www.SteamPoweredRadio.Com

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

I

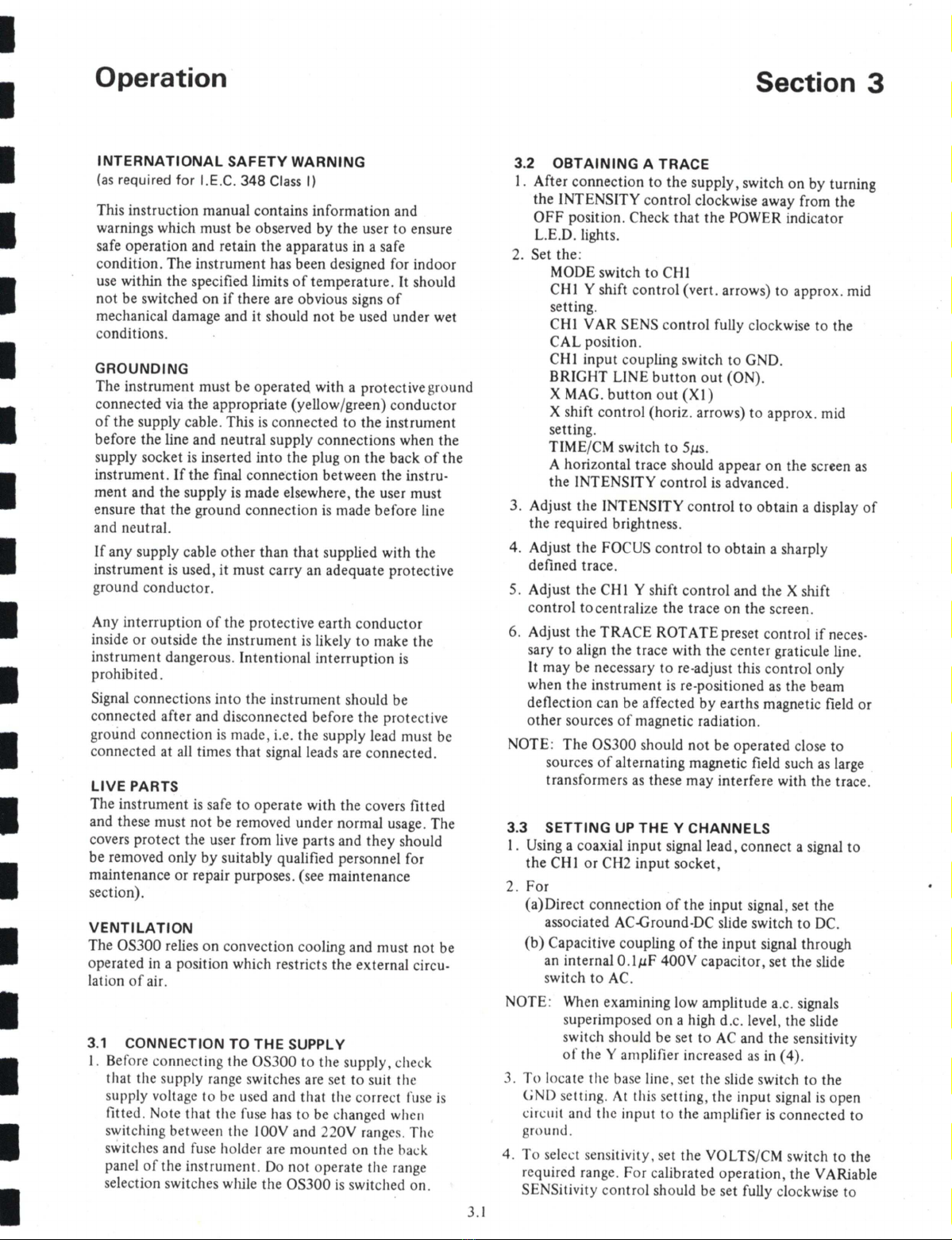

Operation

the CAL position. This control can be used however

to

reduce the gain

of

the relevant amplifier and

obtain any intermediate sensitivity between the

calibrated switched ranges. To set

to

any particular

calibrated sensitivity, the actual variation from the

calibrated range can be set

by

viewing the CAL

I

Volto/pon

the0.IV/cm

or0

.2

V/cm ranges.

If

the

VAR SENS control

is

not moved, the sensitivity will

differ from the calibrated value by approximately the

same proportion on all settings

of

the VOLTS/CM

switch.

To minimi

ze

pick-up at sensitive settings, it

is

essen-

tial

to

ensure that the ground lead connection

is

near

to

the signal point.

