Prostat PRF-911 User manual

P R O F E S S I O N A L

S T A T I C

C O N T R O L

P R O D U C T S

Operations Manual

Concentric Ring

PRF-911

Copyright ©2001-2007 by PROSTAT®Corporation. All rights reserved. Printed in the United States of

America. No part of this manual may be used or reproduced in any manner whatsoever without written

permission. For information contact PROSTAT Corporation, 1072 Tower Lane, Bensenville, IL 60106

PROSTAT is the registered trademark of PROSTAT®Corporation

PRF-911 Concentric Ring

2

TABLE OF CONTENTS

PROSTAT®PRF-911 CONCENTRIC RING

Title Page #

I. Introduction .................................................................................................................... 3

II. Cautions & Warnings ...................................................................................................... 3

III. Equipment Inspection & Initial Preparation for use......................................................... 5

IV. General Operation......................................................................................................... 13

V. Maintenance.................................................................................................................. 20

General Specifications.................................................................................................. 21

PRF-911 Concentric Ring

3

I. Introduction

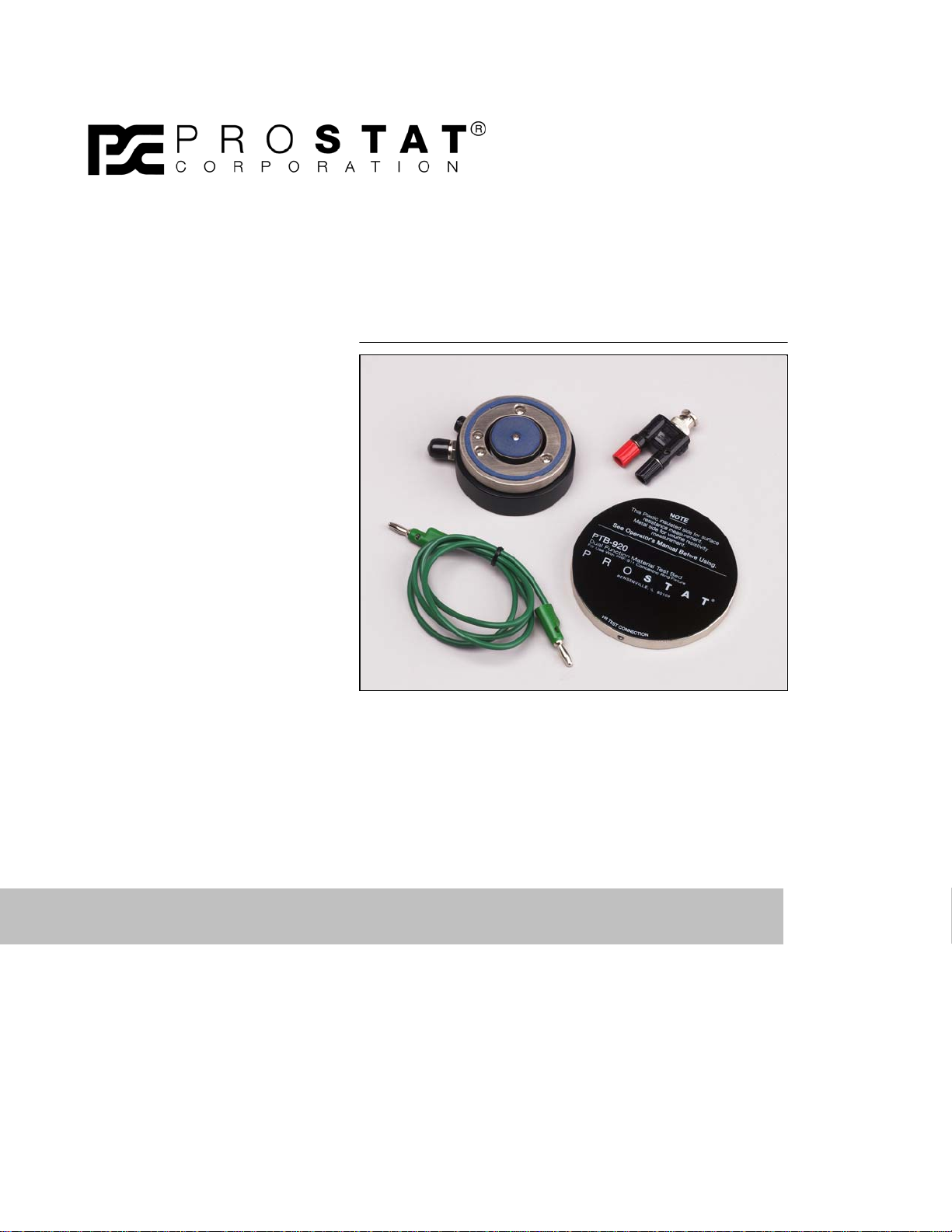

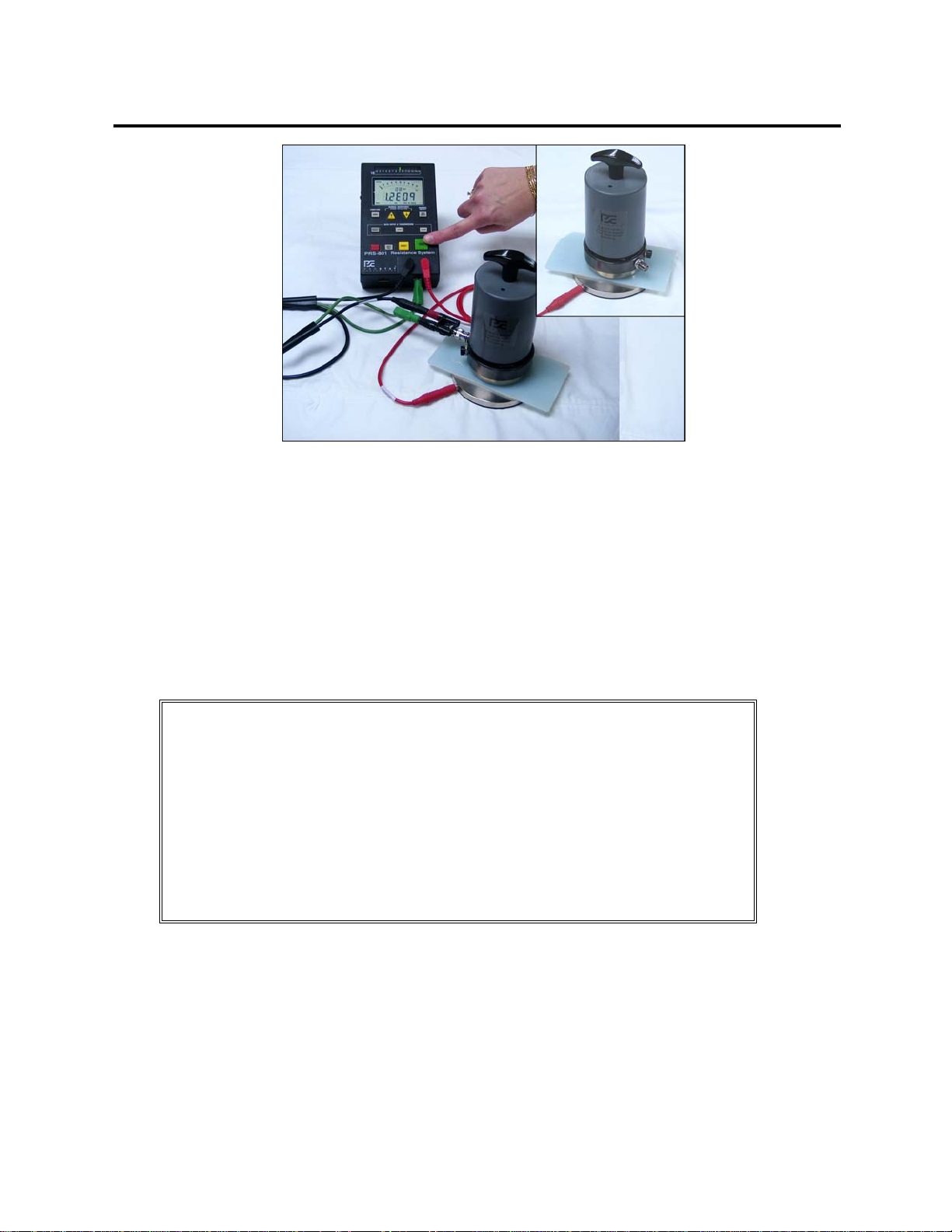

The PROSTAT PRF-911 Concentric Ring and PTB-920 Dual Test Bed work together,

and in conjunction with the Prostat PRS-801 and PRS-812 Resistance Instruments for

measuring Surface Resistance and Volume Resistivity of materials. The size, portability

and construction make this fixture system convenient for auditing flat materials and films

in the field. The concentric Ring with one 5 Ib electrode weight on top approximates

currently recommended resistance and resistivity measurement procedures.

A. PRF-911 Concentric Ring consists of a spring loaded center electrode (D1) and an

outer electrode ring (D2). Both electrodes are covered with highly conductive rubber.

1. Direct surface resistance measurements generally conform to the guidelines as

outlined in the ESD STM 11. 11-2001 Surface Resistance test method.

2. The dimensions of the fixture allow estimation of surface resistivity in

ohms/square. This estimate is obtained by multiplying surface resistance results

obtained herein by 10 times, i.e., adding one order of magnitude.

3. The fixture connections allow the device to be used for making Volume Resistivity

