0330-0653-0M Rev D • DC Load Cell Kit

TABLE OF CONTENTS

INTRODUCTION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 1

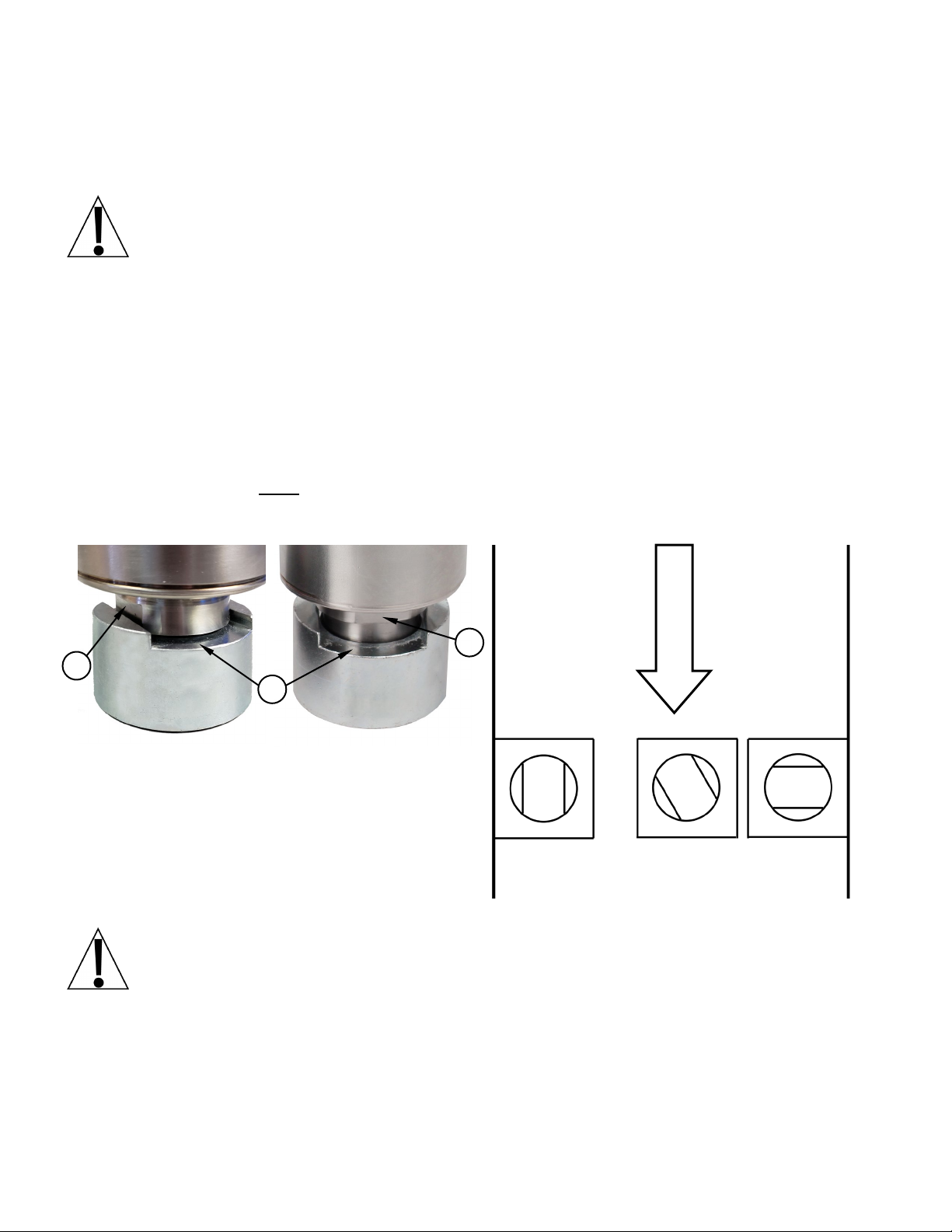

LOAD CELL INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 2

LATERAL AND LONGITUDINAL CHECKING . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 3

INSTALLING LOAD CELL CABLES . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

HOMERUN CABLE INSTALLATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Maximum Homerun Cable Length Chart . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 6

225D Indicator Connection . . . . . . . . ... . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 8

Re-Installing the 225D Indicator Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 10

225DLC Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

825D Indicator Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Re-Installing the 825D Indicator Rear Panel . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 13

825DLC Controller Card . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 14

Load Cell Connection . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 16

GROUNDING INSTALLATION INSTRUCTIONS . . . . . . . . . . . . . . . . . . . . . . . . . . . .

SETUP AND CONFIGURATION . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Digital Scale Setup and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 20

To Begin 225D Setup and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

Addressing Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 21

End Nodes . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

225D Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smart Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 23

Trim Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 24

Span Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

To Begin 825D Setup and Configuration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Login . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 26

Setup Scale Number . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 27

Setup DLC Card 1 . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 28

DLC Card 1 Cell Assignment . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Smart Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .

Zero Calibration . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 42

Trim Cells . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 45

Span Adjust . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . 51

BALANCING WEIGHBRIDGE DEAD LOAD . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . . .