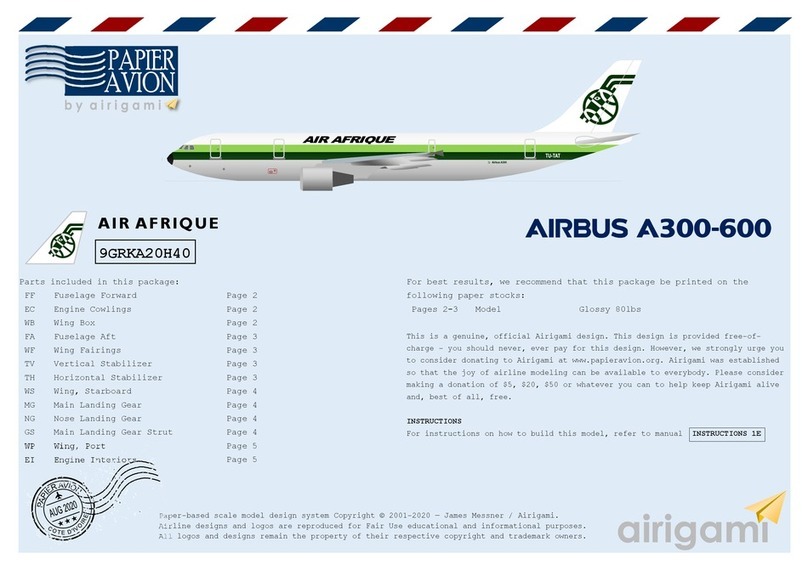

Protos Plastic 500 User manual

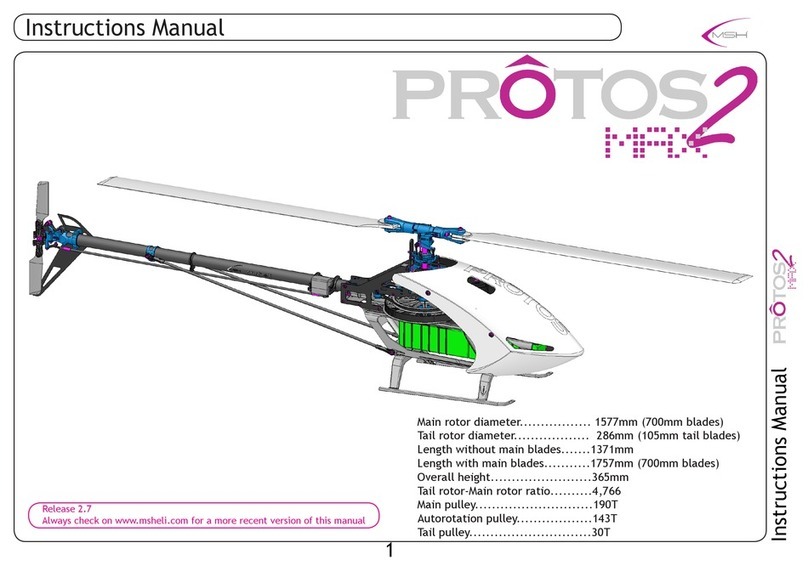

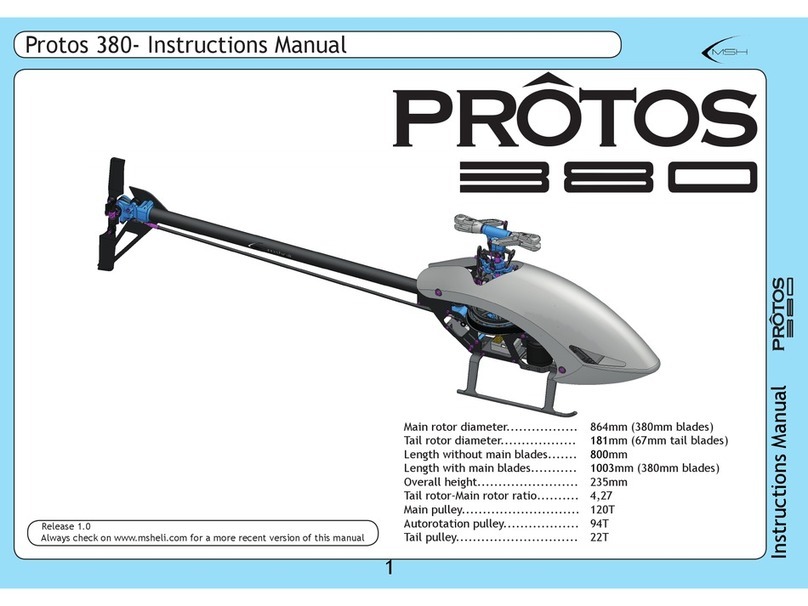

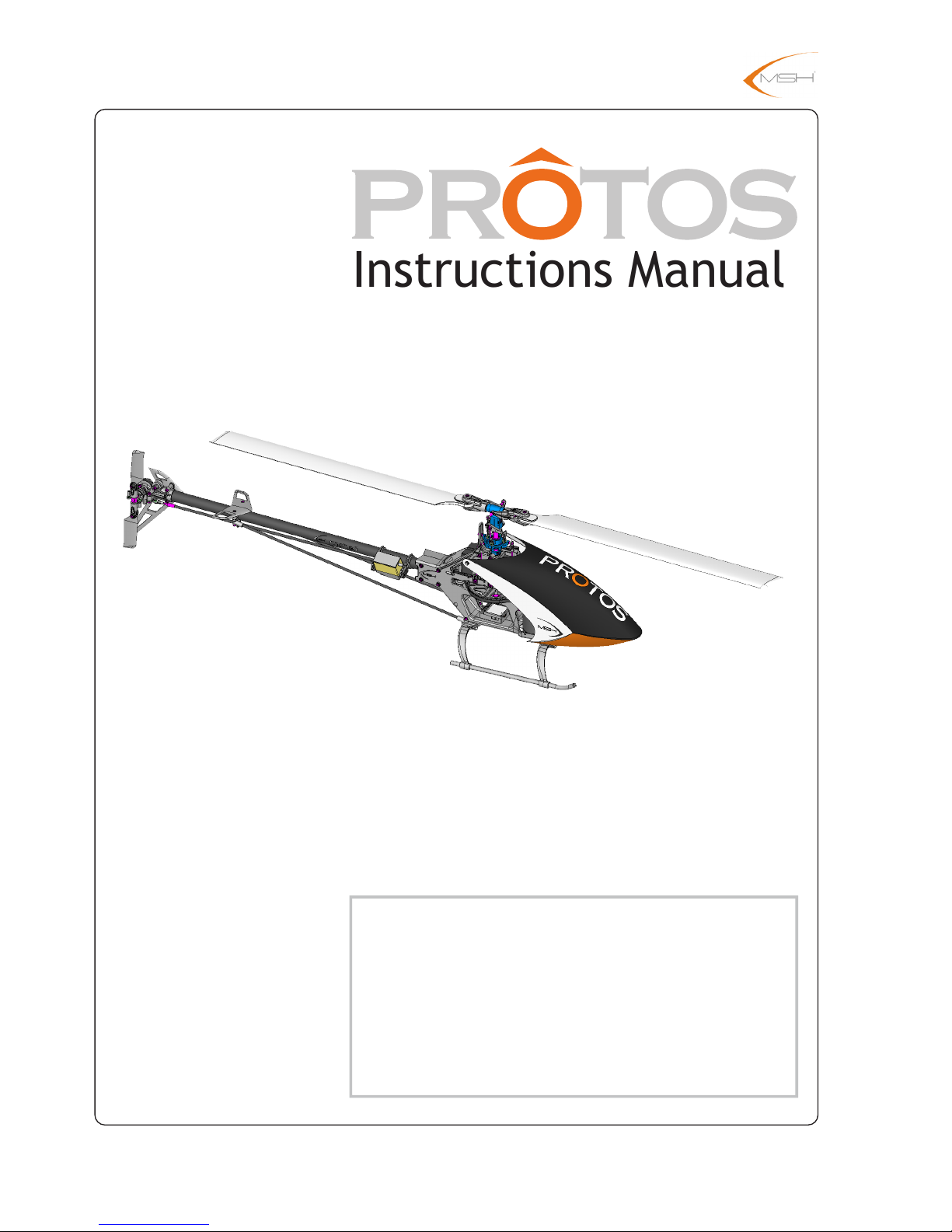

Instructions Manual

RC Helicopter

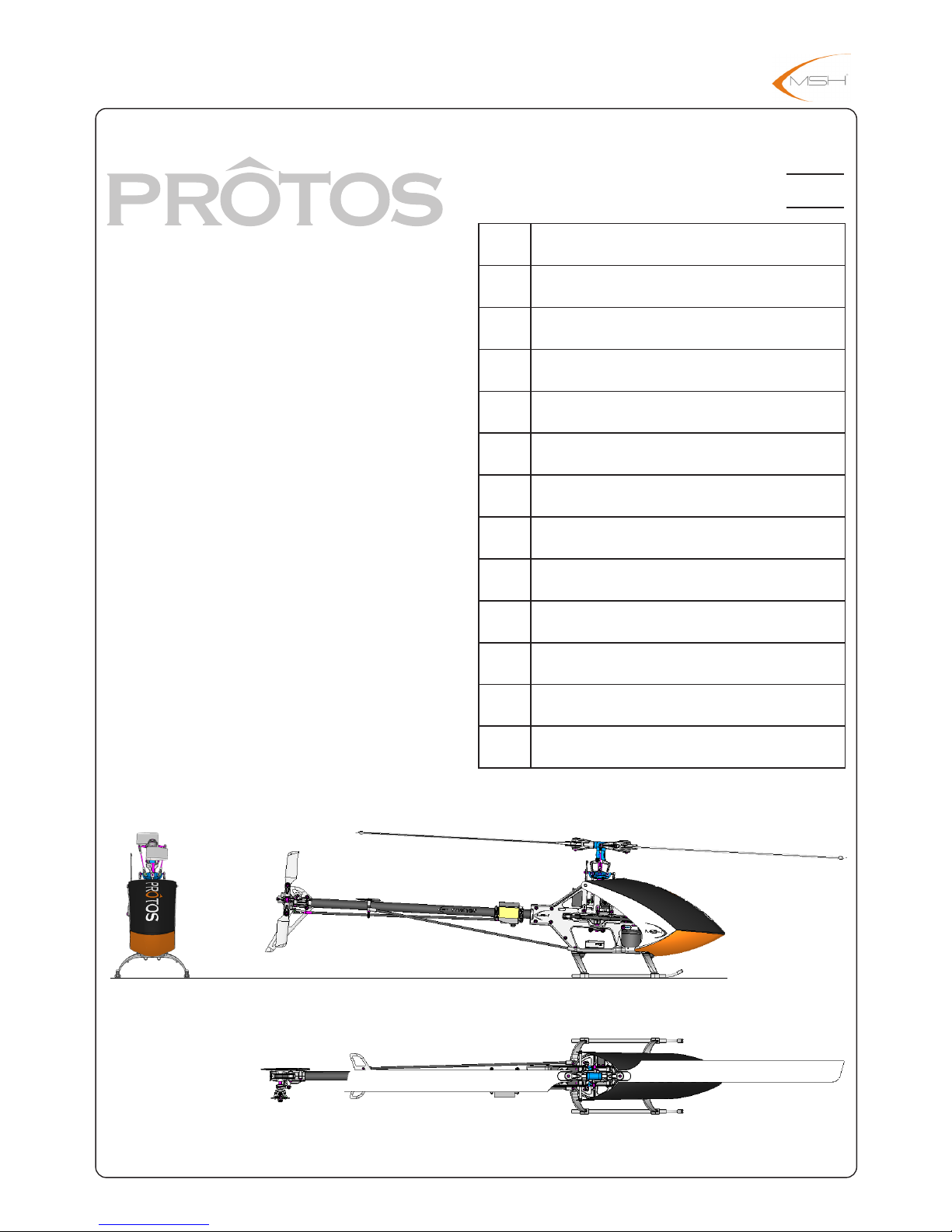

Main rotor diameter : 965mm

Tail rotor diameter : 192mm

Lenght without main blades : 955mm

Lenght with main blades : 1185mm

Main blades lenght : 425mm

Overall height : 270mm

Tail rotor - Main rotor ratio : 4,65

Main pulley : 93T

Weight ready to y with 6sLipo : 1550g(may vary with dierent electronics)

