STS STS809 User manual

V.4.00

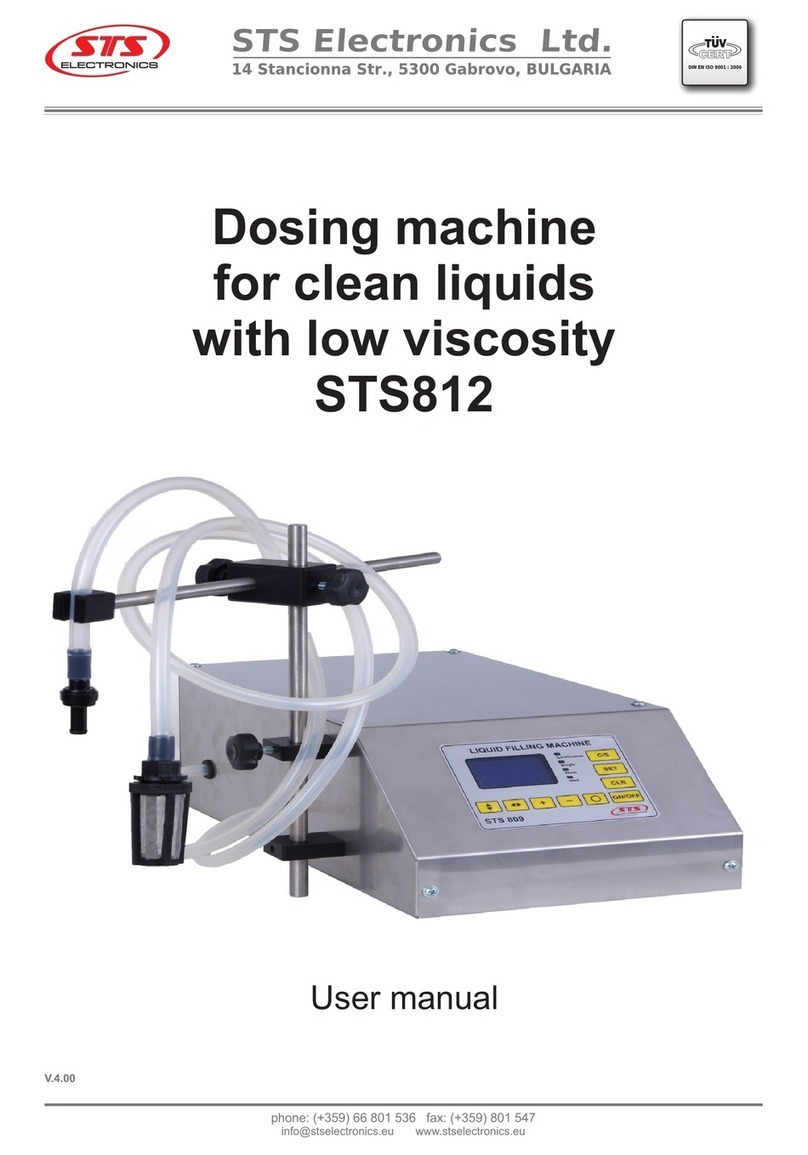

Dosing machine

for clean liquids

with low viscosity

STS809

User manual

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

- 2 - STS809V.4.00

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

Description

STS 809 is a compact portable filling and dosing machine for clean / without solid

particles / liquids, low viscosity (water, olive oil, fuel, etc.).

The control is realized with microcontroller which allows the fluid to flow smoothly and

accurately by controlling the pump in time and speed. There are 10 different dosing programs

with quick access. The number of doses is visualized on the display and can be reset

manually. The dosing modes are two: single dose - start from an external input / pedal / and

continuous operation - alternate work and waiting.

For automation purposes, the machine is equipped with an output which send a signal

for finished work in single dose mode.

The body is made of stainless steel. The filling stand is moveable, providing a high

degree of freedom. The pump is diaphragm for high pressure. The suction filter protects the

pump from the suction of solids and the valve at the outlet which keep from drops after

finishing the dose.

