Prozeda SOLAREG II VISION plus User manual

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 1 -

MICROPROCESSOR-CONTROLLED SYSTEM CONTROL UNIT FOR SOLAR

THERMAL SYSTEMS

SOLAREG II

VISION PLUS

IMPORTANT

!

Before installing and using this device, you must read through the instructions carefully.

Failure to observe the instructions and safety information contained in these installation and

operating instructions will void the guarantee for the device described/installed.

Store these instructions in a safe place.

Installation and Operating Instructions

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 2 -

The described appliance has been made and tested in compliance with CE-guidelines.

1SAFETY INSTRUCTIONS 3

2SYMBOLS AND ABBREVIATIONS 4

3DEVICE DESCRIPTION 5

3.1 Usage 5

3.2 Device features 5

4SYSTEM DIAGRAMS 6

4.1.1 Over voltage protection 7

5DEVICE INSTALLATION 8

5.1 Opening the device (only by qualified personnel) 8

5.2 Wall mounting 9

6ELECTRICAL CONNECTION 10

6.1 230 V connections 11

6.1.1 Overview: 230 V connections for Solareg Vision Plus 11

6.2 Attachment of temperature sensor 11

7OPERATION / INDICATORS 13

7.1 Overview of displays and operating controls 13

7.2 Display – maximum display 14

7.3 Explanation of graphic symbols 14

7.4 Example of device operation 17

8MENU STRUCTURE 18

8.1 Overview 19

8.2 “Info” menu 20

8.3 “Program” menu 21

8.4 “Manual operation” menu 22

8.5 “Basic settings” menu 22

9CONTROLLER FUNCTIONS 24

9.1 General control functions 24

9.1.1 Load storage cylinder 24

9.1.2 Systems with two storages 25

9.1.3 Rotating speed controller 25

9.1.4 Independant controller 25

9.1.5 Thermostat (cooling) 26

9.1.6 Thermostat (heating) 26

9.1.7 Temperature difference control 27

9.1.8 Tube collector 27

9.2 System monitoring 28

9.2.1 Sensor monitoring 28

9.2.2 Flow monitoring 28

9.2.3 Collector protection / Re-cooling 29

9.2.4 System protection function 29

9.2.5 Frost protection 29

9.3 Additional functions 30

9.3.1 Yield estimation / yield metering 30

9.3.2 Engine-hour meter 30

10 RECTIFICATION OF FAULTS 31

10.1 Faults with error message 31

10.2 Faults without error message 32

11 TECHNICAL DATA 33

12 RESISTANCE TABLE PT1000 33

13 LIMITED WARRANTY 34

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 3 -

1 S

AFETY INSTRUCTIONS

This control unit must be disconnected from the mains before any

installation and wiring work is carried out.

This device may only be opened, connected and commissioned by trained

personnel. In so doing, the relevant safety regulations of your country must

be adhered to.

•Prior to any installation or wiring

work on the electric motors, always

fully disconnect the device from the

operating voltage and ensure that the

mains supply cannot be reactivated.

Never mix up the connections for the

protective safety low voltage area

(sensor, flow meter) with the 230 V

connections. This could result in

damage and hazardous voltages to the

device itself and to the attached sensors

and devices.

•Solar thermal systems can become very

hot. There is a risk of being burnt. Take

care when installing the temperature

sensor.

•Install the Solareg Vision Plus in such a

way that no excessive operating

temperatures (>50°C) result, e.g. as a

result of heat sources.

•The device is not protected against

splashing and dripping. You should

therefore install it in a dry location.

•For safety reasons, the system may be

manually operated only for test

purposes. In this operating mode, there

is no monitoring of maximum

temperatures or sensor functions.

•If there are signs of damage to the

control unit, cables or attached pumps

and valves, the systems must not be

operated.

•Check whether the materials used for

the piping, thermal insulation, pumps

and valves are suitable for the

temperatures that will occur in the

system.

If you have any questions concerning your solar thermal system or your control unit, please

contact your installer or supplier for advice.