measurements generally described in ASTM D-257 and ESD STM 11.12-2000

Volume Resistance Measurements. The fixture correction for the area of its center

electrode (D1) is 6.9 cm2.

B. The PTB-920 Dual Test Bed consists of a four inch metal test bed laminated to an

insulated test bed.

1. The insulated acrylic surface is used for surface resistance measurements made

using the ESD STM 11.11-2001 guidelines.

2. The metal (plated aluminum) surface is used for volume resistance and resistivity

measurements made using ESD STM 11.12-2000 guidelines.

C. A BNC/Dual Banana Receptacle adapter is provided for use with the PRF-911

Concentric Ring fixture.

II. Cautions & Warnings

A. As with any electrical device, use proper electrical precautions to avoid personnel

shock.

1. The PRF-911 Concentric Ring fixture operates with power input from resistance

measurement instruments at 10 to 100 volts. An annoying shock to any person

touching it may be possible.

2. Although the current capability is limited, a distinct HAZARD EXISTS in the

person's reaction to a low level electric shock.

3. To avoid personnel shock, do not touch the electrode when power is applied.

PRF-911 Concentric Ring

4

CAUTION

To avoid electrical shock, do not touch the fixture,

electrodes or test bed when power is being applied.

B. The PRF-911 is designed to be used in audit environments at test voltages of 100

volts or less. Exceeding 100 volts greatly enhances the risk of personnel shock

hazards, and may damage or change materials being measured.

1. Do not exceed 100 volts in the audit environment.

CAUTION

Operational test voltages should not exceed

100 volts in the audit environment.

2. Only qualified instrument repair and test personnel should exceed the 100 volt

operation guideline, and do so only under controlled conditions using precautions

against personnel shock.

3. Never exceed 100 volts during instrument test or repair.

C. DO NOT USE THE PRF-911 CONCENTRIC RING if it fails to function during its

continuity inspection test.

CAUTION

Should the continuity check indicate improper

connection to the electrodes, OR the fixture

becomes damaged, do not use the PRF-911

Concentric Ring. Contact PROSTAT Customer

Service Department for further instructions.

D. DO NOT USE THE PRF-911 CONCENTRIC RING if it becomes damaged in any

way.

E. Only qualified instrument repair personnel should open terminal connections or

repair the PRF-911

PRF-911 Concentric Ring

5

F. Do Not Touch Electrode Surfaces: Electrodes will become contaminated with skin

oils.

