Prostat PWA-805 User manual

User Manual

PWA-805

WRIST STRAP AUDITOR FIXTURE

Page

I. Before Using the Instrument 4

II. Safery 4

III. Descripon 4

IV. Accuracy 5

V. Baery Installaon & General Maintenance 6

VI. Normal Operaons 7

VII. Funconally Tesng the PMT-872A 13

General Specicaons 17

Copyright © 2012 by Prostat® Corporaon. All rights reserved. Printed in the United States of America. No part of this

manual may be used or reproduced in any manner whatsoever without wrien permission. For informaon contact

Prostat Corporaon, 1072 Tower Lane, Bensenville, IL 60106 USA

Prostat is the registered trademark of Prostat® Corporaon

4Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

The Prostat PWA-805 Wrist Strap Auditor is designed to determine the condion of a wrist strap as-

sembly. Used with the PRS-801 or PRS-812 Resistance Meters, a resistance measurement can be made

of the full assembly cu and cord, the cu only, or the cord only. This measurement will dene the

operable condion of any standard wrist strap.

A. The PWA-805 unit approximates the basic electrical measurement requirements of the ANSI/ESD

S1.1 wrist strap standard.

B. The intent of the PWA-805 is to provide the ESD auditor with a convenient xture to measure the

exact resistance characteriscs of a wrist strap, rather than generally esmate its approximate

resistance range with an indicang checker.

C. The PWA-805 will provide the four following resistance measurements:

1. Resistance of a wrist strap from the inner, middle posion of the cu to the end of the ground-

ing cord.

2. The resistance between two points on the inner surface of the cu

3. The resistance between two points on the outer surface of the cu

4. The resistance between the cord cu snap and ground connecon

A. As with any electrical device, use proper electrical precauons to avoid personnel shock.

1. The PWA-805 Wrist Strap Auditor xture operates with power input from the Resistance Meter

at 10 to 100 volts, and is capable of delivering an annoying shock to any person touching it.

2. Although the current capability is limited, a disnct HAZARD EXISTS in the person’s reacon to

the shock.

3. To avoid personnel shock, do not touch the can electrodes when power is applied to the xture

To avoid electrical shock, do not touch the xture’s

can electrodes when power is being applied.

B. The PWA-805 is designed to be used in audit environments at test voltages of 100 volts or less.

Exceeding 100 volts greatly enhances the risk of personnel shock hazards and may damage the

xture.

Operaonal test voltages should not exceed

100 volts in the audit environment.

5

Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

C. DO NOT USE THE PWA-805 AUDITOR if it fails to pass its funconal test.

Should the Funconal connuity check indicate improper operaon of the x-

ture, OR the xture becomes damaged, do not use the PWA-805.

Contact Prostat Customer Service Department for further instrucons.

