PROTRAKKER 400DB User manual

REV 1

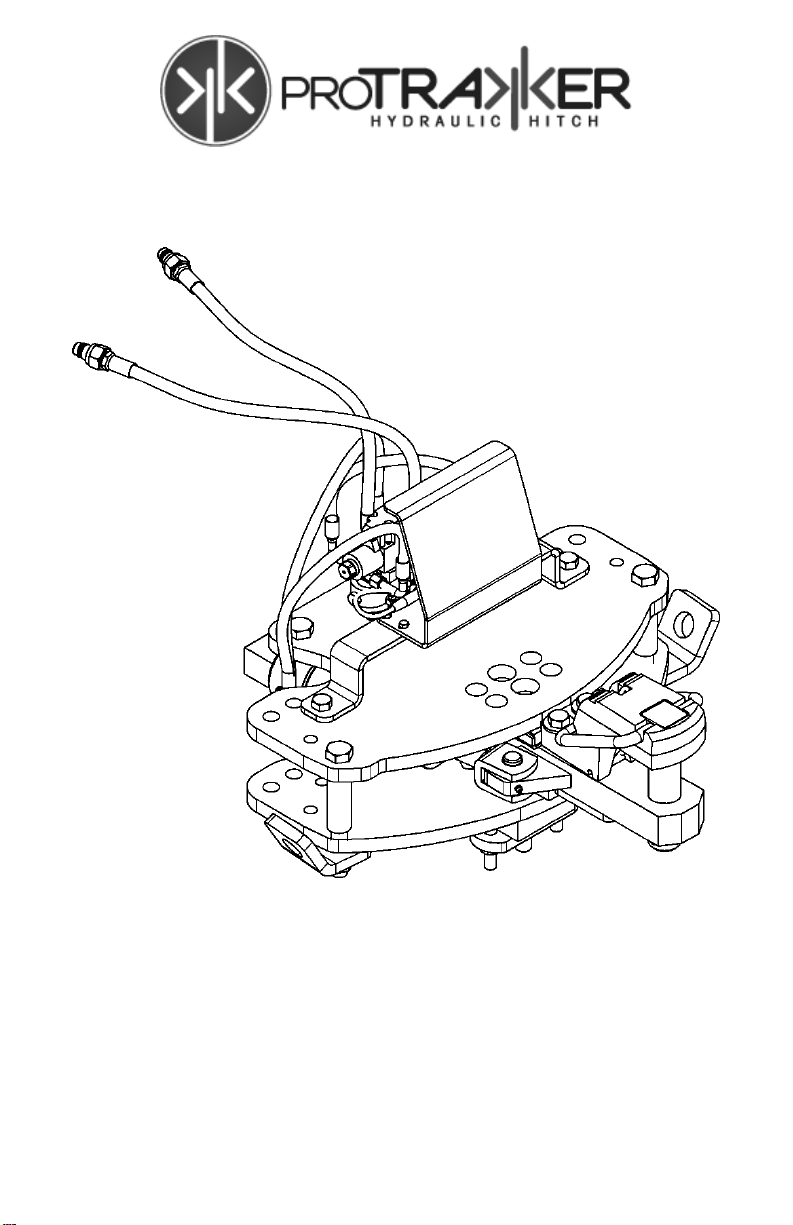

400DB HYDRAULIC HITCH

OWNER’S MANUAL

Page 2

REV 1 www.proTrakker.com

Page 3

REV 1 www.proTrakker.com

Table of Contents

Specifications........................................................................4

Contacting the Company ......................................................4

Safety Instructions ................................................................5

Maintenance .........................................................................6

Troubleshooting....................................................................7

Installation Instructions .........................................................8

Manual Hitch Operation ......................................................21

Parts Diagram: 400DB ASSEMBLY....................................22

Parts Diagram: 400DB DRAWBAR ASSEMBLY.................24

Parts Diagram: 400DB VALVE & COVER...........................26

Parts Diagram: MANIFOLD ASSEMBLY ............................28

Parts Diagram: CAB CONTROL ASSEMBLY.....................29

Protrakker™ Hydraulic Hitch Quick Reference Guide.........30

Page 4

REV 1 www.proTrakker.com

Specifications

Hydraulic Requirements:

Single Hydraulic Outlet, Continuous Duty

Flow Rate: 1.5 gpm

Pressure Range: 2250-3000 psi

Electrical Requirements:

Maximum Current: 3.5 amps

Voltage Range: 9-16 Volts DC

Capacity and Performance:

Maximum Vertical Load: 10,000 lbs

Power Rating: Up to 400 HP

Left/Right Travel: 26 inches

Standards and Limitations:

Not for use with PTO drive-line powered equipment

Contacting the Company

MBW

122 North Des Moines Street

Odebolt, Iowa 51458

U.S.A.

