ProRacing TS2 PRO User manual

User Manual

TS2 PRO

Read before installation

Turbo petrol engines

2

1 Application and Photo montage

..........................................................................................................................

3

2 Proracing overview ............................................................................................................................ 4

4 Petrol Engines Assembly ............................................................................................................................. 7

5 First start-up .................................................................................................................................................. 11

6 Adjustment

.............................................................................................................................

............................................................................................................................. 12

7 Troubleshooting ............................................................................................................................... 14

7 Contact details .............................................................................................................................................. 18

Index

Overview and explanation of the symbols used

Warnings on dangers with important information on use. Please read!

General information on assembly and use.

Tips for easier assembly and use.

1 Applicazione per smartphone (optional)

Android APP iOS APP

Scarica l’app Proracing sul tuo Smartphone e scopri il nuovo piacere di guida.

Normalmente dopo l’acquisto, inviamo tramite mail le foto speciche per il tuo

motore per un montaggio semplice, controlla la mail.

Scansiona con la fotocamera del tuo smarthphone e verrai indirizzato automaticamente

all’app store.

3

4

A

B

C

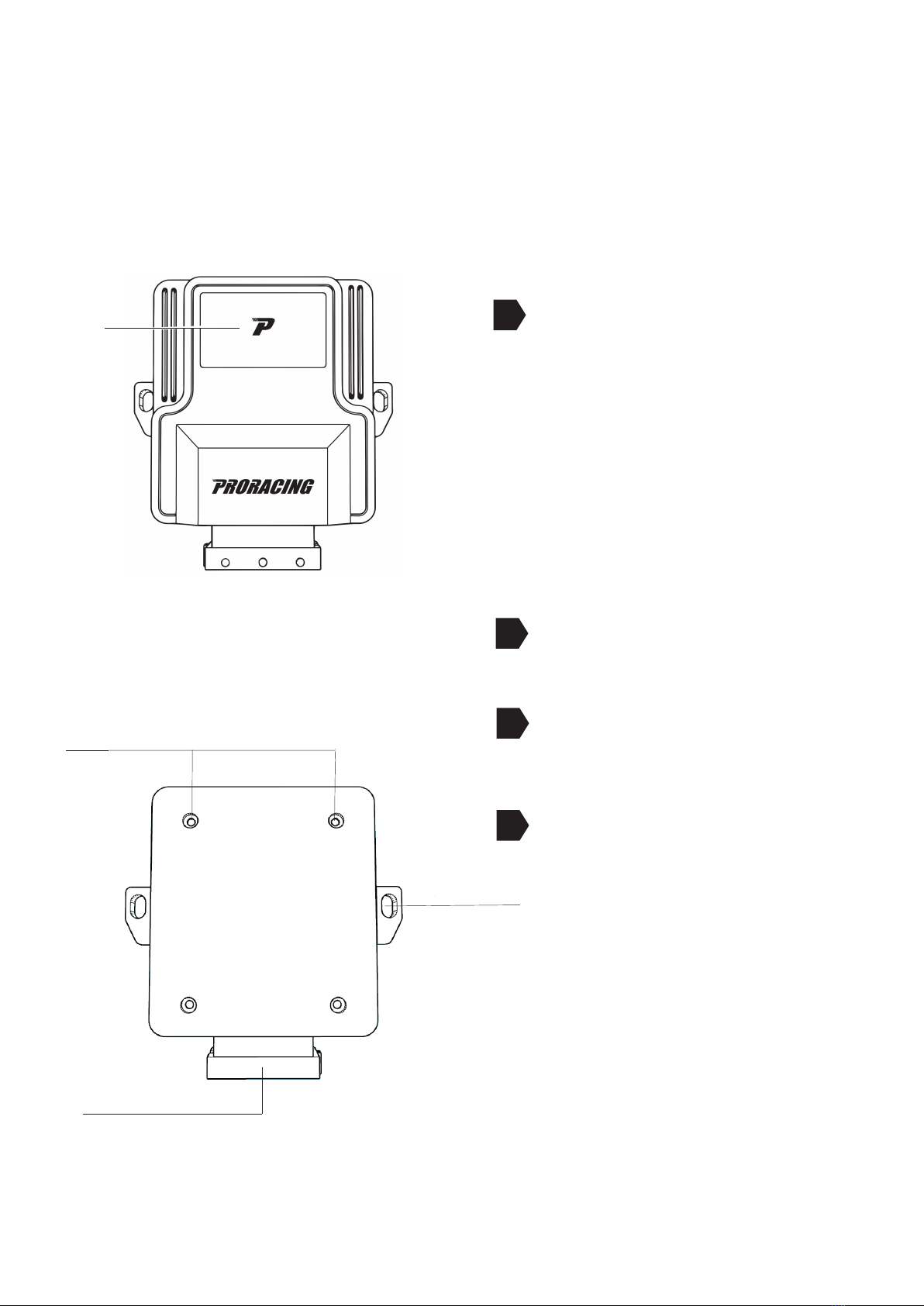

2 Panoramica di Proracing TS2 PRO

Luminous program interface

ECO: Blue color

SPORT: Green color

RACE: Red color

FCI socket connection for xing

of the Proracing TS2 PRO harness

Holes for closing the box opening (TORX)

D Holes for xing with cable ties.

A

D

C

B

5

3 Installation

Phase 1 of 6 - preparing the installation

Wait about 10 minutes before acting, in this way all the electrical equipment will be

deactivated.

•

•

•

•

•

1

2

Let the engine cool down before installing the Proracing ECU, you could burn yourself.

Open the bonnet and keep the doors locked.

Normally, no special tools are required for installation, a wire cutter is sucient to remove

the remains of the clamps. In some cases a torx key to open the control unit and change

to Bosch or Siemens / delphi.

With, Keyless Go or electronic key, be careful to keep the car key at a distance

about 10 meters from the car to be out of radio coverage.

In the event of an anti-theft device, it must be deactivated before starting the installation.

In some rare cases it is possible that the car with the hood open keeps the sensors

active, therefore it is advisable to disconnect the battery positive to avoid generating

an error.

If you have any questions or problems during installation, you can nd answers on

Error removal.

Our customer support is also available - You can open a Ticket

on our website.