G. Do not store or use in damp environments

H. Always store the PRF-911 with its protective cap in place.

III. Equipment Inspection & Initial Preparation for use

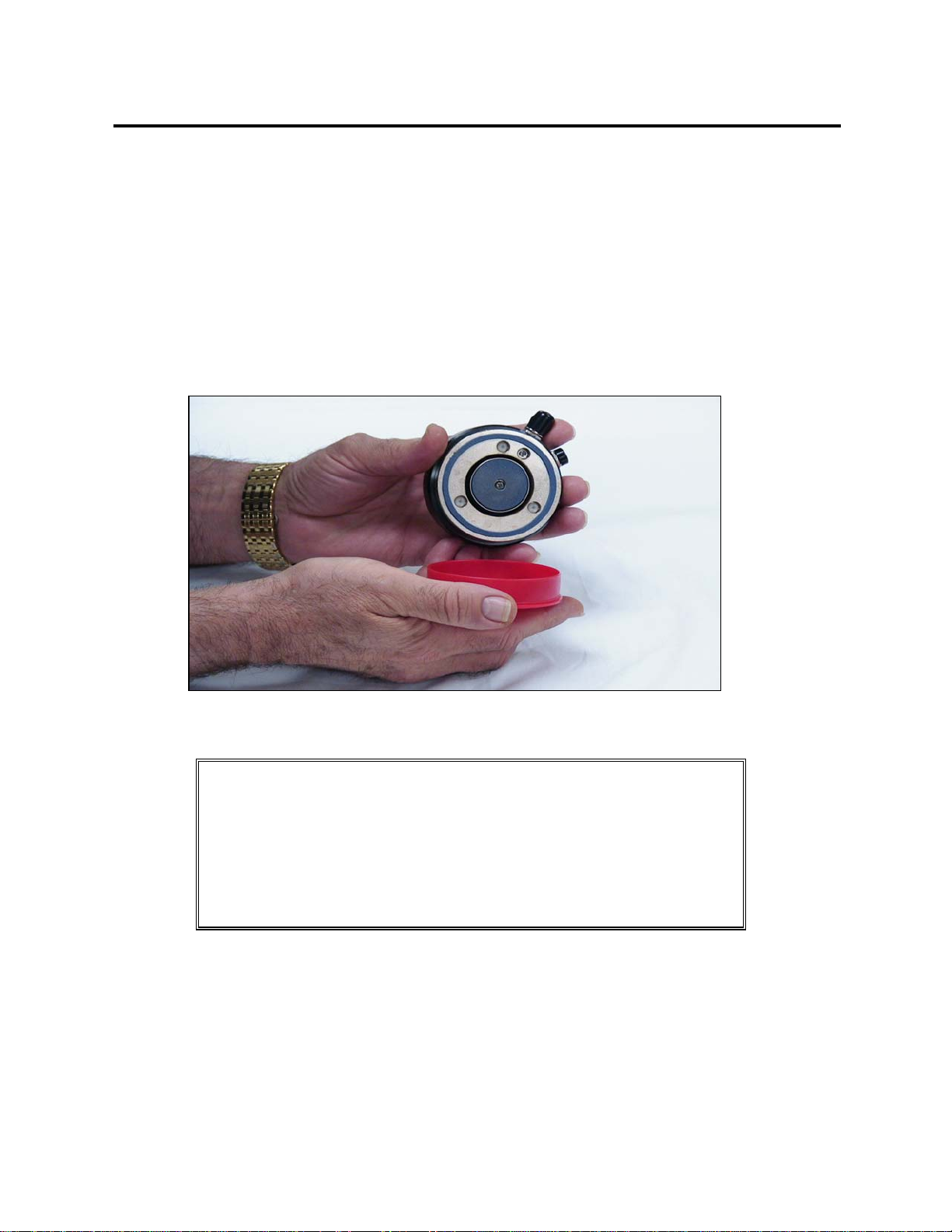

A. PRF-911 Concentric Ring – Equipment and Accessories

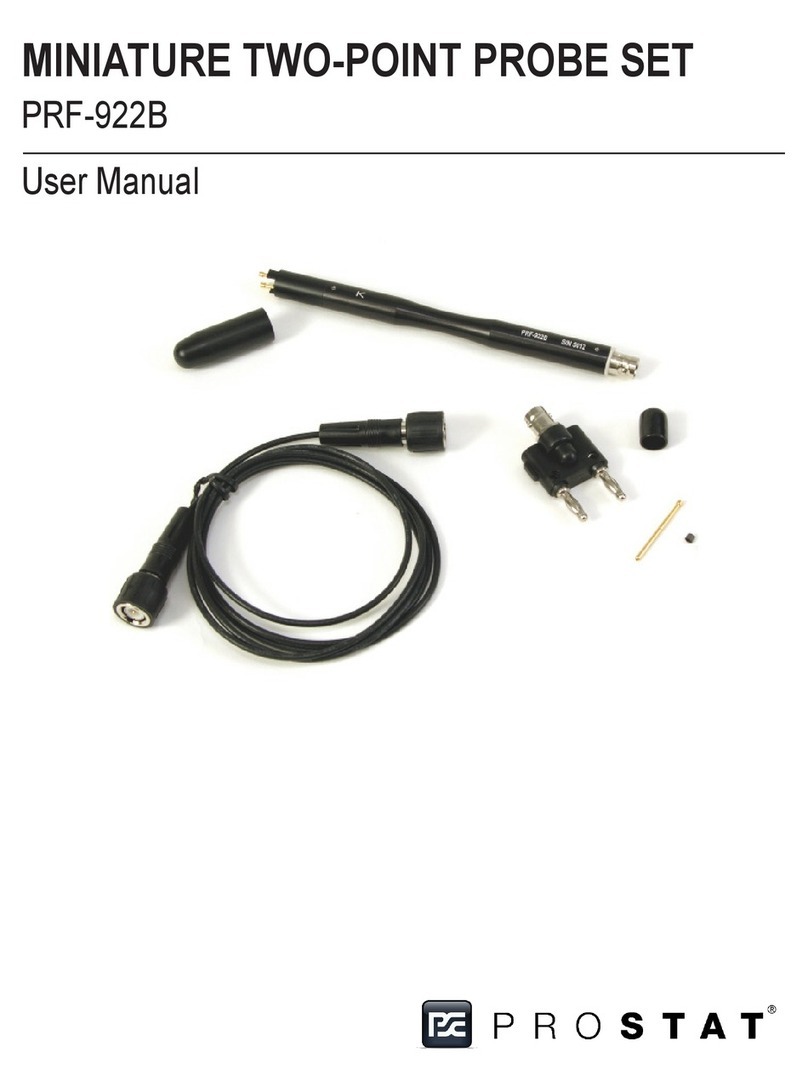

1. PRF-911 Concentric Ring with protective cap

OPERATIONAL HINT

The Red Cap over the Concentric Ring Electrodes

must be removed prior to making a measurement.

The PRF-911 will not operate while the cap is in place.

Replace the red cap for protection when not in use.