Plastic

Flybarless

1

Instructions Manual

RC Helicopter

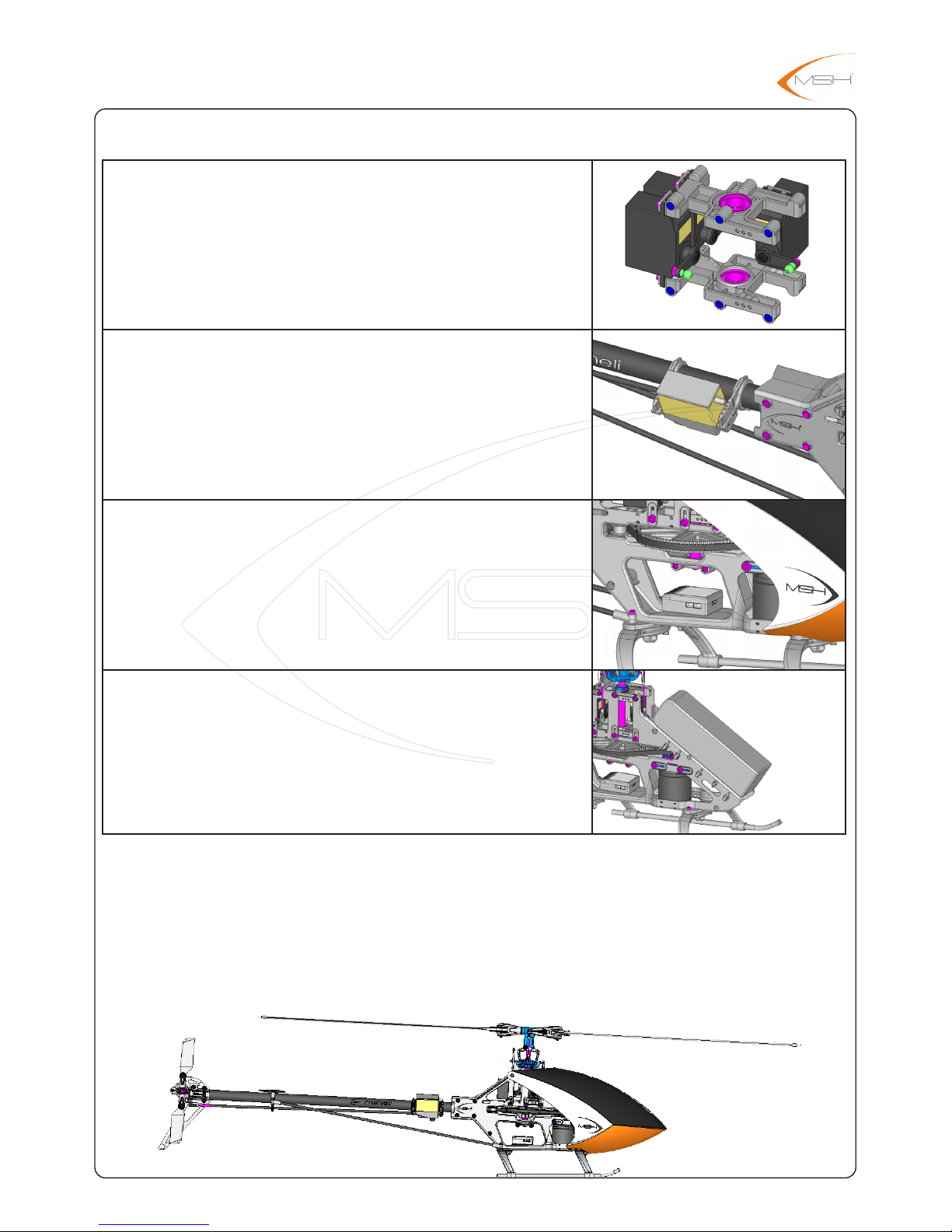

Page Content

3

4

5

6

7-13

14-19

20-28

29-31

32

33

34

35-46

Always follow these rules for safety

Tools required for assembly

R/C equipment required for assembly

Motor pinion teeth choice

Main Frame Assembly

Head Assembly

Tail Assembly

Motor Installation

Battery, ESC and Canopy Installation

Belt Tensioning Diagram

Main blades

Spare parts

Index

2

Operate the helicopter in open areas with no people nearby.

Do NOT operate the helicopter in the following places and situations (or else you risk severe

accidents):

-in places where children gather or people pass through

-in residential areas and parks

-indoors and in limited space

-in windy weather or when there is rain, snow, fog or other precipitation

If you do not observe these instructions you may be held reliable for personal injury or property damage!

Always check the R/C system prior to operating your helicopter.

When the R/C system batteries get weaker,the operational range of the R/C system decreases.

Note that you may lose control of your model when operating it under such conditions.

Keep in mind that other people around you might also be operating a R/C model.

Never use a frequency which someone else is using at the same time.

Radio signals will be mixed and you will lose control of your model.

If the model shows irregular behavior, bring the model to a halt immediately and disconnect the batteries.

Investigate the reason and fix the problem.

Do not operate the model again as long as the problem is not solved, as this may lead to further trouble

and unforeseen accidents.

In order to prevent accidents and personal injury, be sure to observe the following:

Before flying the helicopter, ensure that all screws are tightened.

A single loose screw may cause a major accident.

Replace all broken or defective parts with new ones, as damaged parts lead to crashes.

Never approach a spinning rotor. Keep at least 10 meters/yards away from a spinning rotor blades.

Do not touch the motor immediately after use. It may be hot enough to cause burns.

Perform all necessary maintenance.

PRIOR TO ADJUSTING AND OPERATING YOUR MODEL, OBSERVE THE FOLLOWING

Operate the helicopter only outdoors and out of people’s reach as the main rotor operates at high rpm!

While adjusting, stand at least 10 meters

Novice R/C helicopter pilots should always seek advice from experienced pilots to obtain hints with assembly

and for pre-fight adjustments.

Note that a badly assembled or insuffciently adjusted helicopter is a safety hazard!

In the beginning, novice R/C helicopter pilots should always be assisted by an experienced pilot

and never fly alone!

MSHeli Srl

Italy

Always follow these rules for safety

3

Tools required for assembly

1.5 / 2 / 2.5 mm

Hexagon screw drivers

Philips

Screw driver

Needle nose pliers Thread lock Medium (blue)

Glue widht 2mm aprox.

Slow curing epoxy Soldering iron

4

R/C equipment required for assembly

Swashplate servos supported:

Mini servos

Tail servo supported:

Mini and Regular size servos

Trasmitter / Receiver:

Satellites:

Spektrum : DSM 2 - DSM X

Futaba : S-Bus - S-Bus 2

HOTT SumD

MPX Srxl

Standard receiver: all

Battery pack:

LiPo 4s 3700mAh

LiPo 5s 3300/3700mAh

LiPo 6s 2500mAh/3000mAh

5

Motor pinion teeth choice

Beginner

Sport

Soft 3D

Hard 3D

LiPo 4s

3700mAh

LiPo 5s

3700mAh

LiPo 6s

2500mAh

18T (2400RPM) 15T (2500RPM) -

19T (2550RPM) 16T (2650RPM) 13T (2550RPM)

20T (2650RPM) 17T (2850RPM) 14T (2750RPM)

- 18T (2950RPM) 15T (3000RPM)