6

A

B

3 Installation

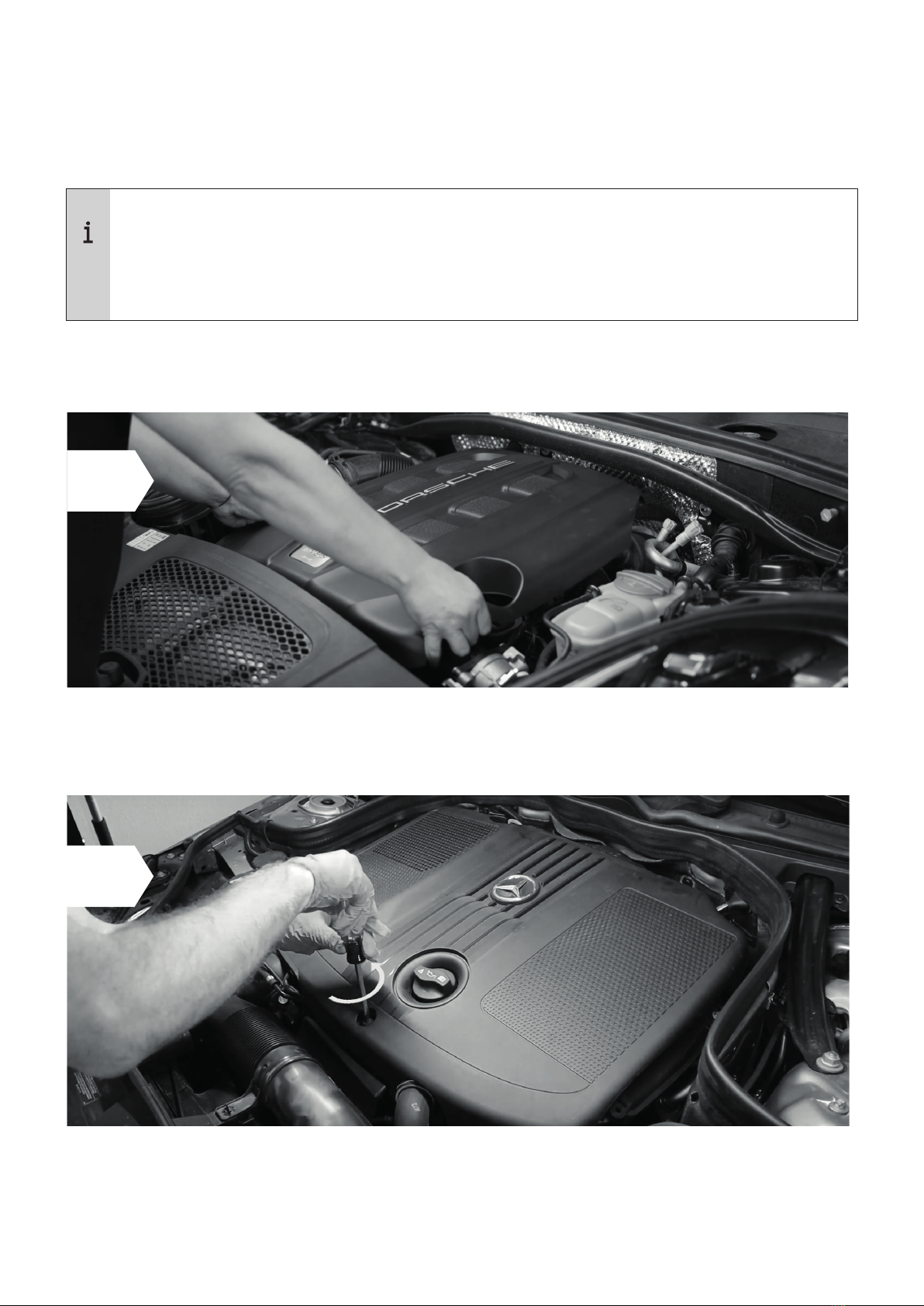

Step 2 of 6 - Remove the engine cover

•

•

•

Normally after purchase, we send specic photos for yours by email

engine for easy editing, then check your mail.

In the following images there will be sample photos. Your car may dier,

However, the installation is very similar.

Normally your engine cover is interlocked with rubber clips (A) or

with one or more screws (B).

Remove the engine cover and set it aside, simply lift upwards by doing

more strength in one side at a time.

In some cases, in order to remove the plastic cover of the motor, it is necessary to unscrew one or

more screws.

If you do not have any engine coverage go directly to Stage 3 for Diesel Engines.