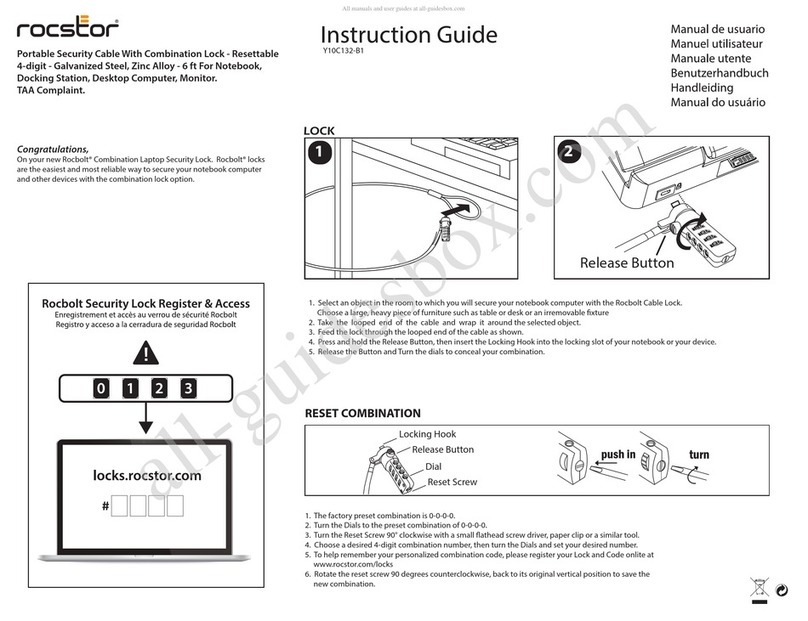

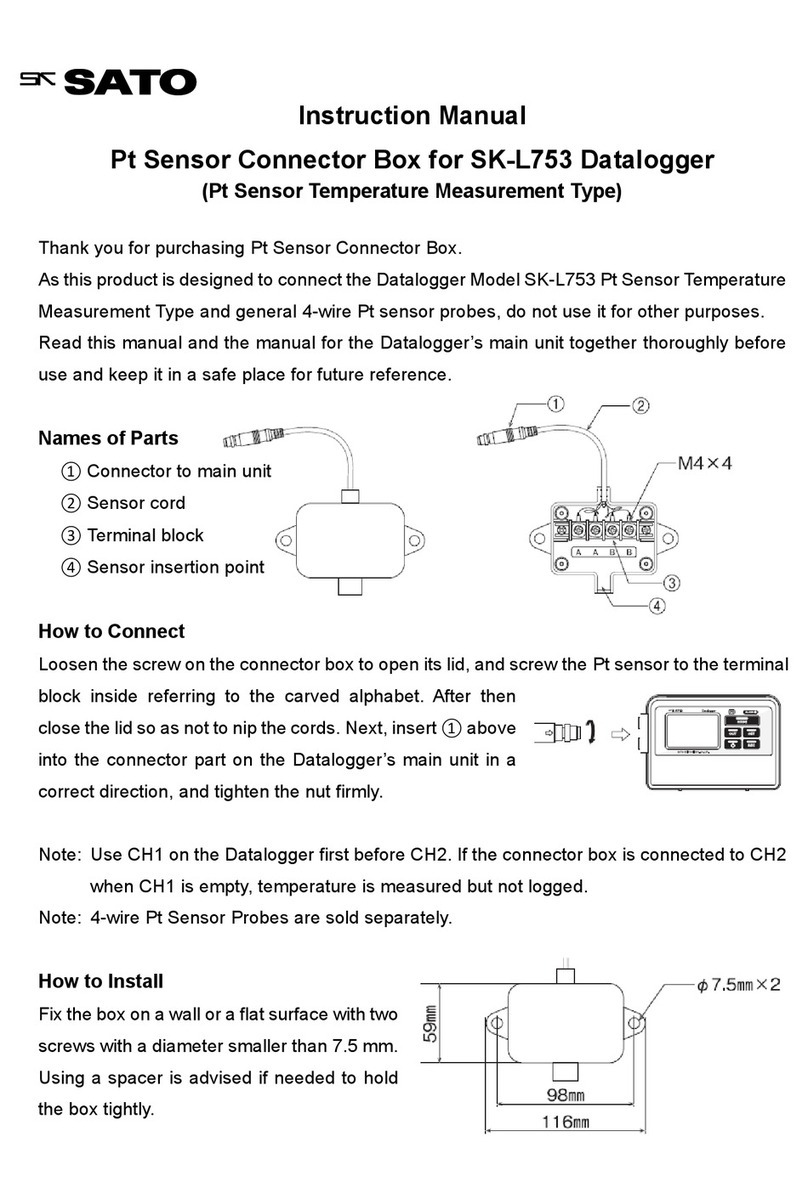

2. BNC/Dual Banana terminal adapter allowing "plug-in" connection to the PRF-911

BNC connector as follows:

a. Direct connection to the center INNER RING electrode, designated D1(RED

BNC)

b. The fixture assembly housing ground is designatyed as FIXT.GRD on the unit

label. When properly used, it helps to reduce the effects of extraneous fields on

material measurements (BLACK BNC)

Figure 1: PRF-911 with protective cap

PRF-911 Concentric Ring

6

3. Black banana receptacle in the fixture housing allows direct connection to the

OUTER RING electrode, designated D2.