Battery

type

Fly

Style

6

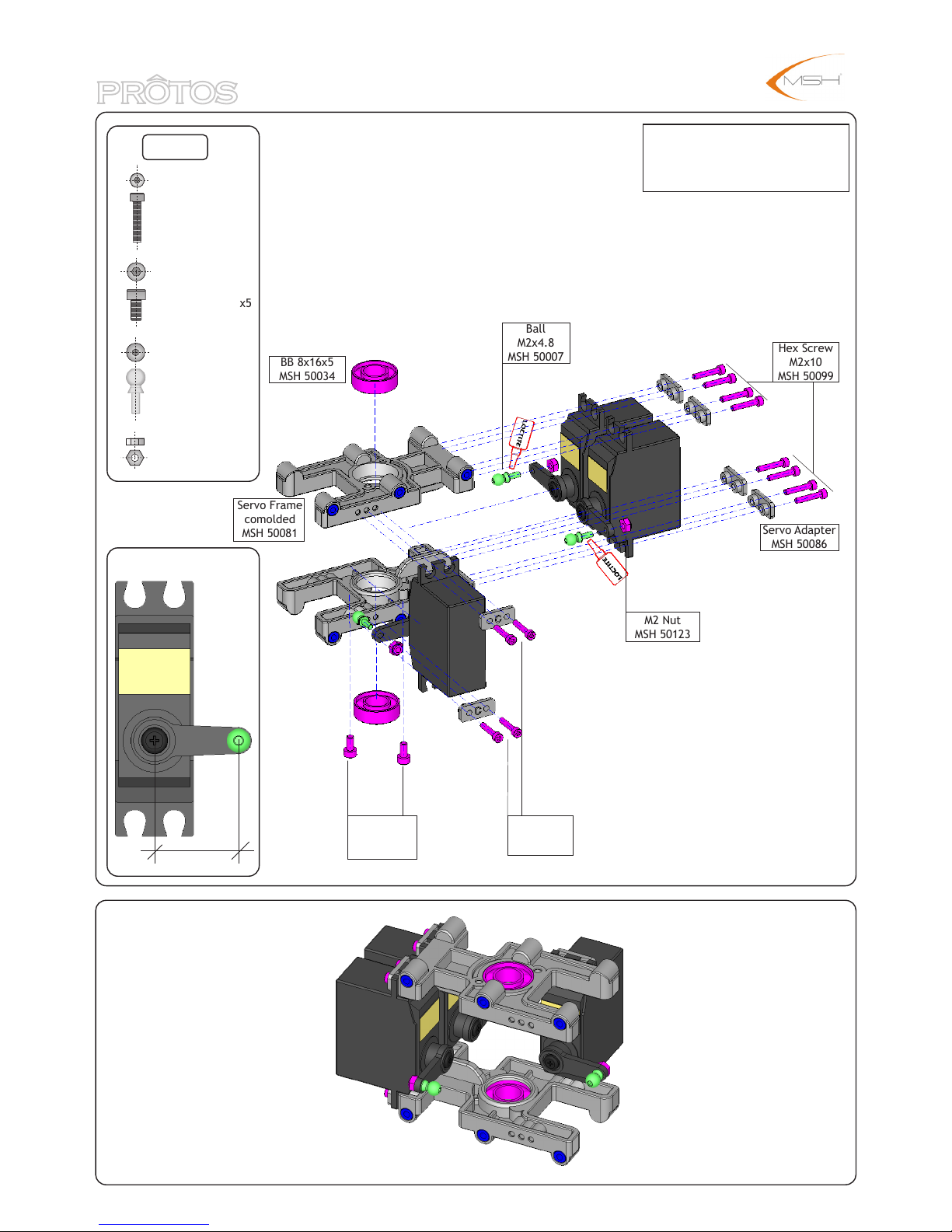

Tips/Instructions

Hex screw M2.5x5 only on

lower servo frame.

BAG-A

Hex Screw M2.5x5

MSH 50101

Ball M2x4.8

MSH 50007

M2 Nut

MSH 50123

Hex Screw

M2.5x5

MSH 50101

Hex Screw

M2x10

MSH 50099

Hex Screw

M2x10

MSH 50099

Servo Adapter

MSH 50086

Ball

M2x4.8

MSH 50007

M2 Nut

MSH 50123

BB 8x16x5

MSH 50034

Servo Frame

comolded

MSH 50081

Hex Screw M2x10

MSH 50099

16 mm

7

Pin 3x14

MSH 50059

Pin 3x14

MSH 50059

BB 3x8x3

MSH 50033

Guide Pulley

MSH 50091

BAG-B

8

Hex Screw

M2.5x8

MSH 50103

Motor Mount

MSH 50028

Hex Screw

M2.5x6

MSH 50102

Caution

Washer

2.6x6.5x1.5

MSH 50146

BAG-B

Hex Screw

M2.5x6

MSH 50102

Hex Screw

M2.5x8

MSH 50103

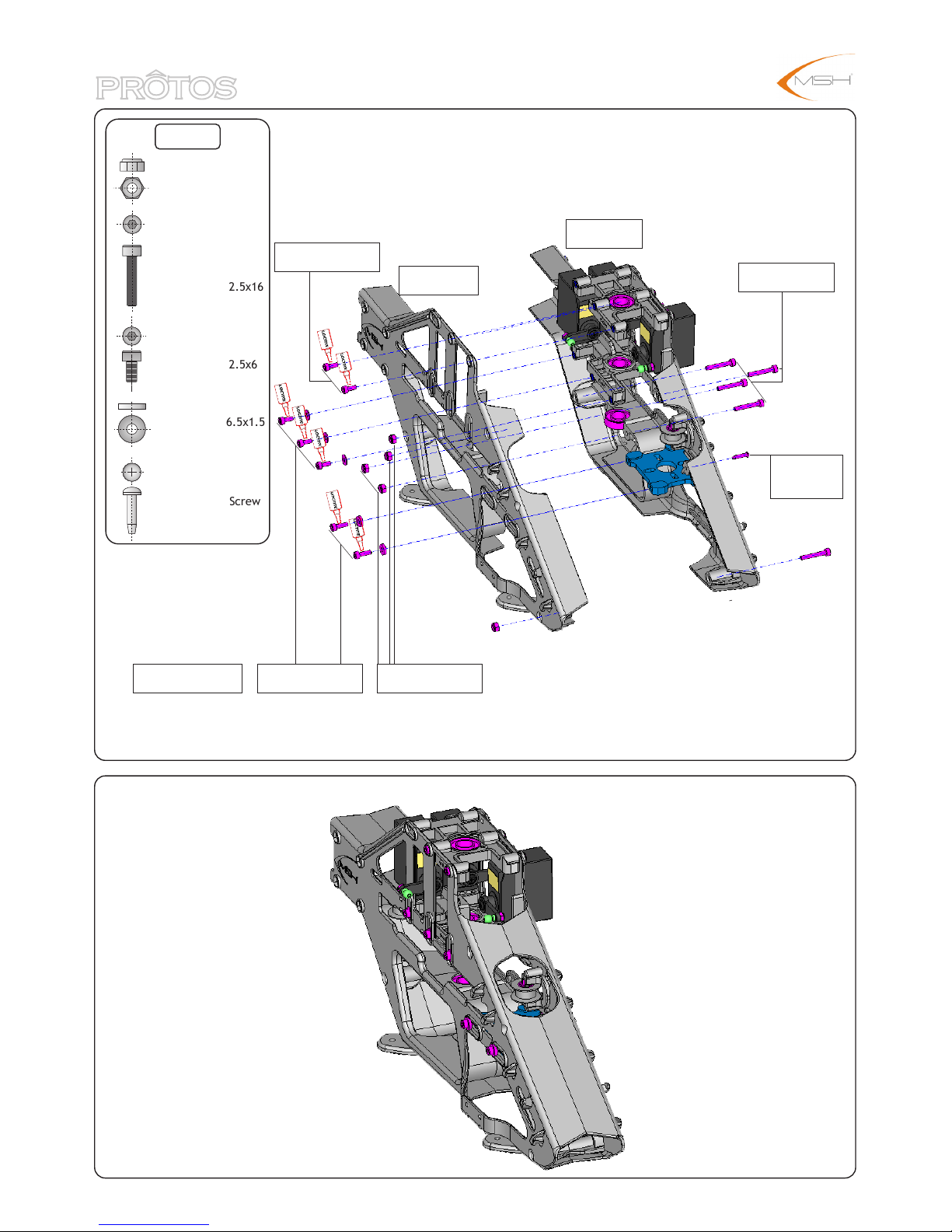

!CAUTION

Use Thread lock on every screw

metal/metal such as screws

that keep the servo frame in place.

