Protect CRW 200 User manual

edition: PROTEKT_EN-01

CRW 200

RETRACTABLE TYPE FALL ARRESTER

RESCUE LIFTING DEVICE

SERVICE MANUAL

CONTENTS

1. CRW 200 Technical pecification.......................................

1.1. Description ...............................................................

1.2. Technical data ..........................................................

1.3. Standards .................................................................

1.4. Identification and marking ........................................

2. Term of ervicing ..............................................................

3. Servicing equipment ..........................................................

4. Servicing operation ..........................................................

4.1. The de ice dismantling ..................................................

4.2. The retracting spring set maintenance and inspection ..

4.3. The drum set maintenance and inspection ....................

4.4 The brake set maintenance and inspection ....................

4.5. The winch unit dismantling and maintenance ................

4.6. The de ice rebuilding ....................................................

5. Po t a embly check .........................................................

6. CRW200 - Spare part ........................................................

2

2

2

2

2

3

3

4

4

6

6

7

9

10

12

13

CRW 200 Ser ice Manual 2/13

1. CRW 200 TECHNICAL SPECIFICATION

1.1 De cription

The CRW200 is a retractable type fall arrester

including rescue lifting de ice.

The retractable type fall arre ter mode. When

a pulling force is applied to the cable wound on

the spool, it unwinds with resistance of the

retracting spring. When pulling force is remo ed,

the cable retracts and is wound back onto the

spool inside the de ice. When the user falls and

the cable starts to unwind rapidly, the de ice is

locking, pre ent unwinding of the cable and

absorb the kinetic energy of the fall.

The re cue lifting device mode. The de ice is

equipped with hand operated winch with

automatic brake which pre ent against self-

contained descent of a person. In the

consequence of cranking, the de ice cable is

mo ed up and down under control.

1.2 Technical data

Max. rated load: 140kg

Min. rated load: 50kg

Working length: 15m

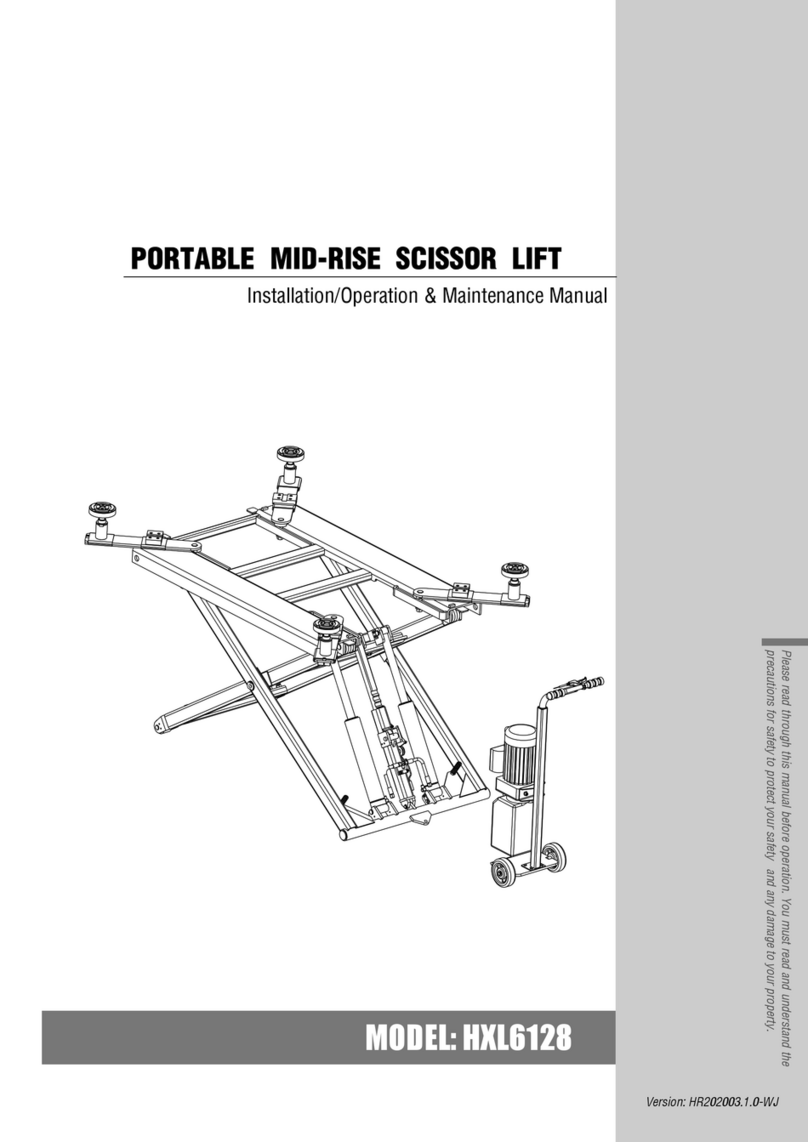

Dimensions: acc. to drawing (in [mm])

Weight: 11kg

Cable diam. 4,8mm

1.3 Standard

EN 360:2002

EN1496:2006 – class B

1.4. Identification and marking

The CRW 200 de ice is marked with four

descripti e elements, with the aid of

identification label placed on the de ice outer

shell and repeated inside.

The identification elements:

• Reference number

• Serial number (a unique 7-digit number).

• Date of manufacture.

• Cable length.

CRW 200 Ser ice Manual 3/13

2. TERMS OF SERVICING

Standard EN 365 regulates the obligation to

ser ice and maintain personal protecti e

equipment (PPE). Such ser icing and

maintenance should also be the responsibility of

e ery user.

After each arre ted fall or exce ive load and

at lea t every 12 month , the retractable type

fall arre ter (re cue lifting device) mu t be

returned for in pection and maintenance

performed by the manufacturer or an

authori ed ervice. The fall arre ter mu t

al o be erviced if any deficiency or

problem occur when u ing the device.

Ser icing and maintenance can be performed by

authorised personnel only. The manufacturer is

not liable for ser icing errors or omissions or

improper ser icing.

In the e ent of any problems or questions, the

manufacturer pro ides all required information

or performs the necessary testing and ser icing

of the de ice.

This ser ice manual is intended as basic

maintenance and ser icing guide only and does

NOT substitute proper training offered by

PROTEKT.

Ser icing and maintenance must meet the

requirements of the EN 360; EN1496 and

EN365 standards and be performed with proper

care and attention.

For correct ordering, ser icing and maintenance

personnel should be familiar with the

specification of replacement parts.

All ser icing and maintenance should be

recorded in the de ice’s IDENTITY CARD.

3. SERVICING EQUIPMENT

Common tools and some special equipment

a ailable from authorised ser ice centres and

the manufacturer are required for ser icing and

maintenance of CR 200. Manufacturer

recommends lubricants shown in the images

below or lubricants with similar specification

should be used in the product.

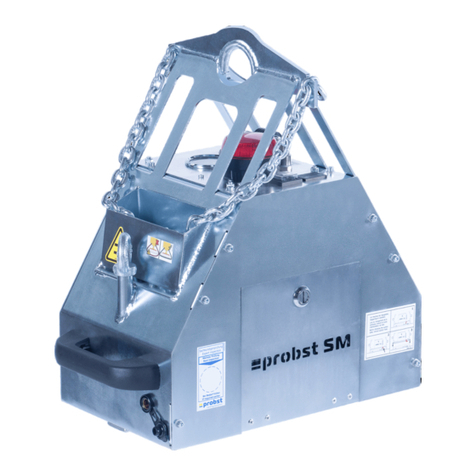

Materials for maintenance

Anticorrosion grease for

lubricating the retracting

spring.

For example: Abel Action

7; D40 or a lubricant with

similar properties.

Anaerobic adhesi e for

thread locking bolts.

- iscosity 5 ± 2Ps

- thread gap 0.1 ÷ 0.3 mm

For example: LOXEAL 55-

03; LOCTITE 262

Thick uni ersal grease –

for example ŁT 40

Basic tools (recommended)

CRS 04 – Rotating Jig.

CRS 04-04 Extension Kit

for CRW200

Torque spanner with 32

mm hexagonal attachment

A pliers for retaining rings

of the diameters: Ø 8mm;

Ø 20mm and Ø 38mm.

Allen wrenchs, size: 3, 4, 5

& 6 mm.

Torx type wrenches: T20 &

T-25

Cross tip screwdri er –

PZ 2/PH 2 (ISO 8764)

Support tools and equipment

Cur ed tip uni ersal pliers.

Flat tip screwdri er.

Diagonal cutter.

Flat brush for cleaning and

application of liquid

lubricants onto mo ing

components.

Hand and eye (or face)

protection equipment.

CRW 200 Ser ice Manual 4/13

4. SERVICING OPERATIONS

Prior to maintenance, please ensure that all

necessary tools, replacement parts and lubricants

are a ailable at hand. When ser icing the

retractable type fall arrester, special attention

should be paid to any problems such as jamming

of the mechanism, corrosion or locked cable. The

source of the problem must be identified.

Carefully check whether all markings are legible.

Inspect the casing unit to see if there are any

cracks, dents or chipped-off pieces. If any

problems are detected, the affected parts should

be replaced.

4.1. The device di mantling

4.1.1

• Unscrew 6 screws (1)

with the aid of Torx type

wrench T-25.

• Open a cover (2) from

cable drum side.

4.1.2

• Take off a clip size 38mm

(3) from cable pilot sleeve

(4).

4.1.3

• Pull out the cable sleeve

(4) from casing opening

(5) and move the cable

out of the opening (5).

• Turn a cable set (6) to the

left direction to release a

retracting spring tension.

4.1.4

• Unscrew M6 bolt (7) and

washer (8).

• Take off the cable drum

set (6) from a shaft

• Take off the parallel key

(9) from the shaft.

1

2

1

3

F

6

8

7

9

6

4

4

5

CRW 200 Ser ice Manual 5/13

4.1.5

• Unscrew the bolt (10)

with the aid of cross tip

screwdri er. Take off the

washer (11) and crank

plate (12).

• Unscrew the (13) bolt

with the aid of Allen

wrench and (14) bolt with

the Allen wrench 3mm.

• Take off the crank (15)

from the shaft.

4.1.6

• Unscrew the (16) nut and

take off the crank shaft.

• Unscrew the (19) screw

with the aid of Allen

wrench 5mm and take off

the (18) spring and (17)

pin.

4.1.7

• Unscrew 6 screws (18)

with the aid of Torx type

wrench T-25.

• Open the cover set (19).

• Unscrew licking unit (20)

and take off the washer

(21)

4.1.8

• Unscrew 3 M8 bolts (22)

with the aid of Allen

wrench 6mm and take off

the winch set (23) from

the casing.

• Take off the locking pin

set (20) from the casing.

4.1.9

• Take off snap ring 20mm

(24) and take off the

brake unit (25) from the

shaft.

• Take off the snap ring

20mm (26) and washer

(27) from the shaft (28).

• Take off the shaft (28)

from the casing

4.1.10

• Clean and inspect: main casing, bush and dog's gear, washer.

• Replace snap ring (26) with new one.

