RotorWay International

Exec 162F Construction Manual

Section 1

Page 2

Rev. 3 10/01

C. There are three types of fits normally used in assembling shafts and bearings:

1. The press fit. A press fit is one which requires a press to install the bearing. It may take anywhere from one

hundred to several hundred pounds of pressure to press the bearing on the shaft. RotorWay does not expect the

builder to work with this type of fit because it will make assembly impossible for a builder in the field.

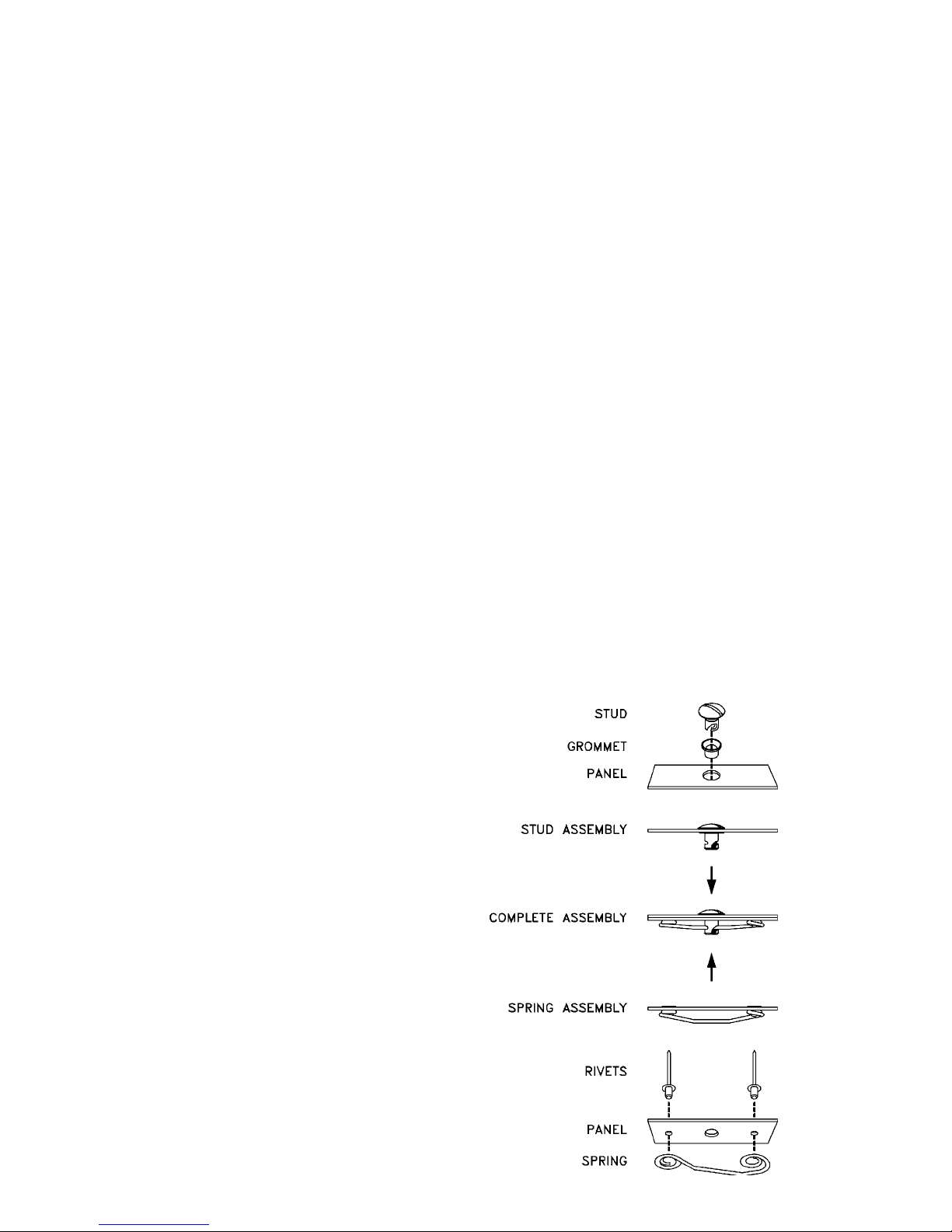

2. The slip fit. A slip fit is one in which the bearing may be rotated onto the shaft by hand. The inner race should be

rotated as the bearing is slid on the shaft. It will take a little hand pressure to force on a slip fit; however, no other

means but hands will need to be used.There are several slip fits used on the EXEC 162F helicopter. In each case,

on final assembly, you will clean the surfaces and coat them with Loctite prior to installing the bearings. A slip fit

plus Loctite results in a fit almost as permanent as a press fit.

3. The loose fit. A loose fit is one in which the bearing may be dropped onto the shaft and will slide in place. If this

fit results in over .001" in airspace around the shaft circumference, it is too loose for a highly loaded operation,

even with the use of Loctite.