Washer

2.6x6.5x1.5

MSH 50146

9

Hex Screw M2.5x6

MSH 50102

M2.5 Nylon Nut

MSH 50124

Hex Screw M2.5x16

MSH 50106

Washer 2.6x6.5x1.5

MSH 50146

BAG-B

Self Tapping Screw

2.2x9.5

MSH 50118

Main Frame L

MSH 50070

Main Frame R

MSH 50066

Hex Screw M2.5x6

MSH 50102

Hex Screw M2.5x8

MSH 50103

Washer 2.6x6.5x1.5

MSH 50146

Nylon Nut M2.5

MSH 50124

Hex Screw 2.5x16

MSH 50106

Self Tapping

Screw

MSH 50118

10

Nylon Nut

M2.5

MSH 50124

Hex Screw

M2.5x16

MSH 50106

Hex Screw

M2.5x10

MSH 50104

Skids

MSH 50089

Landing gear struts

MSH 50087

!CAUTION

Tips/Instructions

BAG-B

Hex Screw

M2.5x10

MSH 50104

Hex Screw

M2.5x16

MSH 50106

Nylon Nut

M2.5

MSH 50124

Slide skids in both struts until "click"

in position. Both struts should "click".

If Skids are hard to slide in position

use an hair drier to heat struts holes.

Do not fully tighten hex screws 2.5x16

yet as they are used later to keep

boom braces in position.

11

Tips/Instructions

BAG-B

Grub Screw

M2.5x12

MSH 50115

Hex Screw

M2.5x8

MSH 50103

Use thread lock on grub screw M2.5x12 on

the side that goes in the servo frame.

Grub screw can be screwed in by hand and

tightened with MSH 50063 (Canopy post)

using the two flat surfaces.

Grub Screw

M2.5x12

MSH 50115

Anti swashplate spin

MSH 50080

Canopy stand

MSH 50063

Hex Screw

M2.5x8

MSH 50103

12

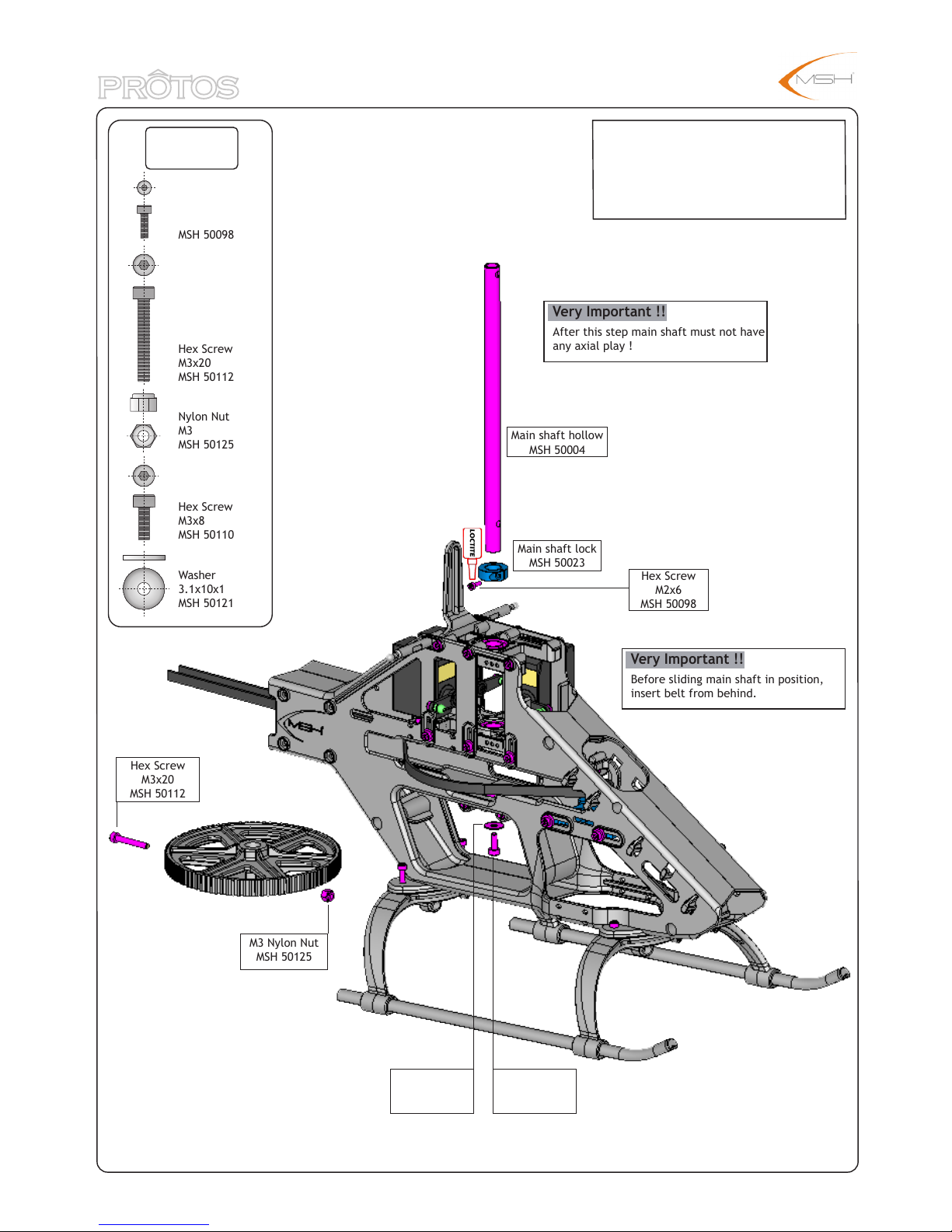

Hex Screw

M2x6

MSH 50098

Main shaft lock

MSH 50023

Main shaft hollow

MSH 50004

Hex Screw

M3x20

MSH 50112

M3 Nylon Nut

MSH 50125

Hex Screw

M3x8

MSH 50110

Washer

3.1x10x1

MSH 50121

Tips/Instructions

Very Important !!

BAG-C

Hex Screw

M2x6

MSH 50098

Hex Screw

M3x20

MSH 50112

Nylon Nut

M3

MSH 50125

Hex Screw

M3x8

MSH 50110

Washer

3.1x10x1

MSH 50121

Make sure hex screw M3x8 is fully tightened

on bottom of main shaft than pulling main

shaft gently lock collar in position.

Main shaft should not have any vertical play.

Before sliding main shaft in position,

insert belt from behind.

Belt from box

Very Important !!

After this step main shaft must not have

any axial play !