10

11

12

13

14

16

17

18

19

15

18

19

21

20

23

22

20

24

25

27

26

28

CRW 200 Ser ice Manual 6/13

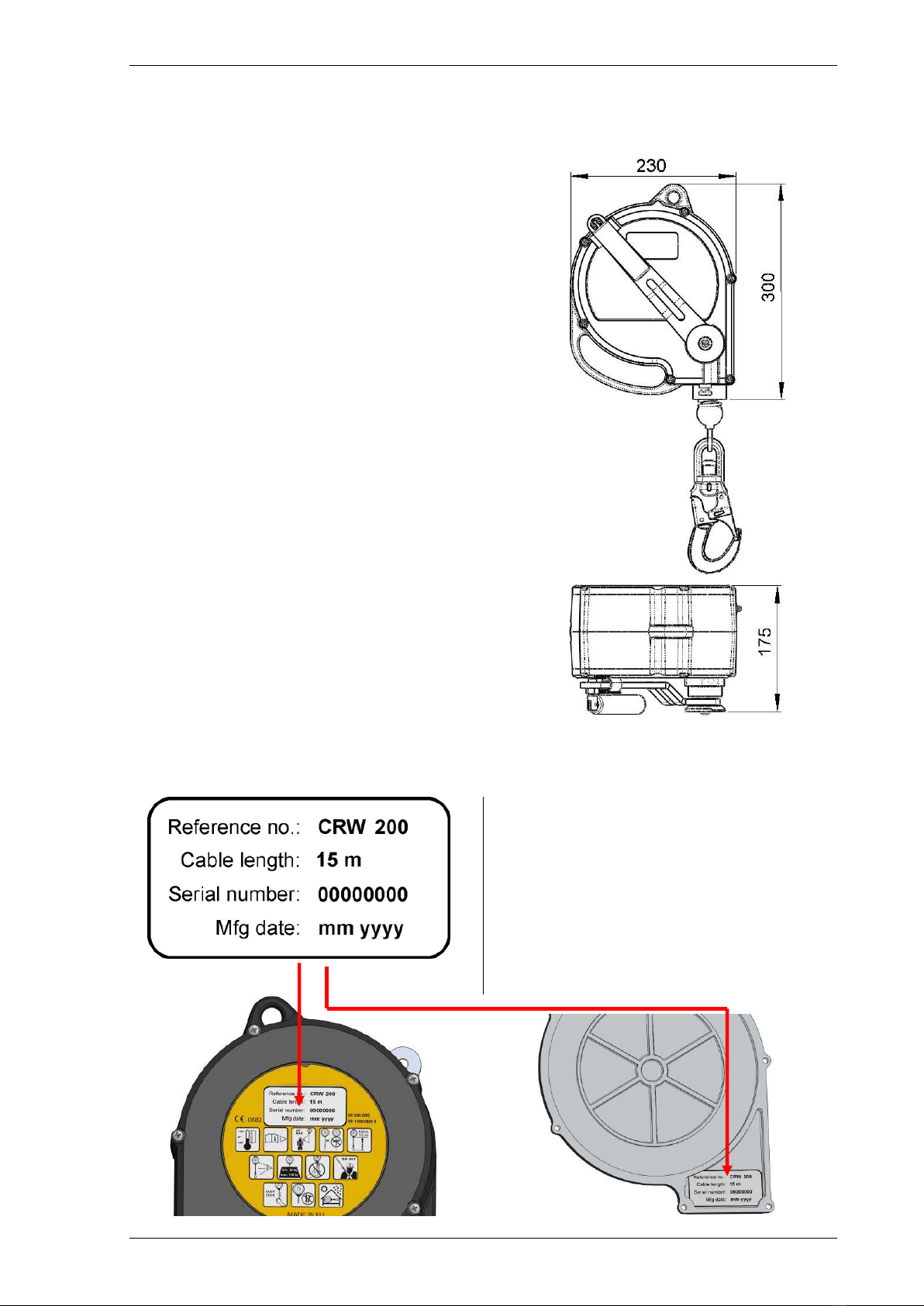

4.2. The retracting pring et maintenance and in pection

4.2.1

• Clean and inspect the

constituent parts. Pay

special attention on the

retracting spring internal

ending (1) shape.

• Lubricate the retracting

spring, using openings

(1) and (2) from cable

drum side.

4.3. The drum et maintenance and in pection

4.3.1

• Prepare the Rotating Jig. Seat the CRS

04-04 Extension Kit (1) in the CRS 04

base (2).

4.3.2

• Install the cable drum set on the

rotating jig.

• Test the connector for correct

operation. If the connector is equipped

with fall indicator, check if it is not

deformed.

• Unwinding the cable from the drum,

inspect it against: broken wires,

unbraided strands, permanent

deformations, excessive corrosion.

• Check the rope ferrules (3) against

cracks or deformation.

• Check if the rope's end (4) project

outside the ferrule.

• Replace the entire cable set in case of

any damages or abnormality.

4.3.3

• Take off the cable drum from the

Rotating Jig.

