INSTALLATION and MAINTENANCE INSTRUCTIONS

SPRING OPERATED ELECTRIC CABLE REELS

NOTE: These instructions are written for machine pull reels.

☞If installing or servicing hand pull reel, use only those steps marked with hand ☞.

All units are provided with right hand rotation unless otherwise

specified. This means that spool rotates counter-clockwise to

wind cable when viewing reel from slip ring side.

Clock-type springs provide power for cable take-up. Spring

tension must be adjusted at time of installation to insure

that cable will rewind completely at all times.

INSTALLATION

1. If reel is supplying power to a machine, insure that

machinery is at position closest to reel.

☞2. Securely mount reel in desired position using 3/8"(M10)

bolts. If reel is not equipped with a pivoting mounting

base, be sure spool centerline is aligned with cable run.

☞3. Position cable guide (optional). Guide must be oriented

so cable pays off reel in a straight line without bends.

Refer to GENERAL ARRANGEMENT DRAWING

on back page.

☞4. Install cable if not included with reel. Refer to CABLE

INSTALLATION section on back page.

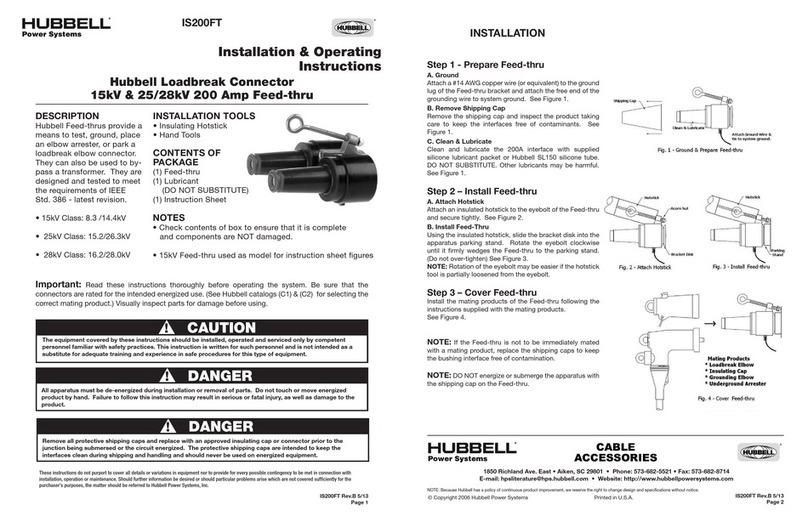

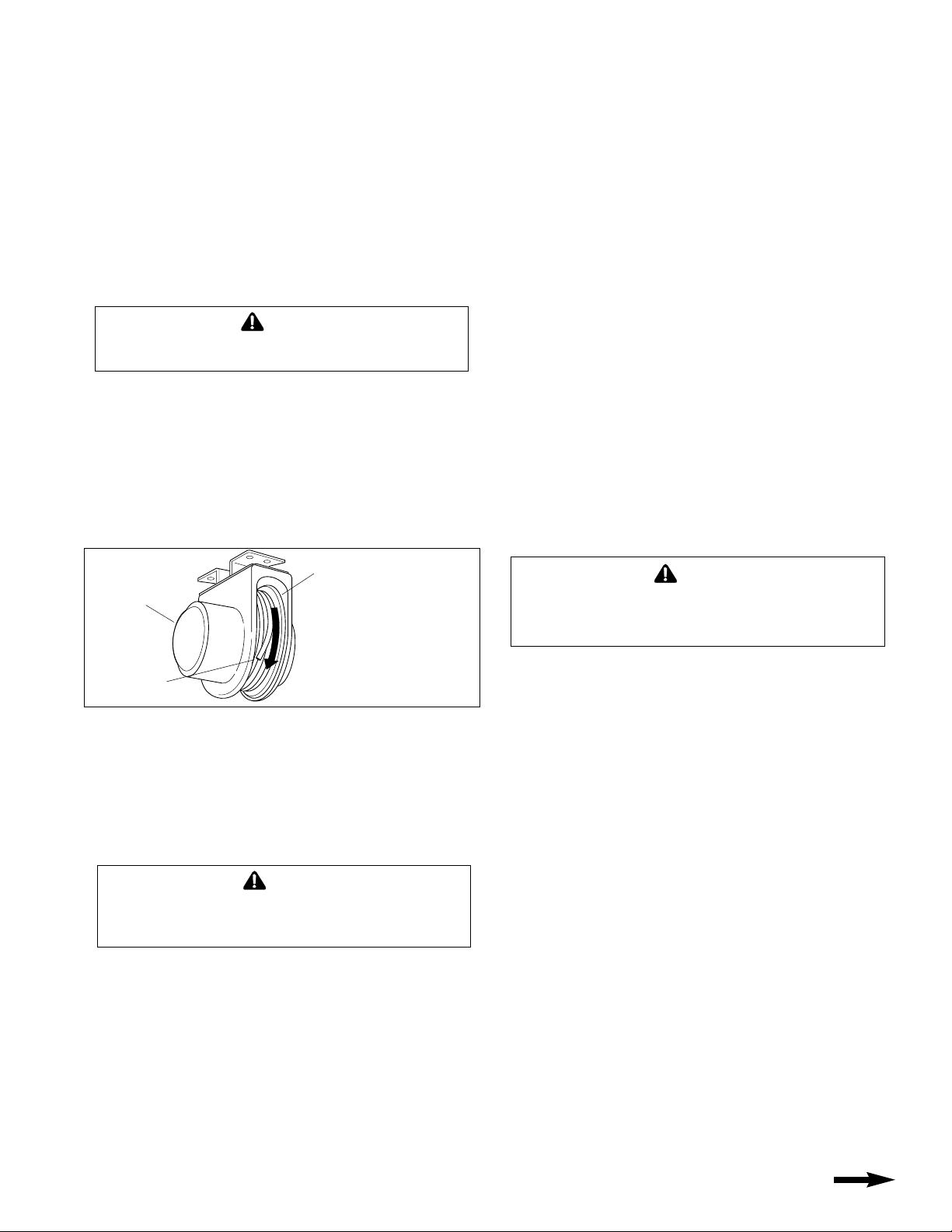

☞5. Adjust spring tension using one of the following methods:

A. If outer end of cable has not been connected, hold

cable end next to the spool and rotate spool in

clockwise direction (when viewed from slip ring side)

until desired tension is achieved. See Figure 1.

B. If outer end of cable has been connected, remove