D. How to Remove Loctited Bearings:

Removing a bearing which has been Loctited in place will require heating the inner race of the bearing. A bearing

puller should be installed on the bearing and a slight pressure applied to it. As the inner race is heated, the bearing will

pop loose. Obviously, the bearing must be replaced on reassembly, as the seals will have been damaged during the

heating process. Do not place heat directly on the shaft, only on the inner race of the bearing.

3. AIRCRAFT (AN) HARDWARE

A. Several types of hardware are used on RotorWay helicopters including standard AN hardware and various military

specifications (MS). Do not substitute the original hardware with bolts made from a lesser strength material. Hardware

store variety nuts and bolts are normally mild steel and are not heat treated. AN hardware is twice as strong as most

mild steel bolts of the same size.

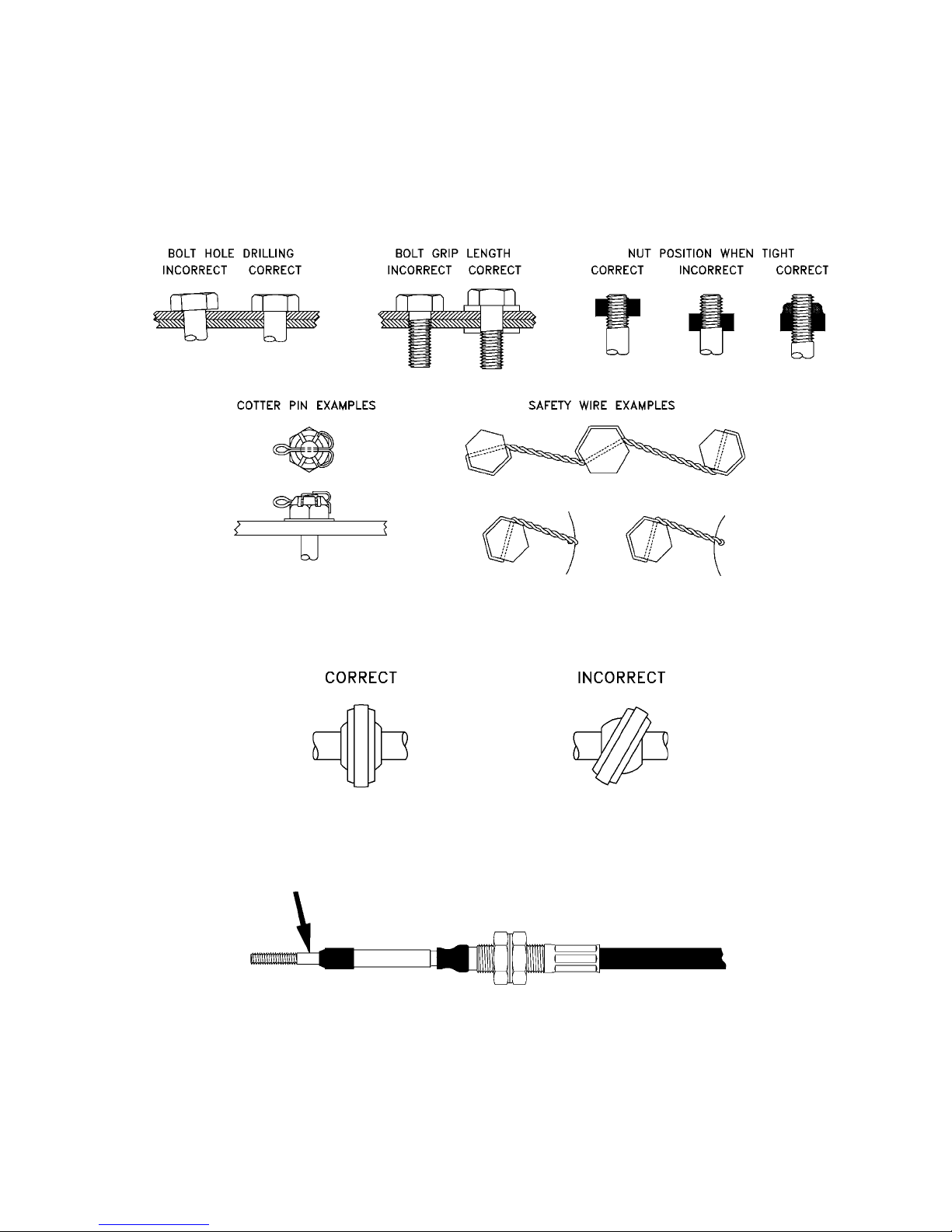

B. Elastic lock nuts (also called fiberlock nuts) are used in many places on the helicopter. These nuts are made with a

fiberous collar in one end to keep them from vibrating off. After tightening, a minimum of 1 and a maximum of 3

threads should extend past the end of the nut. Nuts must not bottom out on the threads. Do not attempt to tap threads

further on an AN bolt. It is acceptable to use up to 2 washers underneath the head of the bolt and/or the nut prior to

going to the next shorter length of bolt. Every length of every size of AN hardware is very difficult to find, therefore the

use of extra washers is occasionally necessary.

C. Unless otherwise noted, all bolts used as pivots or hinges in operation must use castellated nuts and cotter pins.

(Examples: swash plate scissor and tail rotor actuator arm). In these applications, the nut must not be tightened to a

point where the bolt is not free to rotate. The cotter pin should fit snug in the hole.