•

A

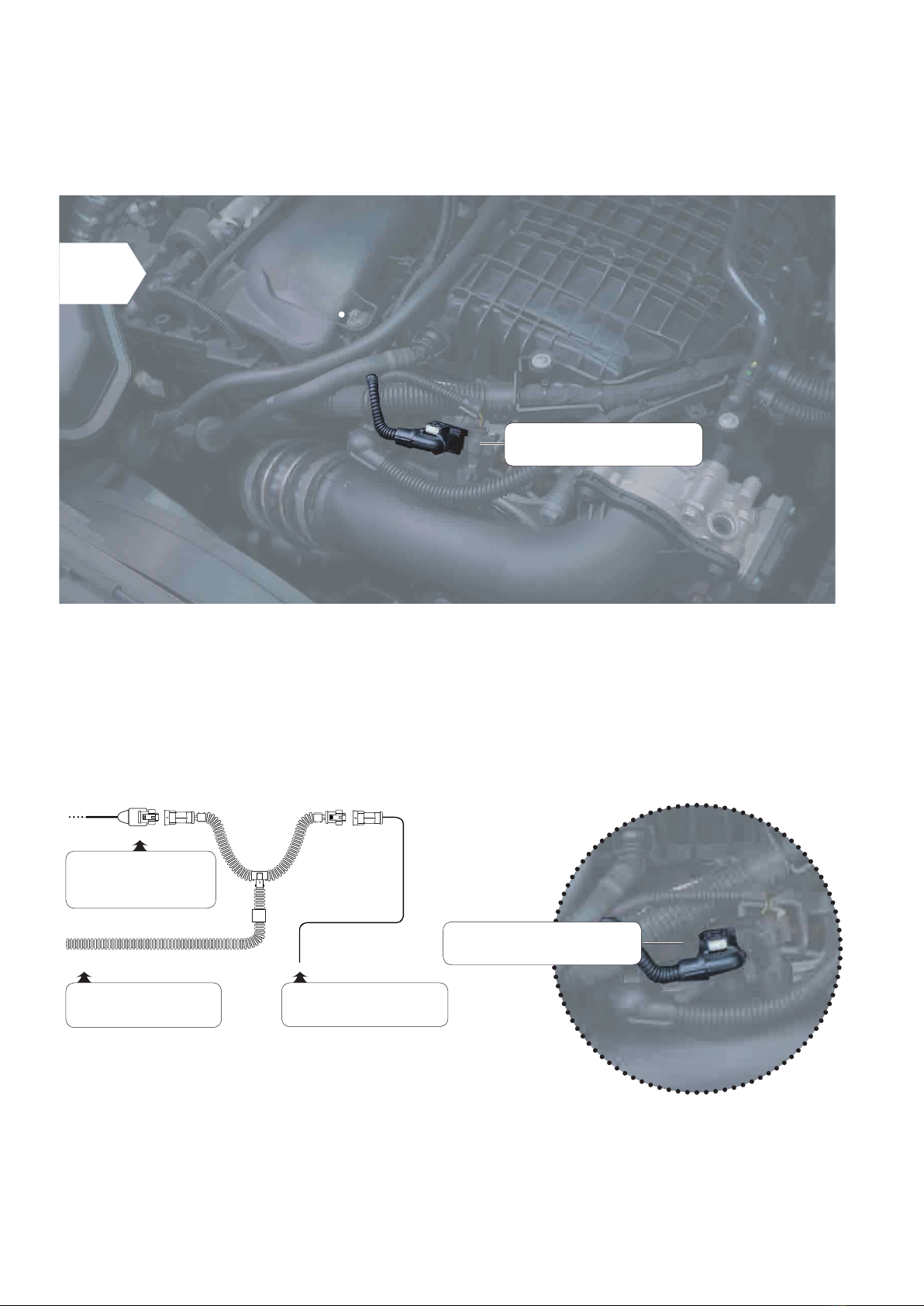

4 Turbo Petrol Installation

Step 4 of 6 - Connect to Supply Pressure

Pressure connection

power supply

Schematic representation:

Cable coming from

ProRacing

Cable with connector

standard o

Pressure connection

power supply

7

First locate the sensors where to connect the wiring, supply pressure sensor and

turbo pressure sensor. Usually the feed sensor is placed on the suction ange,

after the turbo, the second turbo pressure sensor is usually after the throttle on the

intake manifold.

1Supply pressure connection

4 Assembly of turbo petrol engines

•

•

• Make sure the connector's safety clip clicks back into place:

you can hear it by CLICK.

