proril TANK Series User manual

2

Download the manual in your preferred language – scan the QR-code

3

Introduction______________________________________________________________________

4

Safety Information ________________________________________________________________

4

Hazard Notice Symbols

Safety Requirements

Environmental Safety

Product Warranty

Transportation and Storage ________________________________________________________

6

Lifting

Storage

Product Specification______________________________________________________________

6

Model Number Nomentclature

Pump Design

Pump Application Conditions

Product Nameplate

Installation_______________________________________________________________________

7

Pump Installation

Float Switch Loction Installation Requirement

Electrical Connection______________________________________________________________

8

Connection Requirements (External Protection Devices)

Grounding (Earthing)

Connecting the Power Cables

Operation________________________________________________________________________

10

Prior to operation

Trial Operation Non-Float Switch

Trial Operation Float Switch

Operation

Maintenance and Inspection________________________________________________________

12

Maintenance Requirements

Maintenance General Requirements

Troubleshooting__________________________________________________________________

13

Parts Lists_______________________________________________________________________

14

Product Specification Table and Nameplate ___________________________________________

17

Table of Content

4

Dear Customer,

Thank you for choosing a PRORIL submersible pump. This manual provides instructions for the installation,

operation, and maintenance of the pump. Improper use of the product can cause personal injury and damage to

property, and may void the warranty. Upon receiving the pump, it should be inspected for damage or shortages.

Please read this manual carefully before installing and using the product, and keep this manual at hand for future

reference.

Please visit our website www.prorilpumpseurope.com for further technical reference. Thank you!

Please read this manual thoroughly before operating the product, and retain it for future reference. Disregard of

this warning could result in personal accidents and health problems, damage to the product and or product

malfunction.

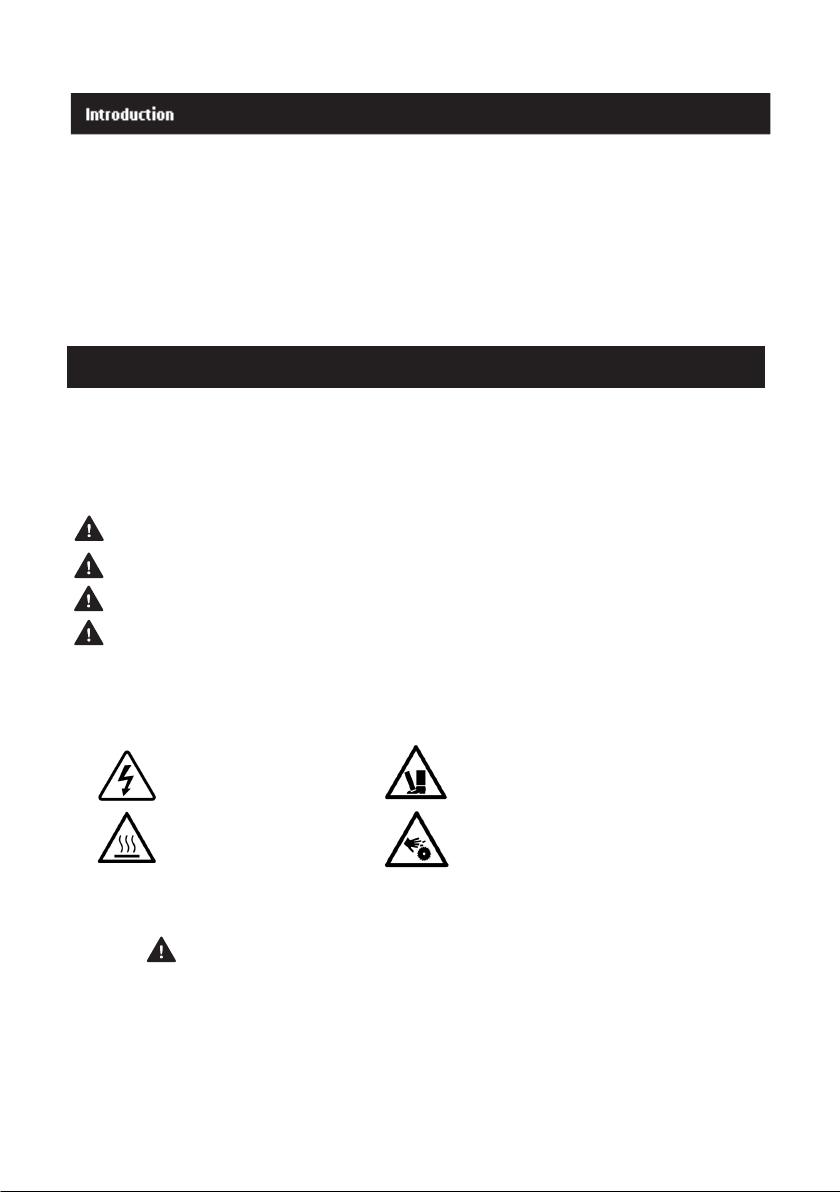

Hazard Notice Symbols

DANGER A hazardous situation which, if not avoided, will result in death or serious injury.

WARNING A hazardous situation which, if not avoided, could result in death or serious injury.

CAUTION A hazardous situation which, if not avoided, will result in minor or moderate injury.

NOTICE A potential situation which, if not avoided, could result in undesirable condition.

Complementary Hazard Notice Symbols

ELECTRICAL HAZARD CRUSH HAZARD

HOT SURFACE HAZARD CUTTING HAZARD

Safety Requirements

DANGER

Risk of electric shock - This pump is supplied with a grounding conductor or grounding-type attachment plug. To

reduce the risk of electric shock, be certain that it is connected to a residual current device or proper grounding-

type receptacle. This pump is NOT intended for use where water is occupied by people.

Safety Information

5

WARNING

•This pump has been evaluated for use with water only.

•Do not operate the product near a potentially explosive environment.

•Do not use the product in the presence of flammable liquids or gases.

•Always turn off and disconnect the pump from the main power and Lock-Out-Tag-Out (LOTO) before

carrying on inspection, maintenance, and adjustment.

•Never attempt to change the settings of all protective devices without consulting with a PRORIL

representative

•The product is designed for moving wastewater, raw and clean water. The following should not be

handled for the pump and your safety:

i ) Flammable, toxic, abrasive, crystallizing, and polymerizing liquid.

ii ) Liquid chemicals and food, alkaline and corrosive liquid.

iii ) High temperature, high viscosity, and high content solid matter liquid.

•Protect the electric plug or the end of the power cable from invasive moisture at all times. Never touch

the piping or electrical connections while the pump is running.

•Never touch the water while the pump is under operation.

•Never put the pump into operation if it has been partially dismantled.

•Hearing protection should be used in case of long exposure to noise.

•Never run the pump without water, do not operate the pump out of water or insufficient water. Do not

use the pump if the power cable is damaged. If you have any questions, please contact our

representative or company.

Environmental Safety

Do not dispose of electrical appliances as unsorted municipal waste, use separate collection facilities.

Contact your local government for information regarding the collection systems available. If electrical appliances

are disposed of in landfills or dumps, hazardous substances can leak into the groundwater and get into the food

chain, damaging your health and well-being.

Product Warranty

PRORIL’s sole obligation under this 12 months warranty shall be limited to the repair or replacement of any parts

that the Seller determines, in its discretion, to be defective. The warranty is void if the damage is caused by the

following factors:

•Improper installation

•Deficient maintenance

•Damage caused by improper use, or abuse.

•Third party modifications or attempted alterations to the pump.

•Normal wear and tear

•The pump has been used for purposes other than those for which it is intended.

PRORIL assumes no liability for the following:

•Body injuries

•Material damages

•Economic Losses

PRORIL reserves the right to change design and specifications without prior notification.

6

CRUSH HAZARD

Stay clear of the suspended load. The unit and components can be heavy. Observe accident prevention

regulations in force.

Lifting

•Make sure the pump is properly secured during transportation and cannot roll or fall over.

•Pay close attention to the pump’s center of gravity and mass. Improper lifting may result in product

damage, injury, or death.

•Always lift the pump by its lifting handle or by using suitable equipment. Use eyebolts or

lifting lugs if available.

•Never lift the pump by the motor cable or hose.

•When the pump will be carried by hand, decide the number of persons considering the mass of the

pump. When lifting the pump, ensure a good handle hold, do not bend your back, (use your knees to

protect your back), look ahead, and move smoothly.

Storage

NOTICE

•Protect the pump against humidity, heat sources, and mechanical damage.

•Do not place heavyweights on the packed product.

•Storage temperature should be within a range of -25°C to 55°C.

•For temperature up to 70°C above, storage must be within a short period and do not exceed 24 hours.

•In cold climates, do not allow water in the pump to freeze.

•After an extended storage time, the pump should be inspected before use.

•Turn the impeller by hand before using the pump.

•Check the seals and the cable entry.

Additional information on the product specific information, e.g. dimensions, specifications,

performance curves for the corresponding model will be provided separately. Please find the product

specification tables and product nameplate on page 17 or contact our representative.

Pump Design

The pump is submersible and driven by an electric motor. The pump is designed for moving wastewater, raw and

clean water. Never operate this product under any conditions other than those that have been specified.

