Proportion-Air QL3 Series Installation and operating instructions

1/4 INQL3-MAR09

03/03/09 WW

QL3 PRESSURE CONTROL VALVE

INSTALLATION & MAINTENANCE INSTRUCTIONS

SPECIFICATIONS

ELECTRICAL

SUPPLY VOLTAGE....................….15-24 VDC

SUPPLY CURRENT...................….250mA max.

COMMAND SIGNAL

VOLTAGE..................…..0-10 VDC

CURRENT..............…….4-20mA differential

COMMAND SIGNAL IMPEDANCE

VOLTAGE..................…..4.7 KΩ

CURRENT..................….100 Ω

ANALOG MONITOR SIGNAL

VOLTAGE...............…….0-10 VDC @ 10mA max

CURRENT……………….4-20mA Sinking or Sourcing

MECHANICAL

PRESSURE RANGES¹...............0 to 5 psig through 0-150 psig

OUTPUT PRESSURE¹................0-100% of range

FLOW RATE

FORWARD & EXHAUST .............25 SCFM max @ 120 psig inlet &

100 psig outlet

(708L/min @ 8.27 BAR inlet & 6.89

Bar outlet)

MIN. CLOSED END VOLUME.…..5 in³

FILTRATION RECOMMENDED…40 micron actual

LINEARITY………………...........…<±0.3% F.S. BFSL ²

HYSTERESIS……………………….0.05% F.S.

ACCURACY ..............................……<±0.4% F.S. ²

RESOLUTION………………………0.05% F.S.

WETTED PARTS‡ .................Elastomers - Buna N (3)

Manifold - Aluminum Nickel Plated

Valves - 430FR SS, 360 Brass

Seal material: Viton & Buna-N

P.Transducer - Utem 1000, Aluminum,

PHYSICAL

OPERATING TEMPERATURE....32-158ºF [0-70ºC]

DIMENSIONS…………………….2in.X2 in.X4.4 IN

(51mmX51mmX111mm)

WEIGHT.................................…....1.06 lb [0.50 Kg]

PROTECTION RATING...........…NEMA 4 / IP65

HOUSING...............................……Aluminum (Anodized)

VOLUME BOOSTER.....................Electroless Nickel Plate

¹ Pressure ranges are customer specified. Custom pressure ranges are avail-

able. Any range 5 to 150.

² Dependent on response adjustments. Valve can be field adjusted for best

response for the actual application

³ Other elastomers are available. Consult factory.

DESCRIPTION

The QL3 is a closed loop electronic pressure regulator consist-

ing of two solenoid valves, an internal pressure transducer, and an

electronic control circuit integrally mounted to a unique volume

booster. The output pressure is proportional to an electrical input

(command signal). The pressure is controlled by activating the

solenoid valves, which apply pressure to the pilot side of the vol-

ume booster. One valve functions as inlet control, the other as

exhaust. The output pressure of the volume booster is measured

by a pressure transducer, which is internally mounted and pro-

vides a feedback signal to the electronic control circuit. This feed-

back signal is compared against the command signal input. Any

differences between the command signal and the pressure feed-

back signal causes one of the solenoid valves to open to adjust the

pressure in the pilot of the volume booster. Pilot pressure is ad-

justed so that desired output pressure is achieved and maintained.

Since it is the actual desired work pressure that is being sensed

and fed back to the control circuit, any mechanical hysteresis of

the air piloted volume booster is automatically compensated for.

This allows for our extraordinary accuracy and repeatability.

The QL3 improves and builds on the proven Proportion-Air

QB3 series high performance by using a current driven variable

orifice solenoid valve and a unique analog PID circuit. This vari-

able orifice solenoid avoids the pressure “steps” prevalent in most

feed and bleed I/P’s. The PID circuit integrates error out quickly

resulting in superior resolution. The combination of a stepless

solenoid valve with a high speed analog PID on a high flow vol-

ume booster allows lots of air to be moved in a hurry, but pre-

cisely.

Command inputs come in a choice of either a 0-10 Vdc or 4-20

mA. The QL3 also provides an electrical monitor signal for out-

put to a panel meter or controller for data acquisition or quality

assurance needs. The monitor signal comes from the internal pres-

sure transducer. All QL3’s come standard with a 0-10 volt moni-

tor signal with 4-20 mA optional. Providing this monitor signal

as part of our standard package eliminates the need to purchase a

separate transducer.

The uniqueness of the volume booster design is that it has no

stamped gaskets or special molded diaphragm or seal parts. All

of the parts related to normal maintenance are standard o-rings.

Complete repair kits are available, but in case emergency repair is

needed parts should be available from any fluid power distributor

or even most neighborhood hardware stores. Since all sealing

parts are o-rings a large variety of chemical compounds are read-

ily available. You can select the compounds, which are most

ideally suited to your process and environment.

The QL3 is used for pressures up to 150 psig. For pressure

ranges between 150 and 500 psig, see the Proportion-Air QB3H

series.