• Unscrew the screwing connection

(5), (6), (7) and dismantle all

parts of the set.

• Check all the parts against:

cracks, deformation and

corrosion. Replace wrong parts if

necessary.

2

1

3

4

5

6

7

2

1

lubricate

CRW 200 Ser ice Manual 7/13

4.3.4

• Rebuild the winch set in reverse

order. Pay attention on the

proper installation of the cable

loop (8) on the pins (9).

4.3.5

• Install the drum on the Rotating

Jig.

• ind the cable by turning the

drum to the right with the aid of

Allen wrench 6mm (10).

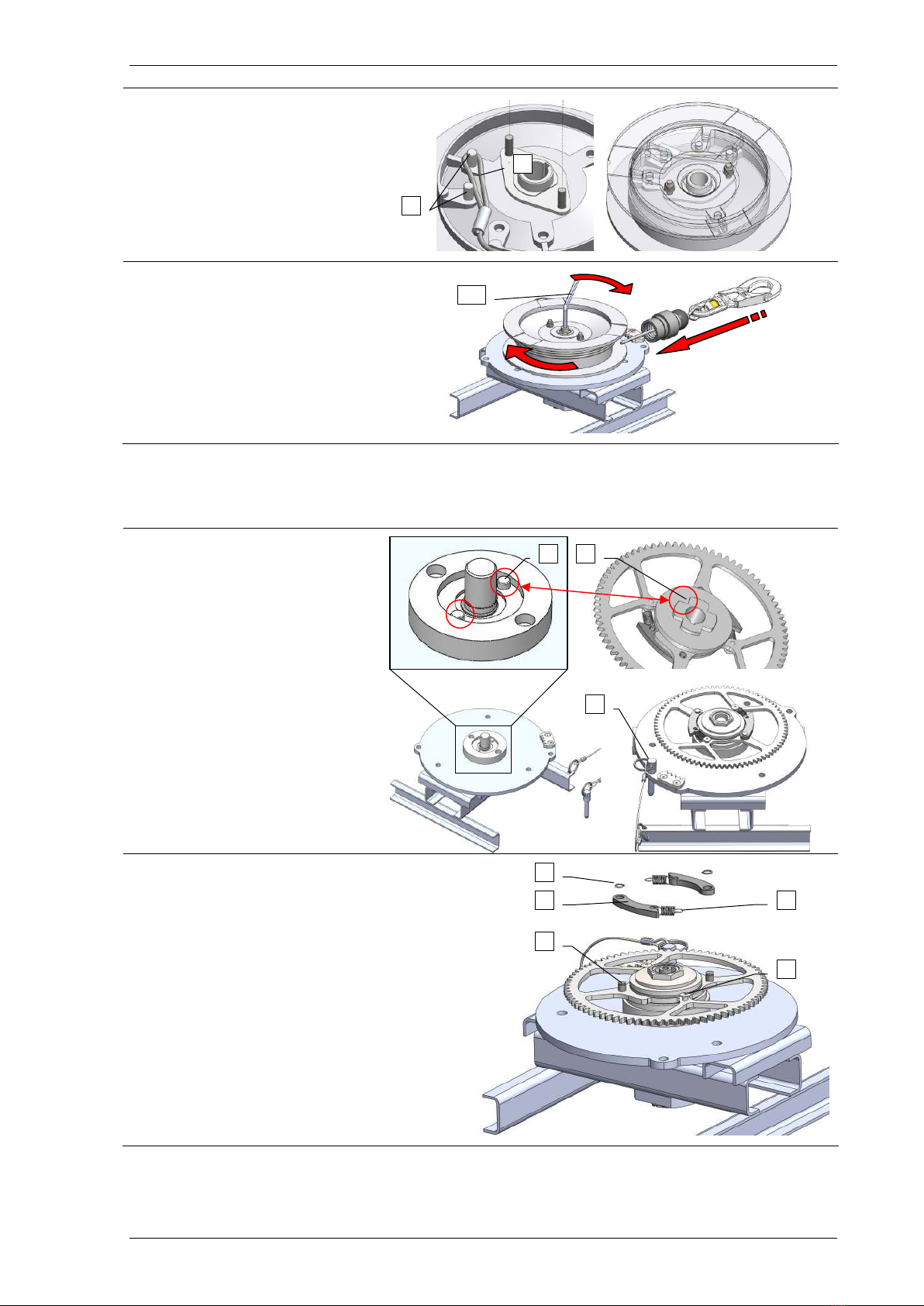

4.4. The brake et maintenance and in pection

4.4.1

• Seat the brake unit on the

Rotating Jig. Pay attention to

lock the Jig's pin (1) in the

part's relief (2).