WARNING

•This pump is neither dust-proof nor explosion-proof. Do not use it at a place where toxic, corrosive, or

explosive gas is present. Use in such a place could cause fire or explosion.

•Do not operate the product under any voltage other than described on the nameplate with the voltage

variation limit within ±10%. Failure to observe this caution may cause malfunction and breakdown of

the product, which may lead to electrical leakage or electrical shock.

•Do not use the product for hot or warm liquid over 40°C, as doing so will damage the product, which

may lead to electrical leakage or electrical shock.

•Do not operate the pump in an area that is exposed to a water pressure that exceeds any conditions

other than those that have been specified.

Transportation and Storage

Product Specification

7

Pump Application Conditions

Conditions

Description

Liquid Temperature

5°C to 40°C (41°F to 104°F)

ph liquid

5-8

Rated Output Variation

±10%

Voltage Variation without overheating

±10%, provided that it does not run

Frequency Variation

±1%

Maximum Allowable Pressure

0.2 MPa (2kgf/cm2) – Discharge pressure

Pump Installation

WARNING

•Before installing the pump, check if the cable and cable entry have not been damaged during

transportation.

•Be aware of the pump's center of gravity and weight. If the pump is not suspendedproperly, it

may lead to injury.

•Never use the pump cable to suspend the pump. Doing so will damage the cab andmay cause

electric shock or fire.

•DO NOT dismantle the product before/during installation without any authorizedinstructions from

PRORIL

NOTICE

The following installation requirement must be implemented:

•Use the pump dimensional drawing to ensure proper installation. If you have anyquestions, please

contact our representative or company.

•Provide a suitable protective barrier around the pump working area.

•Check for any explosion risk before pipe welding or use of any electrical hand tools.

•Remove any remaining debris from the inlet piping system before installing the pump.

CAUTION

During piping work be aware if welding sparks, paint, concrete, etc. come in contact with the pump, it may cause

the pump to malfunction, and current leakage or electric shock may occur.

Pump Design

CAUTION

The pump is partly-completed machinery without safeguard. The pump cannot in itself perform a specific

function, and will only be complete once incorporated into the system including all necessary protective

means/guard and control power circuit. Finally, the system integrator shall take all appropriate measures to

ensure that partly completed machinery can be placed on the market only if it satisfies the relevant provisions

with EN 60204-1 and EN ISO 12100. Safety distance and slot/gap shall comply with table 1, 3, 4 of EN ISO

13857.

The following installation instructions are only applicable when the installation has been designed

following the pump dimensional drawings.

1. Run the cable so that it has no sharp bends, is not pinched, and cannot be drawn into the pump inlet.

Installation

8

2. Connect the discharge pipe. The pump is equipped with a discharge connection for hose or pipe.

Piping work must not create air pocket in the middle of the piping.

NOTICE

The discharge pipe can be run vertically or horizontally, but must be without sharp bends. Excessive bending

could obstruct the flow of water, reduce the pumping volume, or clog the pump.

3. Install a non-return valve if the pump pit is deep, or if the vertical/lateral piping is too long.

4. Lower the pump into the sump pit. Attach a rope, chain, or wire to the handle of the eyebolts for lowering

and lifting the pump.

CAUTION

Make sure that the rope doesn't get tangled or twisted during installation.

5. Place the pump on a horizontal and rigid base, in an area that is free from and does not cause the pump to

take air in. This area must have a sufficient water level and collects water easily. Alternatively, the pump can

be suspended with a lifting chain just above the sump pit bottom. Make sure that the pump cannot rotate at

the startup or during operation.

NOTICE

For the water level required for operating the pump, refer to the pump's dimensional drawing that can be

obtained from our representative or company.

6. Make sure that the impeller rotation is correct.

7. Should there be any problems occurred during installation, please get in touch with a PRORIL

representative.

Float Switch Location Installation Requirement

CAUTION

Place the pump with integrated float switch hardware in an area where the float can properly and easily move

up and down without getting caught with the pit walls, cable, or lifting chains.

ELECTRICAL HAZZARD

•A certified electrician must supervise all electrical work. Comply with all local codes and regulations.

•Before starting work on the unit, make sure that the unit and the control panel are isolated from the

power supply and cannot be energized. This applies to the control circuit as well.

•Leakage into the electrical parts can cause damaged equipment or a blown fuse. Keep the end of

the motor cable above the liquid level.

•Make sure that all unused conductors are insulated.

•There is a risk of electrical shock or explosion if the electrical connections are not correctly carried

out or if there is fault or damage to the product.