8

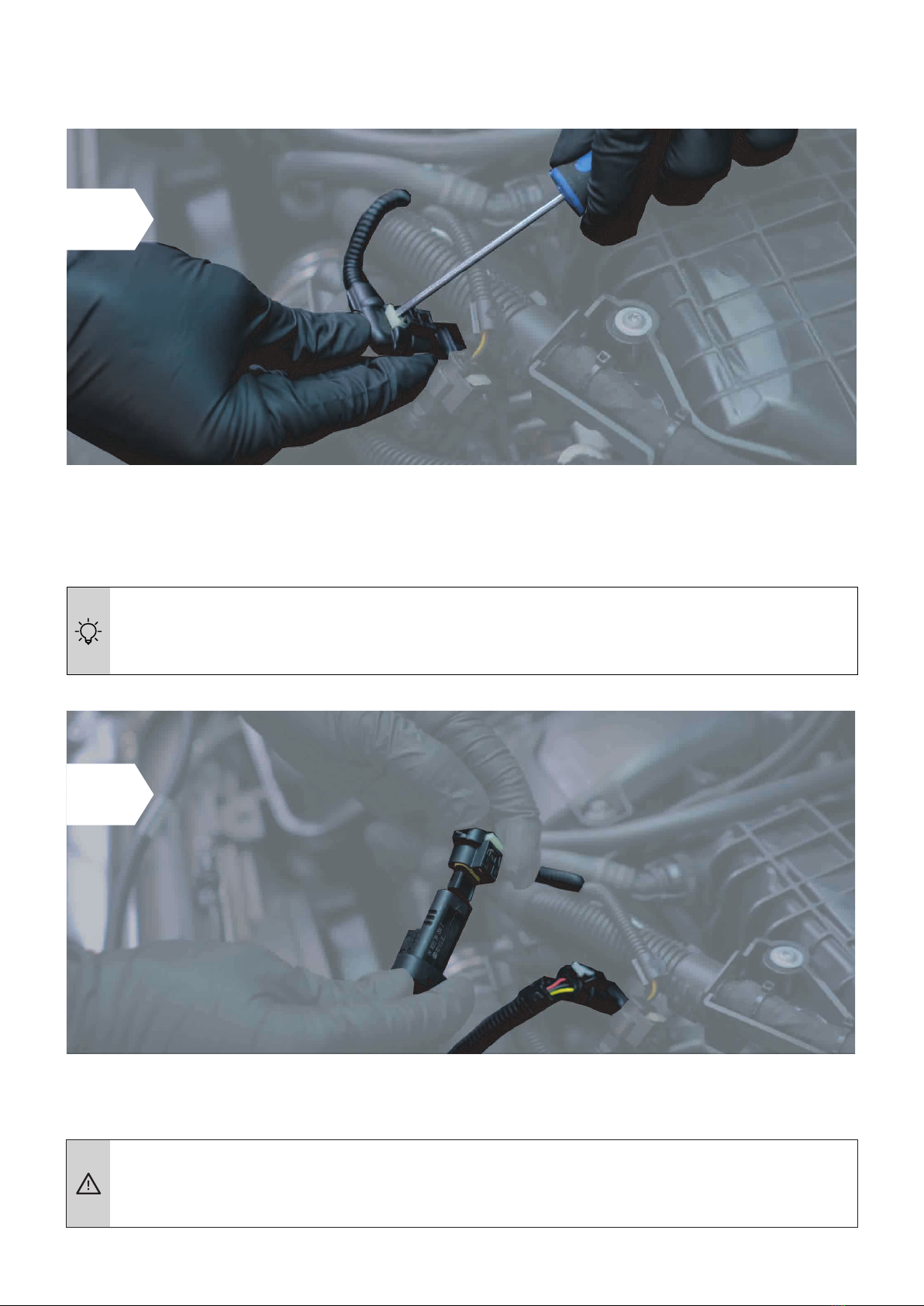

To disconnect the connectors from the sensors it is necessary to press not too hard in order to raise the

release clip or move the safety catch.

We normally have 90% of the photos in the catalog of all engines, check your inbox

registration, at the time of purchase we send the specic photos in our possession.

It intercepts the suction pressure sensor located on the suction ange, releases the connectors and

connect as shown in the gure by interposing the wiring between the car sensor and the engine

wiring.

2

3

4 Assembly of turbo petrol engines

Step 4 of 6 - Connect the suction hose pressure

•

Schematic representation:

Cable coming from

Proracing

Cable with connector

series o

B

Link to

tube pressure

suction

9

Locate the turbo pressure sensor usually located after the throttle body on the

intake manifold, disconnect the connectors and interpose the wiring as shown in the gure

schematized.

1

Pressure connection

of the suction pipe

Pressure connection

of the suction pipe

10

4 Assembly

•

•

• Make sure the connector's safety clip clicks back into place:

you can hear it by CLICK.

To disconnect the connectors from the sensors it is sometimes necessary to raise the safety and then

press the release clip using not too much force and remove the connector.