• Secure the rotating jig table

against rotation with the aid

of pin (3).

4.4.2

• Take off the Φ8 locking ring (4) and the dog

(5) from the dog’s axle (6).

• Detach the dog's spring (7) from the pin (8).

Carefully inspect:

− dogs (5) - attack edge cannot be worn down;

− dog's axle (6) - any axle movement is a

failure.

− the dog’s springs (7) - the spring’s threads

should adhere each other and the spring eye

should be round;

Carefully clean all parts. Replace, if

appropriate.

8

9

9

10

1

2

3

4

6

5

7

8

CRW 200 Ser ice Manual 8/13

4.4.3

Unscrew the M28 nut (9).

4.4.4

Dismantle all the parts:

• M28 Nut (9);

• Spring washer (10);

• Pressure plate (11);

• Friction ring – 1

st

(12);

• Gear (13);

• Friction ring – 2

nd

(14);

• Support plate (15);

• Bush (16).

Check carefully all the parts against

any damages and/ or corrosion.

Metal parts may be cleaned with the

aid of extraction naphtha or similar

solvent. Replace, if appropriate.

Don t clean or repair the friction

ring. If the ring is worn down or

damaged, it should be replaced with

new one.

Assembly the components of the set in

reverse order. (The M28 nut thread

must be greased before screwing)

4.4.5

• Set up a torque spanner with

the torque value of 60 Nm.

• Tight the M28 nut (9) with the

specified torque.

4.4.6

• Attach the dog's springs (17)

to the pins (18).

• Mount the dogs (19) onto

dog's axles (20)

• Secure the dogs with the aid

of Φ8 locking ring (21). Use a

new locking ring.