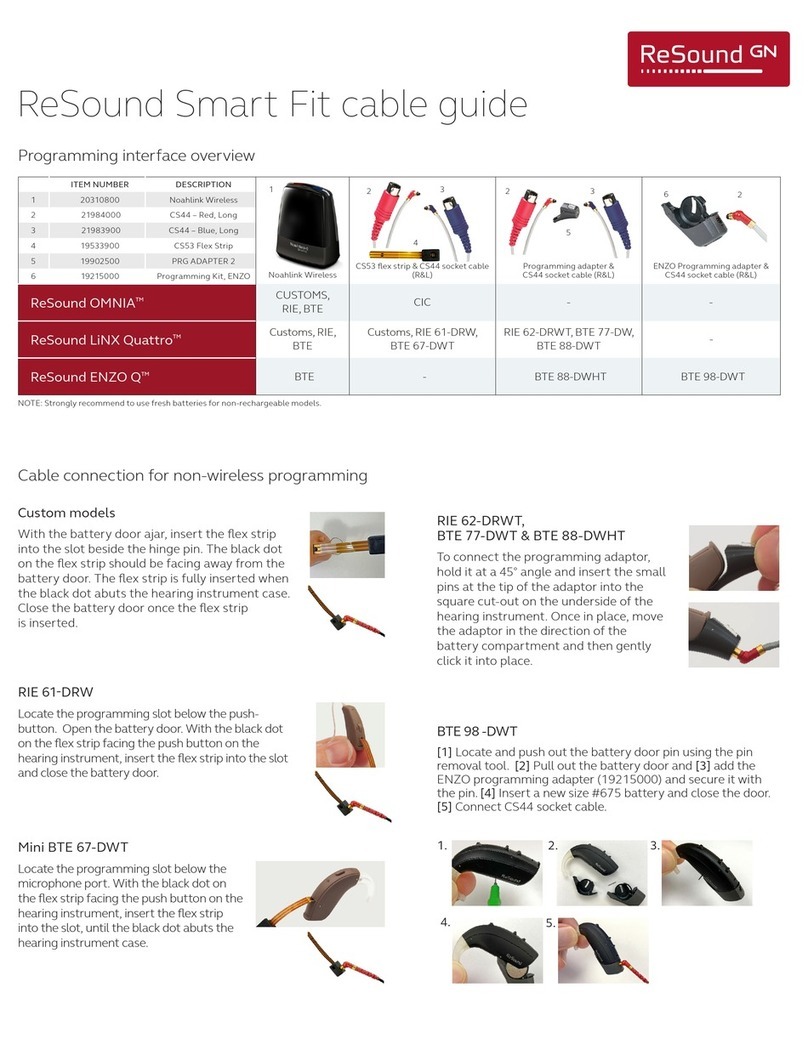

B. Laminated PTB-920 Dual Test Bed

1. The upper Acrylic insulated surface is

employed during surface resistance

measurements in accordance with ESD

STM 11.11-2001

2. The lower metal surface is equipped with a

standard banana receptacle and is

employed when making volume resistivity

measurements as generally described in

ESD STM 11.12-2000.

C. Inspection of the PRF-911 Concentric Ring Figure 3 Dual Test Bed Fixture

1. Before inspecting the PRF-911 Concentric Ring, confirm the calibration of your

resistance instrument. Performing low Resistance Calibration on the Prostat PRS-

801 and PRS-812 Resistance Instruments.

1. Insert Reference Shunt

2. Select Ohms Mode by pressing “Mode” once

3. Press Test to measure shunt. Indication should be 1.02 Ω+/- 0.002 Ω

4. Press Reset to enter data in memory

5. Press Reset and Clear within ½ second. The display should indicate CAL

6. Press Reset to adjust instrument to reference shunt

7. Press Test to confirm 1.02 Ω+/- 0.02 Ω

2. Carefully install BNC/Dual Banana adapter on the fixture BNC connector. Note

that the connection is a bayonet type.

Figure 2: BNC adapter and connection

Figure 3: Dual Test Bed

PRF-911 Concentric Ring

7

a. Position adapter on BNC connector while positioning bayonet studs in

the adapter slots

b. Apply slight pressure and twist clockwise to lock the adapter in-place.

c. NOTE: To remove, apply slight pressure and twist counter clockwise.

3. Remove RED protective cap covering the electrode surfaces

4. Confirming the Fixture Ground and BNC Connection

a. Place PRF-911 Concentric Ring fixture on a flat surface with the

electrodes facing UP .

b. Plug one PRS-801 or PRS-812 Resistance Meter test lead to the BLACK

BNC/Dual Banana adapter receptacles.

c. Attach an alligator clip to the second PRS-801 or PRS-812 test lead. NOTE: TO

AVOID DAMAGE, DO NOT ATTACH ALLIGATOR CLIPS TO ANY

SURFACE OR PORTION OF THE PRF-911 FIXTURE.

d.Gently touch the tip of the clip to the metal collar of the BNC adapter

where the connection is made to the fixture housing. (see figure 5)

e. Select Ohms Mode by pressing “Mode” button once.

1. Push Test Button

2. Resistance Should be < 1 Ω

Fi

g

ure 4: Installin

g

the BNC Ada

p

te

r

1

2

PRF-911 Concentric Ring

8

5. Confirming the Center Electrode

Use the following procedure to confirm proper connection to the fixture's center

electrode (D1) through the installed BNC/Dual Banana adapter. NOTE: Review

resistance instrumentr operating instructions before proceeding:

a. Place PRF-911 Concentric Ring fixture on a flat surface with the

electrodes facing UP.

b. Plug one PRS-801 or PRS-812 Resistance Instrument test lead the RED

BNC/Dual Banana adapter receptacle.

c. Attach an alligator clip to the second PRS-801 or PRS-812 test lead. NOTE: TO

AVOID DAMAGE, DO NOT ATTACH ALLIGATOR CLIPS TO ANY

SURFACE OR PORTION OF THE PRF-911 FIXTURE.

d. Hold the second PRS-801 or PRS-812 test lead by the insulated collar just

behind the alligator clip.

e. GENTLY touch the tip of the alligator clip to the spring loaded center

electrode. (see figure 6)

f. Select Ohms Mode by pressing the “Mode” button once on the PRS-801 or PRS-

812 Resistance Instrument.

1. Push Test Button

2. Resistance Should be < 10 Ω

Figure 5: Confirming Fixture Ground & BNC Connection

PRF-911 Concentric Ring

9

(1) If proper connection is made to the BNC/Dual Banana adapter

the PRS-801 or PRS-812 will indicate low resistance by full meter deflection.

(2) If resistance is high, change the test lead connection to the other BNC/Dual

Banana adapter receptacle and repeat the procedure.

(3) If no continuity indication appears, clean the electrode with 70% solution of

IPA, test the PRS-801 or PRS-812 and lead connections per its operating

instructions and repeat the procedure. (i.e. Install the supplied shunt and test

the low range. Check the cable & connections as well.)

6. Confirming the Outer Electrode

Use the following procedure to confirm proper connection to the fixture's outer ring

electrode (D2) through the frame installed BLACK banana receptacle. NOTE:

Review the resistance instrument’s operating instructions before proceeding.

a. Place PRF-911 Concentric Ring fixture on a flat surface with the

electrodes facing UP .

b. Plug one PRS-801 or PRS-812 Resistance Meter test lead into the BLACK

OUTER RING banana receptacle located in the side of the fixture frame.

c. Attach an alligator clip to the second PRS-801 or PRS-812 Resistance

Instrument test lead. NOTE: TO

AVOID DAMAGE, DO NOT ATTACH ALLIGATOR CLIPS TO ANY

SURFACE OR PORTION OF THE PRF-911 FIXTURE.

Figure 6: Confirming Center Electrode

PRF-911 Concentric Ring

10

d. Hold the second PRS-801 or PRS-812 test lead by the insulated collar just

behind the alligator clip.

e. GENTLY touch the tip of the alligator clip to the narrow outer electrode

ring. (see figure 7)

f. Select Ohms Mode by pressing the “Mode” button once of the PRS-801 or

PRS-812 Resistance Instrument.

1. Push Test Button

2. Resistance Should be < 10 Ω

(1) If proper connection is made through the BLACK receptacle to

the outer ring the PRS-801 or PRS-812 will indicate low.