D. DO NOT USE THE PWA-805 AUDITOR if it becomes damaged in any way.

E. Only qualied instrument repair personnel should open terminal connecons or repair the PWA-

805 AUDITOR.

F. Do not store or use in damp environments

G. Always store the PWA-805 in its protecve case.

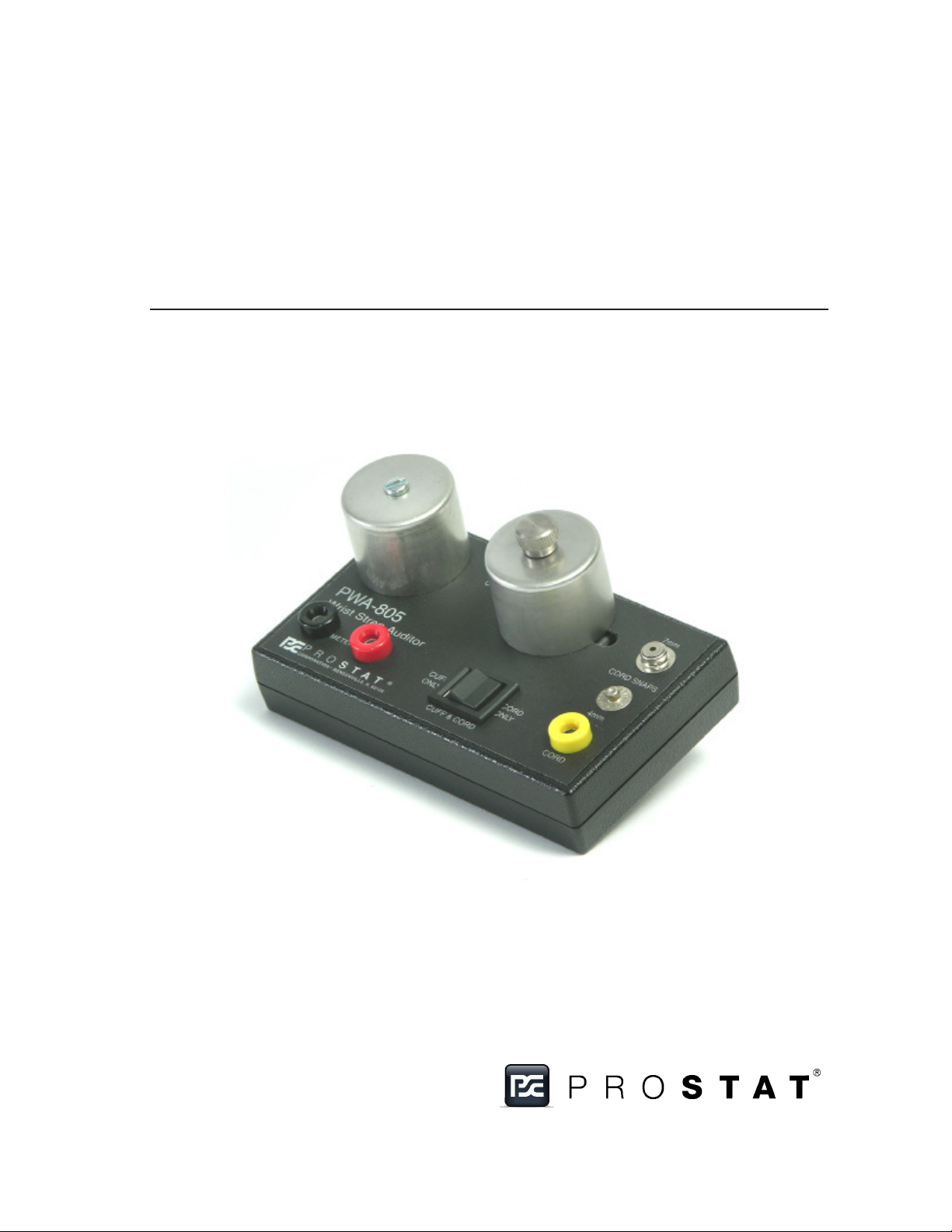

A. Basic Descripon

The PWA-805 Wrist Strap Auditor Fixture consists of two metal cylinder electrodes mounted on a

plasc base and wired to a switch, cord connecon points and meter input receptacles.

1. The metal cylinder (can) electrodes are used to mount wrist strap cus for connuity and resis-

tance measurements.

2. A YELLOW cord receptacle allows the wrist strap grounding cord to be plugged into the xture’s

test circuit.

3. Two meter input receptacles (RED and BLACK) are provided to connect the Resistance Meter

to the xture’s test circuit. The Resistance Meter provides all resistance measurements for the

PWA-805 Auditor.

4. Two male snap posts, one 7 mm and one 4 mm, are provided for mounng the cu snap end

of the grounding cord to the xture circuit during Cord Only measurements.

5. A three posion rocker switch (BLACK) allows resistance measurements of the following wrist

strap components:

a. The Cu and Grounding Cord

b. The Cu Only

c. The Grounding Cord Only

6Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

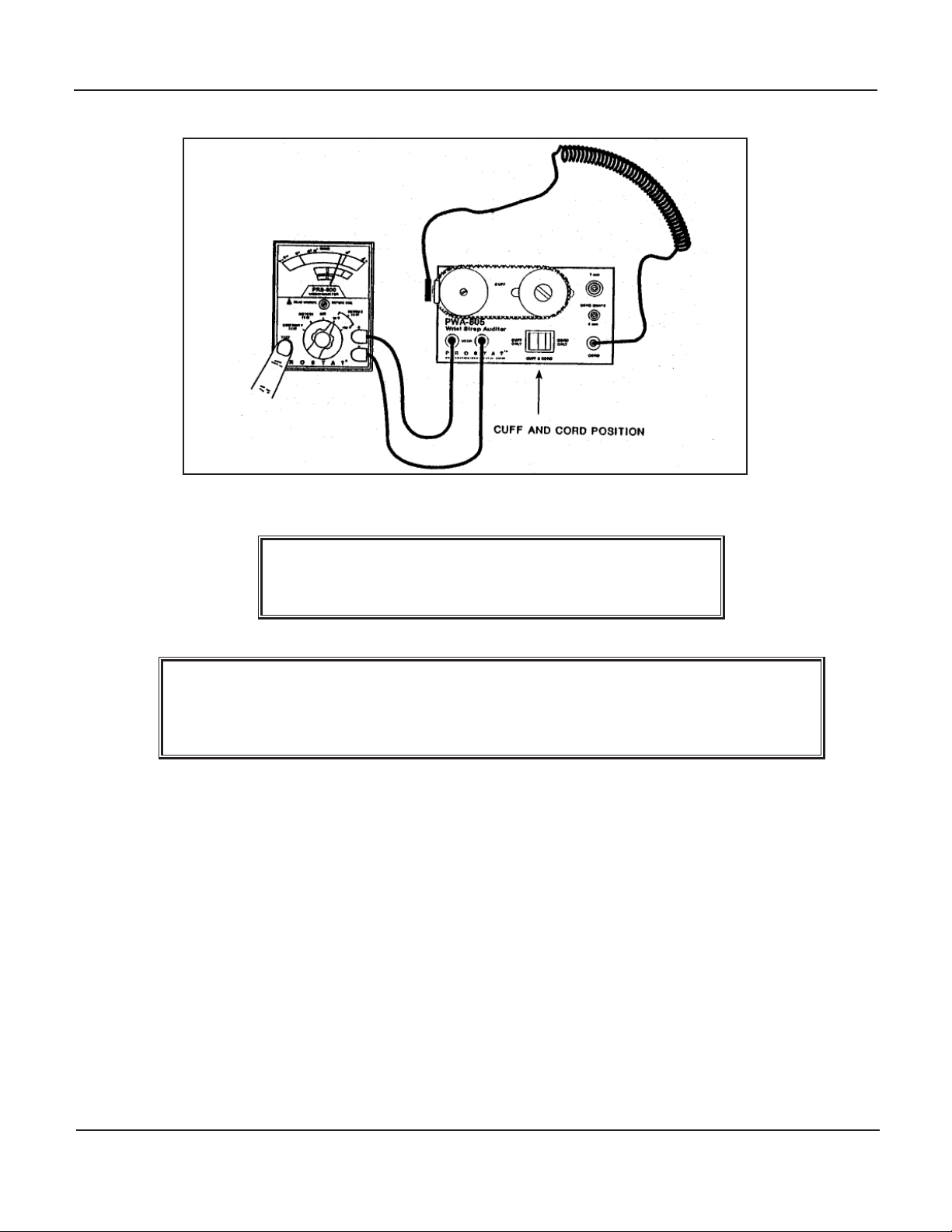

B. Funconal Test of the PWA-805 Wrist Strap Auditor Fixture

1. Funconal Connuity Test of the CUFF & CORD measurement funcon.

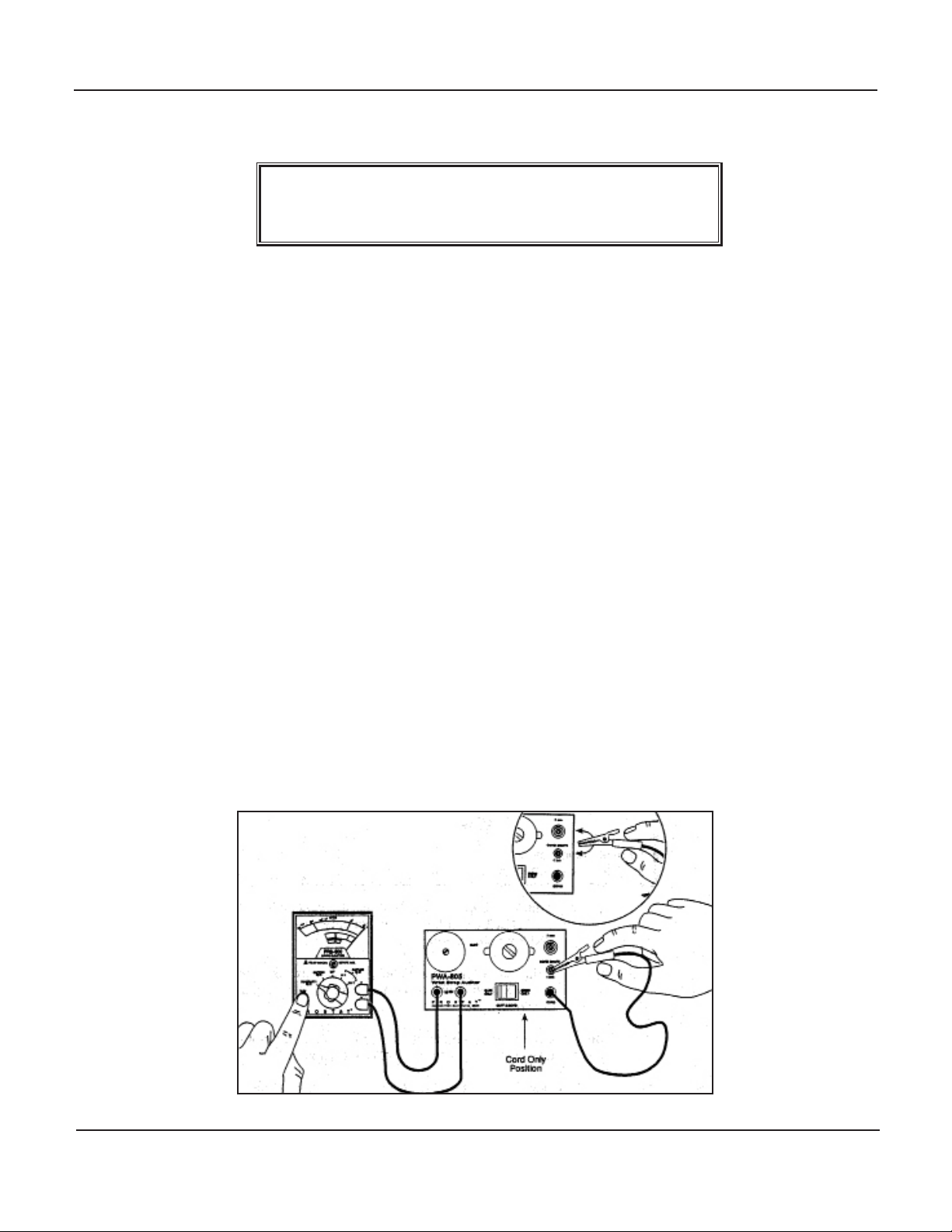

a. Connect the test leads from the Resistance Meter to the PWA-805 Auditor METER recep-

tacles. NOTE: Prior to using the Resistance Meter, read the Operaons Manual.

b. Plug an auxiliary test lead into the YELLOW CORD receptacle. Use a straight test lead

equipped with banana plugs. For ease of handling install an alligator clip on one end of the

test lead.

c. Select the CONTINUITY TEST posion on the Resistance Meter.

d. Touch the free end of the installed test lead to the PWA-805 adjustable can electrode (the

can on the right side of the xture equipped with a knurled, sloed locking screw).

e. Select the xture rocker switch middle posion, labeled CUFF & CORD.