D. Do not use elastic lock nuts on bolts which have cotter pin holes in the threaded end, as the sharp edge of the hole will

cut the locking device rendering it ineffective.

E. All bolts without elastic lock nuts or other locking devices must be safety wired to prevent them from vibrating loose

during flight.

F. Use the following torque specifications on 3/16" through 3/8" bolts, nuts and set screws unless otherwise noted in the

construction drawings or photo sequence:

BOLT SIZE TORQUE

3/16" .................... 4 ft. lbs.

1/4" ...................... 7 ft. lbs.

5/16" .................. 12 ft. lbs.

3/8" .................... 16 ft. lbs.

A bolt and nut installed through thin walled material (or tubing without a bushing) should be tightened until snug and

secure, without causing the material to distort. For example, the bolts which attach the vertical trim fin to the bracket

should not be tightened to the specified torque value if it would crush or distort the airfoil.

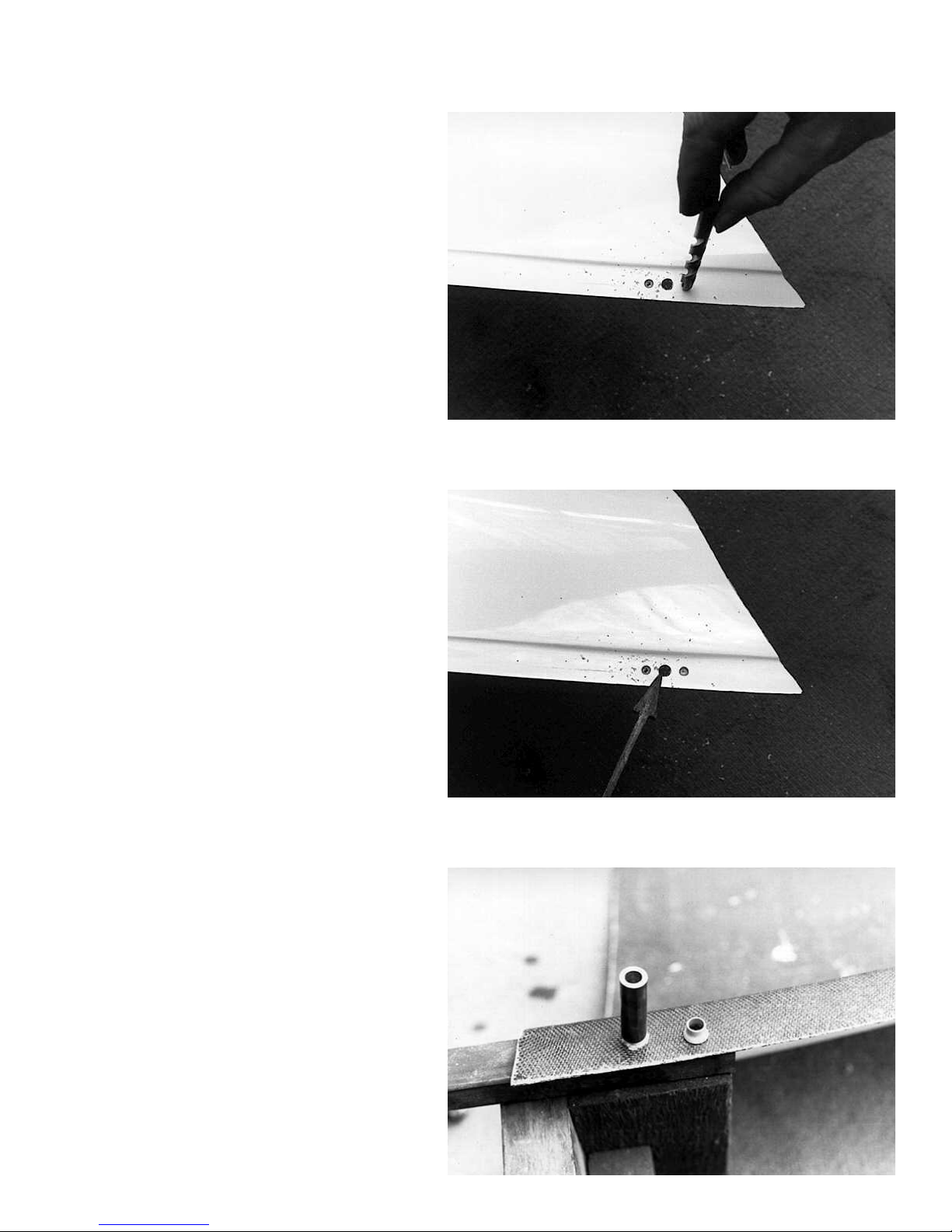

G. Make sure bolt holes are perpendicular (90 degrees) to the surface involved and are not oversized. A bolt in an

incorrectly drilled hole will not carry its shear load until the surface that is in contact with the bolt has deformed.

Contact Rotorway before drilling oversized or elongated holes in critical components, as there are many factors to be

considered.