Before you get started, please read these warnings:

♦ Examine the product. Ensure that you received what

you ordered.

♦ Read this guide first before you start and save it for

later use.

♦ You must have a good understanding of what the ad-

justments are on this product before using them.

♦ All compressed air and power should be shut off before

installing, removing or performing maintenance on this

product.

♦ Installation and use of this product should be under the

supervision and control of properly qualified personnel

in order to avoid the risk of injury or death.

Courtesy of CMA/Flodyne/Hydradyne ▪Motion Control ▪Hydraulic ▪Pneumatic ▪Electrical ▪Mechanical ▪(800) 426-5480 ▪www.cmafh.com

2/4 INQL3-MAR09

03/03/09 WW

Pneumatic Connections

CAUTION: USE ONLY THE THREAD SEALANT

PROVIDED. OTHER SEALANTS SUCH AS PTFE

TAPE AND PTFE PASTE CAN MIGRATE INTO THE

FLUID SYSTEM CAUSING FAILURES.

1. The valve can be mounted in any position without af-

fecting performance. A variety of mounting brackets

(QBT-01, QBT-02, and QBT-03. SEE ordering info)

can be used to attach valve to a panel or wall surface.

2. A typical 40 micron in-line filter is recommended on

the inlet of the QL3 valve. This is available from Pro-

portion-Air as part number FPP-2.

3. A 1/16” plug is supplied with the valve. It can be used

to plug the “Alternate Exhaust Port” if the exhaust

media should be captured or when the valve is used for

vacuum or vacuum through positive pressure control.

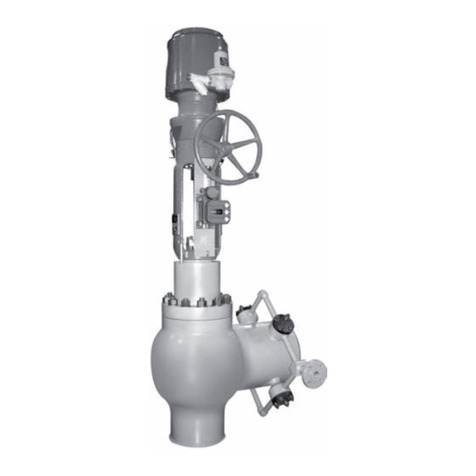

See Figure 1 for port location.

Positive Pressure Units

1. Connect supply pressure to the “I” port (Figure 1) not

to exceed rated supply pressure. (See TABLE 1)

2. Connect the outlet “O” port (Figure 1) to the device

being controlled.

3. The “E” exhaust port can be plumbed to a point out-

side the work area, fitted with a muffler or left open to

atmosphere as the application dictates.

4. Proceed with electrical connection.

CONNECTION PROCEDURE

Electrical Connections

1. Turn off all power before making electrical connec-

tions.

2. Identify the valve’s command input and analog output

using the calibration card included in the package and

the ordering information section on the last page of

this sheet.

3. Proceed to the appropriate section corresponding to the

type of valve being installed.

NOTE: ALL COLOR CODES RELATE TO QL3'S

ORDERED FROM THE FACTORY WITH PRE-

ASSEMBLED QBT-C-X CABLES.

Voltage Command Valves (TFEE)

All voltage command QB3's use a single ended command, mean-

ing the DC Common serves as both the power and command

common.

Current Command Valves (TFIE)

All current command QL3's use a differential current loop scheme

(not isolated), meaning current flow is from Pin 4 to Pin 2 on the

QL3 valve. Some applications may require the common of the

power supply that provides loop power for the 4-20mA command

to be tied to power supply common. The following diagram

shows the correct connection for conventional current flow.

PIN 2 {BLUE}

4-20MA COMMAND (-) PIN 4 {WHITE}

4-20MA COMMAND (+)

PIN 1 {GREEN}

DC COMMON (-)

PIN 6 {BLACK}

DC POWER (+)

PIN 4 {WHITE}

0-10 Vdc COMMAND (+)

PIN 1 {GREEN}

DC COMMON (-)

PIN 6 {BLACK}

DC POWER (+)

POWER AND

COMMAND

Current Monitor Valves

(TFEC or TFIC SINKING OUTPUT)

Use the following wiring diagram for QL3 valves with a current

sinking monitor output.

-

+

PIN 6 {BLACK}

DC POWER (+)

PIN 5 {RED}

4-20mA MONITOR (-)

MA

METER

Voltage Monitor Valves

(TFEE or TFIE)

Use the following wiring diagram for QL3 valves with a voltage

monitor output.

PIN 1 {GREEN}

DC COMMON (-) -

+

PIN 5 {RED}

0-10V MONITOR (+)

V METER

PIN 6 {BLACK}

DC POWER (+)

Current Monitor Valves

(TFES or TFIS SOURCING OUTPUT)

Use the following wiring diagram for QL3 valves with a current

sourcing monitor output.