7

Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

f. Push the TEST buon on the Resistance Meter. The Resistance Meter should indicate 0

Ohms.

To avoid electrical shock, do not touch the xture,

can electrodes when power is being applied.

(1) If the Resistance Meter indicates 0 Ohms, the connuity test for the CUFF & CORD

test funcon is acceptable. Proceed to the CORD ONLY funconal test.

(2) If the meter indicates “innity” or a high resistance check the rocker switch posion

and test lead connecons and repeat the connuity test.

(3) If the Resistance Meter does not indicate 0 Ohms, do not use the PWA-805 Auditor.

Contact Prostat Customer Service.

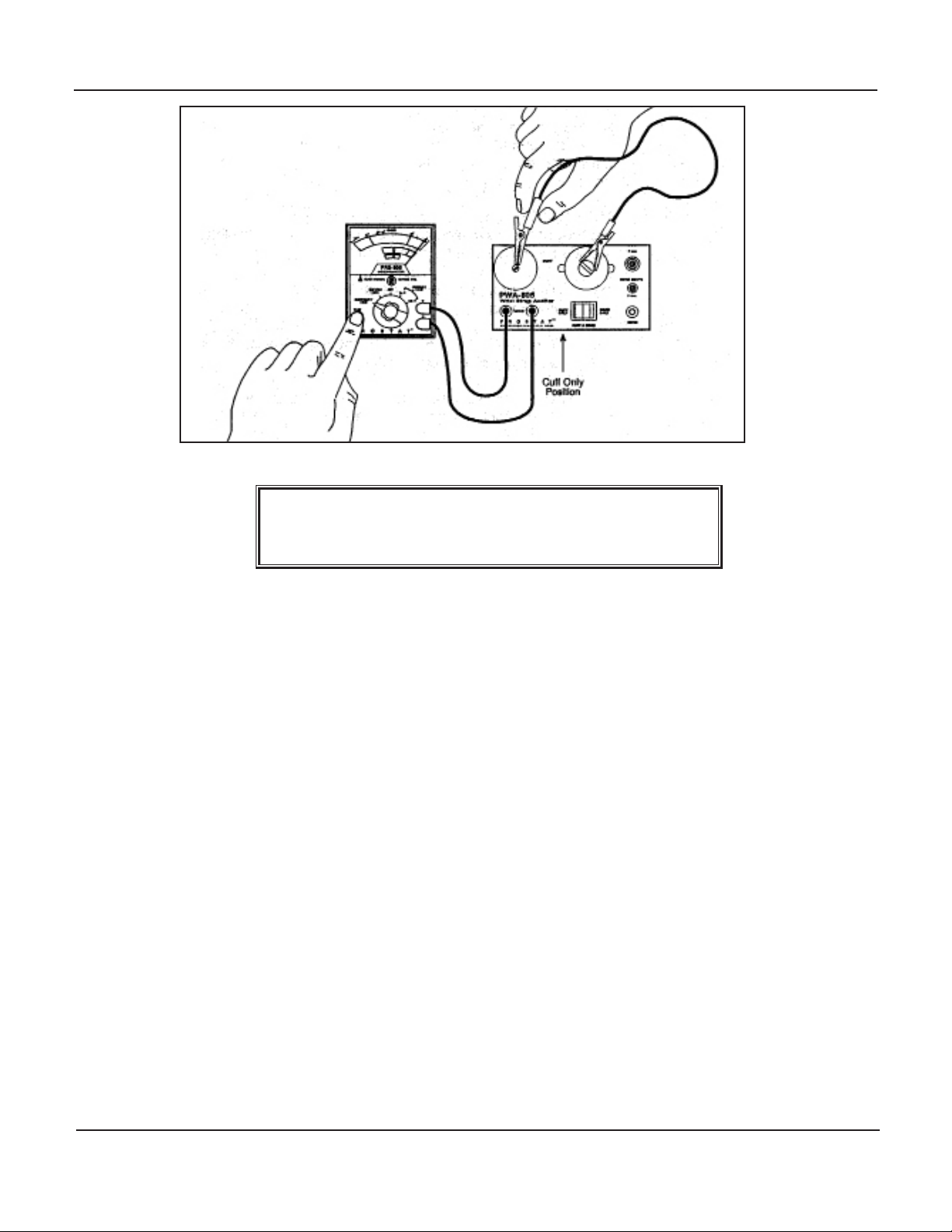

2. Funconal Connuity Test of the CORD ONLY measurement funcon.

a. Connect the test leads from the Resistance Meter to the PWA-805 Auditor METER recep-

tacles. NOTE: Prior to using the Resistance Meter, read the Operaons Manual.

b. Plug an auxiliary test lead into the YELLOW CORD receptacle. Use a straight test lead

equipped with banana plugs. For ease of handling, install an alligator clip on one end of the

test lead.

c. Select the CONTINUITY TEST posion on the Resistance Meter.

d. Touch the free end of the installed test lead to the PWA-805 7 mm male CORD SNAP termi-

nal.

e. Select the xture rocker switch right posion, labeled CORD ONLY.

f. Push the TEST buon on the Resistance Meter. The Resistance Meter should indicate 0

Ohms.

8Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

To avoid electrical shock, do not touch the xture

can electrodes when power is being applied.

(1) If the Resistance Meter indicates 0 Ohms, the connuity test for the 7 mm CORD

ONLY test funcon is acceptable. Proceed to the 4 mm CORD ONLY funconal test.

(2) If the meter indicates “innity” or a high resistance check the rocker switch posion

and test lead connecons and repeat the connuity test.

(3) If the Resistance Meter does not indicate 0 Ohms, do not use the PWA-805 Auditor.

Contact Prostat Customer Service.

g. Touch the free end of the installed test lead to the PWA-805 4 mm male CORD SNAP termi-

nal.

h. Select the xture rocker switch right posion, labeled CORD ONLY.

i. Push the TEST buon on the Resistance Meter. The Resistance Meter should indicate 0

Ohms.

To avoid electrical shock, do not touch the xture

can electrodes when power is being applied.

(1) If the Resistance Meter indicates 0 Ohms, the connuity test for the 4 mm CORD

ONLY test funcon is acceptable. Proceed to the CUFF ONLY funconal test.

(2) If the meter indicates “innity” or a high resistance check the rocker switch posion

and test lead connecons and repeat the connuity test.

(3) If the Resistance Meter does not indicate 0 Ohms, do not use the PWA-805 Auditor.

Contact Prostat Customer Service.

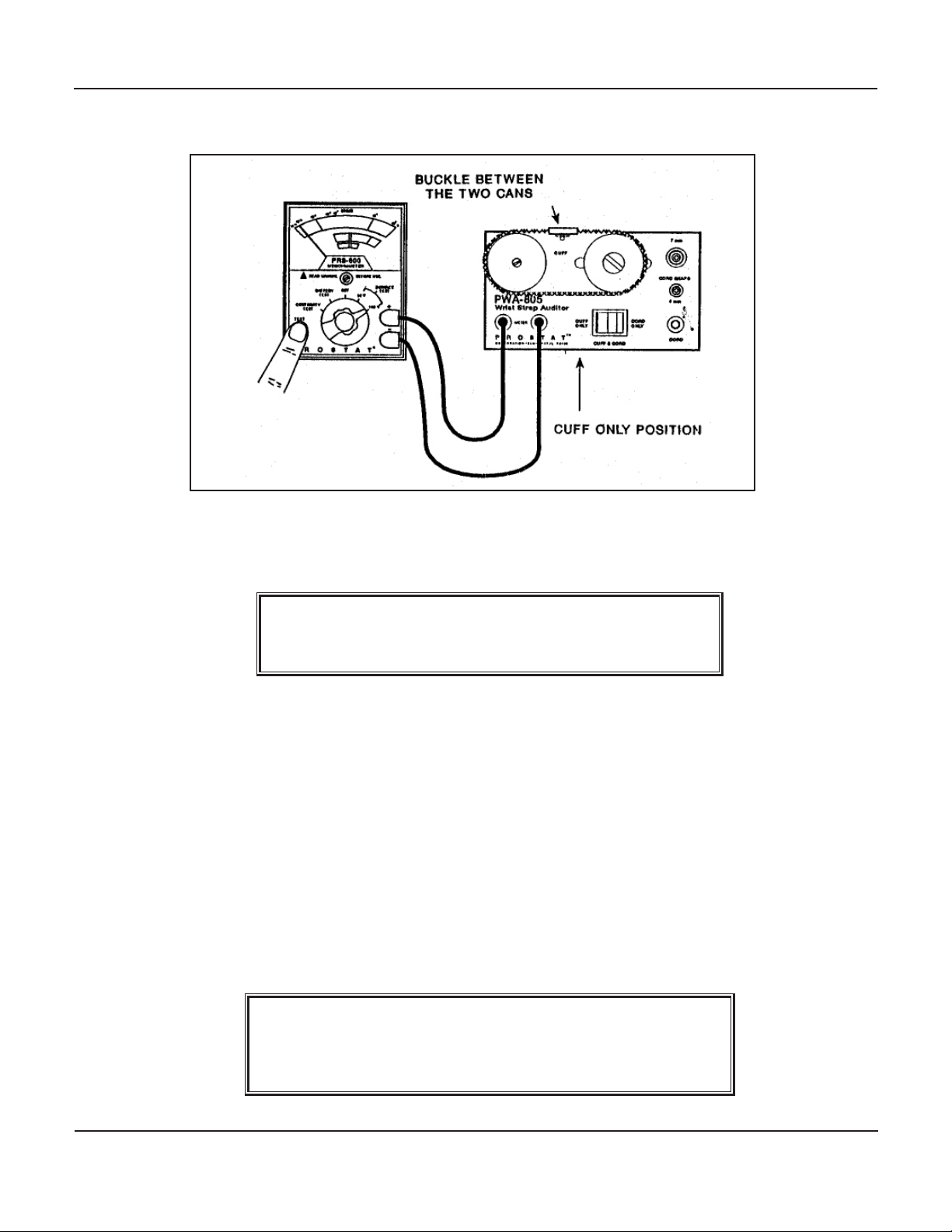

3. Funconal Connuity Test of the CUFF ONLY measurement funcon.

a. Connect the test leads from the Resistance Meter to the PWA-805 Auditor METER recep-

tacles. Prior to using the Resistance Meter, read the Operaons Manual.

b. Aach an auxiliary test lead to the adjustable can electrode (right side of the xture). Use a

straight test lead equipped with banana plugs and two alligator clip.

c. Select the CONTINUITY TEST posion on the Resistance Meter.

d. Touch the free end of the installed test lead to the PWA-805 xed can electrode (the can on

the le side of the xture).

e. Select the xture rocker switch le posion, labeled CUFF ONLY.

f. Push the TEST buon on the Resistance Meter. The Resistance Meter should indicate 0

Ohms.

