3. Always hold the tool firmly in your hands before switching the tool

ON. The reaction to the motor’s torque may cause the tool to twist,

as it accelerates to full speed.

4. Never attempt to change the impact socket's direction of rotation

while it is active. This can damage the interlock feature built into

the switch. Be sure the impact socket has completely stopped and

engage any safety features before changing the rotation direction.

Turn the power off as an added precaution.

5. Do not cool the impact socket with any liquid when hot. This can

damage the the impact socket by weakening the material, making

the accessory unsafe for use.

POWER TOOL PRECAUTIONS

1. Do not use any power tool with a malfunctioning power switch

or control. A power tool that fails to respond to the controls is

dangerous and can cause an injury. A qualified technician must

repair and verify the power tool is operating correctly, before it can

be used.

2. Shut the power off and disconnect the impact wrench from

the power supply (if possible) before making any adjustments,

changing accessories, cleaning, servicing or when storing. Such

preventive safety measures reduce the risk of starting the tool

accidentally.

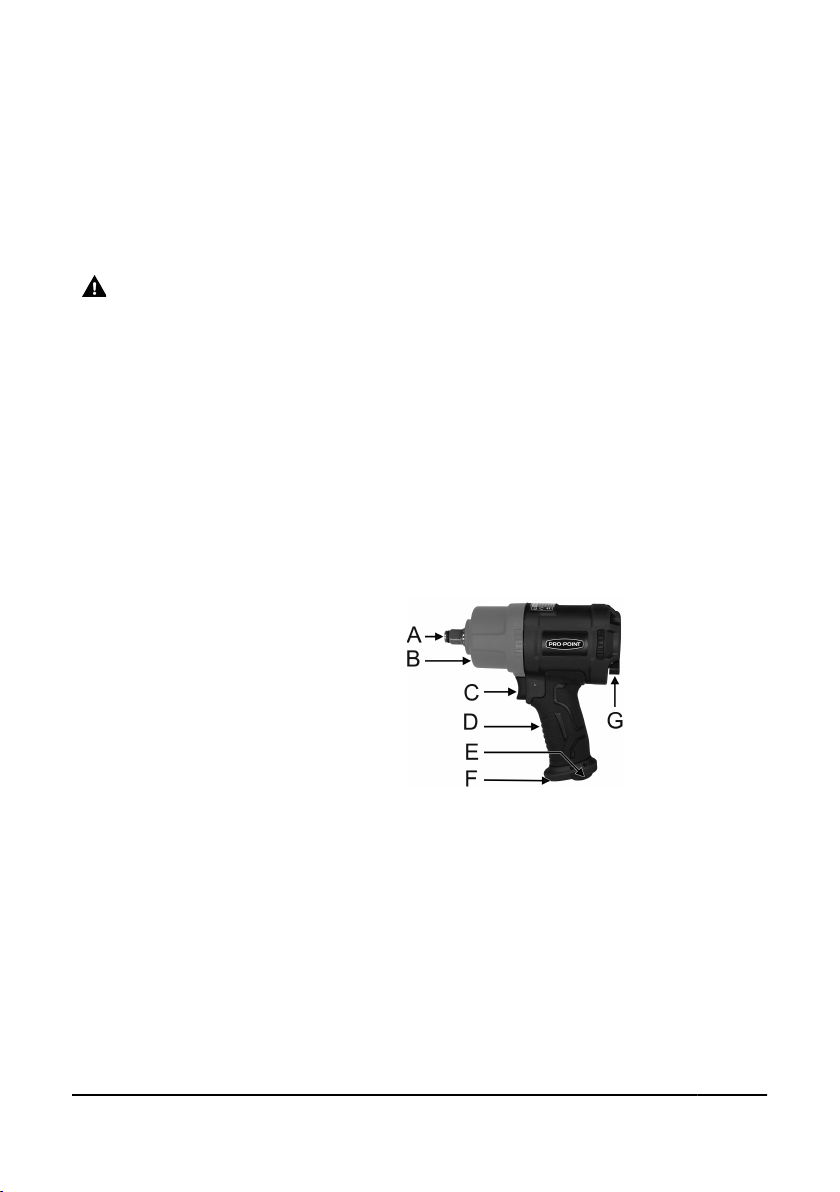

3. Check if the impact wrench's moving parts are misaligned or

binding before each use. Correct the issue before using the impact

wrench to avoid an injury or damage to the tool.

4. Always be aware of the position of your hands relative to the

impact wrench. Avoid awkward hand positions where a sudden slip

could cause a hand to move into the impact socket. Never reach

behind or beneath the impact wrench.

5. Only use accessories that are specifically designed for use with

the impact wrench. Ensure the impact socket is tightly installed.

6. Only use an impact socket that exceeds the Speed rating and

impact rating (see Specifications).

7. Before using the impact wrench on a workpiece, test the impact

wrench by running it at the highest speed rating for at least

30 seconds in a safe position. Stop immediately if there is any

9058421 COMPOSITE AIR IMPACT WRENCH V1.0

Assistance available at www.princessauto.com or 1-800-665-8685 Page 6