ProxiMity Quick-View QV Series Installation and operating instructions

Series QV Quick-View®Rotary Position Indicator/Switch

Specications - Installation and Operating Instructions

Bulletin F-87

Proximity Series QV Quick-View®Rotary Position Indicator/Switch is produced

with up to four individual mechanical or proximity switches. Instructions below include

installation, as well as adjustment procedures for direct drive and lever drive models.

INSTALLATION

1. Mounting kits, when provided include couplers, lever arms and screws for

mounting the position indicator to a valve or actuator. A position indicator is

mounted using direct drive hardware for quarter turn applications (rotational) and

lever drive hardware for converting linear motion to rotary. Tubular spacers are also

provided for some installations.

2. For direct drive models, attach appropriate drive yoke or solid block onto the two

pins,usinga#6-32X1/4˝screwprovided.Donotattempttofabricateyourown

yokes since this a special spring-tempered material. For direct drives, with the

actuator shaft rotated to its counterclockwise position, spread the driving yoke and

slip it down onto the square (or rectangular) shaft of the actuator. Attach bracket

with two hex cap screws. Before tightening screws, operate control slowly with

a wrench or power, and observe that drive shaft and drive yoke are concentric and

perpendicular throughout the complete stroke. Adjust position as required and

tighten all mounting screws. Check concentricity and perpendicularity.

3. Forleverdrivemodels,attachtheappropriatedrivingleverontotheshaft.Do

not tighten. Attach switch and bracket to actuator, making sure that the lever is

free to rotate over the entire range of the actuator stroke. Attach the driving pin

or bolt through the lever arm if slotted, or on the driving side of the lever. (It may

be necessary to loosen or remove the bracket mounting to accomplish this

connection on some actuators.) Operate the actuator very slowly and observe

movement of all pins and levers to be sure there are no interferences. Slide lever

up or down on switch shaft to the most desirable position. When all motions are

made and clearances are adequate, tighten clamp screw on lever that was left

loose above. Now tighten all the mounting screws. Re-check the travel of all levers

and pins for proper clearance throughout the complete stroke of the actuator.

4. Push cover down, then turn it counterclockwise and lift straight up to remove.

Remove inner cover window. Remove the indicator drum.

5. Switches are set at the factory in the counterclockwise position listed below:

2 Switch Unit #1 Open #2 Closed

4 Switch Unit #1, 3 Open #2, 4 Closed

90° rotational travel will reverse all of the above positions.

SPECIFICATIONS

Minimum Rotation Travel - Switches Only: 5°.

Maximum Rotation Travel - Switches Only: 360°.

Temperature Limits: -40 to 180°F (-40 to 82°C).

Switch Type: SPDT.

Electrical SPDT Switch Ratings: QV-X1XXXX: 10A @ 125/250 VAC; 0.5A 125

VDC;10A@24VDCmech.switch;QV-X2XXXX:0.1A@125VAC;0.1A@24

VDCmech.switch;QV-X3XXXX:2A@125VAC;2A@30VDCprox.switch;

QV-X4XXXX:5-25VDCnamursensor;QV-X5XXXX:10-30VDCinductivesensor;

QV-X6XXXX: 10A 125/250 VAC mech. switch.

Lighting Supply Voltage: 24-28VDC.

Enclosure Material: Polycarbonate housing and conduit.

Conduit Entrance: One3/4˝NPT.

Enclosure Rating: NEMA 4, 4X. Optional explosion-proof, rated: Class I, Groups A,

B,C,D;ClassII,GroupsF&G;Div.2.

Max. Altitude: 2000 m (6560 ft).

Agency Approvals: CE, CSA, cULus.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219-879-8000

Fax: 219-872-9057

www.dwyer-inst.com

e-mail: [email protected]

6-32 UNC

1/4 DP [6.350] 1/4

[6.350]

1/4

[6.350]

2-3/8

[60.33]

3-1/16

[77.79]

1-1/2

[38.10]

2 MTG HOLES

1/4-20 UNC

7/16 DP [11.11]

CONDUIT ENTRANCE

3/4 NPT

3 [76.20] CLEARANCE REQUIRED FOR COVER REMOVA

L

4-15/32

[113.5]

1/2

[12.70]

5/16

[7.938] 1/4 DIA. [6.350]

SHAFT LEVER

DRIVE ONLY

1/8 DIA. PINS (2)

4-3/4

[120.7]

MODEL CHART

Example QV -2 1 01 0 1 QV-210101

Series QV Quick-View®valve position indicator/switch

Number of

Switches

0

1

2

3

4

None*

One*

Two*

Three*

Four*

Switch Type 0

1

2

3

4

5

6

No switches*

10A mechanical snap switch

1A mechanical gold contacts

2A Proximity reed switch*

5-25VDCnamursensor

10-30VDCinductivesensor

10A mechanical snap switch

Driving Style 01

02

03

Direct*

Lever*

Namur*

Lighting

Option

0

1

None*

24-28VDCbrightwhiteLED’s

Visual

Indication

0

1

2

None

Standard (open closed)*

Upside down (open closed)*

Additional

Options

EX ClassI,Div.II,GroupsA,B,C&D;Class

II,Div.IIGroupsF&G.