the four spring housing screws and rotate the

entire spring housing clockwise (when viewed

from spring side).

☞6. Feed cable end out through cable guide (if so equipped)

and pay-out cable to maximum working length. At least

one turn of cable should remain on spool. If spool

locks up prior to reaching required length, either reel

was over-tensioned during step 5 or reel capacity has

been exceeded. Failure to correct this condition will

result in shortened spring life and possible damage to

other reel components.

☞7. Attach and adjust cable stop. Complete cable working

end connections.

8. If machine pull application or if no-lock operation is

desired, disengage ratchet lock. See following section.

☞9. Remove slip ring cover and connect individual supply

conductors to terminal block. Replace cover.

☞10. Turn on power to reel.

RATCHET LOCK

If reel is equipped with ratchet lock, reel is shipped with ratchet

lock “engaged”. If constant spring tension is required, lock

may be disengaged by moving the selector lever, located

beneath the spring assembly, to “OFF”.

MAINTENANCE

Periodically oil the bronze flange-bushing located on the

slip ring side of the reel.

The self-aligning bushing located on the spring side of

the reel is made of a self-lubricating, wear -resistant

material that needs no further lubrication.

Periodically inspect brushes on the slip ring assembly.

Replace if badly worn. Remove the slip ring side frame half to

gain access to brushes.

