Promatic Super Hawk User manual

You must treat a clay target launcher with the same cauon that you

would treat a loaded gun.

Assume at all mes that a clay target launcher is

armed and loaded and treat it accordingly

Operang Instrucons

Wobble units - Super Hawk

This document must be read in full before aempng to operate the machine

WARNING

Clay target launchers can be

dangerous and must be treated

with great care at all mes to

avoid accidents.

Never place any bodily part into

the path of any mechanical piece

whilst the machine is in moon or

likely to be so.

2

12v DC Power Source:

This product is designed to be powered from a 12v DC baery, it

SHOULD NOT BE DIRECTLY CONNECTED TO HOUSEHOLD AC POWER

Baery: Where a trap is connected to any other suitable power source

i.e. a Transformer - the relevant secons of instrucons should sll be

observed, i.e. “Disconnect the baery” and applied to this or any other

power source.

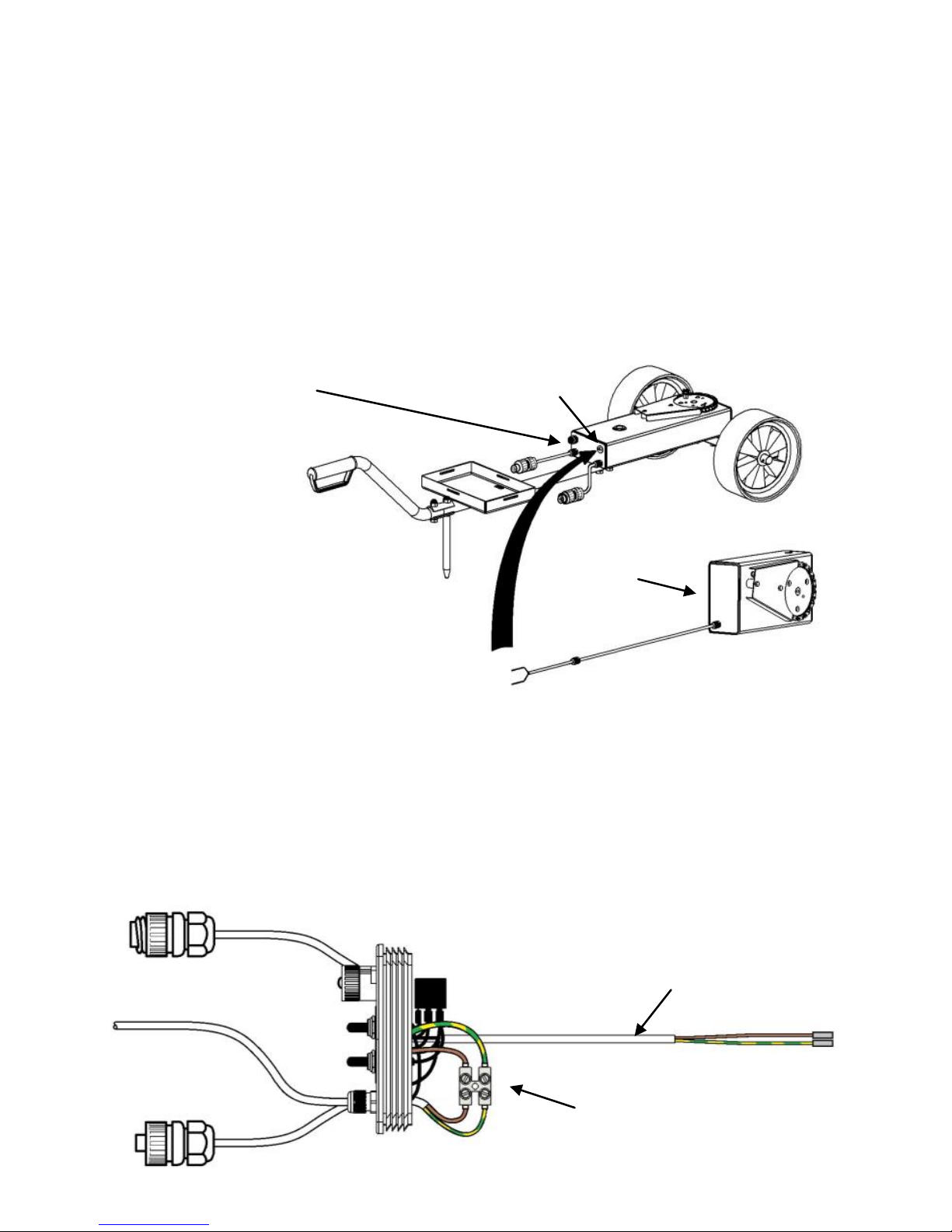

Extension

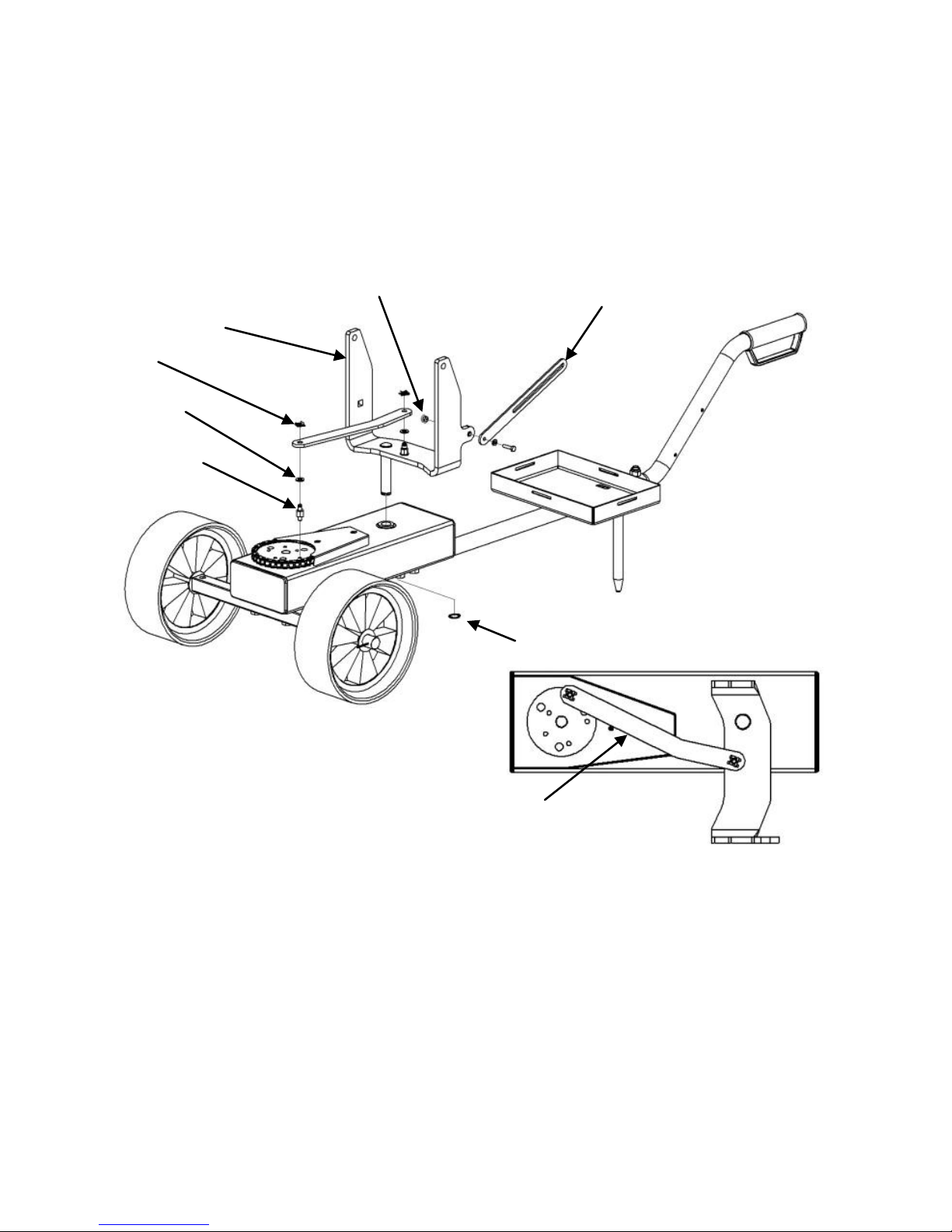

tube &

baery tray

Trolley

handle

Ground Spike

assembly

Rotaon box

WARNING THE TRAP MUST BE MADE SAFE

BEFORE CONTINUING - SEE BACK PAGE

Dis-assemble the trap from its base

The rotaon box forms the basis of the trolley

spine. A swivel piece mounted to this acts as a

mount for the trap and replaces the trap’s ex-

isng base.