Electrical Connections

9

Connection Requirements (External Protection Devices)

•The supply authority must be notified before installing the pump if it will be connected to the public

mains. When the pump is connected to the public power supply, it may cause flickering of

incandescent lamps when started.

•The mains voltage and frequency must agree with the specifications on the data plate. The supply

voltage and frequency variation must be within ±1% of the rated voltage. If the pump can be

connected to different voltages, then the connected voltage is specified by a yellow sticker close to

the cable entry.

•The pump is to be supplied through a residual current device (RCD) having a rated residual current

not exceeding 30mA.

•The fuses and circuit breakers must have the proper rating, and the pump overload (motor

protection breaker) must be connected and set to the rated current according to the data plate and if

applicable the cable chart.

•The starting current in direct-on-line start can be up to six times higher than the rated current. When

start-delta is used, the current is reduced by the factor 0.58 (1/3), which must be taken into account

when setting the circuit breakers.

•The fuse rating and the cables must be in accordance with the local rules and regulations.

•If an intermittent operation is prescribed, then the pump must be provided with monitoring equipment

supporting such operation.

NOTICE

It is possible to control the water level by combining float switches with an analog pressure sensor. Two

additional safety float switches can be installed in the dedicated Control System for high-level and dry-running

alarm.

•The thermal contacts/thermistors must be in use.

•The cables must be in good condition, not have any sharp bends, and not be pinched.

•The voltage drop in long cables must be taken into account. The drive unit's rated voltage measured

at the cable connection point in the pump.

Grounding (Earthing)

ELECTRICAL HAZARD

•You must earth (ground) all electrical equipment. This applies to the pump equipment, the driver,

and any monitoring equipment. Test the earth (ground) lead to verify that it is connected correctly.

•If the motor cable is jerked loose by mistake, the earth (ground) conductor should be the last

conductor to come loose from its terminal. Make sure that the earth (ground) conductor is longer

than the phase conductors. This applies to both ends of the motor cable.

•Risk of electrical shock or burn. You must connect additional earth- (ground-) fault protection device

to the earthed (grounded) connectors if persons are likely to come into physical contact with the

pump or pumped liquids.

•Connecting the Power Cables

CAUTION

Leakage into the electrical parts can cause damaged equipment or a blown fuse. Keep the end of the motor

cable above the liquid level.

1. Check the nameplate for output and voltage required for the pump.

2. Connect the power cables, including ground (earth), to the terminal or starter unit.

3. It is important that the pump should be properly grounded and provided with a leakage breaker to prevent

the users from serious electric shock injury.

4. Firmly tighten the cable entry into its bottom-most position.

10

GRN/YEL

BROWN

BLUE

Connecting the Power Cables

CAUTION

Beware that the power plug varies by country or region.

Single Phase/Three Phase Direct on Line

Three Phase Start - Delta Start

Electrical Circuit Diagrams

Additional information on the product circuit diagram for the corresponding model will be provided separately.

Please contact our representative or company.

Prior to Operation

•Never operate the pump without safety devices installed.

•Never operate the pump with the discharge valve closed.

•Make sure that all safety guards are in place and secure.

•Make sure you have a clear path of retreat.

•Never work alone.

•Beware of the risk of a sudden start if the product is used with a float switch level control and/or

internal contactor.

•Never start the pump while it is suspended, as the pump may jerk and cause serious accidents.

U1

V1

W1

U2

V2

Brown

Blue

Black

Brown

Blue

W2

T1

T2

Earth

Black

White

White

Green/Yellow

Operation

L1 L2

L1 L2 L3 Earth

11

ELECTRICAL HAZARD

Risk of electrical shock. Make sure no one gets closer than 20 m or 65 ft. to the unit when being in contact with

the pumped or mixed liquid.

NOTICE

The noise level of the product is lower than 70 dB However, the noise level of 70 dB may be exceeded in some

installations and at certain operating points on the performance curve. Make sure that you understand the noise

level requirements in the environment where the pump is installed. Failure to do so may result in hearing loss or

violation of local laws.

1. Check and verify the nameplate for output and voltage required for the pump.

2. Check the wiring, power supply voltage, the capacity of the ground leakage circuit breaker, etc.

3. Start the pump.

Trial Operation Non-Float Switch

Run the pump for a short time (1 to 2 seconds) and verify the direction if the rotation of

the impeller. If the starting jerk is counterclockwise (seen from above), the direction of its

rotation is correct. If the direction of rotation is incorrect, two of the wires should be

switched (consult a certified electrician).

CAUTION

•Make sure to check the pump's direction of rotation while the pump is not

submerged in water. Otherwise, the pump will get damage, which may lead

to current leakage and electrical shock.

