OR A TILTED POSITION, UNLESS THE PRODUCT IS PROPERLY SECURED.

6. A PRODUCT ON A ROLL-ABOUT CART SHOULD BE STABLE ON ITS MOUNTING TO THE

CART CAUTION THE CUSTOMER ON THE HAZARDS OF TRYING TO ROLL A CART WITH

SMALL CASTERS ACROSS THRESHOLDS OR DEEP PILE CARPETS.

7. CAUTION CUSTOMERS AGAINST THE USE OF A CART OR STAND WHICH HAS NOT BEEN

GOOD EARTH GROUND LISTED BY UNDERWRITERS LABORATORIES, INC. FOR USE WITH THEIR SPECIFIC MODEL OF

SUCH AS THE WATER TELEVISION RECEIVER OR GENERICALLY APPROVED FOR USE WITH TV'S OF THE SAME OR

PIPE, CONDUIT, ETC. LARGER SCREEN SIZE.

8. CAUTION CUSTOMERS AGAINST THE USE OF EXTENSION CORDS. EXPLAIN THAT A

FOREST OF EXTENSIONS SPROUTING FROM A SINGLE OUTLET CAN LEAD TO DISASTROUS

SUBJECT GRAPHIC SYMBOLS CONSEQUENCES TO HOME AND FAMILY.

The lightening flash with arrowhead symbol, within an equilateral

triangle, is intended to alert the user to the presence of uninsulated

"dangerous voltage" within the product's enclosure that may be of

sufficient magnitude to constitute a risk of electric shock to persons.

The exclamation point within an equilateral triangle is intended to alert

the user to the presence of important operating and maintenance

(servicing) instructions in the literature accompanying the appliance.

PLACE THIS PROBE

ON EACH EXPOSED

METAL PART

2

CAUTION : Before servicing the DVD covered by this service Electrostatically Sensitive (ES) Devices

data and its supplements and ADDENDUMS, read and Some semiconductor (solid state) devices can be

follow the SAFETY PRECAUTIONS NOTE : if unforeseen damaged easily by static electricity. Such components

circumstances create conflict between the following commonly are called Electrostatically Sensitive (ES) Devices.

servicing precautions and any of the safety precautions in Examples of typical ES devices are integrated circuits and

this publications, always follow the safety Precautions. some field effect transistors and semiconductor chip

Remember Safety First: components. The following techniques should be used to

help reduce the incidence of component damage

caused by static electricity.

General Servicing Precautions

1. Immediately before handling any emiconductor

1. Always unplug the DVD DC power cord from the DC component or semiconductor-equipped assembly, drain

power source before: off any electrostatic charge on your body by touching a

(1) Removing or reinstalling any component, circuit board, known earth ground. Alternatively, obtain and wear a

module, or any other assembly. commercially available discharging wrist strap device,

(2) Disconnection or reconnecting any internal electrical which should be removed for potential shock reasons

plug or other electrical connection. prior to applying power to the unit under test.

Caution : A wrong part substitution or incorrect polarity

installation of electrolytic capacitors may result in an 2. After removing an electrical assembly equipped with ES

explosion hazard. devices, place the assembly on a conductive surface

such as aluminum toil, to prevent electrostatic charge

2. Do not spray chemicals on or near this DVD or any of its buildup or exposure of the assembly.

assemblies.

3. Use only a GROUNDED-tip soldering iron to solder or

3. Unless specified otherwise in this service data, clean unsolder ES devices.

electrical contacts by applying an appropriate contact

cleaning solution to the contacts with a pipe cleaner, 4. Use only an anti-static solder removal device. Some

cotton-tipped swab, or comparable soft applicator. solder removal devices not classified a "anti-static" can

Unless specified otherwise in this service data, lubrication generate electrical charges sufficient to damage ES

of contacts is not required. devices.

4. Do not defeat any plug/socket B+ voltage interlocks with 5. Do not use freon-propelled chemicals. These can

which instruments covered by this service manual might generate electrical charge sufficient to damage ES

be equipped. devices.

