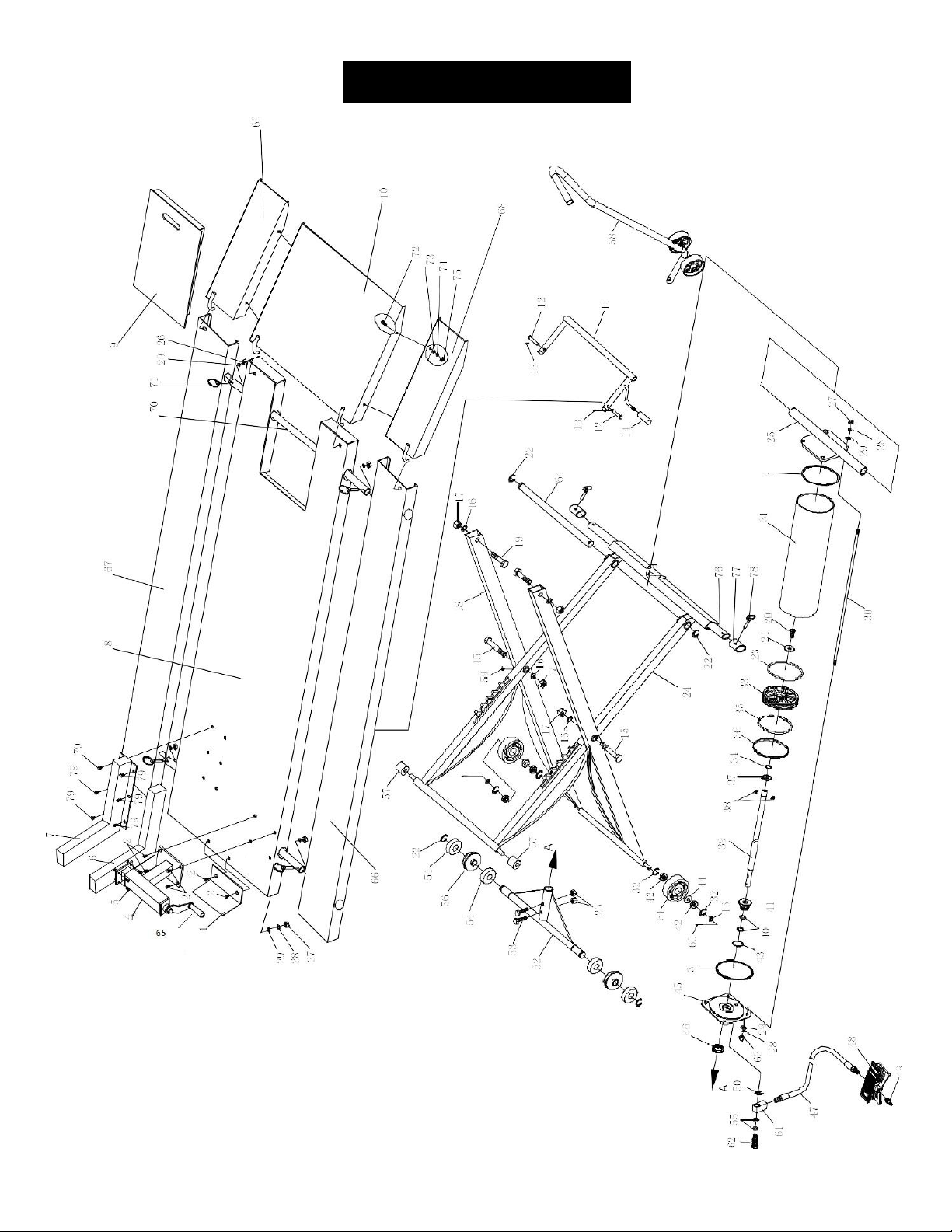

SAFE LIFT OPERATION

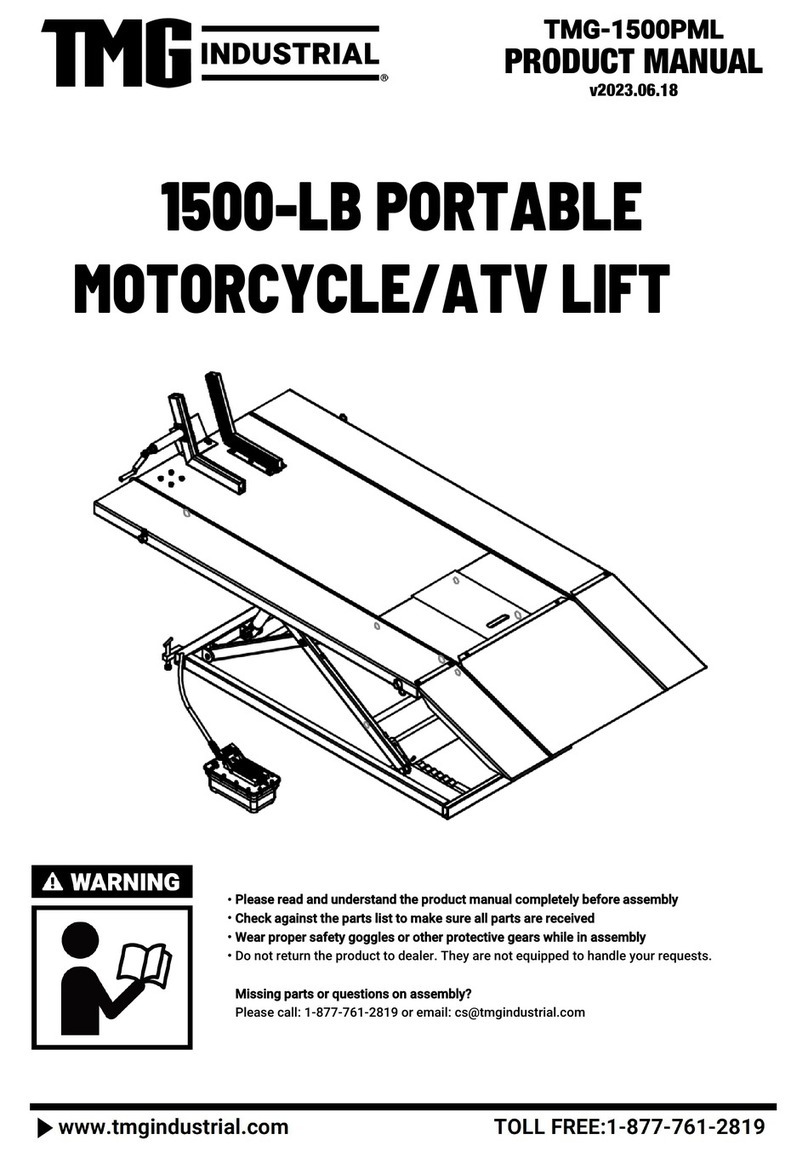

Motorcycle lifts are critical to the operation and profitability of your business. The safe use of this and other lifts in your

shop is critical in preventing employee injuries and damage to customer’s vehicles. Safe operation of a motorcycle lift

requires that only trained employees should be allowed to use the lift.

TRAINING SHOULD INCLUDE, BUT NOT LIMITED TO:

Proper positioning of the vehicle on the table.

Use of the operating controls.

Understanding the lift capacity.

Proper use of jack stands or other load supporting devices.

Proper use, understanding and visual identification of safety lock devices and their operation.

Reviewing the safety rules.

Proper housekeeping procedures (lift area should be free of grease, oil, tools, equipment, trash, and other debris)

A daily inspection of the lift should be completed prior to its use. Safety devices, operating controls, lift arms and

other critical parts should be inspected prior to using the lift.

All maintenance and repairs of the lift should be completed by following the manufacturer’s requirements. Lift repair

parts should meet or exceed OEM specifications. Repairs should only be completed by a qualified lift technician.

The vehicle manufacturer’s recommendations should be used for spotting and lifting the vehicle.

LIFT OPERATION SAFETY

It is important that you know the load limit. Be careful that you do not overload the lift . If you are unsure what the

load limit is, refer to this manual or contact the manufacturer.

The center of gravity should be followed closely to what the manufacturer recommends.

Always make sure you have proper overhead clearance. Additionally, check that attachments, (vehicle signs,

pipes, antennas, etc.) are not in the way.