Toll Free: 877.568.4240 (Monday –Friday, 7:30AM –5:30PM U.S. CST,

Saturday 7:30AM –12:00PM U.S. CST)

Local/International Phone: 1.712.668.4240

Fax: 1.712.668.2311 (24 hours, 7 days/week)

Email: cory@mbwproducts.com

Website: www.proTrakker.com or www.mbwproducts.com

Page 5

REV 1 www.proTrakker.com

Safety Instructions

Read and understand the information in this manual

before installing or operating this system.

Inspect this system for damage and/or wear before

every operation. Replace any damaged or worn

components before using.

Never work alone.

Never operate this system with guarding removed.

When preparing to install or maintain this system, the

tractor wheels need to be blocked to prevent

movement and any jacks or lifts used should be

appropriate for the weight to be lifted, stable and in

good condition.

Hydraulic lines should be inspected for wear and

cracks. Any indication of damage to these lines

should be immediate grounds for replacement of the

line.

Caution should be taken when working on hydraulic

systems. Ensure all pressure in the system is relieved

properly and that the fluid is cool before loosening any

fittings or removing lines.

Use appropriate personal protective equipment (PPE)

when performing maintenance on hydraulic systems,

such as safety glasses with approved side shields,

heavy leather work gloves, and coveralls or an apron.

The tractor 3-point may settle during operation. Be

sure to check and apply chain tension by ‘bumping’

up the 3-point often.

Page 6

REV 1 www.proTrakker.com

Maintenance

Initial Installation: After the first few hours of operations,

check the tightness of all hardware. Substantial wear will

occur to the product and implement if fasteners and

hardware are not properly secured.