6

0 Nm

grea e before

crewing

9

9

20

19

17

18

21

13

12

11

10

9

14

15

16

CRW 200 Ser ice Manual 9/13

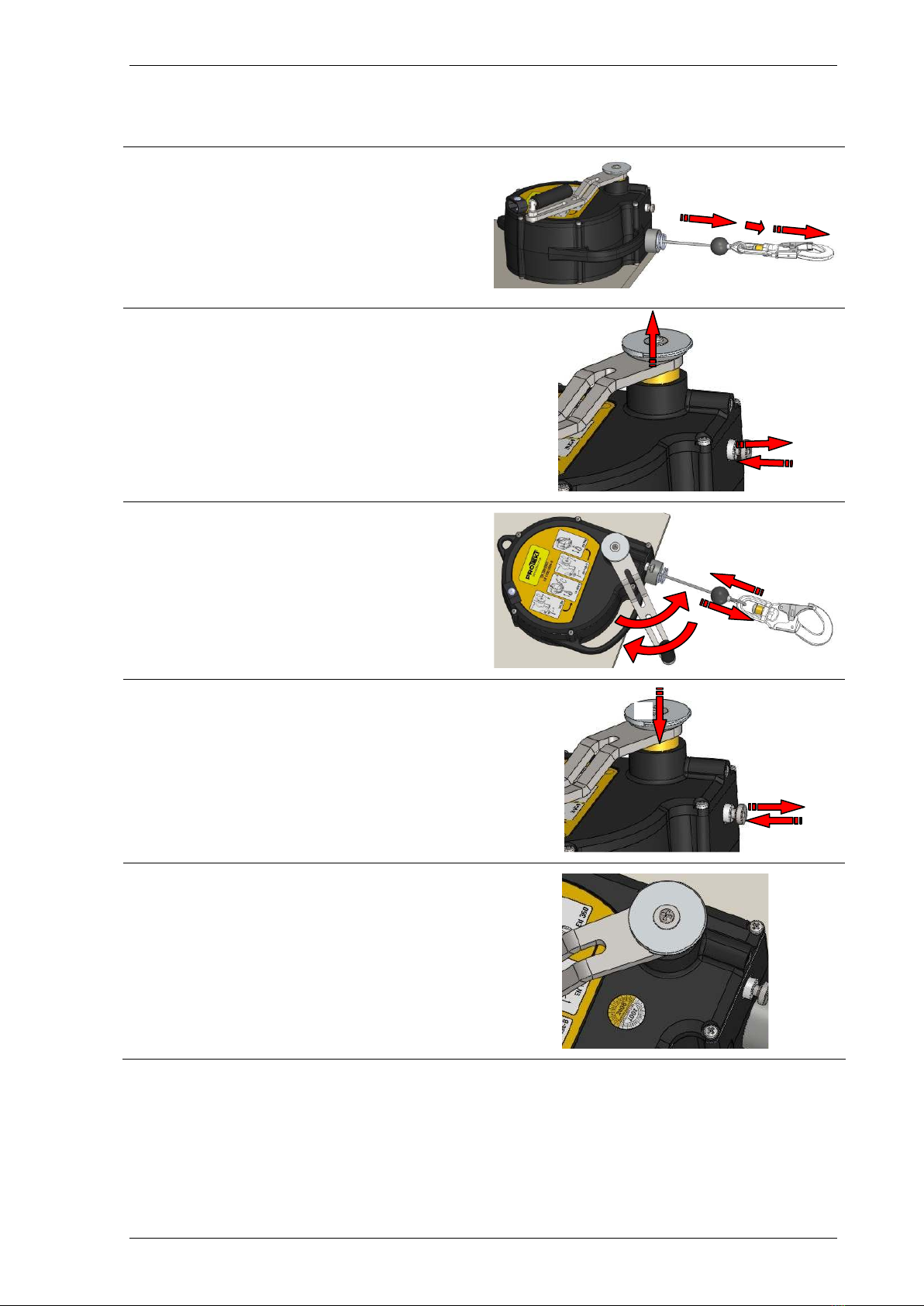

4.5. The winch unit di mantling and maintenance

4.5.1

• Unscrew two M4 screws (1) with the aid of

Torx type wrench T20.

4.5.2

Dismantle winch unit in the following steps:

• Take off the parallel key (2).

• Take off the crank shaft (4) and the parts

(5), (6), (7) from the body (3).

• Take off friction rings (5), (7) and ratchet

wheel (6) from the shaft.

4.5.3

Inspect the parts against any damages or corrosion.

Metal parts may be cleaned with the aid of extraction naphtha or similar solvent.

Don t clean or repair the friction ring. If the ring is worn down or damaged, it should be

replaced with new one.

Rebuild the winch unit in the following steps:

4.5.4

• Put on one friction ring (5) onto shaft.

Grease the shaft in pointed place.

4.5.5

• Put on the ratchet wheel (6) and friction

ring (7) onto shaft.

4.5.6

• Grease in the pointed places.

4.5.7

• Put in the shaft set (8) into body.

• Mount the parallel key (9) in the body slot.

• Screw two M4 bolts (10).

grease

1

2

3

4

5

7

5

1

6

6

7

grease

grease

grease

grease

grease

8

10

9

CRW 200 Ser ice Manual 10/13

4.6. The device rebuilding.

4.6.1

• Grease the main shaft (1) in

the pointed place.

• Mount the shaft (1) into

casing.

• Mount the washer (2) and

Z20 snap ring (3).

4.6.2

• Mount the parallel key (4)

into shaft's slot.

• Mount the brake set (5) onto

shaft.

• Mount the Z20 snap ring (6)

onto shaft.

4.6.3

• Set the locking pin set (7)

into casing hole.

• Set the winch set (8) into

casing, screw preliminary

the locking pin (7) set to

winch set (without

tightening) and screw 3 M6

screws (9).