13

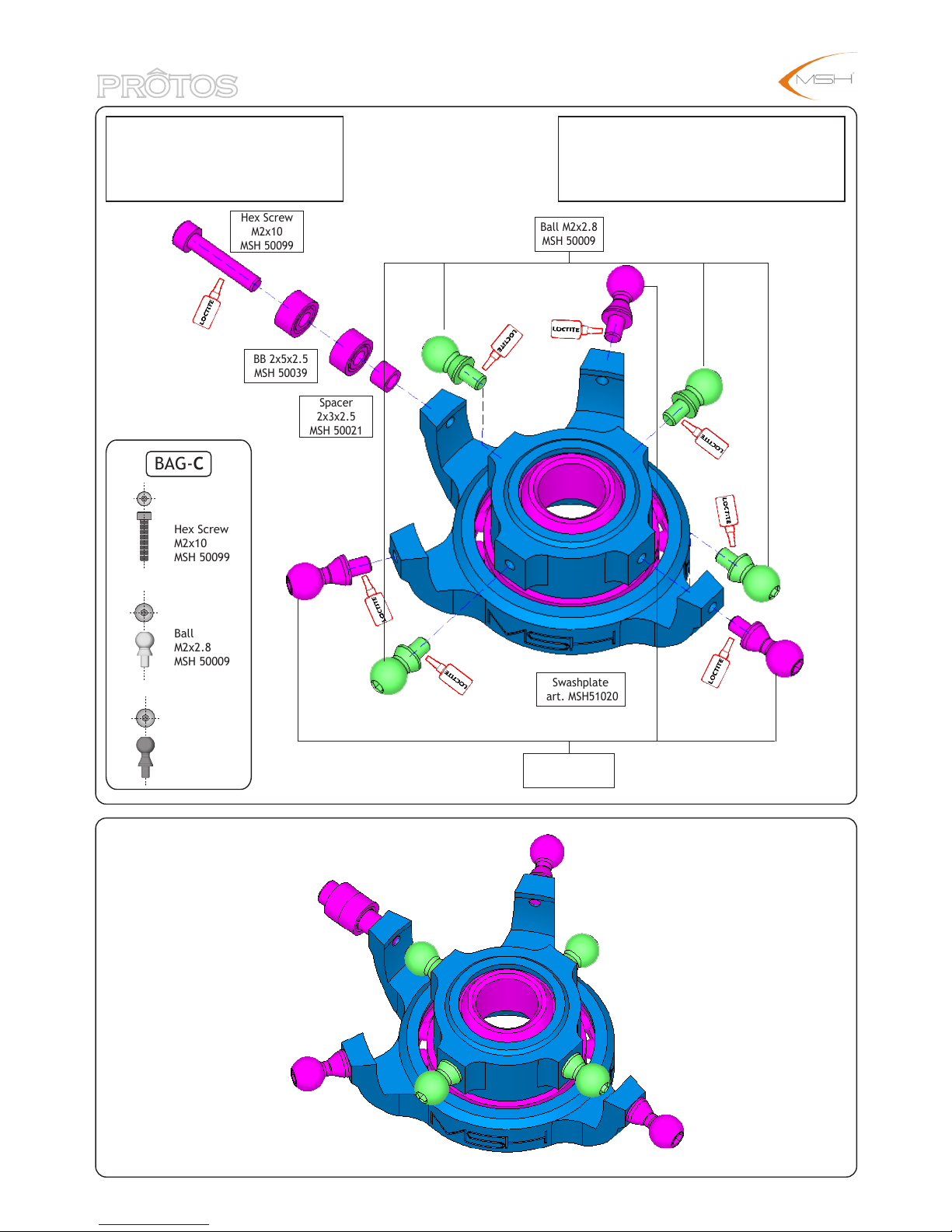

Hex Screw

M2x10

MSH 50099

Spacer

2x3x2.5

MSH 50021

BB 2x5x2.5

MSH 50039

Ball M2x2.8

MSH 50009

Ball M2x2.8 FBL

MSH 50175

Swashplate

art. MSH51020

Tips/Instructions

Use Thread lock on balls and screw M2x10.

BAG-C

Hex Screw

M2x10

MSH 50099

Ball

M2x2.8

MSH 50009

Ball

M2x2.8

MSH

50175

Important

Please pay attention to ball lenght :

Longer on the outer part of swashplate

and Shorter on the inside.

14

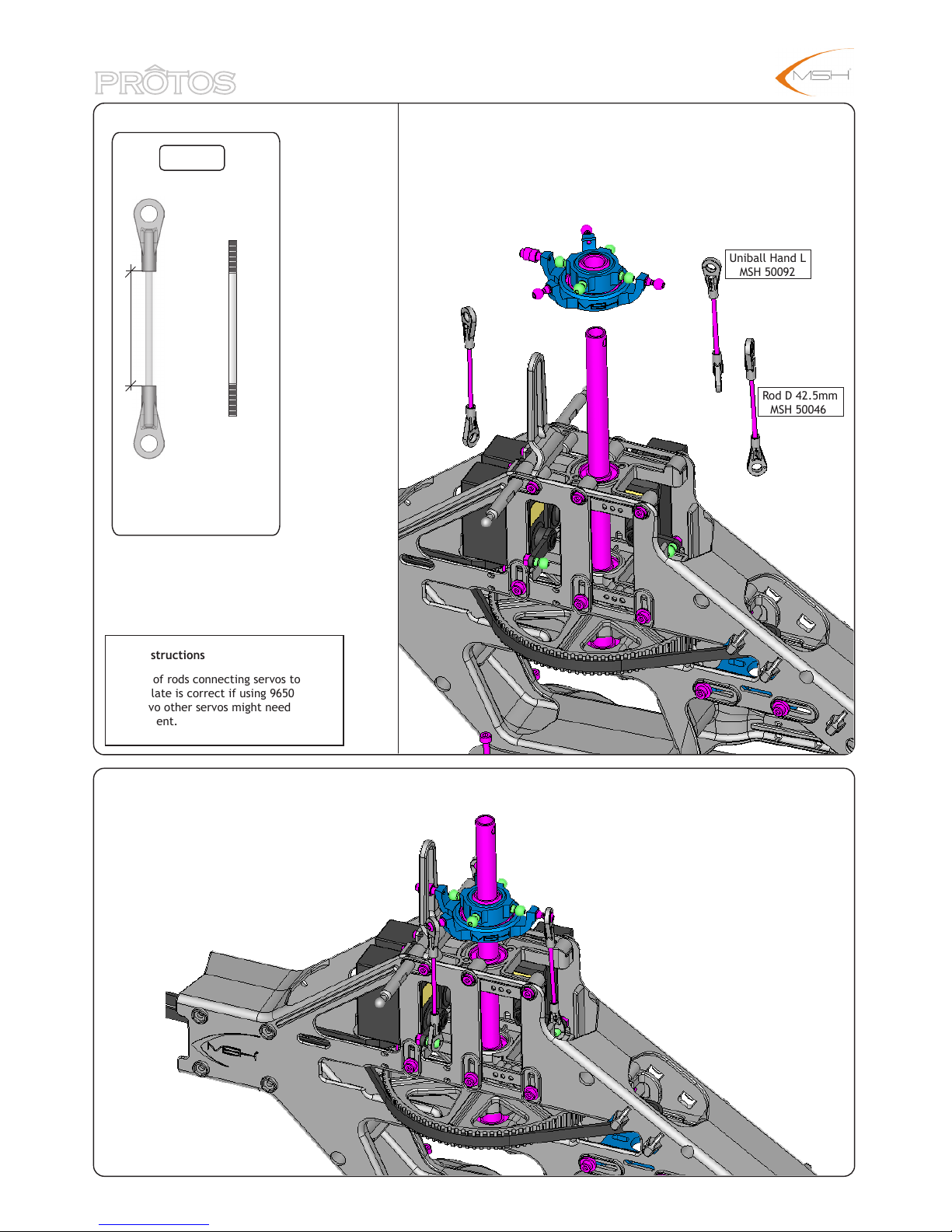

Tips/Instructions

Length of rods connecting servos to

swashplate is correct if using 9650

fut servo other servos might need

adjustment.