Power supply: 220Vac, 50Hz.

Own consumption: < 60VA.

Electrical connecting: cable with plug type 'SHUKO'.

Input ‘start’: NPN.

Output ‘done’: NPN, 100mA.

Maximum capacity /for water/: 3,2 liters / minute.

Fluid operating temperature: 10 ... 55 °C.

Select pump speed: 45, 55, 65, 75, 80, 85, 90, 95, 100 %.

Working time / dosing /: 0,01 ... 99.99 s.

Stand-by Time: 0,01 ... 99.99 s.

Number of dosing programs: 10.

A dose counter: 0000 ... 9999.

Overall dimensions: 185mmW, 130mmH, 350mmD.

/without the filling stand/

Filling stand dimensions: 2х300mm.

Length of the suction hose: 1200mm.

Length of the dosing hose: 800mm.

Diameter of the suction filter: 32mm.

Weight: 3,6 kg.

Connector М12F:

- pin 1 +Vcc /15Vdc/;

- pin 2 output ‘dosing’;

- pin 3 GND;

- pin 4 input ‘start’.

Technical data

- 3 -

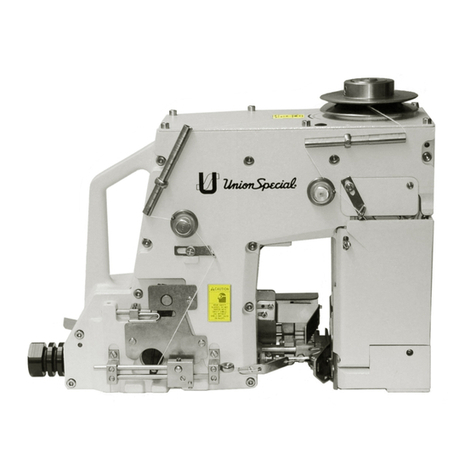

STS 809

LIQUID FILLING MACHINE

Continuous

Single

Work

Wait

+_ON/OFF

C/S

SET

CLR

STS 809

-----------------------------

Version 3.0

-----------------------------

STS809V.4.00

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

Preparation for work and setup.

` Place the machine on a flat surface. Check the suction hose suction filter and install

the outlet valve of the dosing hose - attention for the valve direction. Mount the filling stand -

the shoulder is crosswise. The end of the dosing hose with the valve is mounted in the

bracket. The suction filter is placed in the tank below the liquid level. The position of the

machine should be higher.

Connect the pedal switch by the connector at the rear part of the machine. Connect

the power cable to the rear socket and plug into the power grid.

Power on the machine from the switch near to the power cable. The display shows a

welcome logo the machine name and the software version and goes to the operating mode of

the last working program. By repeatedly pressing the program selection button, we select the

zero program - fig1. Changing parameters for it is easy to access and is easy to set up. The

PUMP SPEED 85%, WORK TIME 03.00s, PAUSE TIME 01.00s is set using the Parameter

Selection, Number, Reduction, and Increment buttons. The change digit is indicated by

blinking underlining. The current parameter is memorized when the next one is passed!