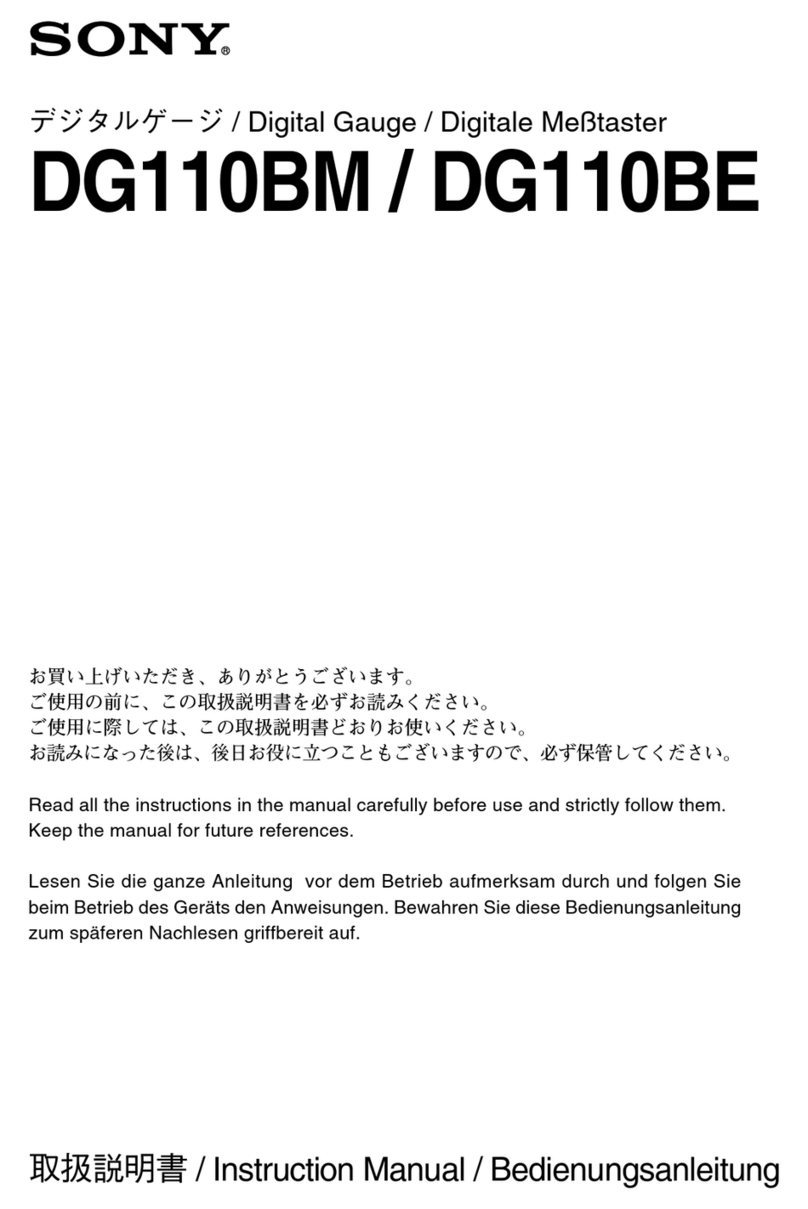

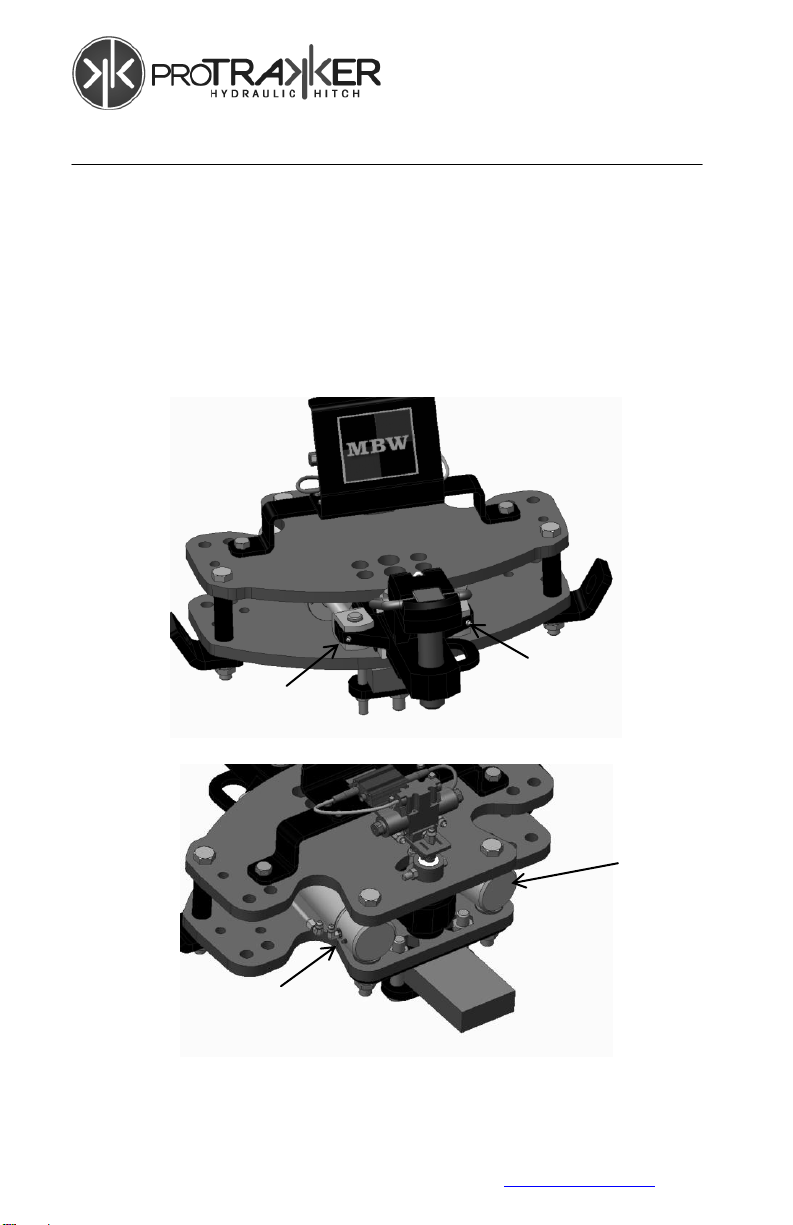

Grease Fittings: Proper lubrication of the 4 grease

locations at 12-hour intervals will dramatically prolong the life

of the product.