9

Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

To avoid electrical shock, do not touch the xture

can electrodes when power is being applied.

(1) If the Resistance Meter indicates 0 Ohms, the connuity test for the CUFF ONLY test

funcon is acceptable, and all funconal tests are completed.

(2) If the meter indicates “innity” or a high resistance check the rocker switch posion

and test lead connecons and repeat the connuity test.

(3) If the Resistance Meter does not indicate 0 Ohms, do not use the PWA-805 Auditor.

Contact Prostat Customer Service.

A. General

1. This operaon will provide the four following resistance measurements:

a. Resistance of a wrist strap from the inner surface, middle posion of the cu to the end

of the grounding cord. This measurement indicates the maximum resistance between the

user and an ESD common ground point.

b. The resistance between two points on the inner surface of the cu. Properly used, this

measurement denes the connuity of the inner cu’s surface between 2 points, 180

°

apart.

(1) Thus, proper connecons of the cu to the wrist buckle may be conrmed.

(2) The connuity around the enre perimeter of the inner cu surface may be

conrmed.

10 Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

c. The resistance between two points on the outer surface of the cu. This measurement

conrms the insulave characteriscs of the cus outer surface.

d. The resistance between the ground cord’s cu snap and its connecon to ground. This

measurement performs two funcons.

(1) It allows the operator to check the ground cord for “opens”

(2) It measures the total resistance of the ground cord conductor resistor and

connecon points.

2. The following procedures require the use of the Resistance Meter. Be sure to read its Opera-

ons Manual and perform its Funconal Test prior to using.

B. Resistance Measurement of a wrist strap assembly CUFF & CORD.

1. Connect the test leads from the Resistance Meter to the PWA-805 Auditor RED and BLACK

METER receptacles.

2. Place the rocker switch in the middle CUFF & CORD posion

The LEFT can electrode in the CUFF & CORD measurement Mode is used to hold the cu me-

chanically; it is not in the measurement circuit. The RIGHT can electrode is in the measure-

ment circuit. Consequently, the inner cu surface must contact the

RIGHT can electrode to obtain an accurate measurement.

3. Mount the wrist strap cu to the PWA-805 xture as follows:

a. Loosen the adjustable RIGHT can electrode and slide it toward the LEFT can electrode.

b. Posion the inner surface of the cu buckle against the LEFT can electrode and hold it

rmly in posion with your le hand.

c. With your right hand, stretch the cu over and onto the adjustable RIGHT can electrode.

d. Slide the adjustable RIGHT can electrode toward the right side of the xture unl there are

1 to 2 pounds of tension on the wrist strap cu.

e. Tighten the RIGHT can electrodes locking screw.

4. Plug the wrist strap’s ground cord banana plug into the YELLOW CORD receptacle.

5. The wrist strap is now mounted on the PWA-80S xture. Be sure:

a. The cu is posioned smoothly on the sides of the two can electrodes

b. The ground cord is properly aached to the cu buckle

c. The ground cord banana plug is fully inserted into the YELLOW CORD receptacle.

6. Select the 10 volt posion on the Resistance Meter and push the TEST buon to obtain a resis-

tance measurement.

11

Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

To avoid electrical shock, do not touch the xture

can electrodes when power is being applied.

During the measurement, one might wish to check for “opens” in the ground cord

or poor connecons by stretching various parts of the cord and observing the

meter indicaon. Wiggling the snap connecons may indicate a loose ng snap.

a. Most US wrist straps are designed to measure approximately 1.0x106 Ohms, ±20 percent,

i.e., 8.0x105 to 1.2x106 Ohms.

b. Specially designed wrist straps used in munions are lower in resistance, while others are

designed for higher resistance levels, as in some internaonal markets.

c. Defecve wrist straps will measure well above 1.0x107 Ohms. CHECK YOUR ESD OPERA-

TIONS STANDARDS TO DEFINE THE PROPER RESISTANCE RANGE FOR OPERATIONAL WRIST

STRAP ASSEMBLIES.

d. If the wrist strap indicates defecve, or you wish to further dene the wrist strap’s charac-

teriscs, proceed with the following measurements.

C. Resistance Measurement of the wrist strap CUFF ONY, Inner Surface.

1. Connect the test leads from the Resistance Meter to the PWA-805 Auditor RED and BLACK

12 Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

METER receptacles.

2. Place the rocker switch in the CUFF ONLY (le) posion

In this Measurement Mode both the LEFT and the RIGHT

can electrodes are in the measurement circuit.

3. Mount the wrist strap cu to the PWA-805 xture as follows:

a. Loosen the adjustable RIGHT can electrode and slide it toward the LEFT can electrode.

b. Posion the inner surface of the cu buckle against the LEFT can electrode and hold it

rmly in posion with your le hand.

c. With your right hand, stretch the cu over and onto the adjustable RIGHT can electrode.

d. Slide the adjustable RIGHT can electrode toward the right side of the xture unl there are

1 to 2 pounds of tension on the wrist strap cu.

e. Tighten the RIGHT can electrodes locking screw.