SPRING REPLACEMENT

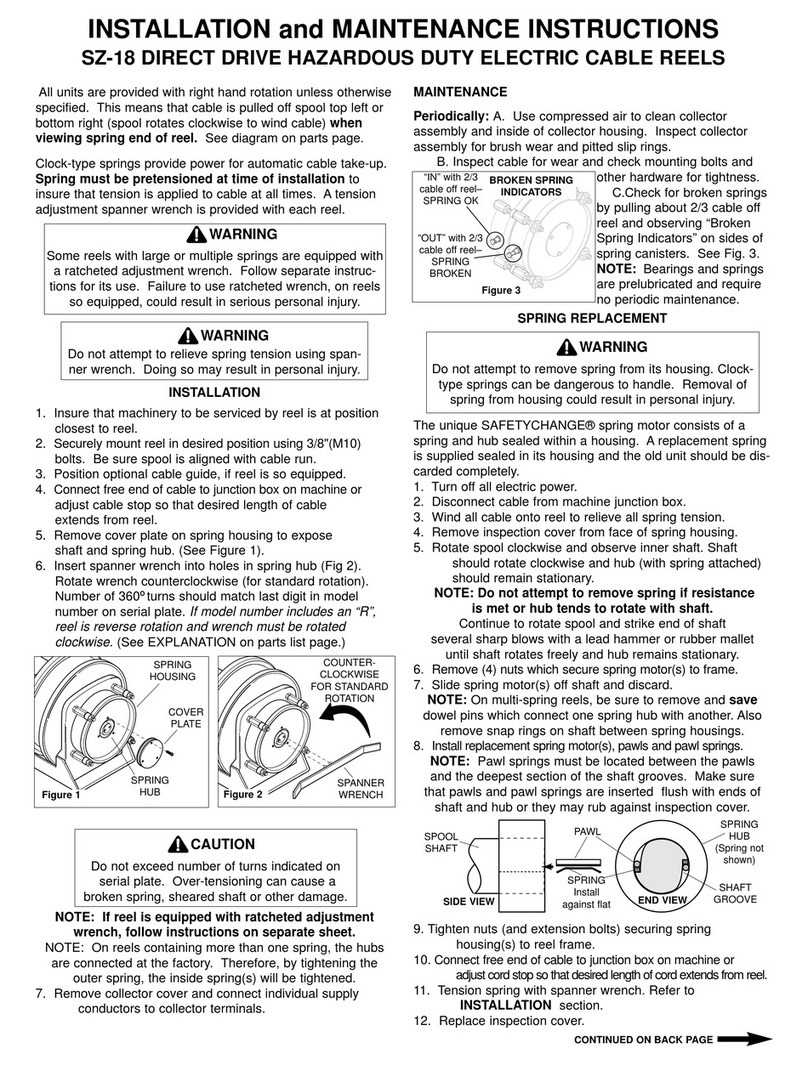

The unique SAFETYCHANGE® spring motor consists of a

spring sealed within a housing. A replacement spring is

supplied sealed in its housing and the old unit should be

discarded completely.

☞1. Turn off all electric power.

☞2. Disconnect cable from working end connections.

☞3. Wind cable onto reel to relieve all spring tension.

☞4. Remove four screws holding spring assembly and

gently slide spring assembly off main shaft.

☞5. Slide new spring assembly onto shaft and reassemble

reel by reversing above steps.

☞6. Adjust spring tension. Refer to INSTALLATION, Step 5.

SLIP RING REPLACEMENT

☞1. Turn off all electric power. Disconnect input wiring.

☞2. Engage ratchet lock to prevent spool from rotating.

☞3. Remove reel from mounting base.

☞4. Remove screws holding slip ring side frame half and

remove frame half.

☞5. Disconnect cable leads from slip ring terminals.

☞6. Remove hardware holding slip ring assembly in

position. Pull slip ring assembly off shaft.

☞7. Install new slip ring assembly on shaft and

re-assemble reel by reversing above steps.

If mounting overhead, provide safety chain between reel

base and mounting surface to prevent accidental reel drop.

CAUTION

Following adjustment, be sure all cable can be drawn off

reel without winding the spring tight. Winding spring tight

could damage spring or cable.

CAUTION

Do not attempt to remove spring from its housing. Clock-

type springs can be dangerous to handle. Removal of

spring from housing could result in personal injury.