(2) If no continuity indication appears, clean the electrode with 70% solution of

IPA, test the PRS-801 or PRS-812 per its operating instructions and repeat

the procedure. (i.e. Install the supplied shunt and test the low range. Check

the cable & connections as well.)

Fi

g

ure 7: Confirmin

g

Outer Electrode

PRF-911 Concentric Ring

11

CAUTION

Should the electrode continuity check indicate

improper connection to the electrodes, do not use

the PRF-911 Concentric Ring. Contact PROSTAT

Customer Service Department for further instructions.

7. Confirming Electrode Contact to the Test Bed

Use the following procedure to confirm positive electrode contact with the PTB-920

Test Bed.

a. With the BNC/Dual Banana adapter installed, place the PRF-911 fixture

on the PTB-920 METAL test surface with the electrodes making contact

with the test bed surface.

b. Connect one PRS-801 or PRS-812 Resistance Meter test lead to the center

INNER RING electrode (D1) BNC adapter receptacle (RED)

c. Connect the second PRS-801 or PRS-812 Resistance Meter test lead to the

metal test bed banana receptacle.

d. Place one five pound NFPA electrode on the PRF-911 fixture housing;

(1) NOTE the compression of the center electrode spring assembly

(2) Visually confirm that the outer electrode makes direct contact

with the metal test bed

Figure 8: Confirming Electrode Contact to Test Bed

PRF-911 Concentric Ring

12

e. Select Ohms Mode by pressing the “Mode” button once of the PRS-801 or

PRS-812 Resistance Instrument.

1. Push Test Button

2. Resistance Should be < 20 Ω

(1) If proper connection is made to the BNC/Dual Banana adapter

and the center electrode is in contact with the metal test bed, the

resistance instrument will indicate low resistance.

(2) If proper continuity indication confirms positive contact of the

center electrode to the metal plate, proceed with testing the outer

electrode continuity, as described in point f.

(3) If no continuity indication appears, change the test lead

connection to the other BNC/Dual Banana adapter receptacle

and repeat the procedure.

(4) If no continuity indication appears, clean the electrode surface with 70%

solution of IPA, test the PRS-801 or PRS-812 per its operating instructions

and repeat the procedure. (i.e. Install the supplied shunt and test the low

range. Check the cable & connections as well.)

f. Remove the PRS-801 or PRS-812 test lead from the BNC/Dual Banana adapter

and install it in the BLACK OUTER RING electrode receptacle located on the

side of the fixture housing.

Fi

g

ure 9: Confirmin

g

Electrode Contact to Test Bed

PRF-911 Concentric Ring

13

g. Select Ohms Mode by pressing “Mode” button once.

1. Push Test Button

2. Resistance Should be < 10 Ω

(1) If proper connection is made through the BLACK receptacle to

the outer ring, and the outer electrode is in contact with the

metal test bed, the PRS-801 or PRS-812 will indicate low resistance is < 10 Ω

(2) If proper continuity indication confirms positive contact of the

outer electrode, the fixture check is completed.

(3) If no continuity indication appears, clean the electrode surface with 70%

solution of IPA , test the PRS-801 or PRS-812 per its operating instructions

and repeat the procedure. (i.e. Install the supplied shunt and test the low

range. Check the cable & connections as well.)

IV. General Operation

A. Surface Resistance Measurement per ESD STM 11.11-2001. Note that this procedure

replaces surface resistivity measurements of electrostatic discharge control materials

previously conducted using ASTM D-257. The following procedure is used to measure

surface resistance in ohms, and convert it to ohms/square if necessary.

1. Items necessary for this procedure

a. PRF-911 Concentric Ring Fixture

b. BNC/Dual Banana Adapter

c. PTB-920 Dual Test Bed

d. PRS-801 or PRS-812 Resistance Instrument and test leads

e.One PROSTAT five pound NFPA electrode

f. One GREEN auxiliary ground reference lead or PRS-801 High Resistance Lead

harness if using PRS-801 Instrument. NOTE: Connection to instrument ground

reference is recommended for measurements of 1.0x10 Ωand higher

g. Clear worksurface

2. Specimen Preparation for Surface Resistance measurement

a. This procedure is designed specifically for measuring planar (flat)

surfaces having relatively smooth surfaces.

b. In the laboratory environment, sample preparation usually includes

cutting a 3x5 inch specimen of the sample material to be tested. This

PRF-911 Concentric Ring

14

insures standard specimen size and minimizes fringe voltages that may

effect the surface resistance measurement.

c. In the auditing process, one often must obtain measurement of a large

piece of material without cutting sample into a proper size specimen.

This type of measurement is considered "indicative"; however, it is

sufficient for obtaining a reasonable indication of the material's surface

resistance PROVIDING only one layer of the material is measured as

described below.

3. PRF-911 Concentric Ring Fixture Preparation

a. Install the BNC/Dual Banana adapter on the PRF-911 fixture

b. Check proper battery level of the PRS-801 or PRS-812 Resistance Instrument

and connect the meter leads to the PRF-911 Fixture as follows:

(1) Install the instrument negative (-) lead of the PRS-801 or PRS-812

Resistance Instrument to the RED BNC adapter receptacle connected to the

center INNER RING electrode (D1).

(2) Install the positive (+) lead to the BLACK receptacle connected to the OUTER

RING electrode (D2).

(3) To enhance the accuracy of the measurement, connect a

GREEN auxiliary ground lead to the BNC adapter fixture ground

receptacle, and the other end of the lead to the instrument’s ground

reference, if so equipped.

c. Place the PTB-920 Dual Test Bed on a worksurface with the insulated

acrylic surface facing UP .

Fi

g

ure 10: PRF-911 Fixture Pre

p

aration

Instrument Ground Reference

Positive ( + ) Test

Voltage Power Lead

Negative ( - ) Sensing Lead

PRF-911 Concentric Ring

15

4. To Measure the Material under test

a. Place the specimen to be tested on the insulated PTB-920 test bed with

the surface to be tested facing UP.

b. Remove the protective cap covering the PRF-911 fixture electrodes and

position the fixture on the test material in the approximate center of the

test bed.

c. Place the five pound PROSTAT NFPA electrode directly on top of the

PRF-911 fixture housing. Note the center electrode spring compression

and contact of the outer electrode ring with the material under test.

OPERATIONAL NOTE

The electrode assembly weighs approximately 28

ounces. The center electrode spring counters the

fixture weight with approximately 30 ounces when

fullyextended. When the five pound NFPA electrode

is positioned on the fixture housing, both the outer ring

and the center electrodes have approximately five

pounds total pressure across both surfaces.

d. When operating PRS-801 or PRS-812 Resistance Instruments in Automatic or

Automatic/Manual, simply press the GREEN TEST button to initiate the

measurement sequence.