As supplied your trap will be ed to a pressed

steel base plate (with diagonal braces) it should

be removed from this base complete with its

rear support stay, this stay and some of the

exisng fasteners will be required to complete

this assembly.

Assemble the Rotaon box to the trolley base:

Fit the trolley axle to the front (gear wheel) end

of the rotaon box, t the bolts from below

with the nuts secured inside the rotaon box.

For each wheel t a brass washer before &

aer and secure in place using a split pin.

Fit the extension tube baery tray assembly to

the rear end of the rotaon box, followed by

the trolley handle using the ground spike and

clam-plate assembly to complete the joint as

shown below.

Trolley

axle

3

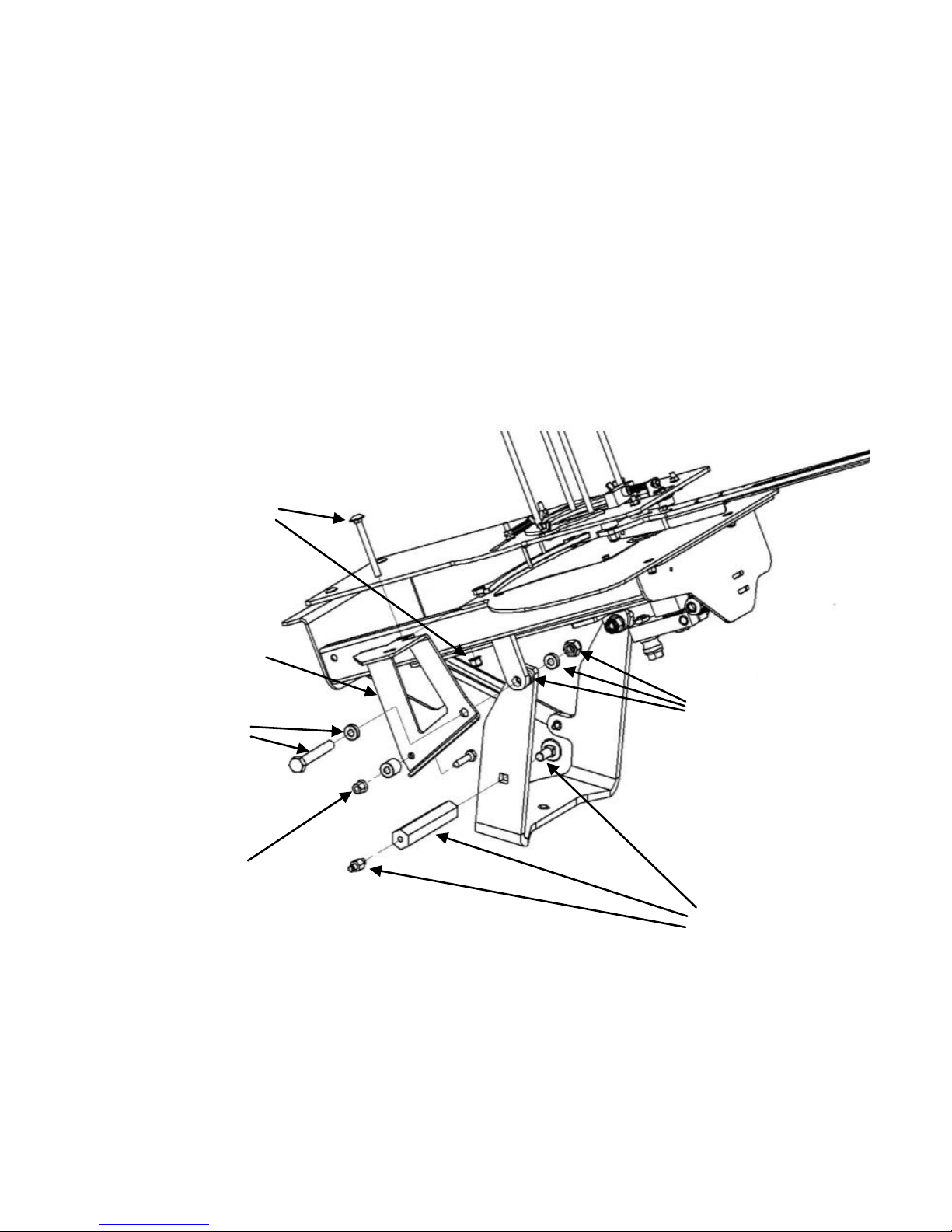

Fit Trap mount & connect linkage to rotaon wheel:

(All versions)

Insert the trap mount’s lower pin through the bearing in the rotaon box as shown

below, secure with the circlip provided. Fit a threaded spigot to the trap mount, then

t a lightly greased washer, aach the short end of the linkage as shown below and

secure with a spring clip which simply slides into the ne groove, snapping in place

over the end of the sha.

Fit the other threaded spigot into any of the holes of the rotang wheel, t another

lightly greased washer to this spigot and connect the other end of the linkage with a

spring clip as before.

Mount the trap onto the base:

The trap should now be mounted onto the trap carrier. Use a nylock nut and washer on

the pivot points, ghten these unl the trap can just pivot freely on the base without

any resistance being felt.

Rear support stay:

If a rotaon box only is ed (DTL trap) the rear support stay (removed from the old

trap base) should be ed to the trap mount using the original bolt & washer as shown

above. Note this is xed into the hexagonal hole in the trap carrier using the locking

nut “backwards” i.e. the hexagon is placed into the hole and the bolt ed through it

so that the ange is on the inside of the trap carrier locking the assembly in place.

If an elevaon box is to be ed (ABT trap) the rear support stay should not be ed as

this could allow the frame to become locked causing damage to the elevaon motor or

linkage.

Circlip

Trap mount Rear support stay

Clip

Washer

Threaded

Spigot

Circlip

Trap mount

Rear support stay

Clip

Washer

Threaded

Spigot

Inverted anged nut

Note orientaon of linkage

4

B

D

C

A

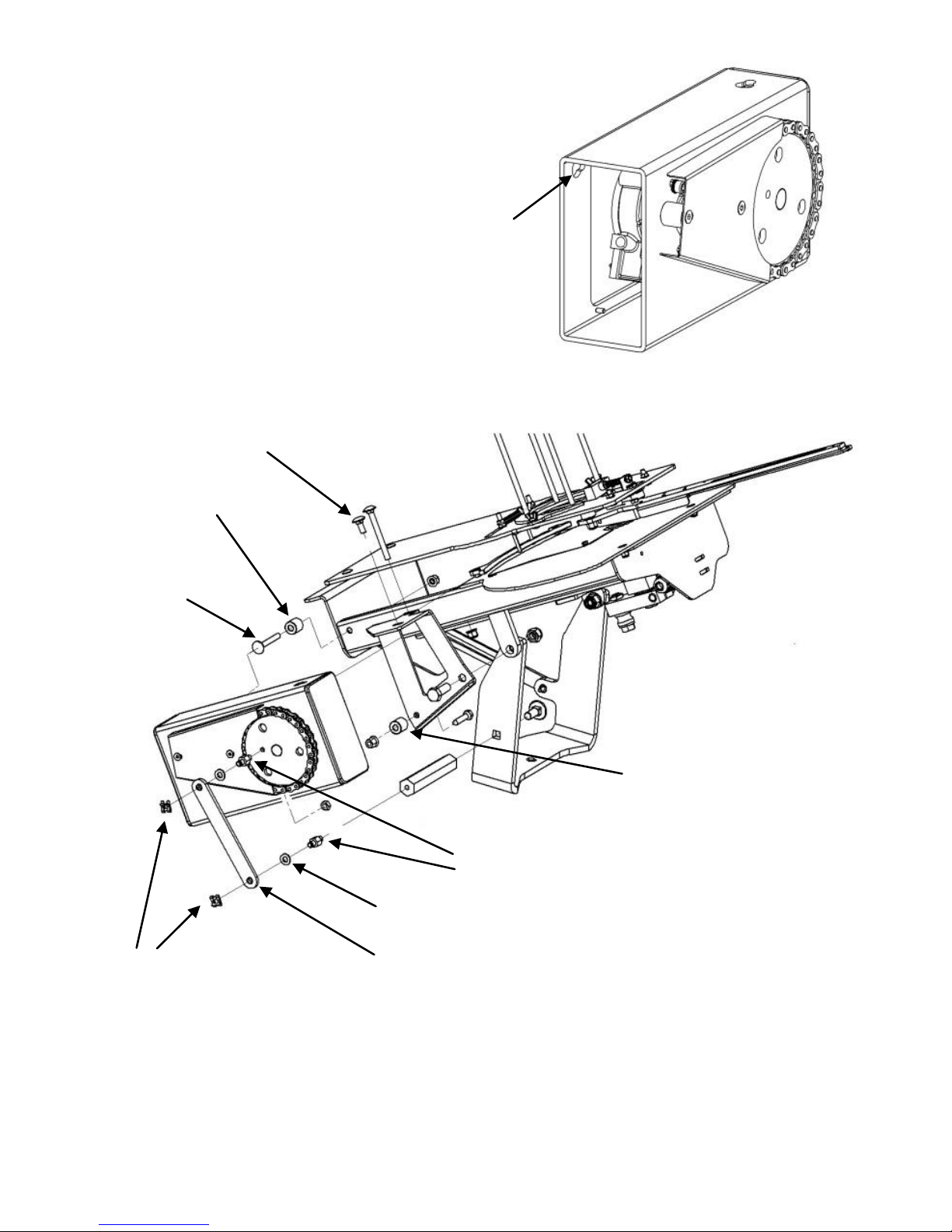

Elevaon box

mounng bracket

B

Assemble the Elevaon box and bracket (Where ed)

Insert the short M12 cup square bolt into the mounng hole in the side of the swivel

bracket and t the long hexagonal stud onto it (A on diagram) ghtening this securely

to the frame member, next insert a threaded spigot into the other end and ghten this

in place.

Aach the elevaon box mounng bracket to the trap’s right hand pivot point using

the longer M12 hex head bolt and 3 washers (B on diagram) lightly grease the centre

washer (between trap pivot and mount, then secure this assembly on the inside with