Be sure that prior to the vehicle being raised the motorcycle is secured to the table.

Prior to being raised, make sure there is no one standing closer than six feet from the lift.

After positioning the vehicle on the lift, make sure the ignition is off, overhead obstructions are cleared, and the trans-

mission is in neutral.

The lift should be raised just until the vehicle’s wheels are about one foot off the ground. If contact with the vehicle is

uneven or it appears that the vehicle is not sitting secure, carefully lower the lift and readjust.

Always consider potential problems that might cause a vehicle to slip, i.e., heavy cargo, etc.

Pay attention when walking under a vehicle that is up on the lift.

DO NOT leave the controls while the lift is still in motion.

DO NOT stand directly in front of the vehicle or in the bay when vehicle is being loaded into position.

DO NOT Go near vehicle or attempt to work on the vehicle when being raised or lowered.

REMAIN CLEAR of lift when raising or lowering vehicle.

DO NOT rock the vehicle while on the lift or remove any heavy component from vehicle that may cause excessive

weight shift.

Always lower the vehicle down slowly and smoothly.

ONLY TRAINED OPERATORS should operate this lift. All non-trained personnel should be kept away from work area.

Never let non-trained personnel come in contact with, or operate lift.

USE LIFT CORRECTLY. Use lift in the proper manner. Never use lifting adapters other than what is approved by the

manufacturer.

DO NOT override self-closing lift controls.

CLEAR AREA if vehicle is on danger of falling.

STAY ALERT. Watch what you are doing. Use common sense. Be aware.

CHECK FOR DAMAGED PARTS. Check for alignment of moving parts, breakage of parts or any condition that may

affect its operation. Do not use lift if any component is broken or damaged.