Bolts: If the 1” bolts become loose for any reason, they must

be tightened to 580 ft-lbs. Check the bolts periodically.

2

1

3

4

Page 7

REV 1 www.proTrakker.com

Troubleshooting

Problem: The hydraulic hitch does not move

The tractor hydraulics are

not active.

Make sure the hydraulic hoses are

hooked up correctly (line labeled

pressure; the other line return).

Poor electrical connection.

Check indicator lights on the hydraulic

block coil connectors. If no light, check

cable connections. If lights show, then

replace the coil.

Problem: The hydraulic hitch moves the wrong direction

The tractor hydraulics are

reversed

Make sure the hydraulic hoses are

hooked up correctly (line labeled

pressure; the other line return).

Problem: The hydraulic hitch seems very “jerky” and seems to

“hunt” when the tractor is at a standstill.

The hydraulic flow is too

fast

Turn the oil flow way down. The slower

the hitch moves, the better it will

perform.

If your tractor hydraulics will not turn

down far enough, MBW offers a needle

valve to put inline.

Too much 3-point

movement

Tighten up drawbar and/or 3-point slap.

When the hitch stops it will sense any

looseness or slop and a chain reaction

will occur.

Page 8

REV 1 www.proTrakker.com

Installation Instructions

Tractor Preparation

Before installing the 400DB, park the tractor on a smooth

level floor with adequate clearance to work around the

drawbar area.

Hitch Preparation

Use a lift or hoist to lift the 400DB assembly.

If the tractor is equipped with a drop-style drawbar, be sure

that the drop is down. The Protrakker Hydraulic Hitch

requires a minimum mounting clearance of 14 1/4 inches

between the center of the draw-pin hole and rear of the

tractor support casting.

WARNING!

Installation of this system will change the leverage on the rear

of the tractor. Some implement/tractor combinations may

require added weight to the front of the tractor to improve

handling. Test the steering performance of the tractor with the

implement in all configurations before use and add weight if

needed. Review your tractor’s specifications for instructions

and limitations.

Page 9

REV 1 www.proTrakker.com

Mounting Hardware

ITEM

PART #

DESCRIPTION

QTY Provided

1

B10-400DB

BOLT 1 X 6

1

2

B12-400DB

BOLT 1 X 5

2

3

B13

BOLT 3/4 X 6

2

4

MB15-400DB

CLAMP PLATE 3/4 IN THICK

3

5

MB32-400DB

CLAMP PLATE 1/2 IN THICK

3

6

MB33-400DB

CLAMP PLATE 1/4 IN THICK

2

7

MB40-400DB

REAR CLAMP PLATE

1

8

MB81-400DB

SPACER BUSHING

1

9

N6

LOCKNUT 3/4

2

10

W5

1IN LOCKNUT NC

1

11

W8

1IN NUT NF G9

2

CH1

DRAWBAR SUPPORT CHAINS (not shown)

2

Page 10

REV 1 www.proTrakker.com

Determine Proper Mounting Configuration

Note: The mounting hardware included with the ProTrakker

unit is compatible with common straight or offset drawbars.

Not all hardware will be used. Some drawbars may require

additions or modifications to the hardware to allow the unit to

be properly mounted. Contact MBW if you are not certain if

your drawbar is compatible with the hardware provided.

Different combinations of

supplied spacer plates

will be used depending on

offset in tractor drawbar.

Example: ¾ & ½ inch

thick spacers used with a

1 ¼ offset drawbar

Spacer plates used to

ensure the hitch is level

after installation.

A wedge spacer is available for

mounting to sloped drawbar

surfaces. Contact MBW if Wedge

is required. The wedge may

need to be modified to match

the drawbar slope.

The drawbar spacer

bushing is inserted into

the drawbar hole.

Page 11

REV 1 www.proTrakker.com

Protrakker Hydraulic Hitch Preparation:

Drop both Hex Nuts

into the front of the

Protrakker Hitch.

Page 12

REV 1 www.proTrakker.com

Ensure you have the proper spacer plates positioned on the

tractor drawbar correctly. Use a straightedge as shown to

figure out how many spacer plates you need. Note: Straight

tractor drawbars will not require spacer plates in-between

Protrakker Hitch and tractor drawbar, but will be needed on

the bottom side of the tractor drawbar to properly space

bolts.