an M12 Nyloc nut. Similarly secure the trap’s le hand pivot point using the shorter

M12 hex head bolt and 3 washers, again apply grease to the centre washer and secure

with an M12 Nyloc nut. Do not over-ghten as these are the main pivot points.

Fix the bracket to the trap frame using the Long Cup square bolt vercally through trap

frame (C on diagram) secure below with an M8 nyloc nut.

At the rear of the bracket loosely place the M8x40 Cup square bolt and the shorter

nylon spacer (D on diagram) but do not t the nut yet.

Check that the trap pivots freely on its mount without any resistance being felt (too

much resistance would cause premature wear to the elevaon components as well as

excessive baery drain.

Fit the Elevaon box to the bracket

Remove the large black plasc plugs from the ends of the elevaon box (taking care

not to dislodge the electrical wiring from the motor) this will allow a clear view of the

internal keyhole slots in the rear face of the box.

The elevaon box has two keyhole shaped slots in its rear face, however on this model

these are not used in the convenonal manner.

Fit the elevaon box to the bracket at the front by passing the M10 hex head bolt

through the forward keyhole slot and securing internally with a Nyloc nut (Do not fully

ghten yet).

5

Each of the threaded spigots should now be ed with a lightly greased washer, fol-

lowed by the crank ed between them. The crank is secured by a spring clip at each

end which simply slides into the ne groove, snapping in place over the end of the

sha.

Keyhole

slot

At the rear of the trap pass the M8

cup square bolt through the rear key-

hole slot and the longer nylon spacer,

passing the bolt through into the hole

in the trap’s side frame ensuring that

the ats of the cup square head sit

properly within the thin part of the

keyhole slot before securing with a

Nyloc nut (Do not fully ghten yet).

Returning to the front of the elevaon

box, place the short M8 Cup square

bolt (Upper xing bolt on diagram

below) through the keyhole slot in the

upper face and securing internally

with a Nyloc nut.

At this stage all three nuts should be

fully ghtened and the plasc end

caps replaced.