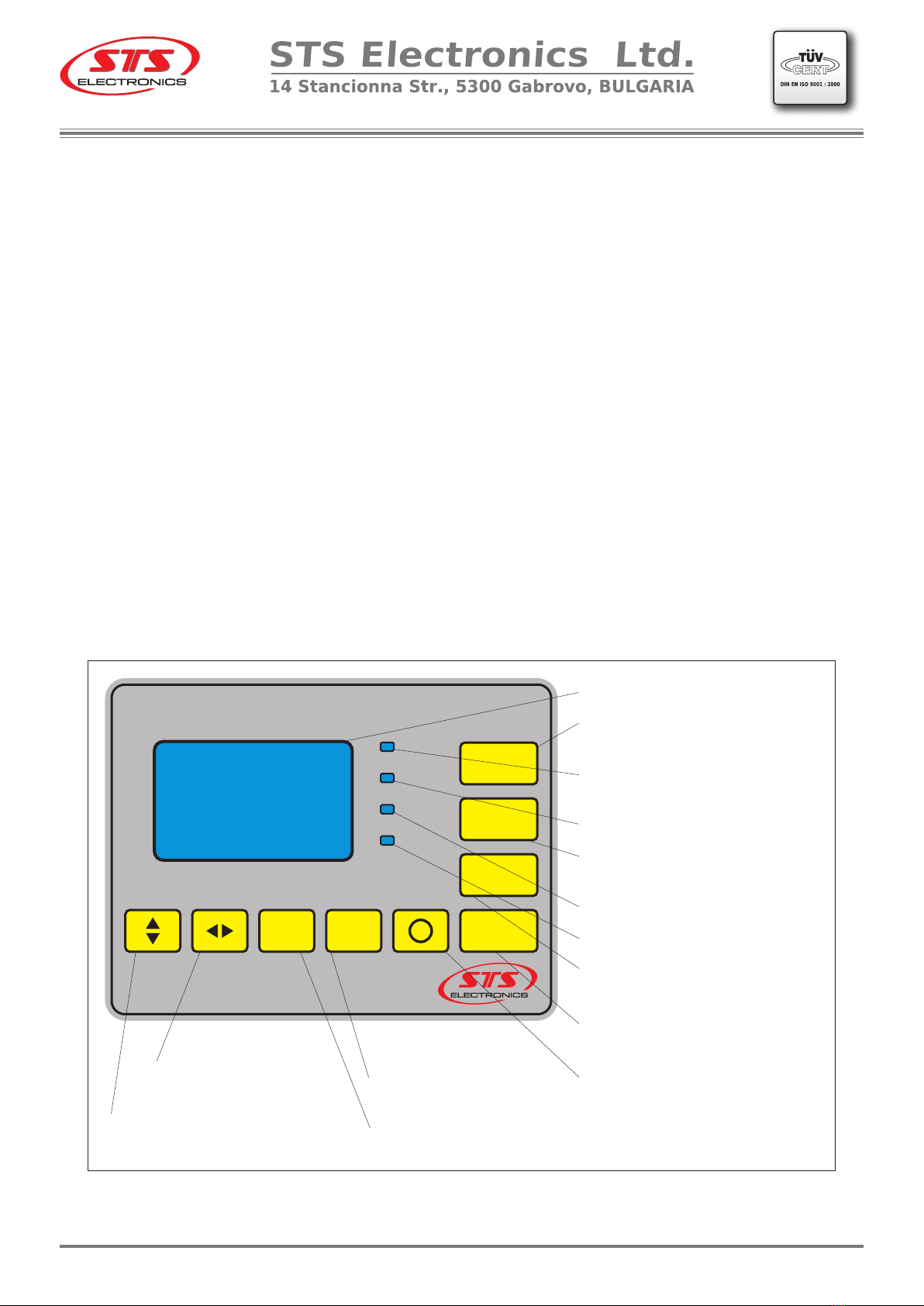

LCD

Indication -

continuous work

Indication - single dose

Indication - work

Indication - wait

Single dose button

/ continuous work

Menu access button

for programming

Button for reset the

dose counter

Selection button

work / wait

Selection button

for a program

Increase button

Selection button

for parameter change

Selection button

for number change

Decrease button

LIQUID FILLING

MACHINE

- 4 - STS809V.4.00

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

With change of parameters and control starts, the dosing time and the desired speed

are set. The machine can be stopped at any time by pressing the ( ON / OFF) button!

` Parameters can only be changed when the machine is stopped (Wait).

With an already specified mode, the parameters can be saved in any of the other 9

programs. With the created base of programs the machine can be setup to operate quickly

with various liquids and vessels.