•Never hold the handle while checking the direction of rotation. The starting

jerk may be very violent.

•Operate the pump from 3 to 10 minutes and perform the following checks:

•Using an AC ammeter (clamp), measure the operating current at the phases U, V, and W that are

connected to the terminal board.

•Using an AC voltmeter (tester), measure the voltage at the terminal board.

Conditions

Description

Rated Output Variation

±10%

Voltage Variation without overheating

±10%, provided that it does not run

Frequency Variation

±1%

•Proceed with the normal operation if no abnormal conditions are found during the trial operation.

12

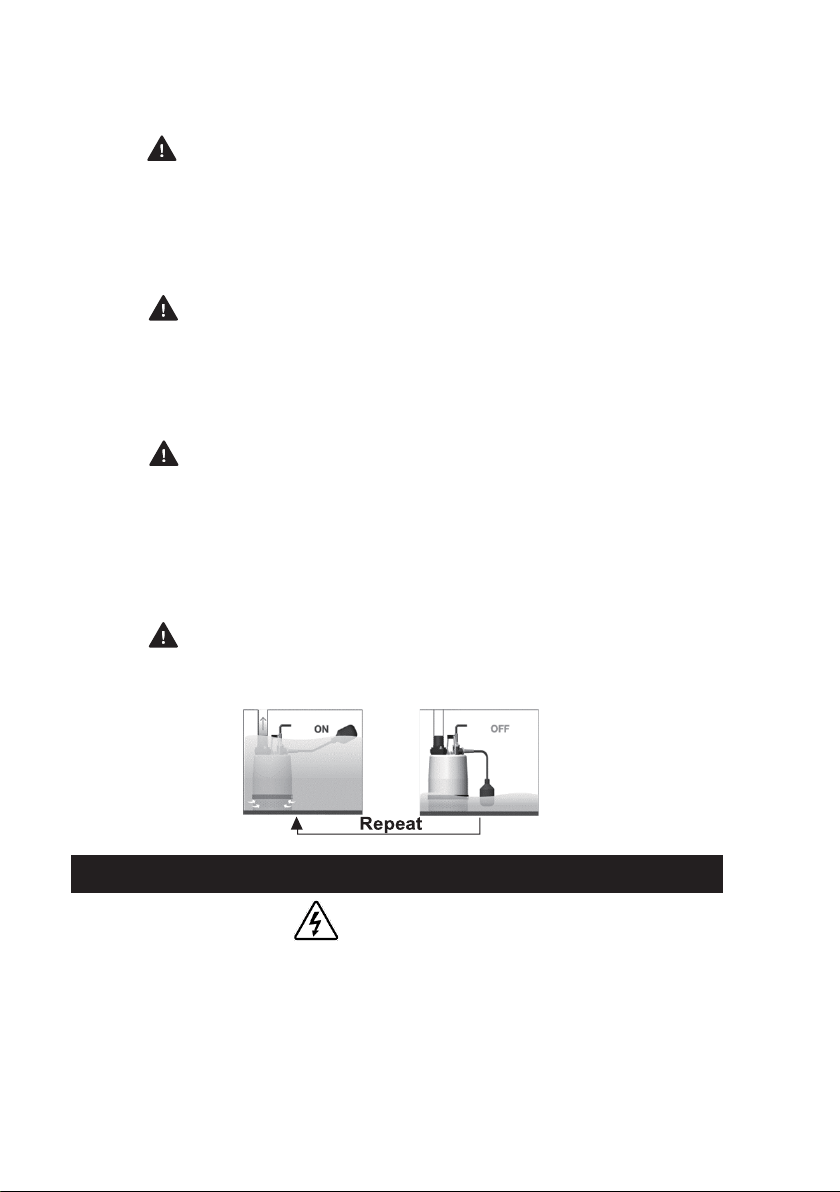

Trial Operation Float Switch

1. Direct the float switch downward.

2. Raise the float to its highest location. This will cause the pump to start.

3. Next, return the float switch to its original position. This will cause the pump to stop

4. Perform steps (2) and (3) consecutively two or more times to verify the operation.

Operation

HOT SURFACE HAZARD

Do not touch the product with bare hands during or immediately after the operation, as the product may become

very hot during operation. Failure to observe this caution may lead to being burned.

CAUTION

•Do not run the pump dry or operate it with its gate valve closed, as doing so will damage the

product, which may lead to electrical leakage or electrical shock.

•Pollution of the liquid could occur due to leakage of lubricants. Never use the product for potable

water.

1. Pay attention to the water level during operation.

2. Do not operate the pump at the lowest water level longer than 30 minutes. For details on the lowest water

level, refer to the dimensioning drawing, which is provided separately.