5. Do not apply AC power to this DVD and/or any of its 6. Do not remove a replacement ES device from its

electrical assemblies unless all solid-state device heat protective package until immediately before you are

sinks are correctly installed ready to install it. (Most replacement ES devices are

.packaged with leads electrically shorted together by

6. Always connect test instrument ground lead to the conductive foam, aluminum foil, or comparable

appropriate ground before connection the test conductive material.)

instrument positive lead. Always remove the test

instrument ground lead last. 7. Immediately before removing the protective material

from the leads of a replacement ES device, touch the

protective material to the chassis or circuit assembly into

Insulation Checking Procedure which the device will be installed.

Disconnect the attachment plug trom the AC outlet and Caution : Be sure no power is applied to the chassis or

turn the power on. Connect an insulation resistance circuit, and observe all other safety precautions.

meter(500V) to the blades of the attachment plug. The

insulation resistance between each blade of the 8. Minimize bodily motions when handling unpackaged

attachment plug and accessible conductive parts (Note 1) replacement ES devices. (Normally harmless motion

should be more than 1M ohm. such as the brushing together of your clothes fabric or

the lifting of your foot from a carpeted floor can

Note 1 : Accessible Conductive Parts including Metal generate static electricity sufficient to damage an ES

panels, input terminals, Earphone jacks, etc. device.)