WARNING

CONTINUED ON BACK PAGE

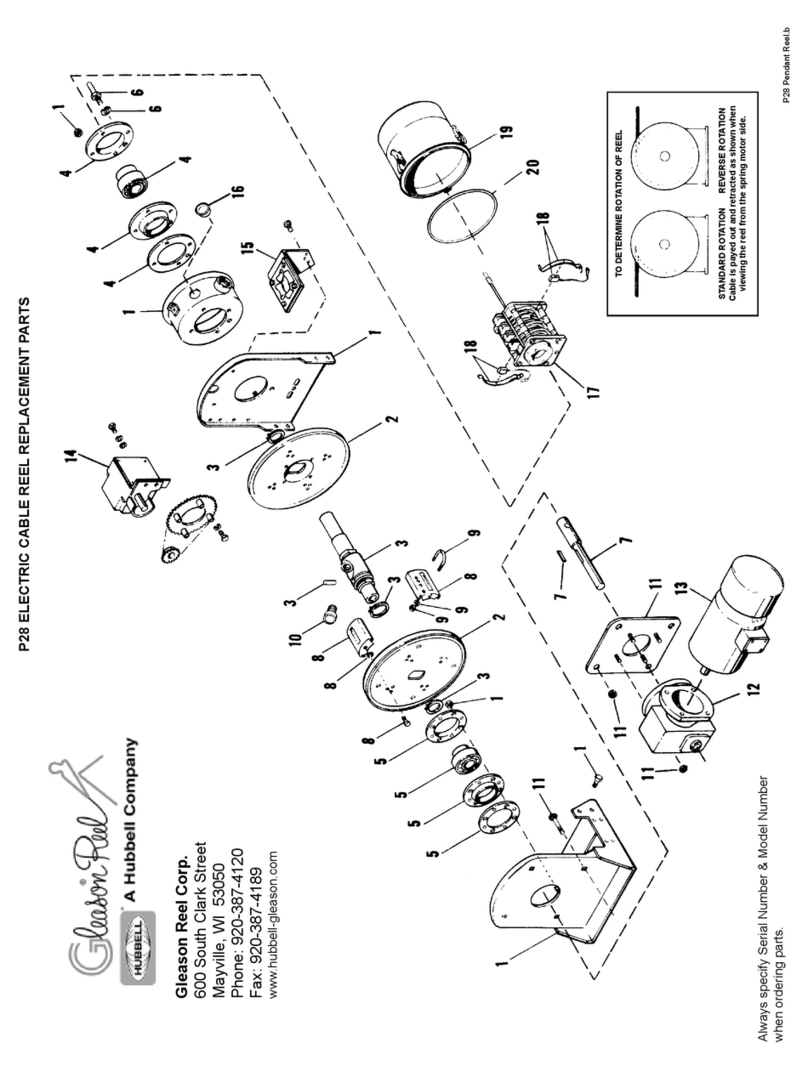

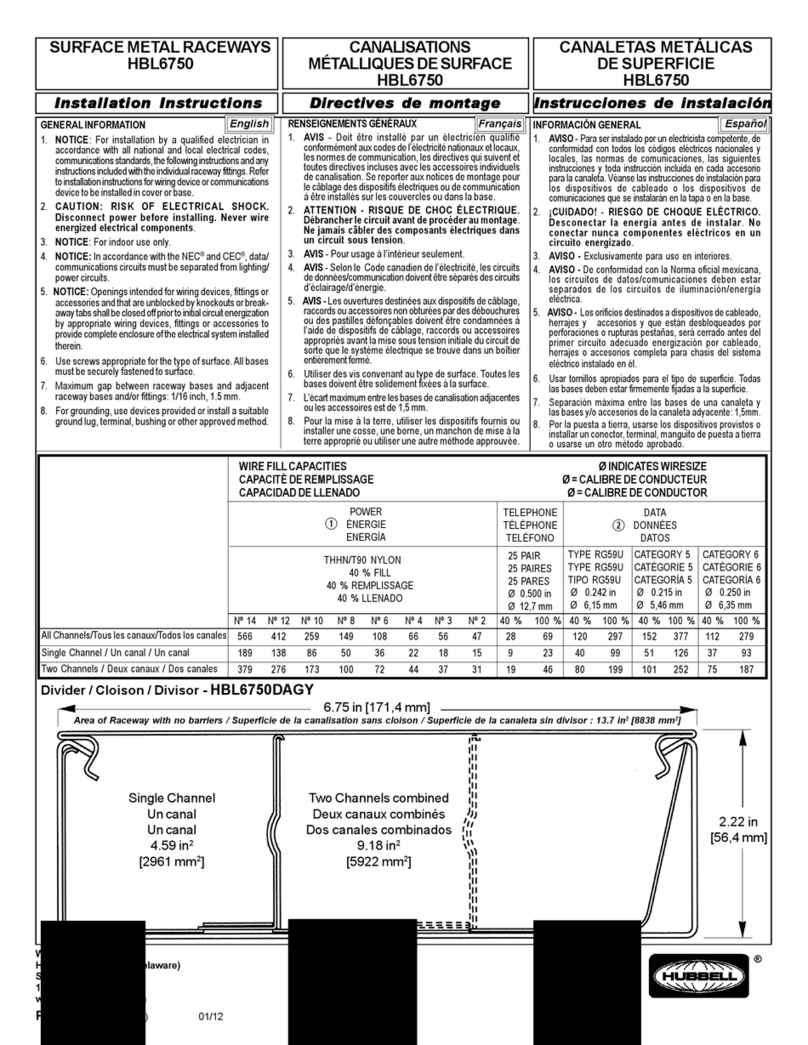

Figure 1 SPOOL

SLIP RING

SIDE

END OF

CABLE

ADJUST SPRING TENSION

BY HOLDING CABLE END

AGAINST SPOOL AND

ROTATING SPOOL.

DO NOT

OVER-TENSION SPRING.

CABLE REMOVAL

Use the following procedure to remove worn or damaged cable

from reel prior to installation of new cable.

1. Move machine serviced by reel to a position closest to

reel. Spring will still be under pre-tension at this point.

☞2. Turn off all electric power.

☞3. Disconnect cable from machine or other fixtures.

Wind cable onto spool to relieve all spring tension.

NOTE: Once all tension is removed from spring, spool cannot

rotate further. Forcing spool to rotate could damage spring.