-

+

MA

PIN 1 {GREEN}

DC COMMON (-)

METER

PIN 5 {RED}

SIGNAL OUT

Courtesy of CMA/Flodyne/Hydradyne ▪Motion Control ▪Hydraulic ▪Pneumatic ▪Electrical ▪Mechanical ▪(800) 426-5480 ▪www.cmafh.com

3/4 INQL3-MAR09

03/03/09 WW

RE-CALIBRATION PROCEDURE :

All QL3 control valves come calibrated from the factory by

trained personnel using precision calibration equipment.

The QL3 valve is a closed loop control valve using a preci-

sion electronic pressure sensor. Typical drift is less than

1% over the life of the product. If your QL3 valve appears

to be out of calibration by more than 1%, it is not likely to

be the QL3. Check the system for plumbing leakage, wir-

ing and electronic signal levels. Verify the accuracy of

your measuring equipment before re-calibrating. Consult

factory if you have any questions or require assistance.

For valves ordered with MAX. calibrated pressure Max. inlet pressure

5 through 10 psi positive 15 psig (1 bar)

10.1 up to 30 psig (0.70 up to 2 bar) 35 psig (2.4 bar)

31 up to 100 psig (2.1 up to 7 bar) 110 psig (7.6 bar)

101 up to 150 psig (7 up to 10.3 bar) 165 psig (11.4 bar)

RATED INLET PRESSURE FOR STANDARD QB3 VALVES

TABLE 1

Calibration

Access Cap

Figure 2

I

E

O

OUTLET

To Application

EXHAUST

INLET

Figure 1

Alternate Exhaust Port

Courtesy of CMA/Flodyne/Hydradyne ▪Motion Control ▪Hydraulic ▪Pneumatic ▪Electrical ▪Mechanical ▪(800) 426-5480 ▪www.cmafh.com

4/4 INQL3-MAR09

03/03/09 WW

PROPORTION-AIR, INC. BOX 218 MCCORDSVILLE, IN USA 46055

PHONE: (317)335-2602 FAX: (317)335-3853

INTERNET – www.proportionair.com E-MAIL – info@proportionair.com

Proportion-Air products are warranted to the original purchaser only against defects in material or workmanship for one (1) year from the date of manufac-

ture. The extent of Proportion-Air's liability under this warranty is limited to repair or replacement of the defective unit at Proportion-Air's option. Pro-

portion-Air shall have no liability under this warranty where improper installation or filtration occurred.

All specifications are subject to change without notice. THIS WARRANTY IS GIVEN IN LIEU OF, AND BUYER HEREBY EXPRESSLY

WAIVES, WARRANTIES OR LIABILITIES, EXPRESSED, IMPLIED OR STATUTORY, INCLUDING WITHOUT LIMITATION ANY

OBLIGATION OF PROPORTION-AIR WITH REGARD TO CONSEQUENTIAL DAMAGES, WARRANTIES OF MERCHANTABILITY,

DESCRIPTION, AND FITNESS FOR A PARTICULAR PURPOSE.

............................................................................................................................................................................................................

WARNING: Installation and use of this product should be under the supervision and control of properly qualified personnel in order to avoid the risk of

injury or death.

ORDERING INFORMATION

QL 3 T F E E xxx A Ø 8

SERIES SIZE

3 = 1/4” NPT Ports

CONTAINER

COMMAND

INPUT

MONITOR

SIGNAL

MAXIMUM

CALIBRATED

RANGE

5-150 psig*

EXAMPLES

100 = 0-100 PSI

* Check special options

for Pressure ranges not

starting at “0” psig .

E = 0-10 VDC

I = 4-20 MA

T = IMPACT ALUM.

E = 0-10VDC

C = 4-20 MA Sinking

S = 4-20MA Sourcing

PRE-ASSEMBLED POWER CORD

QBT-C-6

Length in feet (Other length are

available from 1 to 25 feet)

QB3 CONTROL VALVE

DIMENSIONS in (mm)

MONITOR

NOTES:

1.) ALL PORTS 1/4-18 NPT

(except alternate exhaust)

MOUNTING BRACKET

QBT-01 QBT-02

40 MICRON FILTER 1/4

NPT(Recommended)

FPP-2

QBT-03

FACTORY SET-

TINGS BASED

ON YOUR

APPLICATION

PARAMETERS

Courtesy of CMA/Flodyne/Hydradyne ▪Motion Control ▪Hydraulic ▪Pneumatic ▪Electrical ▪Mechanical ▪(800) 426-5480 ▪www.cmafh.com

Table of contents

Other Proportion-Air Control Unit manuals

Popular Control Unit manuals by other brands

MG

MG R3-CT4B instruction manual

Trenz Electronic

Trenz Electronic TE0712 TRM manual

Westinghouse

Westinghouse 7880040 Installation and operating instructions

Samson

Samson 41-23 Series Mounting and operating instructions

Armstrong

Armstrong GD-30 instructions

Leviton

Leviton GreenMAX RPM00-100 installation manual