SERVICING PRECAUTIONS

3

TR+

FO+

TR-

FO-

VCC

GND

GND

LD

V/2

VR

PD

VC

VA

GND

VB

VD

VDS

GND

V/2

VCC

GND

LD

VC

VR

PD

VA

VE

GND

VF

VB

1

10

20

30

CN2

CN7

1SLOAD-

SLOAD+

CN3

A2

A1

H-

H1-

H1+

H2-

H2+

H3-

H3+

H+

1

11

CN6

1SLED+

SLED-

CN8

1SW1-1

RFGND

CN5

1 SW-1

SW-2

GND

SW-4/6

GND

SW-3

TO PICK UP MECHANISM CHASSIS

TO PICK UP MECHANISM CHASSIS

RF AMP

U2

SP3721

SERVO

&TRAY

DRIVER

BA5954

&BA6849

SERVO AND DVD PROCESSOR

M5705

33.8688MHz

MPEG-2 DECODER

U5

VEDIO ENCODER

EEPROM

W29C011AP-15

16MSDRAM

HY57V16160DTC

16MSDRAM

HY57V16160DTC

8MFLASH

CS4340

AUDIO DAC

CN202

1

10

+5V

+5V

+5V

DGND

DGND

DGND

DGND

+12V

SLOAD-

SLOAD+

CN203

1

10

20

AGND

AGND

SW1

SW2

SW4/6

SW3

STB

DATA

CLK

MPEG_CMD

L

R

PARKING

AGND

AGND

AGND

AGND

MIC_ON

AGND

AIN

AGND

VD

AGND

AMUTE

1

CVBS1

CVBS2

SPDIF

VGND

VGND

DGND

CN204

U9 U10

U1

U8

U7

SST39VF800

U12

U502

TO MAIN BOARD

TO MAIN BOARD

SERVO AND DECODER BOARD

U4

A3

TO PICK UP

MECHANISM

CHASSIS

TO PICK UP

MECHANISM

CHASSIS

TO PICK UP

MECHANISM

CHASSIS

27MHz

Y1

Y3

BLOCK DIAGRAM

TO THE

EXTERIOR

TO PICK UP

MECHANISM

CHASSIS

4

MAINBORAD BLOCK DIAGRAM

+5V

+5V

+5V

DGND

DGND

DGND

+12V

SLOAD-

SLOAD+

1

10

20

AGND

AGND

SW1

SW2

SW4/6

SW3

STB

DATA

CLK

MPEG_CMD

L

R

PARKING

AGND

AGND

AGND

AGND

MIC_ON

AGND

AIN

AGND

VD

AGND

AMUTE

1

10

DGND

DGND

LCD_INH

CCB-LCD-CE

CCB-LCD-DO

CCB-CL

CCB-DI

PAN_INH

SW4-6

POWER-LED

EJECT

ENCODER_B

ENCODER_A

8V

REMOTE

P5V

U201

TMP87CM21DF-100

LB1641

TEA6320T

8M 32.768k

1

AUXL

AAGND

AAGND

AUXR

BA3121F

U504

U301

TDA7386

TLC2272

U601 U602

U503

GND

LIGHT

PAKING

TEL MUTE

FL-

FL+

FR-

FR+

RR+

RR-

RL+

RL-

AMP.CONT

AUTO.CONT

ACC+

B+

1

10

1

10

BUS

B+

AGND

ACC

NC

R-CH

L-CH

VM1

DGND

DGND

DGND

1

FRONT-L

FRONT-R

AGND

AGND

AGND

SBW

CN601

REAR-L

REAR-R

AGND

AGND

CN604

TLC2272

U604

U701

Pt2257

U706

TLC2272

U101

TC9257F

U102

FAE347-A28

U707

LC72722M

TO KEY BOARD

TO SERVO AND DECODER BORAD

TO SERVO AND DECODER BORAD

OPERATIONAL AMPLIFIER

POWER AMPLIFIER

SOUND FADER CONTROL

8BIT MCU

U203

MOTOR DIRVER

TUNER RECEIVER

GROUND ISOLATION AMPLIFIER

RDS

Signal-Processing

PLL

OPERATIONAL

AMPLIFIER

DGND

CN201

CN402

1

10

CN301CN2 CN501

7.2M

TO THE

EXTERIOR

TO THE

EXTERIOR

TO THE

EXTERIOR

TO THE

EXTERIOR

TO THE

EXTERIOR

BA3121F

U501

GROUND ISOLATION AMPLIFIER

5

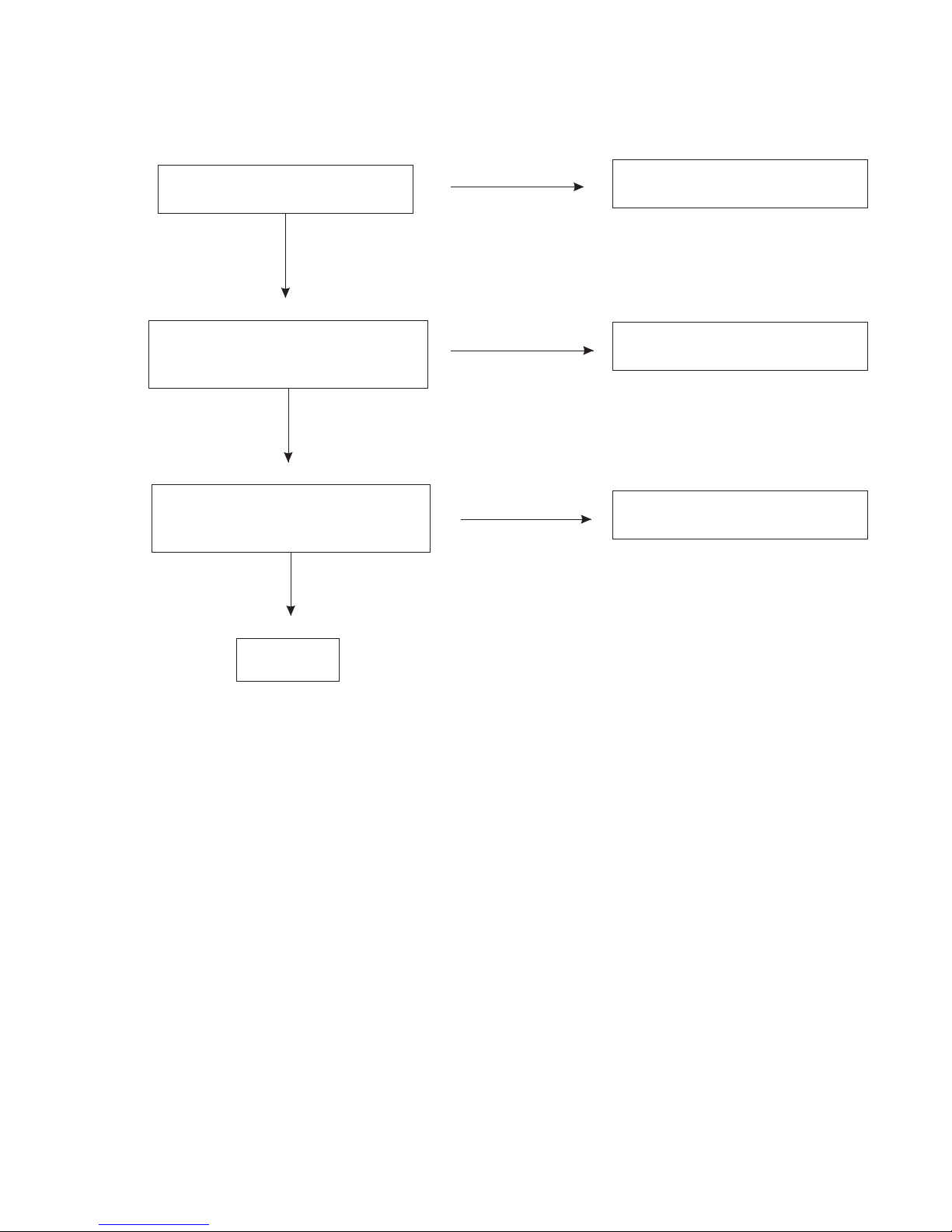

Electrical Trouble Shooting Guide

Connection of unit is correct

Setting of unit is correct

Is power noraml?

Is fluoresce

display corrct?

Is open/close

noraml?

Is audio normal?

Can disc be read?

Is video normal?

Normal

Refer to power guide

Refer to display guide

Refer to open/close guide

Refer to read disc guide