*EX, Explosion-proof option available.

Note: The 1st, 2nd, 3rd and 6th codes can not all be zero.

ADJUSTMENT PROCEDURE

1. Using wrench or power, rotate the actuator shaft to extreme clockwise position

for direct drive applications. For linear applications, operate actuator to full closed

position. All switches should change to their appropriate functions.

2. The cam can be relocated and repositioned by loosening the set screw. To adjust

manual cams grasp cam on knurled segment of cam surface. Rotate cam

clockwise or counterclockwise to obtain correct actuation point. Feeling or sound

of clicks indicates incremental adjustments. Applying pressure on cam in direction

of actuation segment of cam surface, and rotating, eliminates incremental

adjustments. Stop rotating and release pressure on the cam when it is at proper

actuation point; this allows engagement of cam to spline. Check circuit to verify

contact at proper point. Rotate the shaft counterclockwise. Repeat all steps above

as necessary. Lock cam on spine with set screw provided for additional security.

3. Operate actuator to extreme opposite position to verify correct operation of

switch(es). Readjust as required.

4. ReplaceOPEN/CLOSEDindicatordrummakingsureincomingwiresaretucked

in so as not to rub against the drum. Replace cover window making sure it lines

up correctly with indicator to display the proper indication of valve position. Replace

snap-on cover.

WIRING

Complete all electrical wiring in accordance with Local and National Codes. Tighten all

screws. (Sealed leads are provided from the factory on request).

MAINTENANCE

The Series QV Rotary Position Indicator/Switch is not eld serviceable and should

be returned if repair is needed (eld repair should not be attempted and may void

warranty). Be sure to include a brief description of the problem plus any relevant

application notes. Contact customer service to receive a return goods authorization

number before shipping

Printed in U.S.A. 11/20 FR# 440980-00 Rev. 5©Copyright2020DwyerInstruments,Inc.

DWYER INSTRUMENTS, INC.

P.O. BOX 373 • MICHIGAN CITY, INDIANA 46360, U.S.A.

Phone: 219-879-8000

Fax: 219-872-9057

www.dwyer-inst.com

e-mail: [email protected]

24 VDC

POWER

SUPPLY

A-700

AVAILABLE

UPON

REQUEST

120 VAC

LIGHTING OPTION

CONDUIT

ENTRY

SWITCHING OPTION

NOTE: SWITCHES SHOWN ACTUATED BY THE CAMS

IN FULLY COUNTERCLOCKWISE POSITION.

SW 1

BOTTOM

SWITCH

SW 2

ABPVE 1ST

SWITCH

SW 3

ABOVE

2ND SWITCH

SW 4

TOP

SWITCH

HAZARDOUS LOCATIONS

• Keep cover tightly closed when in operation.

• De-energizesupplycircuitbeforeopening.

• To prevent ignition of hazardous locations, replace cover before energizing the

electrical circuits.

WARNING

ZONES DANGEREUSES

• Laisserlecouverclebienfermélorsquel’unitéestenservice.

• Couperlecircuitd’alimentationavantd’ouvrir.

• And’empêchertouteignitiondansdeszonesdangereuses,replacerlecouvercle

avant de mettre les circuits électriques sous tension.

AVERTISSEMENT

This symbol indicates waste electrical products should not be disposed

of with household waste. Please recycle where facilities exist. Check with

your Local Authority or retailer for recycling advice.