The initial test voltage will be less than 10 volts (<10V), then increase based on

the material under test resistance range.

Proper test voltage protocol for resistance measurements of ESD Control

materials follows:

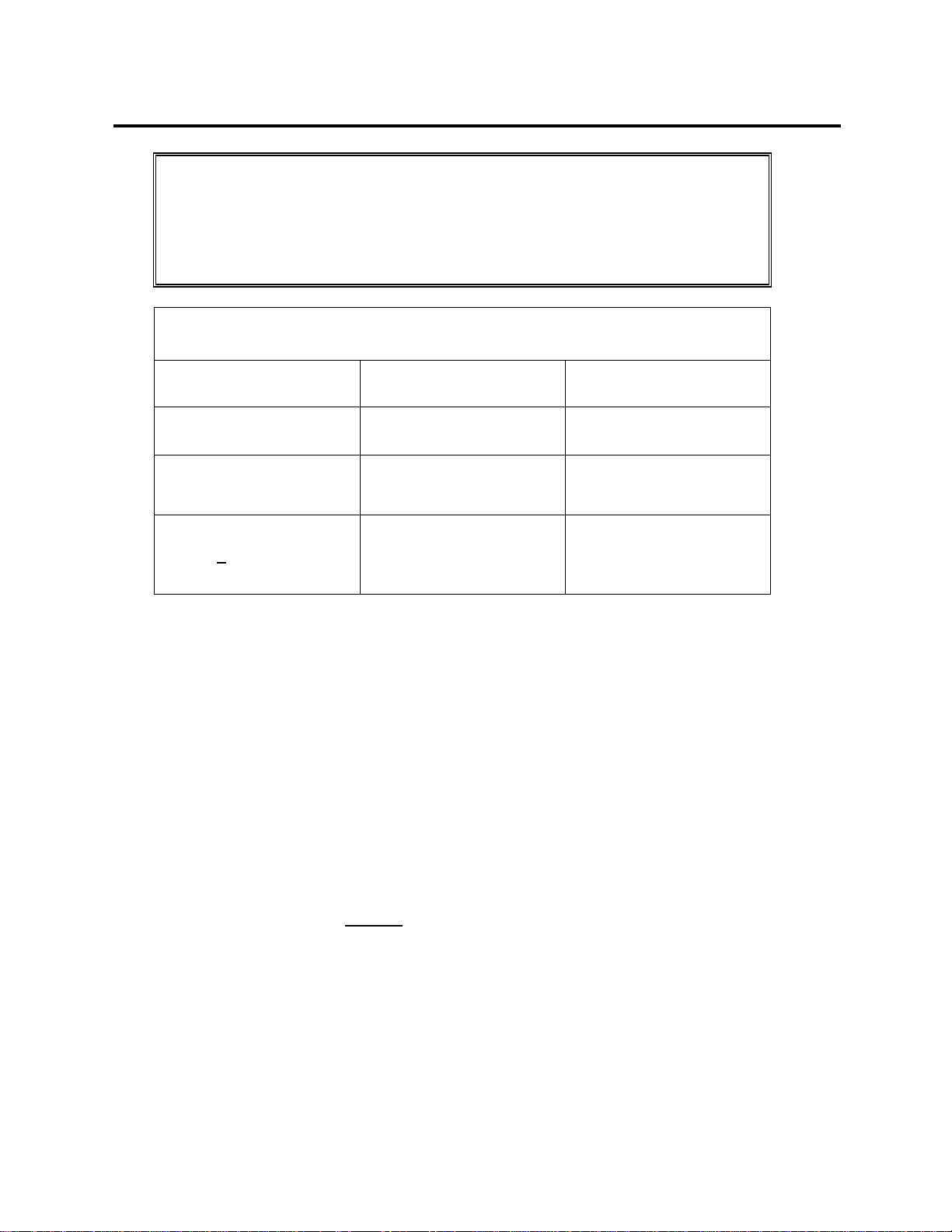

Resistance Range (Ω) Test Voltage (V) Remarks

< 1.0 x 104< 10V

Voltage is variable.

Electrification 2-5 sec.

1.0 x 104 to < 1.0 x 10610V Constant Voltage

Preferred. Electrification

2-5 sec.

>1.0 x 106100V

Constant Voltage

Preferred. Electrification

based on system

characteristics

PRF-911 Concentric Ring

16

(1) If the indicated measurement on the PRS-801 or PRS-812 Resistance

Instrument is less than 1.0x106Ohms, record the indicated measurement in

Ohms after approximately 2 to 5 seconds of electrification.

(2) If the indicated measurement on the Resistance Instrument is greater than

1.0x106Ohms:

(a) If using the PRS-801 or PRS-812 Resistance Instrument, in Automatic

Mode the unit will automatically increase the test voltage to 100 Volts, and

control electrification period.

(b) See instrument operations manual for detailed information on resistance

range, test voltage and electrification adjustment details.

5. To estimate Surface Resistivity in Ohms/square when using the ESD STM 11.11-

2001 Surface Resistance Measurement (Ohms), multiply the measurement results

by 10. To accomplish this, simply increase the order of magnitude (exponent) by 1.

For example:

a. If the recorded ESD STM 11.11-2001 Surface Resistance measurement is

2.0x105 Ohms, increase the 105exponent to 106to obtain 2.0x106Ohms/square.

b. If the recorded ESD STM 11.11-2001 Surface Resistance measurement is

5.0x108 Ohms, increase the 108exponent to 109to obtain 5.0x109Ohms/square.

B. Volume Resistivity Measurement per ESD STM 11.12-2000

1. Items necessary for this procedure

a. PRF-911 Concentric Ring Fixture

b. BNC/Dual Banana Adapter

c. PTB-920 Dual Test Bed

d. PRS-801 or PRS-812 Resistance Meter and test leads

e. One PROSTAT five pound NFPA electrode.

f. One GREEN auxiliary ground lead (OPTIONAL)

g. A micrometer to accurately measure the test materials thickness in cm

h. Clear worksurface

2. Specimen Preparation for Volume Resistivity measurement

PRF-911 Concentric Ring

17

a. This procedure is designed specifically for measuring planar (flat)

surfaces having relatively smooth surfaces.

b. In the laboratory environment, sample preparation usually includes

cutting a 3x5 inch specimen of the sample material to be tested. This

insures standard specimen size and minimizes fringe voltages that may

effect the measurement. However, using the outer electrode as a guard ring,

these effects are minimized to some degree.

c. In the auditing process, one often must obtain measurement of a large

piece of material without cutting sample into a proper size specimen.