3. If the built-in motor safety is activated, the pump will shut down and restart automatically.

Regular checkups and preventive maintenance will ensure a more reliable and safe operation. An initial

inspection of the pump within 3 to 4 months after installation is recommended.

Subsequent inspections/maintenance can be carried out every 6 months.

WARNING

•Always disconnect and lock out the pump from the power supply before inspecting the pump.

•Make sure that the pump cannot roll or fall over to injure people and damage property.

•Rinse the pump thoroughly with clean water before working on the pump.

•The pump should not be activated if it is partially dismantled.

Maintenance Requirements

•Allow all system and pump components to cool before handling them.

•Make sure that the pump and its components have been thoroughly cleaned.

•Inspect and verify that there is no damage on the pump exterior, and that the bolts and nuts have

not loosened.

•Do not open any vent or drain valve or remove any plugs while the system is pressurized.

•Make sure the pump is isolated from the system.

Maintenance General Guidelines

•Clean all parts thoroughly, especially O-rings grooves.

•Change all O-rings, and gasket.

•During assembly or service of the pumps, it is recommended that the screws be tightened to

approximately 6- Nm (4.5 6 ft-lb). The tightening torque ensures the parts are correctly fastened and

that the pump will operate as intended

Maintenance and Inspection

13

CUTTING HAZARD

Worn impellers often have very sharp edges. Be very careful when replacing them.