It intercepts the suction pressure sensor located on the suction ange, releases the connectors and

connect as shown in the gure by interposing the wiring between the car sensor and the engine wiring.

2

3

Instructions for disconnecting the suction hose pressure connector are available on the

enclosed sheet. Disconnect the connector correctly.

5 First start-up

Phase 5 of 6 - First start test.

Phase 6 of 6 - End of installation.

•

•

•

•

•

•

•

Carry out a rst function test

•

•

Connect the control unit to the wiring.

Please note that after about 1 minute it goes into standbay mode and turns o but this is normal.

Rest Proracing with the harness securely possibly already clamped in such a way

that no moving part of the engine can create problems.

Now start the engine and check that the ECU turns on.

Turn o the engine and complete the installation of the wiring with the supplied cable ties.

If the car does not start regularly or you have reports on the dashboard

proceed with the paragraph '' Removing errors ''

Of course, our customer service is also at your disposal.

Route the corrugated pipe of the wiring along a suitable point and secure it with cable ties.

When choosing the xing point of Proracing also make sure that it is

protected from water, strong heat and vibration.

Do not put Proracing in a bag as this can form condensation

of water.

Do not x the wiring on parts that can get hot at very high temperatures,

(e.g. exhaust manifold, dpf or turbochargers.

11

If the control unit turns on during installation with the ignition o, it means that

during the connection there was still residual current in the car's wiring.

This can cause in some cases an error in the dashboard, the control unit

Engine ECU may have detected a wiring harness disconnection.

1

2

16

A

6 Adjustment without application

Factory setting.

adjustments available on the version without Application:

In case the starting setting of your Proracing is

A-0 we recommend these power steps:

Selettore S1 S2

Performance level 1 B 0

Performance level 2 C 0

Performance level 3 D 0

In case the starting setting of your Proracing is

8-4 we recommend these power steps:

Selettore S1 S2

Performance level 1 9 4

Performance level 2 A 4

Performance level 3 B 4

In case the starting setting of your Proracing is

A-4 we recommend these power steps:

Selettore S1 S2

Performance level 1 B 4

Performance level 2 C 4

Performance level 3 D 4

We ship the ECU with the appropriate setting for your vehicle.

Our setting increases the engine power leaving room for improvement, without

aect the reliability of the engine, giving smoother running and optimizing fuel consumption.

However, the default basic value is always indicated in the consignment note.