5. For vertical movement

of

the trace, adjust the Y shift

controls (identified by the vertical arrows).

6. Any trace movement under no-signal conditions,

when the setting

of

the VOLTS/DIV switch

is

altered,

can be overcome by adjustment

of

the relevant preset

front panel balance control.

This control will only need adjustment at infrequent

intervals. Before adjusting the BAL control however,

ensure that the input coupling switch

is

set

to

GND.

No adjustment should be made until a minimum

of

15

min. warm-up time has lapsed after switch-on, or

immediately after any large change

of

ambient

temperature.

3.4 DISPLAY MODES

The MODE switch determines the form

of

the display.

I.

For single trace display

of

one Y input against the

timebase this switch should be set

to

CHI or CH2 and

the input signal applied to the appropriate input

connector.

2. For dual trace simultaneous display

of

both

Y inputs

against the timebase, this switch should be set

to

DUAL. Two modes

of

beam switching are used and

selected automatically by the sweep rate selected by

the TIME/CM switch. The alternate mode

is

used at

fast sweep rates between 0.2ms/cm and 0.5µs/cm.

At the slower rates from 0.2s/cm

to

0.5ms/cm the

chop mode operates at approx. 500kHz.

3. In the ADD mode, the single trace generated against

the timebase

is

the algebraic sum

of

the CHI and CH2

deflections.

If

the INV CH2

button

is

operated the direction

of

Y

deflection for that channel

is

reversed .

If

used in the

ADD mode, this facility allows the difference

between the CHI and CH2 inputs to be displayed.

The

INV

CH2

button

has no effect on the polarity

of

internal CH2 trigger.

When

examining small differences between large

signals, the effect

of

small errors between the sensit-

ivities

of

the two channels can be overcome by first

connecting one input to

both

channels simultaneously

3

.2

Section 3

and adjusting one

or

other

of

the VARiable SENSitivity

controls

to

obtain a straight line.

4. In the

X-Y

mode, the timebase

is

disabled and the

CH2 input

is

displayed

as

the vertical Y deflection

against the CHI input displayed

as

horizontal, X

deflection. The CHI shift control

is

inoperative and

X position

is

determined only by the X shift control.

The XI 0

MAG

facility

is

also inoperative. X deflection

sensitivity being determined by the CHl controls

only. The X bandwidth

is

limited to

1MHz

and

relative phase shift between X and Y deflections may

exceed 3° above 50kHz.

3.5 TIMEBASE AND X EXPANSION

The sweep speed

of

the internal timebase

is

determined

by

the setting

of

the TIME/CM switch. The VARiable

SWEEP speed control should be set fully clockwise in

the CAL position for calibrated operation

of

the time•

base. This control

is

used

to

slow the sweep rate to

obtain any intermediate sweep rate, between the

calibrated ranges.

For horizontal shift

of

the trace, adjust the X shift

control (horizontal arrows). If close examination

of

any

portion

of

the trace

is

required,

Xl0

expansion can be

introduced by operation

of

the

MAG

button

. This

provides

an

effective trace length

of

l00cm and any

portion

of

this may be selected for viewing on the screen

by operation

of

the X shift control.

3.6 TRIGGER

The timebase may be triggered internally from the CHl

or

CH2 signals by operation

of

the corresponding

TRIGGER

button,

irrespective

of

whether the selected

channel

is

being displayed. Alternatively, the timebase

may be triggered from an external signal applied to the

EXT TRIG sockets when both CHl and CH2 buttons are

operated simultaneously.

Trigger

will

occur at a level on the signal which may be

set by the TRIG LEVEL control with the slope deter-

mined by the ±

button

. When this

button

is

out,

it will

occur

on

a positive-going transition

of

the signal through

the trigger level. When it

is

pushed in, trigger will occur

on

the negative-going transition. Normally triggering can

be obtained from internal deflection signals greater than

2mm

pk/pk

up to about 2MHz but the sensitivity

reduces to about 1cm

pk/pk

at 20MHz. Corresponding

external sensitivity

is

0.25V

pk/pk

to 2MHz and 1.25V

pk/pk

at 20MHz.

With A.C. coupling, the low frequency sensitivity

reduces to Icm

pk/pk

at about 2Hz.

The Ext Trig input impedance

is

approx. I00k/1

0pF

and

c.:are

should be taken not to apply more than 250V d.c.

or pk, a.c. to this socket.

When the BRIGI

IT

LINE

button

is

out or O , the time-

base will free run

in

the absence

of

a correct trigger

sig

nal, to display a bright line or

un

synchronizeddisplay