Refer to video guide

Refer to audio guide

NO

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

Is LOGOout? Refer to logo guide

YES

NO

Is tuner normal? Refer to tuner guide

YES

NO

Is CDC normal? Refer to cdc guide

YES

NO

6

A Power Circuit abnormal(For main board)

START

Is 1pin of Q404 DC 12V? Check D307

Is 40pin of U201 DC 5V?

Is 33pin of U201 DC 5V?

Is 5pin of Q404 DC 12V?

Is 2pin of U404 DC 5V?

Is net of 8V DC 8V?

Is 39pin of U201 DC 3.3V?

Normal

YES

NO

Check Q401 U403 L401and peripheral

components.

Check U201 and peripheral components

Check Q404 Q408 and peripheral components

Check U404 and peripheral components

Check ZD439 and peripheral components

Check U402 and peripheral

components

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

Is 26pin of U201 DC 5V?

Check Zd401 and peripheral components.

NO

YES

Check ACC and ACC fuse.

7

B Display abnormal (For main board)

START

Does the screen appear?

Is display normal?

Normal

Check if pin14 of CN201voltage of DC 8V?

Check if pin 16 of 201 voltage of DC5V?

Check the key board according to key

schematic

Cn

Check the key board according to key

schematic

YES

NO

YES

NO

8

C IN/OUT abnormal (For main board)

THE disc can't be injected

Is 7,8pin of Lb1641 DC 12V?

Is Voltagebetween 2 and 10pin ofLb1641

DC 4.6V after eject-key being pressed?

Is voltage between 2 and 1pin of

cn7 at S&D board DC 4.5V?

Check R205 R245 L201

2.Check Zd201 ,Lb1641

Check connection between main

board and S&D board

1.Check cn8 at S&D board , connection

between it and MCU

Normal

YES

YES

YES

NO

NO

NO

9

D Logo Display abnormal(For S&D board(SERVO and Decoder board))

Is vlotage for CN202 normal?

No Logo display

Having picture,no color or color

disappered during playback.

Check Connection of Main board and

S&D board

Change S&D board

Check decoder part and change Y1

Normal

YES

NO

YES

NO

YES

NO

10

E Read disc abnormal(For S&D board)

DISC IN

Focus on?

Is laser normal?

Does the disc turn?

Can TOC be read?

Refer to Focus abnormal

Refer to laser abnormal

Refer to disc turn abnormal

Refer to TOC abnormal

Normal

YES

YES

YES

YES

NO

NO

NO

NO

11

F Video abnormal

Only Logo display

Having picture, no colour or colour

disappeared during playback.

Having picture, but picture

disappeared during playback.

Check the connection of M5705 and Zr36748

Check decoder part and change Y2

Check decoder part and change Y2

Normal

YES

YES

YES

NO

NO

NO

12

G Audio abnormal(For main board)

Is the rear channel normal?

Is the front channel and

sbw channel normal?

Is the power amplifier

normal?

Normal

Refer to rear out abnormal

Refer to front out abnormal

YES

YES

YES

NO

NO

NO Check U301 and peripheral components.

13

H Turner abnormal(For main board)

Auto search abnormal

Is 13pin of U101 9V?

Is X101 oscillating?