This setting is an example that identies A-0

•

•

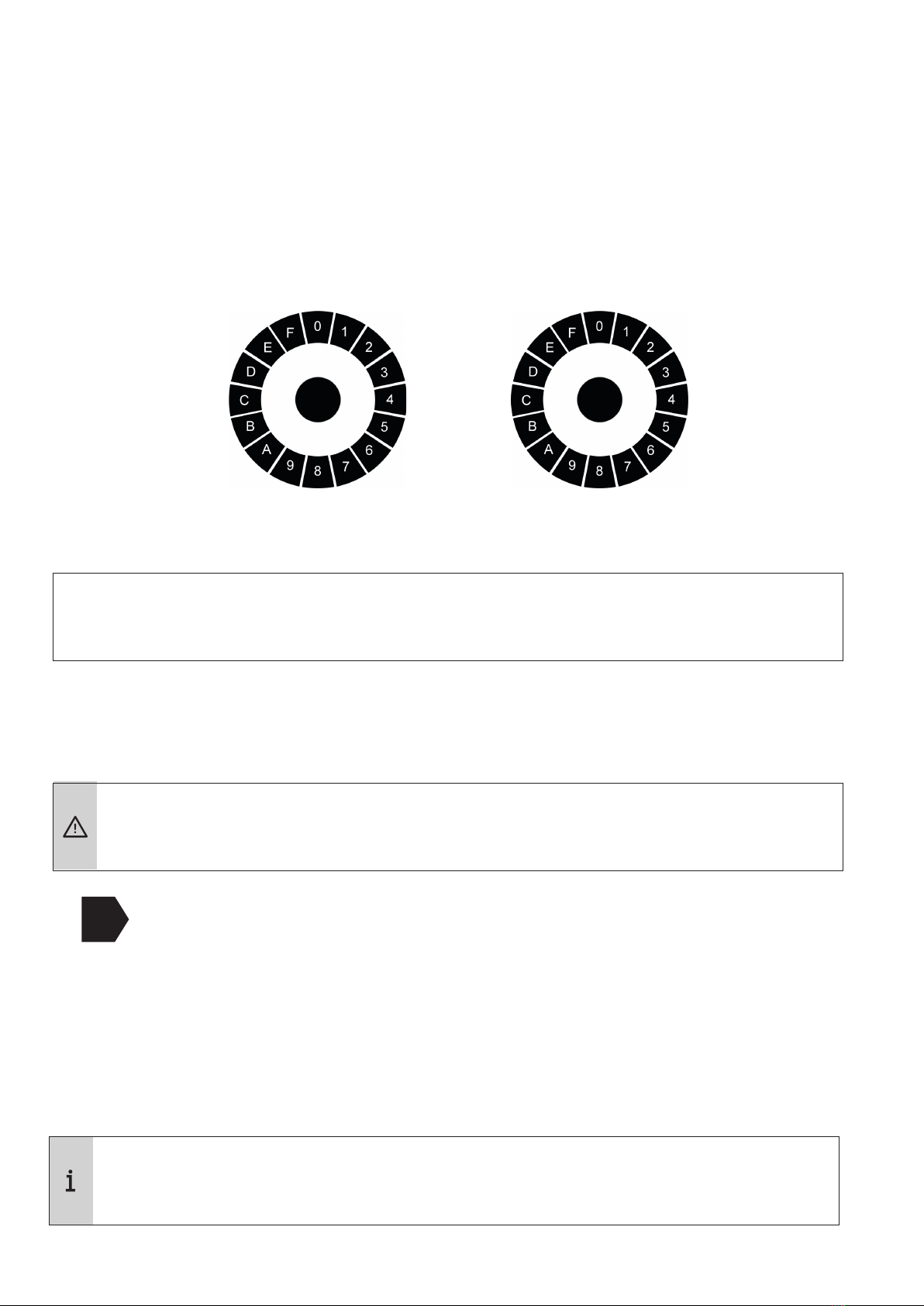

Proracing is congured specically for your car, all parameters are adjusted for one

uid delivery and with an adequate compromise between consumption and power increases. In some

however, it is possible to further modify the settings by unscrewing the torx and opening the

control unit. Inside there are two selectors called S1 and S2, the same selectors are present

in the smartphone application on the setting page.

17

The technicians of Proracing according to your needs can help you to calibrate in a manner

optimal (we advise you to always ask).

6 Custom adjustment.

Selettore S1: Selettore S2:

If you incorrectly change the selector parameters you may no longer have the performance

optimal, even send it to the Recovery system.

Warning: the higher setting is not always the same as the greater increase in power.

Problems with serrations, the gear is not smooth?

If while driving you feel gaps accelerating or an irregular trend, you can

use selector S2 by raising the adjustment and bringing it to position 4.

If the serration is less noticeable but still noticeable bring it into place

5 or 6 or 7.

•

•

If you change the S1 and S2 settings and have purchased the TS2 PRO version with bluetooth le

eco sport and race mappings will be recreated via argorithm based on the settings

selected.

S1 S2

The S1 selector modies power and torque, we recommend increasing one step at a time in a

clockwise direction.

The S2 selector is responsible for the duration of the performances for a greater range of revolutions,

normally this selector should not be touched to prevent the car from going into protection.

The minimum setting is 8, the maximum setting is 7 and is distributed in this sequence:

MIN 8-9-A-B-C-D-E-F-0-1-2-3-4-5-6-7 MAX

-Does the automatic gearbox give abnormal bumps at high revs?

7 Troubleshooting

Error description How to intervene

No increase of

power or porformance

they are not enough

perceptible

•

•

•

On the chapter "custom adjustment" you can nd

info on how to best set up to further increase

the performances.

Normally it is sucient to move selector S1 by one position

clockwise.