Other ProxiMity Switch manuals

Popular Switch manuals by other brands

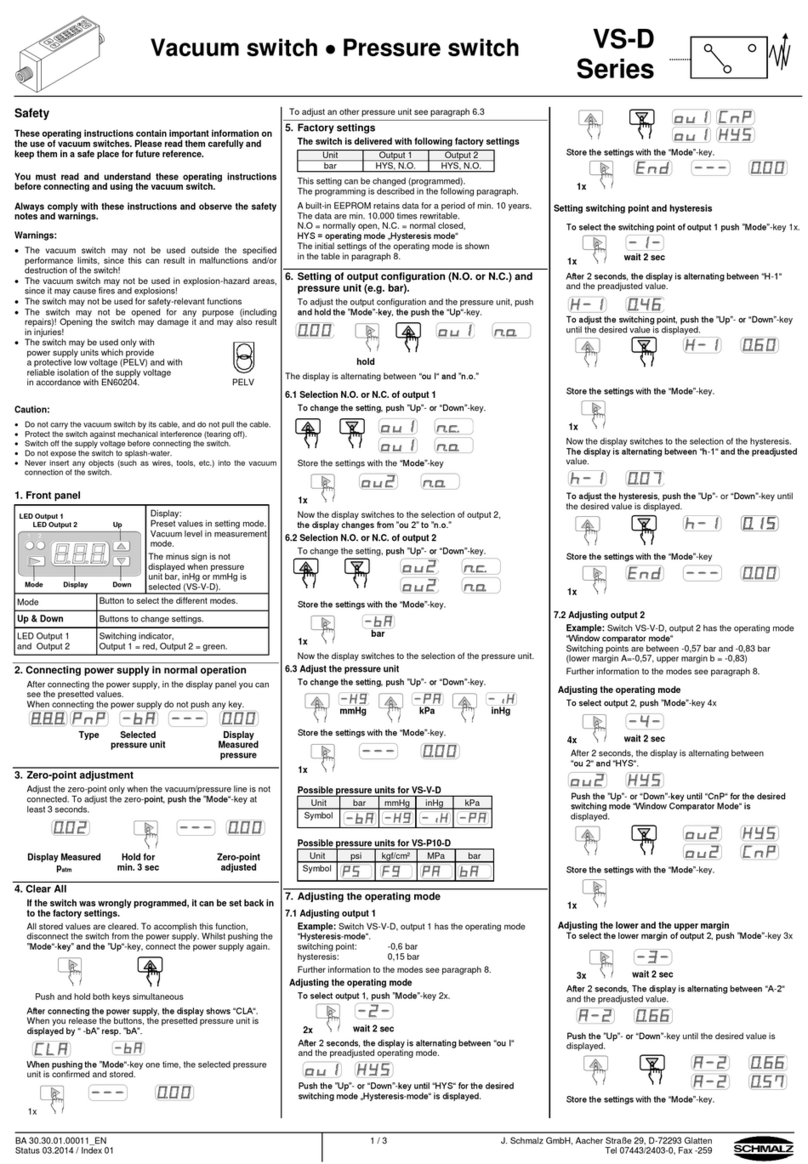

Schmalz

Schmalz VS-V-D-PNP operating instructions

IBM

IBM 2498B24 - System Storage SAN24B-4 Switch Installation, service and user guide

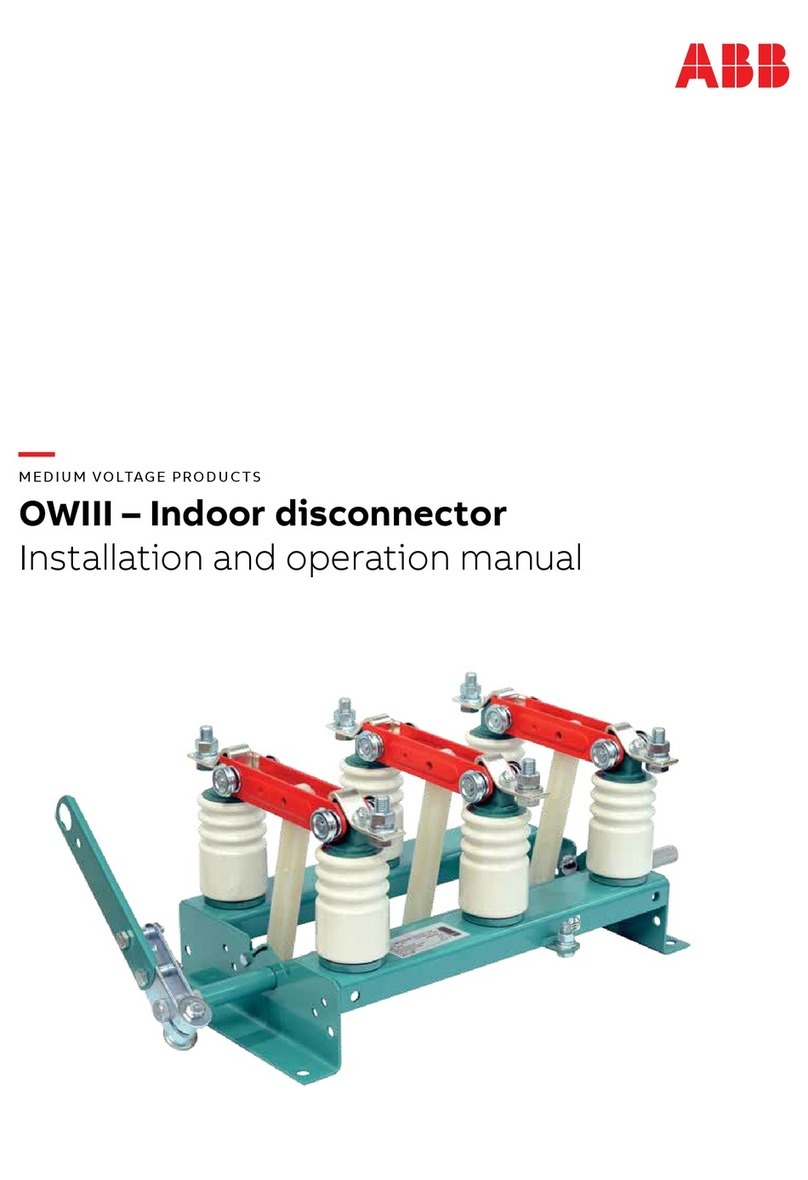

ABB

ABB OWIII Installation and operation manual

SUCO

SUCO 0340 Series operating instructions

Digisol

Digisol DG-GS1510HPEV2 Hardware installation guide

HP

HP 316095-B21 - StorageWorks Edge Switch 2/24 instructions