☞4. Remove four screws holding spring assembly and

gently slide assembly off main shaft.

☞5. Locking and hoist duty reels only, remove slip ring cover.

☞6. Unwind cable from spool. Remove cable clamp.

☞7. Disconnect cable leads: On locking and hoist duty

reels, disconnect leads from junction block on spool.

On watertight reels, pull cable out of hole in spool,

exposing slip ring leads. Disconnect.

☞8. Install new cable following directions below.

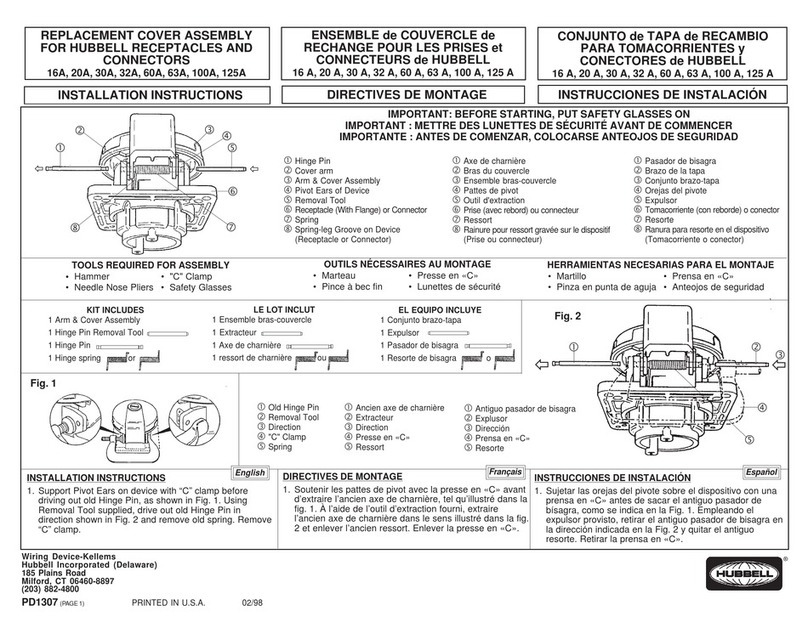

CABLE INSTALLATION

Use the following procedure to replace cable or if reel was

ordered without cable. Refer to CABLE INSTALLATION

REFERENCE DRAWING, below.

☞1. Unspool new cable from shipping spool and lay out

to eliminate twist.