To operate in continuous mode with already specified parameters and selected

program press the C/S button. The LED for single turns off and the one for continuous mode

turns on. The start of filling is done with a single push and release of the external pedal. The

LED for the mode is blinking. By pushing the pedal again set a pause of the mode / the LED

stop blinking and lights continuously /.

To maintain dosage accuracy, it is necessary to maintain a constant level in the

pumping vessel!

After finishing work, the system must be cleaned!

By the button for single dose / continuous - Single is selected, which is

indicated by the LED. A control vessel is placed under the valve. By pressing

the work / wait button (ON / OFF) the machine is allowed to operate. By

pressing the pedal you need to start several times until the air from hose is

out of the system.

To change or set parameters in programs 1 .. 9, the machine must be

stopped / Wait /.

By pressing the program selection key (O), the desired program is

entered or changed. Press and hold the SET button. The screen shown in

fig.3 is displayed. The button is released.

The PUMP SPEED xx%, WORK TIME xx.xxx, PAUSE TIME xx.xxx

can be change with the buttons for selecting a parameter, digit, decrease,

and increase. The change digit is indicated by blinking underlining.

Save the set values is done again by pressing and holding the SET

button until the screen shown in fig.2 is displayed.

Working with the menu and setting parameters.

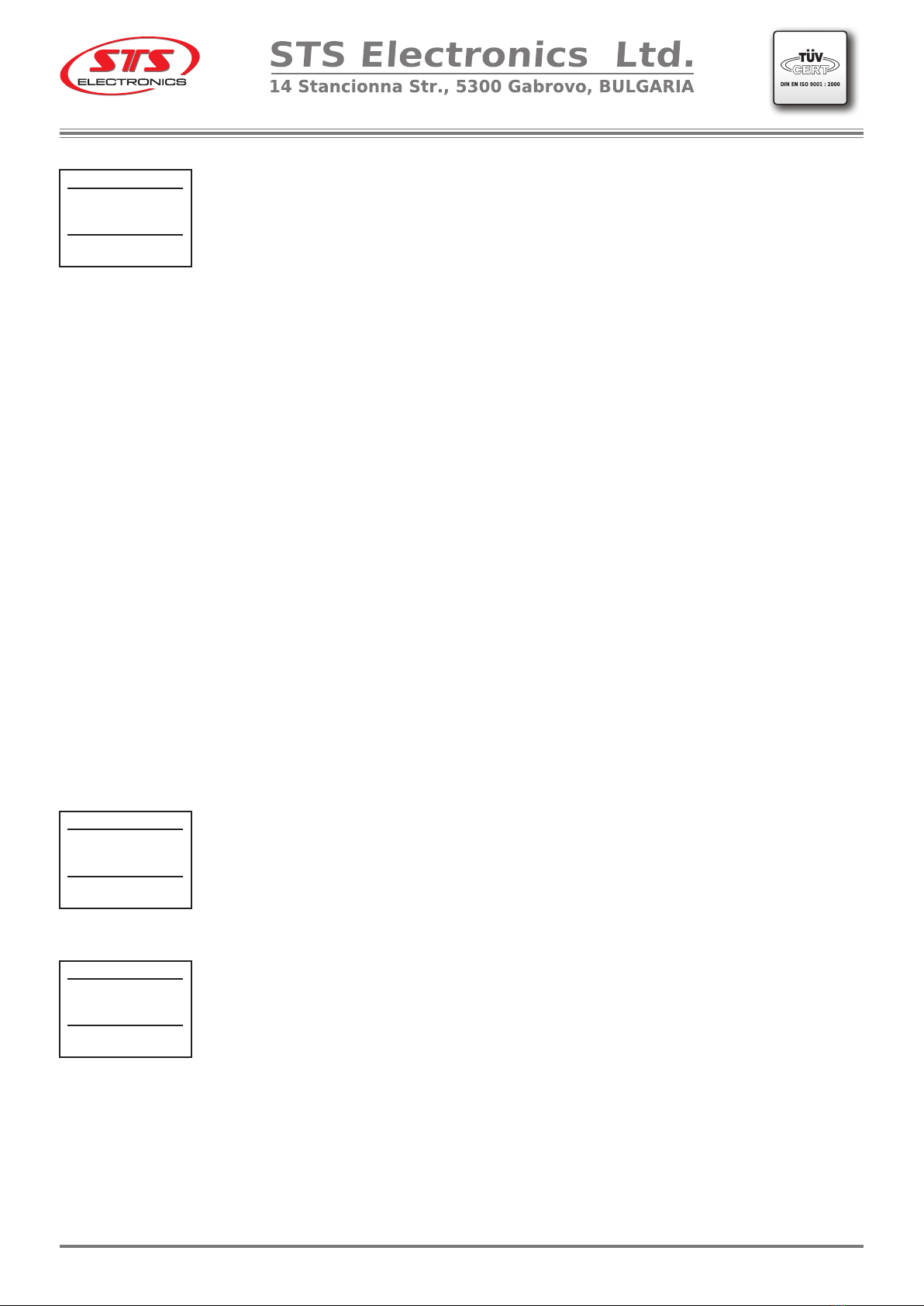

PROGRAM No 0

PUMP SPEED

WORK TIME

PAUSE TIME

85%

03.00 s

01.00 s

0000

NUMBER FILINGS

fig.1

PROGRAM No 6

PUMP SPEED

WORK TIME

PAUSE TIME

85%

03.00 s

01.00 s

0000

NUMBER FILINGS

fig.2

PROGRAM No6 PROG

PUMP SPEED

WORK TIME

PAUSE TIME

85%

03.00 s

01.00 s

0000

NUMBER FILINGS

fig.3

- 5 - STS809V.4.00

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

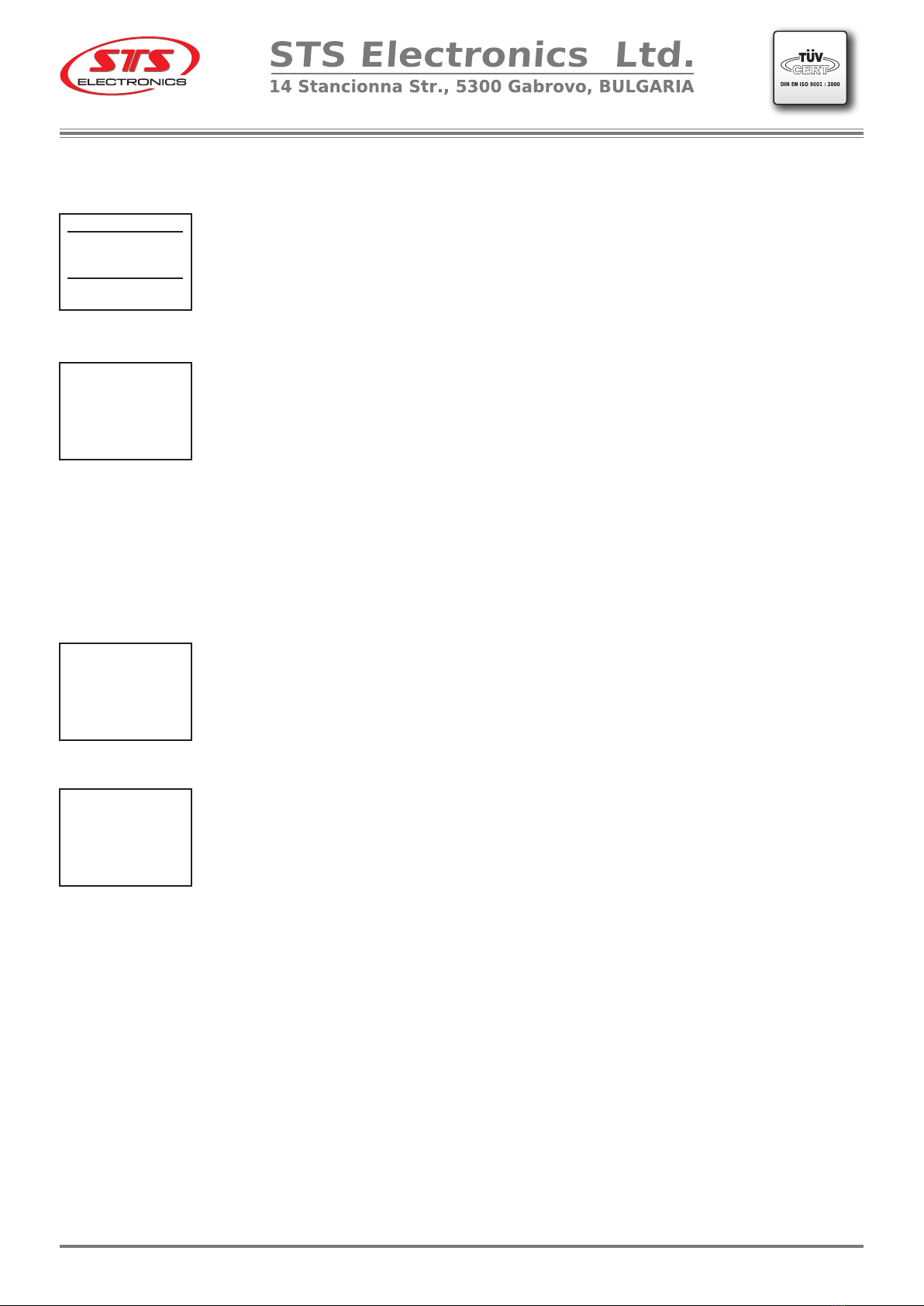

Setting the display contrast.

To change the contrast of the display, the machine must be stopped

/Wait /.

By pressing the program selection key (O), the zero program is

selected - fig.4. Press and hold the SET button. The screen in fig.5 is

displayed. The button is released.

By pressing decreasing and increasing /+ and - / buttons, the desired

contrast is set.

To save the set values again, press and hold the SET key until the

screen of fig. 4 is displayed.

Change the display language BG / EN,

setting the time for reverse suction

When the power is off press and hold the button /ON/OFF/. Turn on

the power. An advertising logo is displayed on the display, followed by a

language selection menu. The button is released.

By tapping the number selector button, it switches to 'e' / figure 6/ for

English and 'b' / figure 7/ for Bulgarian. It is confirmed by pressing the

parameter selection button.