Mounng

bolt

Nylon spacer

(Long)

Clip Crank

Threaded Spigots

Upper xing bolt

Washer

Nylon spacer

(Short)

6

Elevaon

box

Blanking plug

Control panel

Connecng the electrical wiring:

Remove the black end plug (control panel) from the rotaon box.

The electrical assembly within the rotaon box has controls for rotaon and elevaon.

The elevaon box is connected into the exisng rotaon box, undo and discard the

white or light coloured blanking plug on the rotaon box and pass the wiring from the

elevaon box through into the rotaon box.

It is advisable to slacken the rear part of the gland to allow it to spin on the cable dur-

ing ng - this prevents the cable from twisng as the gland is screwed in.

Once the cable is in place ghten the gland into the threaded hole and t the plasc

nut to secure it in place, re-ghten the front part to seal the cable against moisture

ingress and prevent it pulling out in use.

The wiring for the elevaon unit is ed with metal boot-lace ends, and should be

ed into the terminal block connectors a shown below.

Elevaon box cable

Connecon to trap

Connector for

re buon Terminal block for elevaon

motor connecon

Rotaon motor

power cable

(ed)

Connect the wiring to the

terminal block.

The cable supplied will have

Brown and green/yellow wires

ed with metal boot-lace ends

(there may also be a blue wire cut

back—this is not used)

The brown wire should be connected to the terminal with the brown wire in it.

The green/yellow wire should be connected to the terminal with the green/yellow

wire in it.

Ensure that the screws are fully ghtened and that the gland is secure to prevent the

cable pulling out in use.

Replace the black end plug (control panel) in the end of the rotaon box ensuring that

the relays are passed inside the box and that no wires become trapped. Tap the plug

home with rm hand pressure near the edges.

7

Connect the baery:

Secure the baery to the tray using the Velcro strap(s) provided.

Ensure that the main power switch on the trap, as well as the two switches on the con-

trol panel are in the OFF (centre) posion before connecng to the baery.

The RED connector goes onto the + (or red coloured) baery terminal

The BLUE connector goes onto the - (or black coloured) baery terminal

How to operate:

Rotaon Funcon - Seng the switch down to the ROTATION posion will allow to

motor to run connuously varying the angle of the target le-to right. Pushing the

switch upwards to the NUDGE posion will give a momentary burst of movement for as

long as you connue to hold the switch toggle (automacally springing back to the OFF

posion when released) this will allow a xed trajectory to be selected.

Using the oponal holes on the rotaon disc a narrower or wider target eld can be

selected as desired.

The elevaon funcon (where ed) works in the same way, note that the pitch and

gearing of the two funcons has been designed so that the target movement in each

plane is not the same, and once the mechanisms have run for a few turns the move-

ment becomes unpredictable, making the targets that bit more challenging.

Refer to the main operang instrucons for details of specic features and operaon of

the trap, and the leaet provided with any radio which may have been purchased.

Motor wiring:

If any motor wiring has been supplied loose, or has been disconnected at any me

during trap assembly, reconnect as follows:

Warning:

THE TRAP MUST BE IN SAFE MODE BEFORE CONTINUING - SEE BACK

PAGE FOR INSTUCTIONS ON HOW TO DO THIS.

8

Promatic Inc.

801, Mid America drive

Plattsburg

MO 64477

USA.

Toll Free: 888.767.2529

Fax: 816.539.0257

E-mail: sales@promatic.biz

Website: www.promatic.biz

Promatic International Ltd.

Hooton Road

Hooton

South Wirral

CH66 7PA

United Kingdom

Tel: +44 (0) 151 327 2220 (General)

Fax: +44 (0) 151 3277075

E-mail info@promatic.co.uk

Website: www.promatic.co.uk

Super Hawk Wobble Version 1.6 March 2019

Safe Mode Procedure - Warning: Stand at rear of machine only

1. To disarm the machine press the red test fire button at the rear of the machine and

immediately push the on/off toggle switch upwards to the dis-arm position before the

machine re-arms.

2. Hold the toggle switch upwards until the throwing arm is pointing towards the front

of the machine.

3. Release the toggle switch and disconnect the baery/power source from the

machine .

Spring Removal / Tensioning:

Removal of, or tensioning of the spring can be carried out only in

the disarmed condition.

Table of contents

Other Promatic Accessories manuals