Rod D 42.5mm

MSH 50046

Uniball Hand L

MSH 50092

BAG-C

Fut

9650

Rod D

42.5mm

MSH 50046

28 mm

15

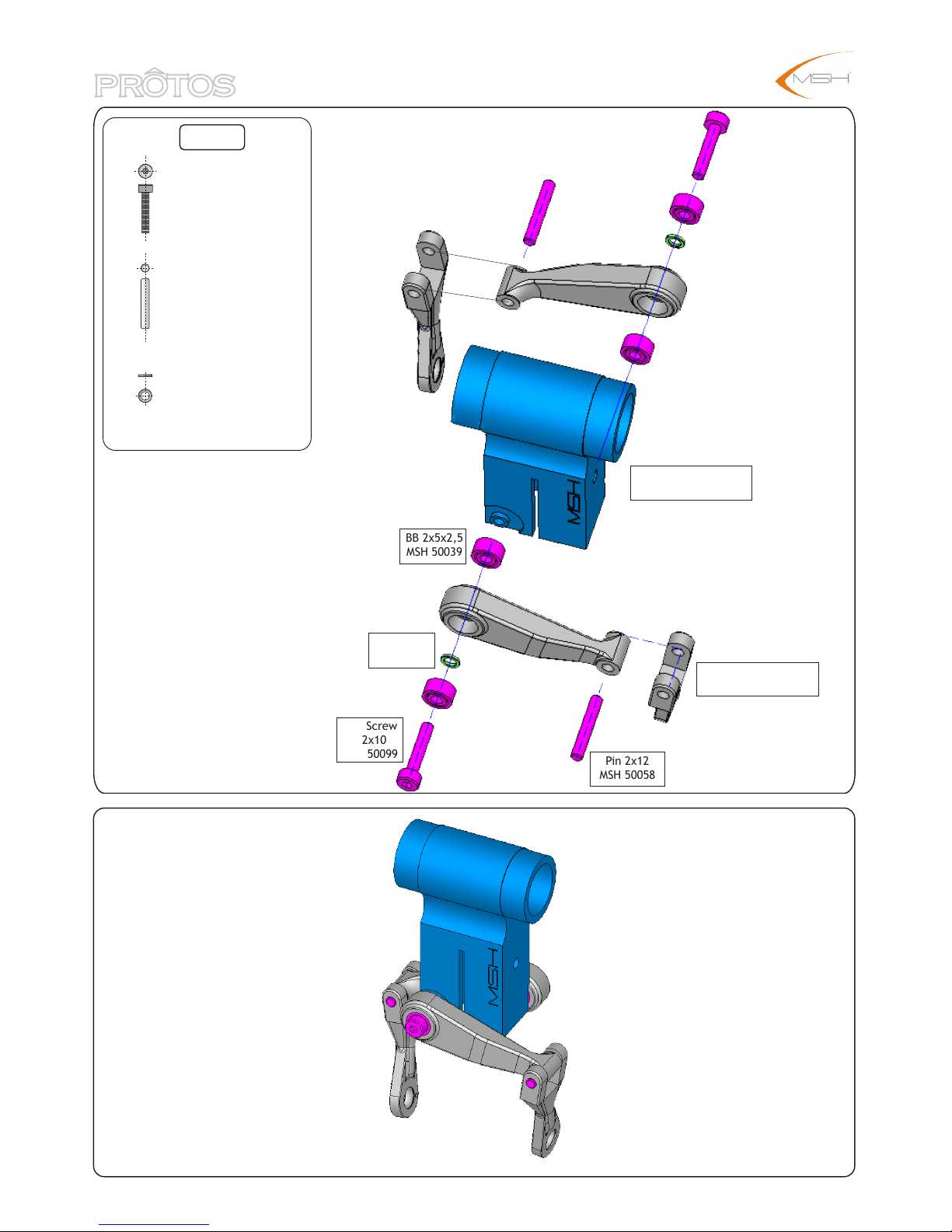

BAG-D

Hex Screw

M2x10

MSH 50099

BB 2x5x2,5

MSH 50039

Hex Screw

M2x10

MSH 50099

Pin 2x12

MSH 50058

Washout Pin

2x12

MSH 50058

BB spacer

MSH 40012

Wash out uniball arm

MSH 50097

Low flybarless hub

MSH 50206

BB spacer

2.1x3.2x0.5

MSH 40012

16

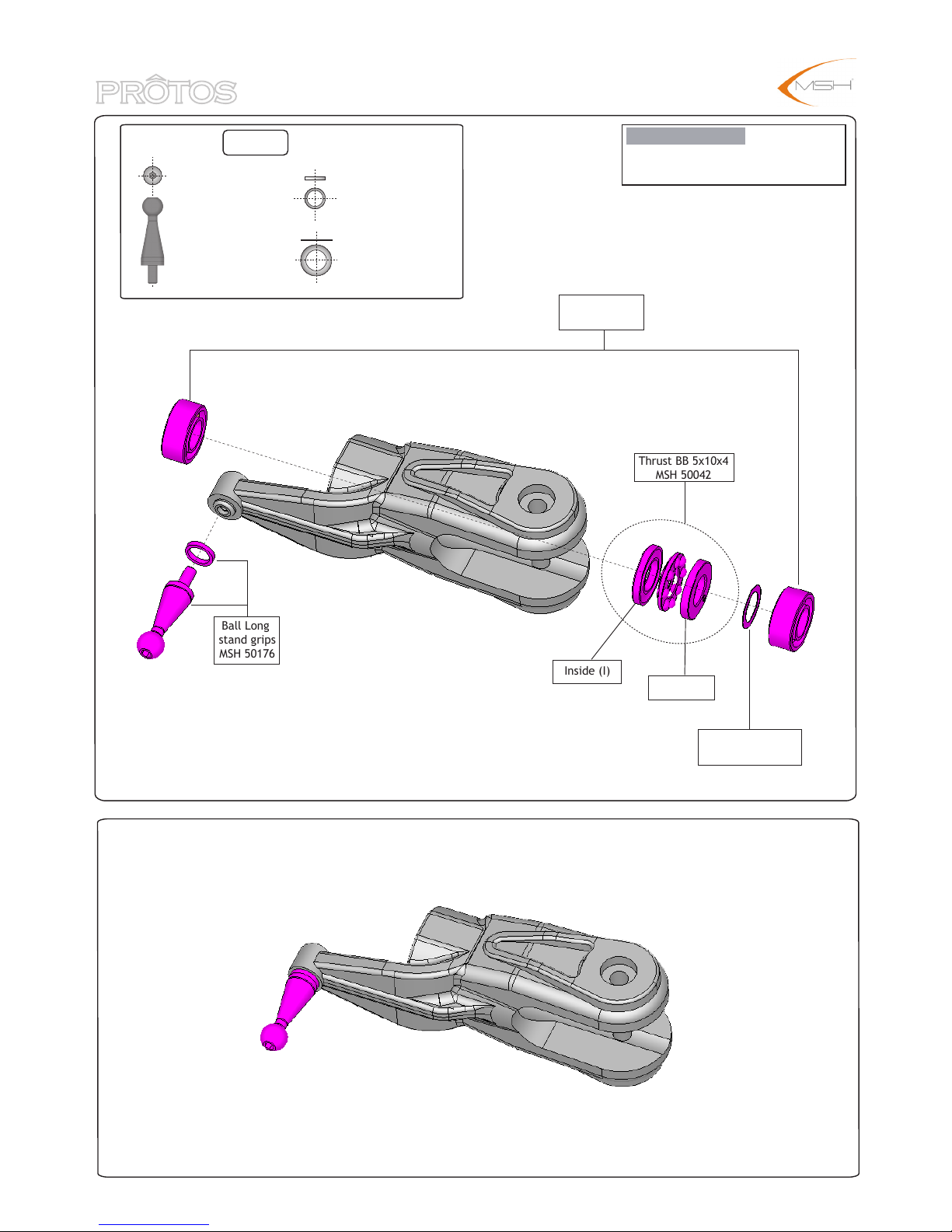

BAG-D

Ball Long

stand grips

MSH 50176

Ball Long

stand grips

MSH 50176

Thrust BB 5x10x4

MSH 50042

Inside (I)

Outside (O)

BB 5x10x4

MSH 50034

Washer 5x7.5x0.2

MSH 50135

Washer

5x7.5x0.2

MSH 50135

Ball Long

stand grips washer

5x3.9x0.8

MSH 50176

Very Important !!

Do not over tight balls on plastic.

Just 1/8 turn after completely seated.

17

Tips/Instructions

!CAUTION

BAG-D

Use thread lock on screws M3x8.

Thrust bearings flange with bigger

hole inward, flange with smaller hole

outward.

Spindle spacer is a stepped washer,

please make sure that, the stepped

side faces BB 5x10x4.

Washer

3.1x8x1

MSH 50122

Spindle Spacer

MSH 50011