Troubleshooting

14

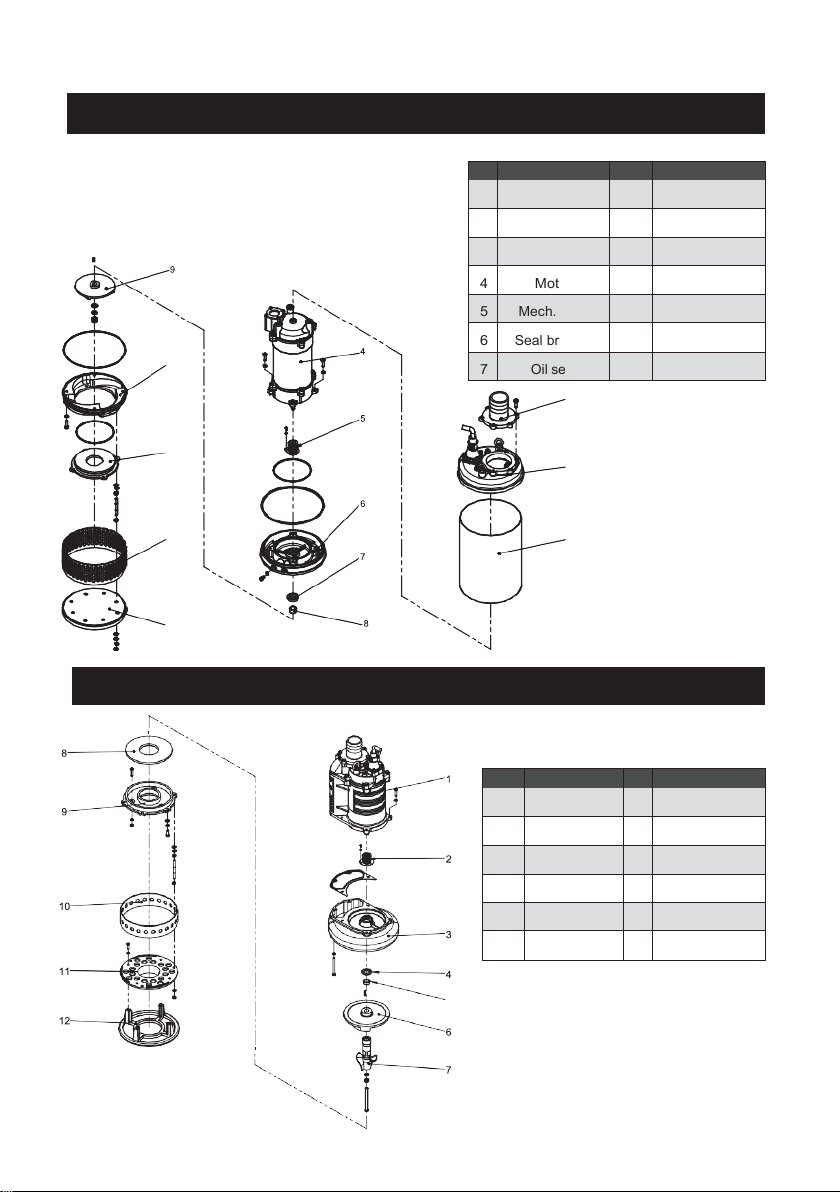

No

enomination

No

Denomination

1

Discharge

8

Shaft sleeve

2

Upper cover

9

Impeller

3

Outer case

10

Pump casing

4

Motor

11

Inlet plate

5

Mech. Seal

12

Strainer

6

Seal bracket

13

Base plate

7

Oil seal

No

enomination

No

Denomination

1

Motor

7

Agitator

2

Mech. Seal

8

Wear plate

3

Pump casing

9

Inlet plate

4

Oil seal

10

Strainer

5

Shaft sleeve

11

Strainer Base

6

Impeller

12

Base plate

Part List Tank / Tank Slim Pumps

10

11

12

13

Part List Titan / Stormy / Stormy Pro Pumps

15

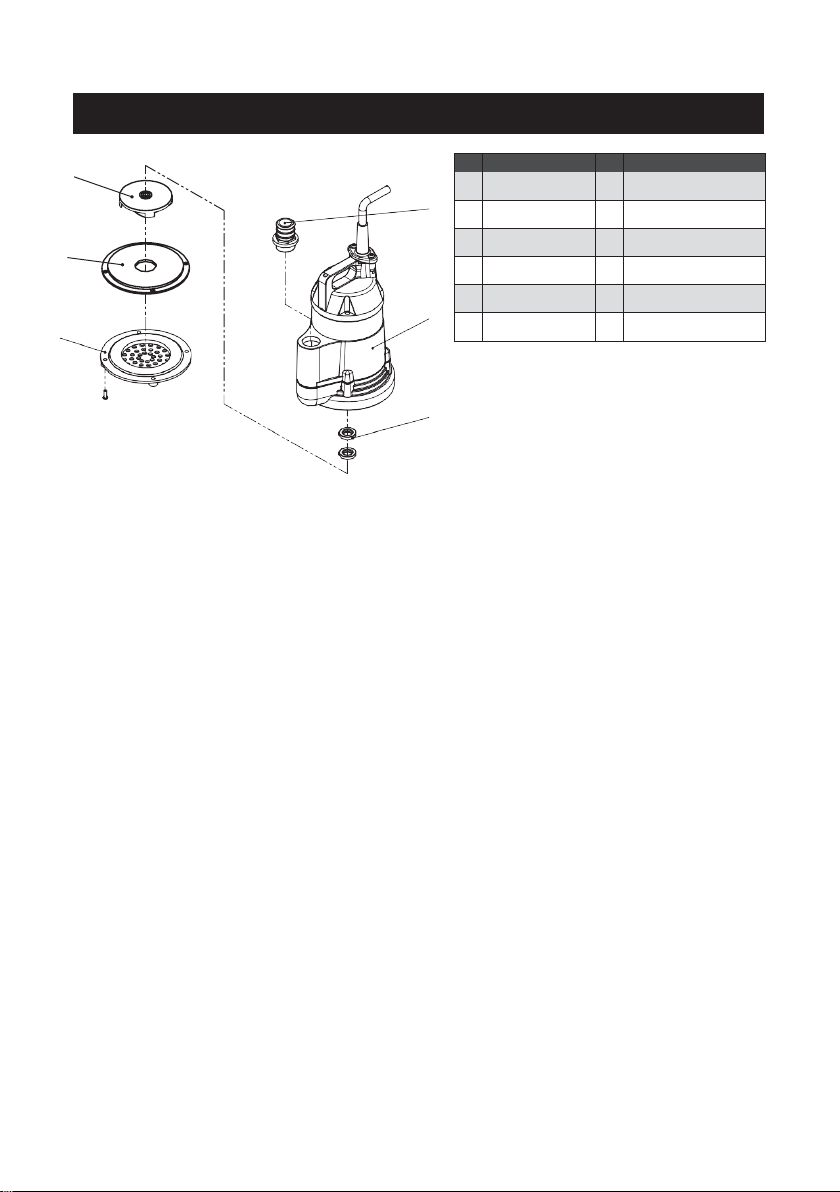

enomination

No

Denomination

1

Motor

7

Pump casing

2

Mech. Seal

8

Flange

3

Pump casing

9

Discharge elbow

4

Oil seal

5

Shaft sleeve

6

Impeller

enomination

No

Denomination

1

Motor

7

Pump casing

2

Mech. Seal

8

Flange

3

Pump casing

9

Discharge elbow

4

Oil seal

5

Shaft sleeve

6

Impeller

Part List GOCUT / GOFLOW/ GOSPIN / GOVOX/-G/-U/-S / GOMAX /

X-VOX Pumps

Part List SMART / LITE / VOX / X-SMART Pumps

16

enomination

No

Denomination

1

Motor

7

Pump casing

2

Mech. Seal

8

Flange

3

Pump casing

9

Discharge elbow

4

Oil seal

5

Shaft sleeve

6

Impeller

Part List SAVVY / JUMBO / BASE Pumps

4

5

17

18

1st Letter (year)