4. Disconnect the wrist strap’s ground cord from the cu buckle.

5. The wrist strap cu is now mounted on the PWA-805 xture. Be sure the cu is posioned

smoothly on the sides of the two can electrodes.

6. Select the 10 volt posion on the Resistance Meter and push the TEST buon to obtain a resis-

tance measurement.

13

Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

To avoid electrical shock, do not touch the xture

can electrodes when power is being applied.

a. Most US wrist strap cus are designed to indicate very conducve, well below 1.0x105

Ohms.

b. Defecve wrist strap cus will measure well above 1.0x106 Ohms. CHECK YOUR ESD OPERA-

TIONS STANDARDS TO DEFINE THE PROPER RESISTANCE RANGE FOR OPERATIONAL WRIST

STRAP ASSEMBLIES.

c. Reposion the cu by sliding it 90 degrees around the can electrodes. Repeat the cu mea-

surement with buckle between cans.

D. Resistance Measurement of the wrist strap CUFF ONLY, Outer Surface.

1. Connect the test leads from the Resistance Meter to the PWA-805 Auditor RED and BLACK

METER receptacles.

2. Place the rocker switch in the CUFF ONLY (le) posion

In this Measurement Mode both the LEFT and the RIGHT

can electrodes are in the measurement circuit.

3. Mount the wrist strap cu to the PWA-805 xture as follows. Note: Be sure the ground cord is

disconnected.

a. Loosen the adjustable RIGHT can electrode and slide it toward the LEFT can electrode.

b. Posion the outer surface of the cu against the LEFT can electrode and hold it rmly in

posion with your le hand. Posion the buckle between the 2 cans.

c. With your right hand, stretch the cu over and onto the adjustable RIGHT can electrode.

Posion the cu buckle between the can

electrodes to prevent the buckle from aecng the

outer cu resistance measurement.

d. Slide the adjustable RIGHT can electrode toward the right side of the xture unl there are

1 to 2 pounds of tension on the wrist strap cu.

e. Tighten the RIGHT can electrodes locking screw.

14 Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

4. The wrist strap cu is now mounted on the PWA-805 xture. Be sure the cu is posioned

smoothly on the sides of the two can erectrodes and the buckle is between the cans.

5. Select the 10 volt posion on the Resistance Meter and push the TEST buon to obtain a resis-

tance measurement.

To avoid electrical shock, do not touch the xture

can electrodes when power is being applied.

a. Most US wrist strap cu outer surfaces are designed to indicate high resistance (insulave)

and measure well above 1.0x109 Ohms.

b. Defecve wrist strap cus will measure well below 1.0x109 Ohms. CHECK YOUR ESD OPERA-

TIONS STANDARDS TO DEFINE THE PROPER RESISTANCE RANGE FOR OPERATIONAL WRIST

STRAP ASSEMBLIES.