Is 12pin of U101 9V at FM

mode and 0V at AM mode?

Normal

Autosearch normal

but audio abnormal

Is 3,4,29,30pin of

U503 normal?

Normal

RDS abnormal

Normal

Check P9V, if P9V is 9V,check Q110 Q115

and peripheral components.

If P9V is 0V, check according to main board

power schematic

Check Tc9257 X101 and peripheral components

Check 17pin of Tc9257 Q103 Q108 and

peripheral components

Check connection between 16,17pin of U101

and U503

Replace U503

Check U707 and peripheral components

YES

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

NO

14

I CDC abnormal(For main board)

CDC does not work

Is 2,4pin of CDC normal? Check Fb503

Is connection of 1pin of CDC with U201 normal?

Normal

Check correlative print wire

CDC audio abnormal

Is 1,7pin of U501 normal?

Is 3,4,29,30pin ofU503 normal?

Normal

Is pin8 of U501 Dc9? If not, check correlative printed wire

else, check peripheral components.

If still abnormal, change U501

Check U503 and peripheral components.

Is 31pin of U503 DC9V?

If still abnormal, change U503

YES

YES

YES

YES

NO

NO

NO

NO

15

No focus

Does normal voltage at FO+

and FO- of CN2?

Does normal voltage

at U9 pin 14,7?

Does data output at U2 pin42?

Normal

J Focus abnormal(For S&D board)

1. Check connection cord..

2. Replace pickup

1.Check connection between 14,7pin of BA5954

and FCS+,FCS- of CN2

2.Check if Y3 normal operation

3.Check BA5954 and peripheral components.

1.Check connection between U2 and U9

2.Check connection between U2 and peripheral

components.

Check U2 and peripheral components.

Is 28,30,35,58pin of U2 DC5V?

Is normal voltage at 18,26,27pin of U2? Check U3 and peripheral components

YES

YES

YES

YES

YES

NO

NO

NO

NO

NO

16

No laser

Does normal voltage at pin 25 of U2?

K Laser abnormal(For S&D board)

Does normal voltage at 24,22pin of U2?

Does normal Voltage at cathode of D2,D3?

Normal

YES

YES

YES

1.Check connections between M5705 and

Sp3721

2.check Sp3721 and peripheral components.

Check Sp3721 and peripheral components

YES

Check Q1 Q2 and peripheral components

Change pick up

17

L Turn abnormal(For S&D board)

Disc doesn't turn

Check if voltage of H- and H+,H1-and H1+,H2-

and H2+,H3- and H3+ of CN3 are different.

Check If voltage of 11 and 12 pin of

U9 are different.

Check if voltage of 26 pin of U2 is normal

Check if voltage of 13,9 pin of u2 is normal

Normal

Check connection of mechanism

Check connections between Ba 5954 and

CN6

check Ba5954 and peripheral components

Check connections between Sp3721 pin 26

and Ba5954 pin 4,27

Check Sp3721 and peripheral components.

Check connections between U2 5,23 pins and

U1 pins 13,9

Check U1 and peripheral components

YES

YES

YES

YES

NO

NO

NO

NO

18

M TOC abnormal(For S&D board)

TOC does not read

Limited switch is closed.

Is laser on?

Is FOK normal?

Does normal A, B, C, D signal at 11-14

pin of U2?

Does normal RFIN at 2 pin of U1?

Normal

Refer to laser guide

Check slide motor and connections to decoder

board.

1.Check connections between 11,13 pin of U2

and 13pin of CN2

2.Check 12,14pin of U2 and 15pin of CN2

3.Replace pickup

1.Check connection between U1 and U2.

2.Check U2 and peripheral components

YES

YES

YES

NO

NO

NO

19

N Rear out abnormal(For main board)

Rear out no sound or

sound abnormal

Is the 13,15 pin of

CN603 normal?

Is the 4,14 pin of

U603 abnormal?

Is the 1,7 pin of

U604 abnormal?

Is mute control normal?

Normal

Check connections between Main board and

S&D board

Check connections between CN603 and U603

Check U604 and peripheral components

Check Q605 Q607 Q609 Q610 and peripheral

components

YES

YES

YES

YES

YES

NO

NO

NO

NO

20

Other manuals for DVD-557

1

Table of contents

Other Prology Car Video System manuals