This type of measurement is considered "indicative"; however, it is

sufficient for obtaining a reasonable indication of the material's volume

resistance.

3. PRF-911 Concentric Ring Fixture Preparation

a. Install the BNC/Dual Banana adapter on the PRF-911 fixture

b. Check proper battery level of the Resistance Instrument and connect its leads

to the PRF-911 Fixture as follows:

(1) Install the negative (-) lead of the PRS-801 or PRS-812 Resistance

Instrument to the RED BNC adapter receptacle connected to the center

electrode (01)'.

(2) Install the positive (+) lead of the PRS-801 or PRS-812 Resistance Instrument

to the banana receptacle located on the edge of the PTB-920 metal test bed.

(3) Install the GREEN auxiliary ground reference lead to the Black BNC

receptacle and the other end of the lead to the instrument ground reference.

c. Place the PTB-920 Dual Test Bed on a worksurface with the conductive

metal surface facing UP.

PRF-911 Concentric Ring

18

4. To Measure the Material under test

a. Place the specimen to be tested on the metal PTB-920 test bed.

b. Remove the PRF-911 fixture electrode protective cap and position the

fixture on the test material in the approximate center of the test bed.

c. Place the five pound PROSTAT NFPA electrode directly on top of the

PRF-911 fixture housing. Note the center electrode spring compression

and contact of the outer electrode ring with the material under test.

OPERATIONAL NOTE

The electrode assembly weighs approximately 28

ounces. The center electrode spring counters the

fixture weight with approximately 30 ounces when

fully extended. When the five pound NFPA electrode

is positioned on the fixture housing, the outer ring and

center electrodes have approximately five pounds total

pressure across both surfaces.

d. Select Test while in the Automatic Mode -- be sure no personnel are in contact

with the material or PRF-911.

Figure 11: Fixture Preparation (Continued)

PRF-911 Concentric Ring

19

OPERATIONAL WARNING

TO AVOID PERSONNEL SHOCK, DO NOT TOUCH

THE MATERIAL UNDER TEST, THE PRF-911

CONCENTRIC FIXTURE OR TEST BED DURING

ANY MEASUREMENT CYCLE.

Proper test voltage protocol for resistance measurements of ESD Control

materials follows:

Resistance Range (Ω) Test Voltage (V) Remarks

< 1.0 x 104< 10V

Voltage is variable.

Electrification 2-5 sec.

1.0 x 104 to < 1.0 x 10610V Constant Voltage

Preferred. Electrification

2-5 sec.

>1.0 x 106100V

Constant Voltage

Preferred. Electrification

based on system

characteristics

(1) If the indicated measurement on the PRS-801 or PRS-812 Resistance

Instrument is less than 1.0x106Ohms, record the indicated measurement in

Ohms after approximately 2 to 5 seconds of electrification.

(2) If the indicated measurement on the PRS-801 or PRS-812 Resistance

Instrument is greater than 1.0x106Ohms:

(a) Select 100 Volts on the test instrument if using PRS-801 or PRS-812

Resistance Instruments. They will automatically shift to 100 Volts.

(b) After instrument’s electrification record the indicated measurement in

Ohms.

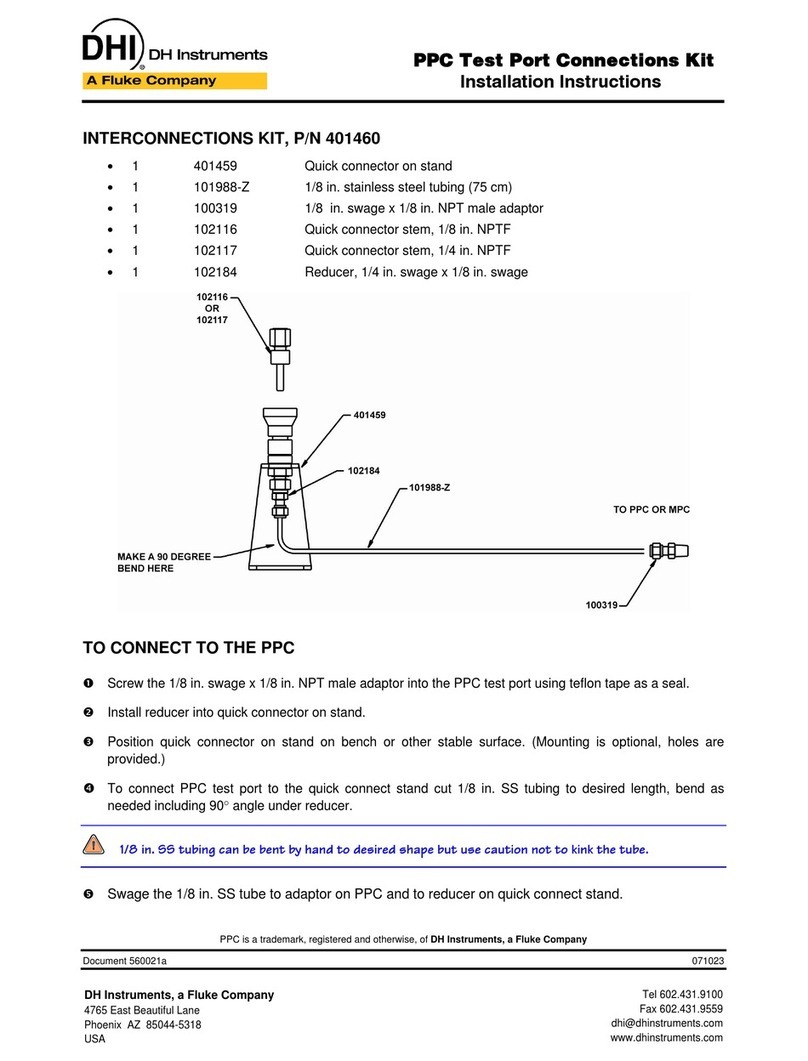

5. To calculate Volume Resistivity in Ohms-cm use the following formula.

Volume

Resistivity = 6.9 cm2x RIOhm

in Ohm-cm t cm

where,

6.9 cm2is the AREA of the center electrode's (D1) contact surface with

the material

t = The thickness of the material in centimeters (cm)

RI= The Resistance as indicated on the PRS-801 or PRS-812 or the

Resistance Instrument of choice in ohms.

Table of contents

Other Prostat Cables And Connectors manuals