NOTE: This step is not essential, but will aid in winding

operation of the reel and prolong cable life.

☞2. Remove slip ring cover.

☞3. Remove four screws holding spring assembly and

gently slide spring assembly off main shaft.

☞4. Connect cable leads: On locking and hoist duty reels,

feed one end of the cable through opening in spool

and connect cable leads to junction box on spool.

(See drawing below).

On watertight reels, connect cable leads to slip ring

leads (slip ring leads should extend thru hole in

spool). Following connection, tuck leads and cable

end inside spool.

☞5. Secure cable using cable clamp on spool.

☞6. Wind the cable onto the reel spool by hand rotating

spool in counter-clockwise direction (when viewed from

slip ring side).

☞6. Slide spring assembly onto shaft and secure with

four screws.

☞7. Replace slip ring cover, if removed.

☞8. Complete cable installation using steps 5 thru 10 under

INSTALLATION on page one.

SPRING ADJUSTMENT

INCREASE TENSION:

A. If outer end of cable has not been connected, hold

cable end next to spool and rotate in clockwise direction

(when viewed from slip ring side) until desired tension

is achieved. Refer to Page 1, Figure 1.

–OR–

B. If outer cable has been connected, remove the four

spring housing screws and rotate the entire spring

housing clockwise.

DECREASE TENSION:

1. Remove as much spring tension as possible by retracting

cable to cable stop or by moving machinery to position

closest to reel.

2. Remove four spring housing screws and rotate entire spring

housing counterclockwise (when viewed from spring side).

Printed in USA Bulletin No. 602152.c

HUBBELL

®

Workplace Solutions

P.O. Box 26 •600 South Clark St.