Drop all three bolts

into rear of the

Protrakker Hitch

Page 13

REV 1 www.proTrakker.com

Mounting the Protrakker Hydraulic Hitch

Using a forklift or chain hoist, position the Protrakker

Hydraulic Hitch over the tractor drawbar as shown. Center

the Protrakker Hitch directly over the tractor drawbar with the

draw-pin hole lined up over the center or the corresponding

Protrakker Hitch mounting hole. Carefully lower the

Protrakker Hitch down ensuring all bolts and spacers fall into

place.

Page 14

REV 1 www.proTrakker.com

Install Hammerstrap at Front of Drawbar

Note: The mounting hardware included with the ProTrakker

unit is compatible with common straight or offset drawbars.

Some drawbars may require additions or modifications to the

hardware to allow the unit to be properly mounted. Contact

MBW if you are not certain if your drawbar is compatible with

the hardware provided.

Install 3/4” thick hammer strap clamp (F) and spacer bushing

(G) underneath tractor drawbar and secure with 3/4” flanged

nuts (D).

D

F

G

Page 15

REV 1 www.proTrakker.com

Install Hammerstrap at Rear of Drawbar

With the rear Protrakker Hitch bolts secured, slide

underneath of hitch and install front Protrakker Hitch

hammerstrap (F). Carefully thread the bolts (B) into hex nuts

(C) at the front of the Protrakker Hitch.

BE SURE THE HAMMERSTRAP CLAMP IS LEVEL WITH

THE HITCH. THE WEDGE CLAMP OR OTHER

MODIFICATIONS MAY BE NEEDED IF POSITIONED ON

THE SLOPE OF THE TRACTOR DRAWBAR.

F

B

C

Page 16

REV 1 www.proTrakker.com

4 Inch Wide Drawbars

4 inch wide drawbars will require the 1¾” OD and 2” OD

spacer bushings to eliminate gap between the bolts and

drawbar.

1¾” OD

BUSHING

2” OD

BUSHING

4” WIDE

DRAWBAR

Inspect the installation to

ensure there is minimal gap

between the bolts or bushings

and the drawbar. If your

drawbar width is not

accommodated by bolt

positions and bushings,

contact MBW for special

components.

Page 17

REV 1 www.proTrakker.com

Tighten Mounting Hardware

With all the hardware in place, remove chain hoist and

tighten 3/4” bolts and nuts to a torque 350 foot pounds and

1” bolts to a torque of 580 foot pounds.