Spindle Spacer

MSH 50011

Washer

3.1x8x1

MSH 50122

Dumper main head 500

MSH 50202

HUB SIDE BLADE SIDE

Hex Screw

M3x8 button head

MSH 50147

Hex Screw

M3x8

MSH 50110

18

Hex Screw M3x16

MSH 70083

BAG-D

Hex Screw

M3x16

MSH 70083

Rod D

42,5 mm

MSH 50046

27.1mm

Uniball Hands

MSH 50032

Nylon Nut

M3

MSH 50125

Nylon Nut

M3

MSH 50125

19

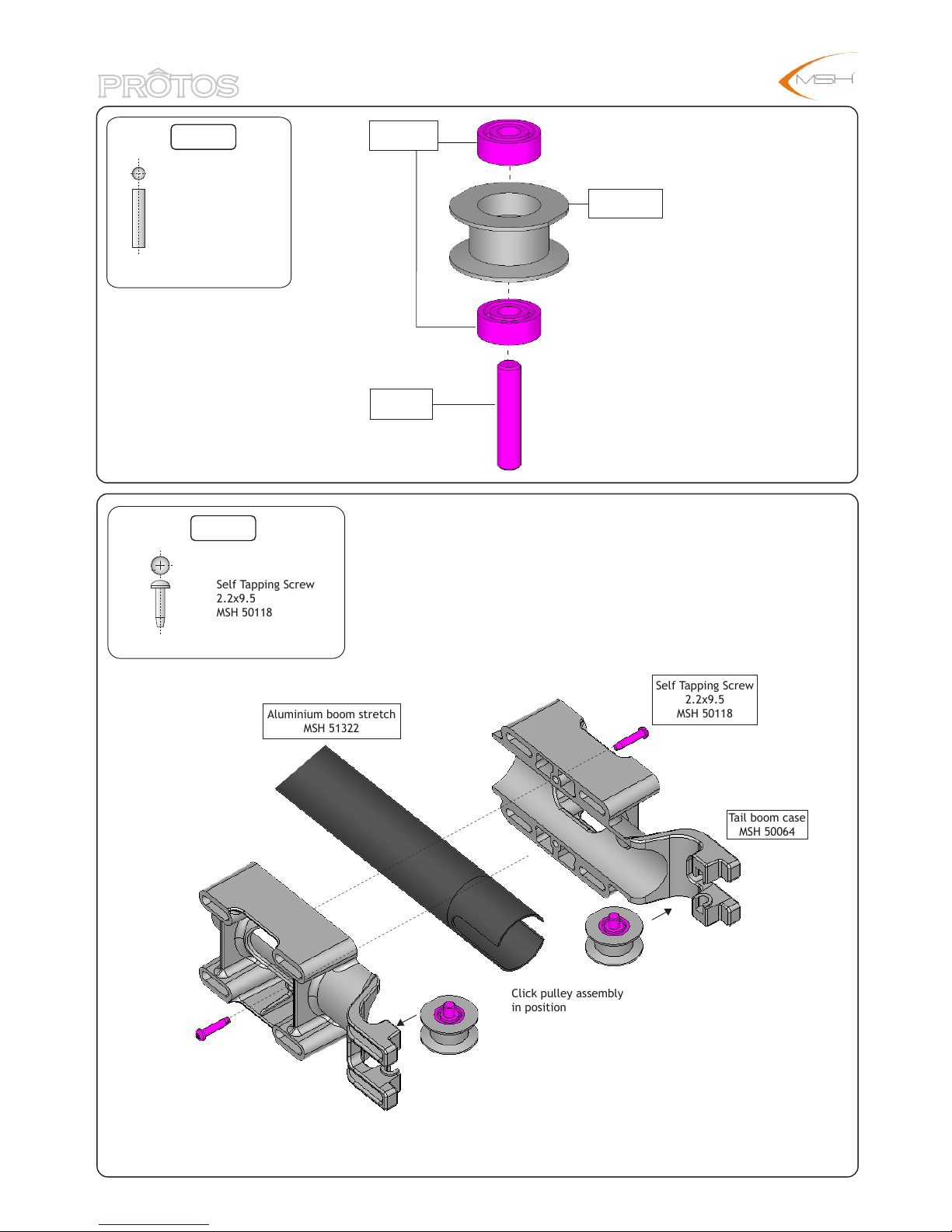

BAG-E

Self Tapping Screw

2.2x9.5

MSH 50118

Self Tapping Screw

2.2x9.5

MSH 50118

Aluminium boom stretch

MSH 51322

Click pulley assembly

in position

Pin 3x14

MSH 50059

BAG-E

Pin 3x14

MSH 50059

BB 3x8x3

MSH 50033

Guide Pulley

MSH 50091

Tail boom case

MSH 50064

20

Table of contents

Other Protos Toy manuals

Popular Toy manuals by other brands

RotorWay

RotorWay Exec 162 Construction manual

Enabling Devices

Enabling Devices Dance and Move BeatBo 9231 user guide

Gemmy

Gemmy AIRBLOWN INFLATABLE 25663 instructions

Fisher-Price

Fisher-Price V4377 manual

Mega Bloks

Mega Bloks 3-in-1 Ride-On Firetruck instructions

PlayMonster

PlayMonster Fuzzikins Unicorn Sleepover FF009 instructions