Language select

fig.6

e

Language select

fig.7

b

------------------------------

------------------------------

PROGRAM No 0

PUMP SPEED

WORK TIME

PAUSE TIME

85%

03.00 s

01.00 s

0000

NUMBER FILINGS

fig.4

CONTRAST

MINUS

fig.5

PLUS

------------------------------

>>>>

------------------------------

NOTES

STS809V.4.00

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

STS809V.4.00

GENERAL CONDITIONS for usage of electronic devices:

The electronic devices are intended to be used in normal climate

conditions in an environment with a normal fire-safety, and without any

aggressive to the body material liquids and gases.

GUARANTEE CONDITIONS:

The guarantee period is 12 months from the date of selling.

The manufacturer does not take responsibility in the following cases:

- non-observance of storage conditions;

- non-observance of transport conditions;

- non-observance of operational conditions;

- natural disasters;

The guarantee is only valid if the device is mechanically intact, and there

is no sign of attempts for eliminating damage by unauthorized personnel.

Transportation expenses are on customer’s account.

Attention: No organic dissolvent agents should be used for cleaning the

front panel!

FACTORY NUMBER:_______________________________________

phone: (+359) 66 801 536 fax: (+359) 801 547

[email protected] www.stselectronics.eu

Table of contents

Other STS Industrial Equipment manuals