- 6 -

WHEN YOU SEE THIS SYMBOL

SAFETY

2

ATTENTION!

BE ALERT

YOUR SAFETY IS INVOLVED

This symbol «SAFETY ALERT» is used in this manual

and on the safety decals on the Snowblower. It warns you

of the possibility of danger. Carefully read, understand and

follow all safety recommendations before operating the

Snowblower.

1) Careful operation is the best assurance against acci-

dents. Carefully read this manual and follow all

recommendations before operating your Snowblower.

It is the owner’s responsibility to make sure that anyone

who will operate the Snowblower will read this manual

before operating the equipment.

2) Familiarize yourself with all controls and always be

ready to stop the Snowblower quickly in case of

emergency.

3) Never let a child operate the Snowblower.

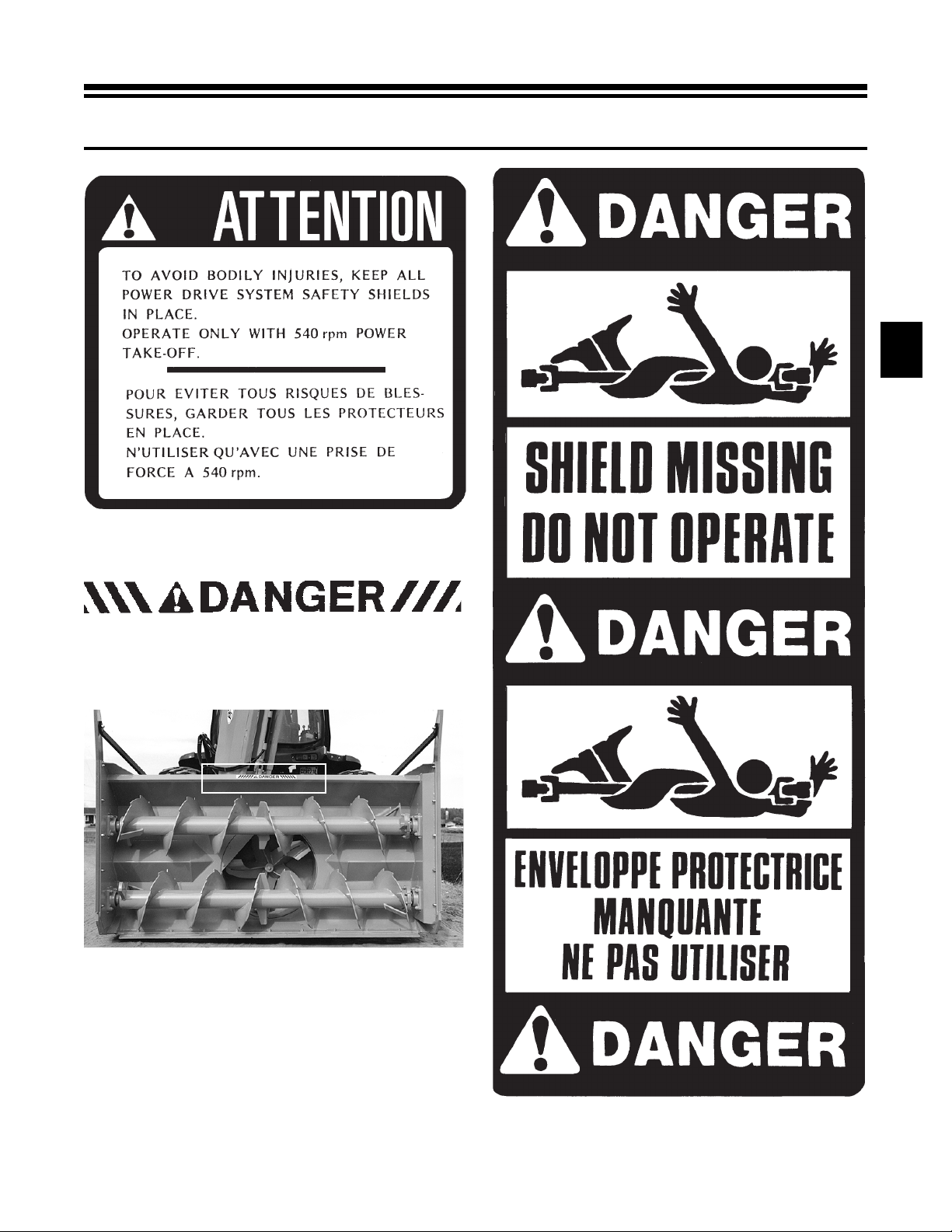

4) Do not modify the Snowblower. Any non authorized

modification may affect the efficiency and/or safety of

the equipment and will automatically void the warranty.

5) Never operate the Snowblower with defective parts or

if damaged in any way. Have it repaired before

operating.

6) Make sure all fasteners are in place and properly

secured or tightened. Refer to torque chart on page 41.

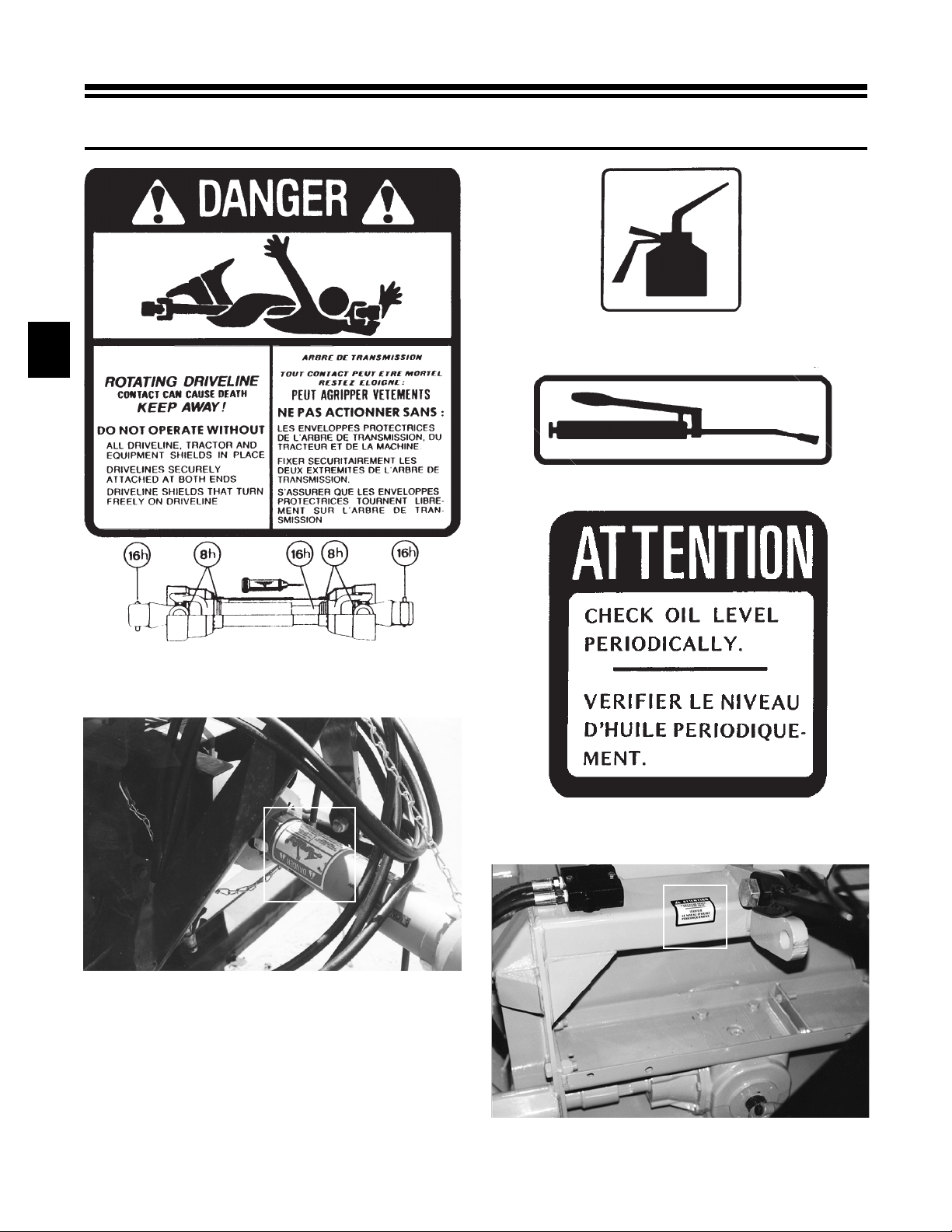

7) Avoid wearing loose fitting clothing when working

with the Snowblower. These could get entangled in

moving parts of the equipment and cause accidents.

GENERAL SAFETY

8) Prolonged exposure to noise may hamper hearing.

Protect yourself by wearing adequate protection

devices.

9) Hydraulic fluids under pressure can damage your skin.

Do not use your hands to locate a leak.

10) Before the beginning of the snow season, inspect all

areas where the Snowblower will be used and remove

any object which may cause an accident and/or damage

the equipment.

11) Never operate your Snowblower in poor visibility or

without proper lighting conditions.

SAFETY IN OPERATION

1) Be sure there are no obstructions around the equipment

and that no one stands near the equipment when in

operation.

2) Do not operate an engine in a confined or non

ventilated area.

3) Do not perform any adjustments, cleaning, maintenance

or repairs with the engine running. The engine must be

stopped and the P.T.O. disengaged. Preferably remove

the key from the ignition.

4) Wear adequate clothing when working in cold or windy

conditions.

5) Adjust skid shoes for proper ground clearance of

scraper blade, especially in rough terrain or soft ground

conditions.

6) Before operating, make sure the P.T.O. is properly

installed and secured.

7) Before starting-up the Snowblower, make sure the

auger and drum areas are free of ice.

8) Put P.T.O. control in neutral position before starting

engine.

9) Keep hands, feet and clothing away from moving parts

of the Snowblower. Stay away from the discharge

chute.