2nd Letter (month)

Numbers

A = 2016

N = December

Continuous number

sequence from

production

Examples:

CP 1026 ( 2018 /

November / 1026th

pump )

BS 1496 ( 2017 /

August / 1496th pump)

BN 1135 ( 2017 /

December / 1135th

pump )

B = 2017

P = November

C = 2018

Q = October

D = 2019

R = September

E = 2020

S = August

F = 2021

T = July

G = 2022

U = June

H = 2023

V = May

I = 2024

W = April

J = 2025

X = March

K = 2026

Y = February

L = 2027

Z = January

Description

19

WWW.PRORIL.COM

NO. 51, GUANGHUA RD. DASHE DISTRICT KAOHSIUNG CITY 815, TAIWAN

TEL : + 886 7 351 2306

MADE IN TAIWAN REV. MN:2021-01

2021 PRORIL. The original instruction is in English. All non-English instructions are translations of the original

instruction.

This manual suits for next models

15

Table of contents

Popular Water Pump manuals by other brands

Pentair

Pentair WCFIX 260V/3 instruction manual

OSAKA VACUUM

OSAKA VACUUM TG390M/420M Series instruction manual

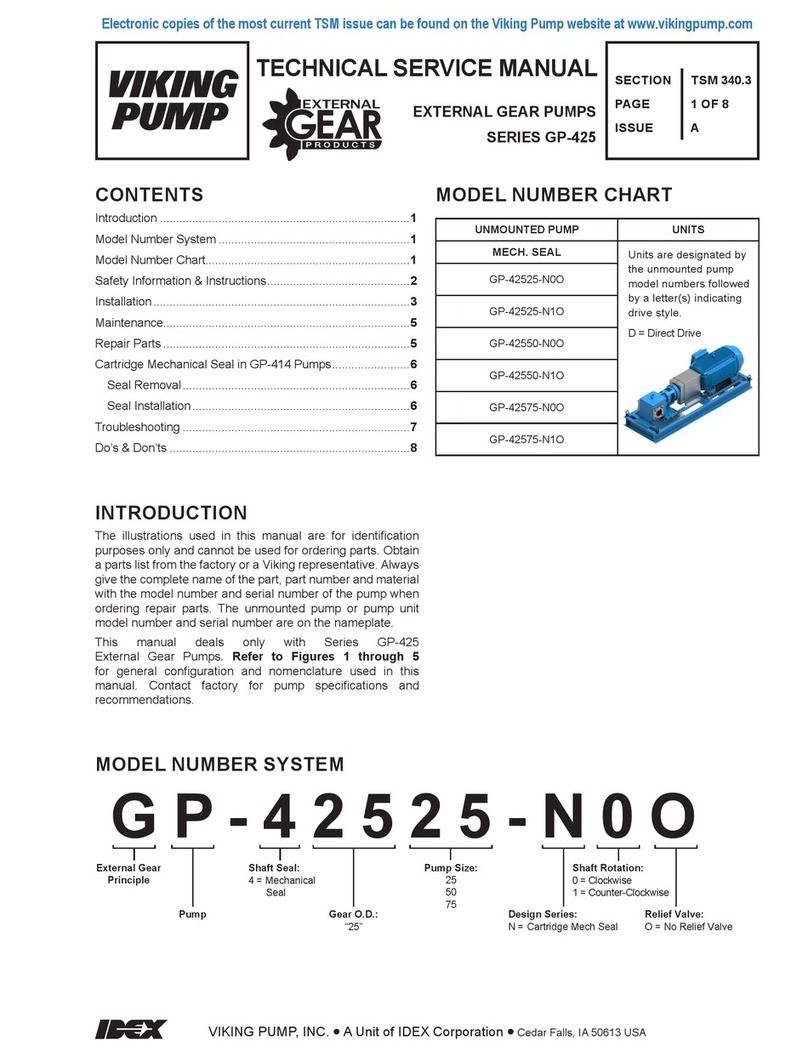

Viking pump

Viking pump GP-425 SERIES Technical & service manual

Parkside

Parkside PHWW 1200 A1 Translation of the original instructions

Carlisle Fluid Technologies

Carlisle Fluid Technologies Binks E2-30 Service manual

Penguin

Penguin MTD Series manual