6. Repeat the outer cu surface measurements at 100 volts.

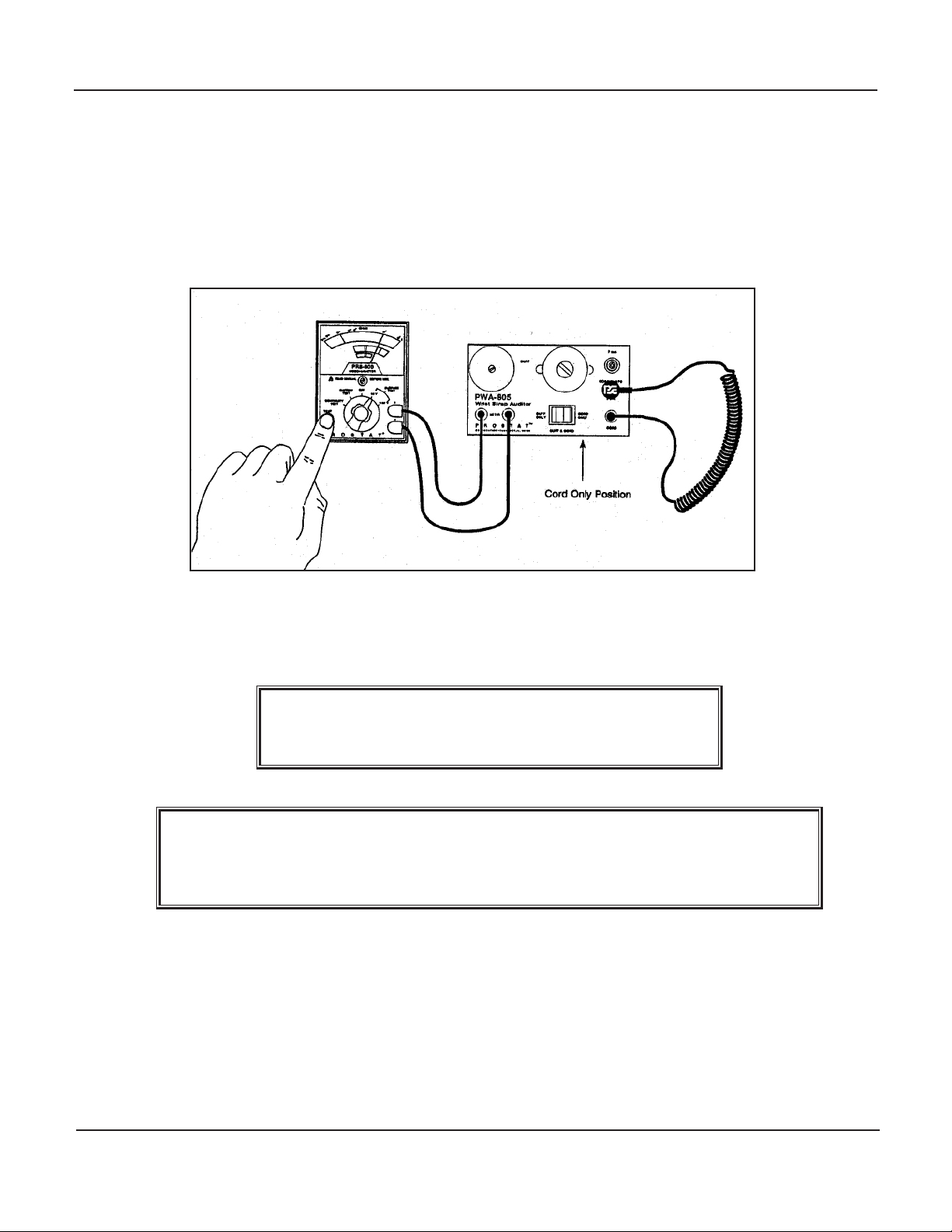

E. Resistance Measurement of a wrist strap ground cord, i.e., CORD ONLY

1. Connect the test leads from the Resistance Meter to the PWA-805 Auditor RED and BLACK

METER receptacles.

2. Place the rocker switch in the right CORD ONL Y posion

In this measurement mode, both the 7 mm and the 4 mm

CORD SNAPs, as well as the YELLOW CORD receptacle

are in the measurement circuit.

15

Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

3. Do Not Mount the wrist strap cu to the PWA-805 xture for this test. If it is mounted, it is not

part of the measurement circuit and may remain in posion.

4. Plug the wrist strap’s ground cord banana plug into the YELLOW CORD receptacle.

5. Aach the buckle connecon snap assembly to either the 7 mm or 4 mm snap post.

6. The wrist strap ground cord is now mounted on the PWA-805 xture. Be sure: The ground cord

banana plug is fully inserted into the YELLOW CORD receptacle.

7. Select the 10 volt posion on the Resistance Meter and push the TEST buon to obtain a resis-

tance measurement.

To avoid electrical shock, do not touch the xture

can electrodes when power is being applied.

During the measurement, one might wish to check for “opens” in the ground cord

or poor connecons by stretching various parts of the cord and observing the

meter indicaon. Wiggling the snap connecons may indicate a loose ng snap.

a. Most US wrist strap cord assemblies are designed to measure approximately 1.0x106 Ohms,

±20 percent, i.e., 8.0x105 to 1.2x106 Ohms.

b. Specially designed wrist straps used in munions are lower in resistance, while others are

designed for higher resistance levels, as in someinternaonal markets.

c. Defecve wrist straps will measure well above 1.0x107 Ohms. CHECK YOUR ESD OPERA-

TIONS STANDARDS TO DEFINE THE PROPER RESISTANCE RANGE FOR OPERATIONAL WRIST

STRAP ASSEMBLIES.

16 Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

The user serviceable parts in the PWA-80S Wrist Strap Auditor are basically terminal connecons.

A. Care should be take to keep all connecons free from dirt and dust.

B. Occasionally a snap post may loosen. Tighten with a an appropriate screw driver. The xture case

may require opening to lock terminal connecons.

C. If in doubt, contact Prostat Customer Service for assistance or return of the unit.

Fixture Case: 4.6” L x 2.75” W x 0.95” H inches

Wrist Strap Two (2) top mounted metal cylinders: 1 xed, 1 adjustable for cu size

Cylinders: Cylinder Diameter: 1.25. x 1.0. H

Adjustable cylinder equipped with knurled locking screw for posioning

Comtrols: Three posion rocker switch: (1) Cu Only [Resistance between Cylinders]

(2) Cu & Cord Assembly [Resistance from cord ground point to cu cylinder];

(3) Cord Only [Resistance from cord ground point to cu snap connecons]

Connecons: Resistance Meter: 2 banana receptacles for meter leads

Cord Groundable Point: 1 banana receptacle

2 Cord Cu Snaps: 1 each 7mm diameter, 1 each 4mm diameter

Power: Not Applicable. The xture is used in conjuncon with the Resistance Meter and

test leads.

Weight: 4.5 oz.

Warranty: One year limited warranty

17

Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

18 Rev. A / January 1995

PWA-805 Wrist Strap Auditor Fixture

PROFESSIONAL STATIC CONTROL PRODUCTS

Corporate Headquarters • 1072 Tower Lane • Bensenville, IL 60106 • 630-238-8883 • Fax: 630-238-9717 • 1-855-STATIC1 • www.prostatcorp.com

Prostat Corporaon

Specicaons are subject to change without noce.

All Prostat trademarks and trade names are the property of Prostat Corporaon.

All other trademarks and trade names are the property of their respecve companies.

Other manuals for PWA-805

1

Other Prostat Test Equipment manuals