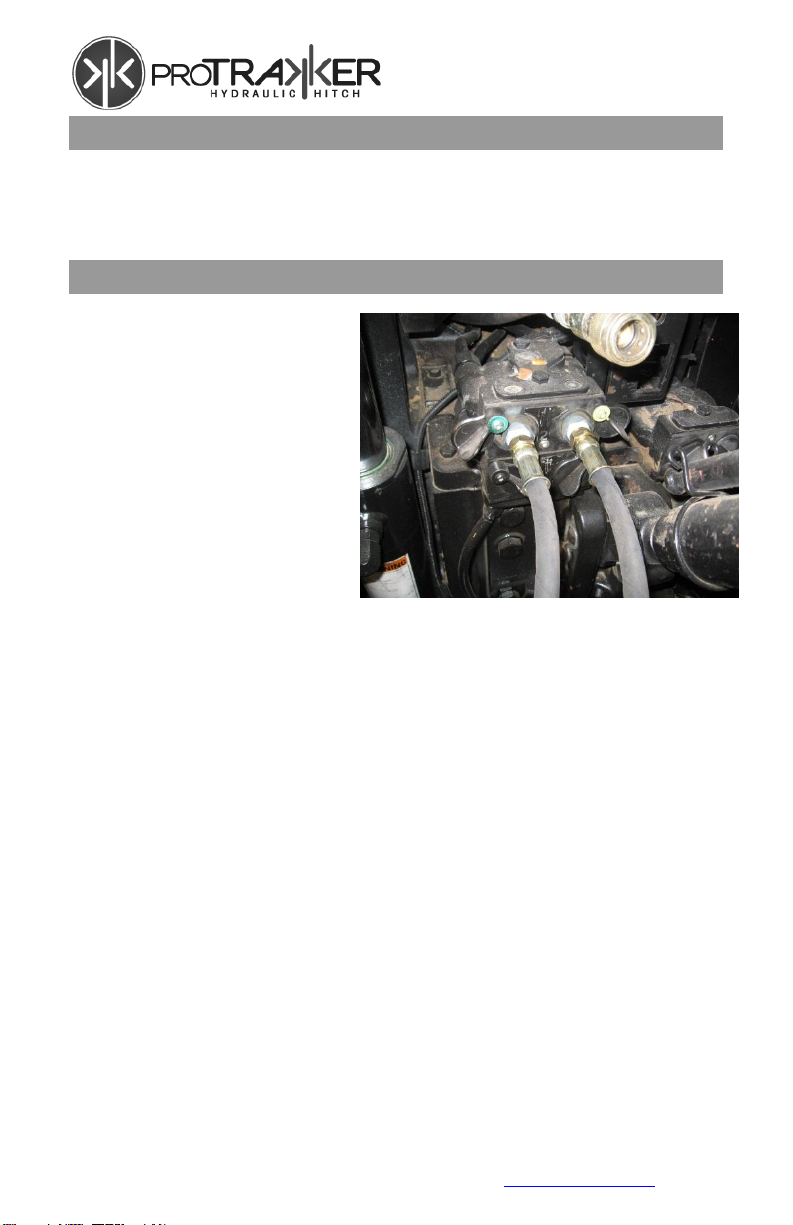

Connect Hydraulic Hoses

Connect the supply lines

to the tractor remote

outlets so that the line

labeled pressure line is

pressure and the other

line being return.

Page 18

REV 1 www.proTrakker.com

Install Drawbar Stabilizer Chains

With the two-point of the tractor in the complete raised

position, loop the chain through the drawbar stabilizer chain

brackets located on each side of the Protrakker Hitch and

over the tractor two-point as shown.

Hook the chains as tight as possible. With chains hooked,

lower the tractor’s two-point approximately six inches and

tighten each chain one more link only. Raise the two-point

up and tie-up excess chain.

WARNING

CHAINS MUST BE INSTALLED AS INSTRUCTED.

FAILURE TO PROPERLY INSTALL STABILIZER

CHAINS COULD RESULT IN SERIOUS INJURY AND

DAMAGE TO EQUIPMENT

WARNING

HYDRAULIC DRIFT WILL CAUSE SLACK IN THE

SAFETY CHAINS. ALWAYS CHECK FOR HYDRAULIC

DRIFT ON THE 3-POINT SYSTEM BEFORE USING

THE DRAWBAR. CHECK FOR DRIFT OFTEN WHILE

USING THE DRAWBAR.

Stabilizer Chain

Brackets

Page 19

REV 1 www.proTrakker.com

Be sure the tractor drawbar remains down on the support

casting. Chains are made to help stabilize the drawbar, and

not made to carry the entire load.

Mounting the Console

The RAM Mounting System provided

gives you many options for mounting

your console. It fits many different sizes

of monitor bars inside the tractor cab.

Install Power and Control Cables

Install the four-pin cable to the

control box on the Protrakker

Hitch. Carefully route the four-

pin cable up to the tractor cab.

Install the four-pin connector to

the console and then install the

remaining two-pin power cable.

Page 20

REV 1 www.proTrakker.com

Route the power cable to a reliable 12-volt supply. We

recommend going directly to the battery.

Red wire = positive

Black wire = negative

Powering Up

With the control console in the off

position, start up the tractor. Lock the

correct hydraulic lever into place and

turn console to manual mode. Using

left and right jog button, observe the

indicator and hitch moving. Switch to

auto mode and take tractor to a hillside

to observe auto mode working. Note:

If these modes are not working

properly switch around the

pressure and return lines.

Manual Mode: This function enables

the operator to move the hitch left or

right by using the jog switch.

Auto Mode: This function enables the hitch to sense side

hill slope and automatically compensates to establish level

reference value.

Gain Function: This enables the operator from the cab to

adjust the Hitch travel more or less per degree of slope.

This is particularly useful when switching to implements with

different pin to axle lengths.

GPS Ready Models: Follow steps 1-7 for mounting

instructions.

GPS wiring harness will be plugged into the Protrakker’s

position sensor cable. All further set-ups will be done by your

GPS provider.

Table of contents