Example: if S1 is in position 8, move it to position 9

as indicated in the “customized adjustment” chapter.

The diesel engine under load

in acceleration ago

perceive a noise

of injection stronger than

normal?

•

•

•

Jerks in acceleration. • If you have jerks at the start or acceleration probably

the automatic transmission is adapting, so we recommend

proceed with the automatic adaptation.

•

•

Serrations in

acceleration in the high mids

regimes or trend

not uid at all

adjustments (eco-sport-race).

•

•

•

•

14

If you've been experiencing dash warning lights issues or don't feel enough power boost here

nd the rst support. If you do not nd the information you are looking for, you can contact assistance

customers.

If it is a noticeable increase in injection noise

under load rst take a test drive, you might hear

in acceleration a ticking.

This is absolutely normal as you are increasing

the injection pressures the noise will be more perceptible and present.

To make this noise less emphasized, lower the

race in sport adjustment or lowering the boost.

During the adaptation phase, the accelerator accompanies the throttle.

It is possible to eliminate tears by lowering the adjustment.

If in acceleration you feel jaggedness or lack of power

you have to act on the S2 selector, moving it to one more setting

high.

Usually setting the S2 selector in position 4 causes the problem

is obviated.

If setting position 4 has not solved it, move the selector

S2 in position 5 - 6 or at most 7.

Go to the custom adjustment chapter.

7 Troubleshooting

Error description How to intervene

The control light

engine or other warning

lights in the dashboard

remain on.

•

•

•

•

•

After installation, warning lights on the dashboard came on

giving error?

This does not always result in a real problem given that

if you have disconnected any connectors in the engine when it was

present current, this may have generated an error that does not

aect on the correct functioning of the motor, but it could weaken

performance for recovery system.

There is no need to worry, just turn o the light or

the reports.

Normally the lights turn o by themselves after a cycle of 5 restarts

or after about 100 / 200km.

It is possible to connect the connectors in reverse by reversing the

polarity, this surely generates an error in the dashboard.

Normally we always send photographic material afterwards

the purchase by e-mail that shows how the insertion takes place

corrected of some types of connectors that mistakenly can

be entered incorrectly.

An adjustment that is too high or higher than that allowed by the

vehicle manufacturer may result in protection or losses

sudden power. It is sucient to lower the setting

via app or external keypad. This way they will be avoided

other reports.

Dashboard light

for the control of

engine continuously

lit after a certain

walking time.

If the warning light on the dashboard does not go out by itself it

means that that particular car model needs a reset via

OBD2 diagnosis socket.

Our technicians have a specic OBD2 reset for sale

for a do-it-yourself removal via Smartphone-APP.

Or have your auto mechanic / electrician reset the lights.

15

16

7 Troubleshooting

Error description How to intervene

The car does not start

after installation.

The problem is certainly due to the fact that:

1. It is possible to connect the connectors in reverse by reversing

the polarity, this surely generates an error in the dashboard.

Normally after the purchase, we always send photographic material

by email showing how the insertion takes place

corrected of some types of connectors that mistakenly can

be entered incorrectly. Check the photos submitted

by mail, correct or incorrect.

2. You have intercepted the wrong sensors. The connectors are

identical but if the wiring is connected not respecting the correct

sensors the car will not start.

3. The bosch / siemens fuel system does not match

when adjusting Proracing, go to the Bosch / Siemens chapter

No savings of

fuel

•

•

•

If you are testing your car's performance with mapping

Proracing and testing you are using your full power

engine, consumption will be altered by sporty driving.

To make a comparison of consumption reduction it is necessary

to report driving focused only on fuel economy, before and after

the installation of Proracing.

To optimize the consumption of your car you can modify

your driving style as indicated in the chapter of our website

www.pro-racing.it in the ECO-FUEL section.

8 Contact details

Legal information

PRORACING by Privi Auto

Via Federico Confalonieri 50

20099 Sesto San Giovanni

-MI-

VAT number : 06494530964

mail: [email protected]

web: www.pro-racing.it

Our customer service is available in the dedicated section on our website www.pro.racing.it

Other ProRacing Automobile Accessories manuals