Mayville, WI 53050

Phone 920–387–5195

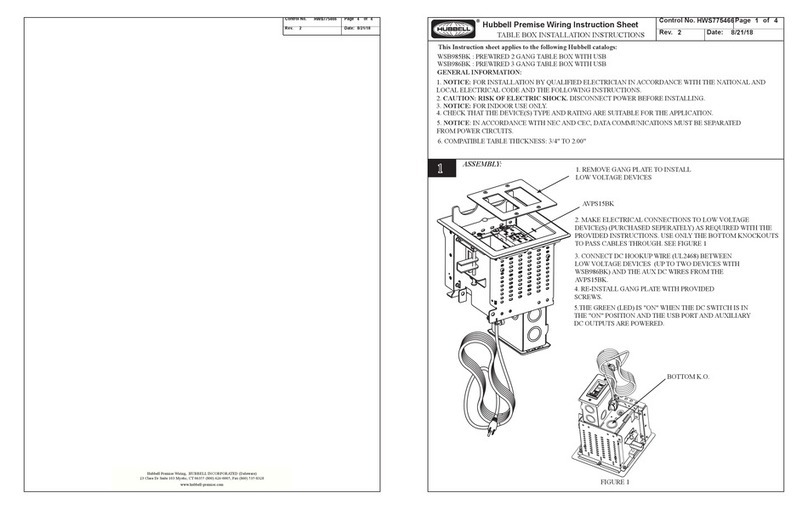

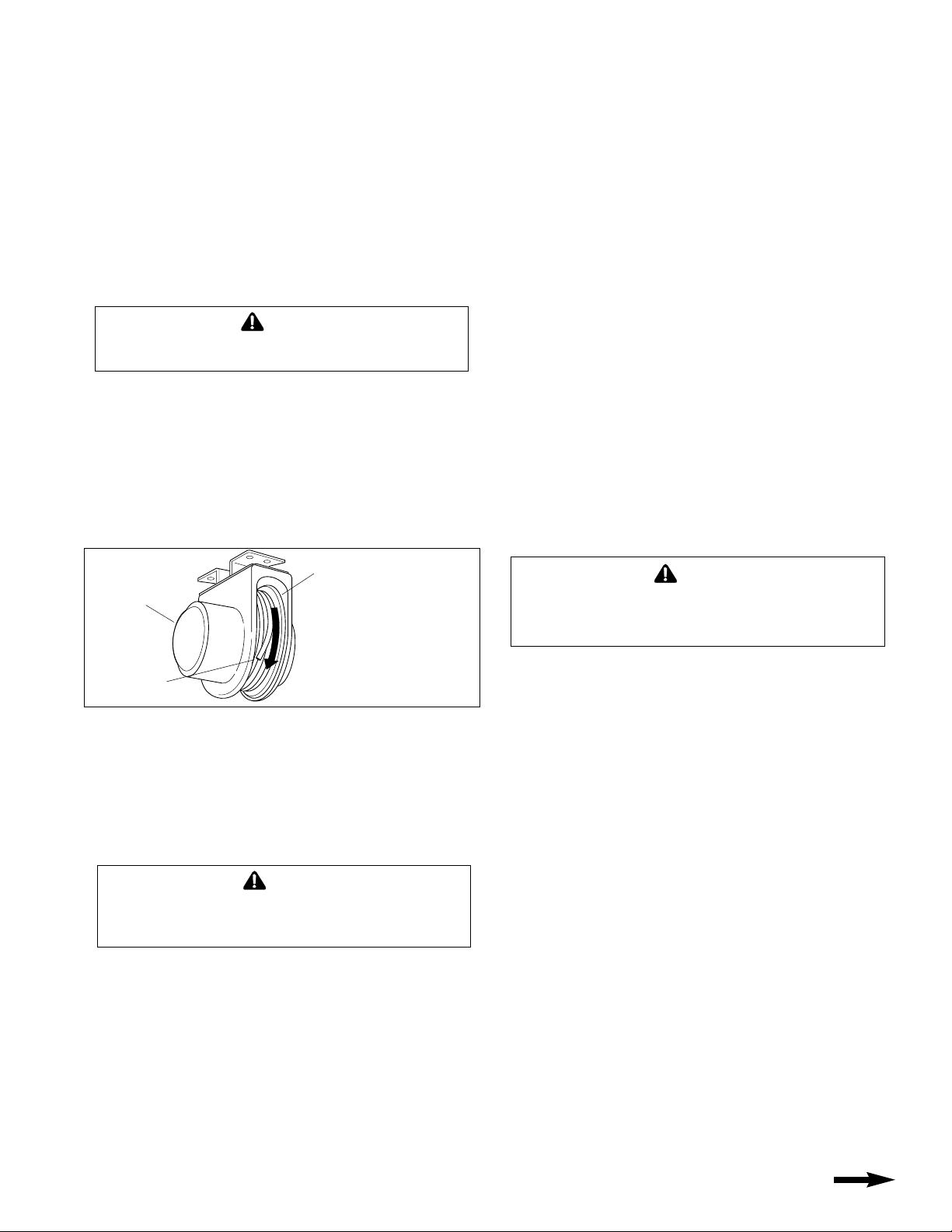

INSTALL CABLE THIS

DIRECTION. CONNECT

TO JUNCTION BLOCK

ON SPOOL

JUNCTION

BLOCK

INSTALL CABLE THIS

DIRECTION. CONNECT TO

SLIP RING LEADS

SLIP

RING

LEADS

SLIP RING

ASSEMBLY

MOUNTING

BASE

SUPPLY CABLE–CONNECT TO

LEADS FROM SLIP RING AT

TERMINAL BLOCK

TERMINAL

BLOCK

SPOOL

SPOOL

SPOOL ROTATION TO

WIND CABLE–

VIEWED FROM SPRING

MOTOR SIDE

SPRING

MOTOR SLIP RING

COVER

SLIP

RING

COVER

LINE

ENTRANCE

(NPT)

SLIP RING

ASSEMBLY

SPRING

MOTOR

PAYOFF

DIRECTION–

OPTIONAL

CABLE GUIDE

LOCATIONS

PAYOFF

DIRECTION–

OPTIONAL

CABLE GUIDE

LOCATIONS

PIVOTING

MOUNTING

BASE

SPOOL ROTATION TO

WIND CABLE–

VIEWED FROM SPRING

MOTOR SIDE

SUPPLY CABLE–CONNECT TO LEADS

FROM SLIP RING AT TERMINAL BLOCK

TERMINAL

BLOCK

CABLE INSTALLATION REFERENCE DRAWINGS

LOCKING & HOIST DUTY REELS WATERTIGHT REELS