• Tight the locking pin set (7)

screwing connection to

winch set (8).

4.6.4

• Turning with the main shaft, position

the shaft's groove (9) opposite the

retracting spring ending (10) so that

inserting of the spring ending into

groove is possible.

• Put on the retracting spring cover set

(11) on the base. Pay attention to

insert the ending (10) of the retracting

spring into shaft's groove (9) and the

hole (12) on the winch set body (13).

• ith the aid of Torx type wrench T25

screw 6 x M5 bolts (14).

4.6.5

• Mount the parallel pin (15);

spring-G (16) and M10

screw (17) into cover's hole.

• Mount the crank nut (18)

onto crank shaft.

grease

1

2

3

4

5

6

7

9

8

7

grease

10

9

14

13

12

11

grease

15

16

17

18

CRW 200 Ser ice Manual 11/13

4.6.6

• Mount the crank (19) and

the screws (20) and (21).

Glue the screws with the aid

of anaerobic adhesive.

• By turning the crank to the

right, tight the winch brake.

(You should listen sound

like - "click ... click ... click).

• Mount the crank plate (22)

onto shaft. Pay attention to

position the crank plate in

relation to crank according

arrangement (23).

• Fix the crank plate with the

aid of washer (24) and M5

screw (25). Glue the screw

with the aid of anaerobic

adhesive.

4.6.7

• Mount the parallel key (26)

into shaft slot and put the

drum set (27) on the shaft.

• Fix the drum set with the aid

of M6 screw (28) and

washer (29).

4.6.8

• Rotate the drum unit 8 full

turns to the left in order to

make initial tension of the

retracting spring.

• Insert the cable and the

bumper’s spring set (30)

into casing slot.

• Mount the Z38 locking ring

(31) onto bush.

4.6.9

• Mount the drum's cover (32)

onto body.

• Fix the cover with the aid of

6 x M5 screws (33). Use the

Torx type wrench T25.

anaerobic

adhesi e

click ... click ... click

x

8

19

glue

21

20

23

22

24

25

glue

glue

25

21

20

26

27

28

29

30

31

33

32

CRW 200 Ser ice Manual 12/13

5. POST-ASSEMBLY CHECK

5.1

Under EN360 mode:

• unwind the cable fully from the device,

• during unwinding, pull the cable abruptly –

make sure that the dogs engage,

• release the cable - make sure that the

cable retracts.

5.2

Change over the device to EN1496 mode

• unlock the winch with the aid of the locking

pin,

• pull the crank plate,

• lock the winch by loosening the locking pin.

5.3

By turning the crank in both direction make

sure that the cable is moved.

6.4

Back to EN360 mode.

5.5.4

Apply the next inspection sticker and mark

relevant date in the next year.

* * * * * * * *

3

1

2

1

3

2

CRW 200 Ser ice Manual 13/13

6. CRW 200 - SPARE PARTS

Table of contents

Popular Lifting System manuals by other brands

PALAZZANI

PALAZZANI RAGNO XTJ 32 / C Operation and maintenance manual

Harmar Mobility

Harmar Mobility Pinnacle Installation and service manual

Herkules Hebetechnik GmbH

Herkules Hebetechnik GmbH K1200-HLS-64 Operating manual and test record

morse

morse 400A-96-114 Operator's manual

Sealey

Sealey MC500 instructions

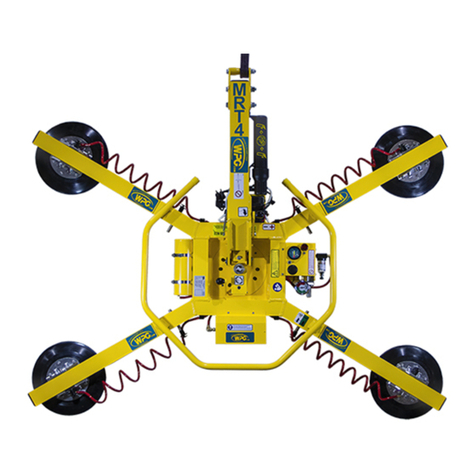

WPG

WPG MRT411LDC operating instructions