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 4 -

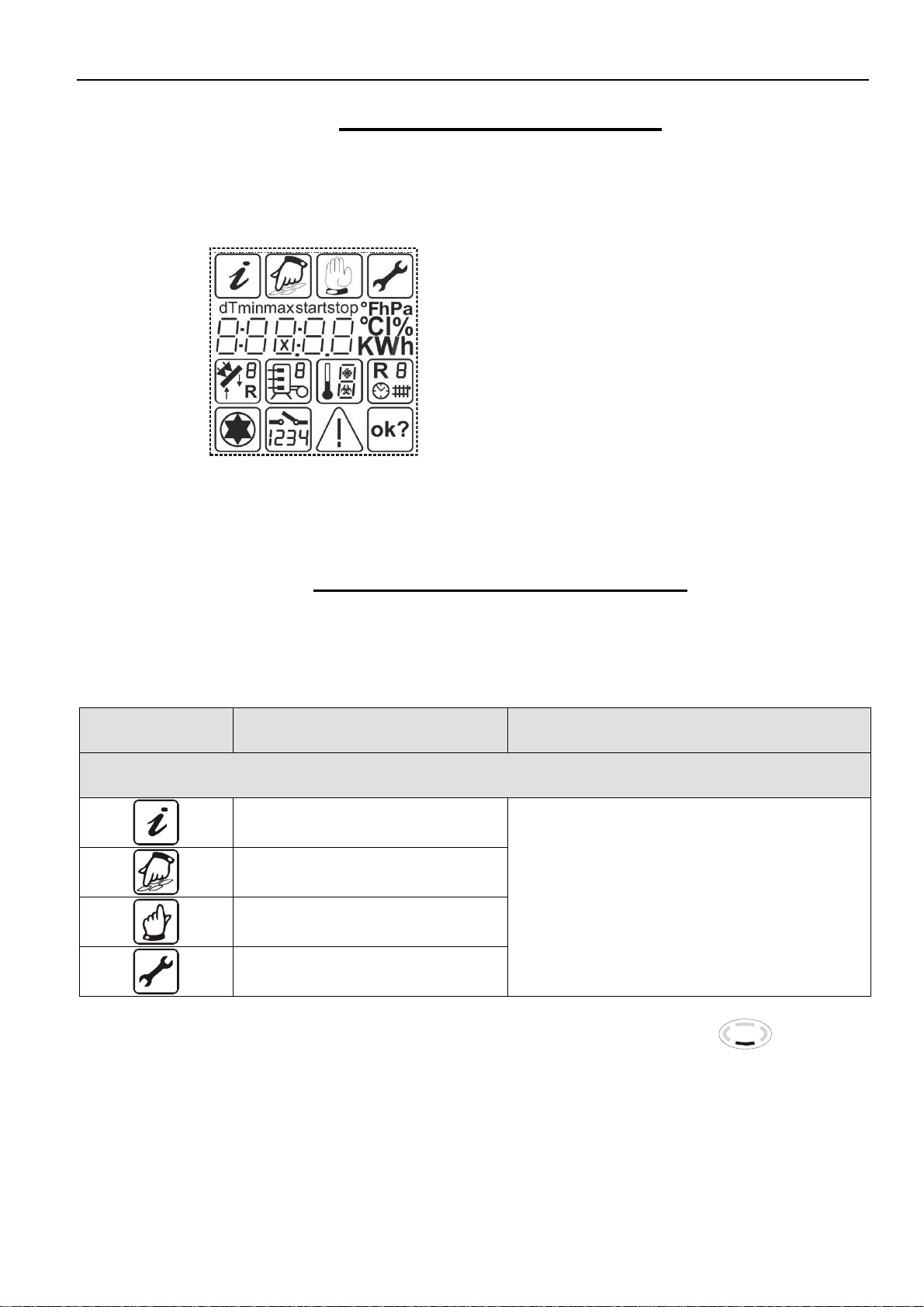

2 S

YMBOLS AND ABBREVIATIONS

Explanation of symbols used in operating instructions:

Warning!

This symbol indicates potential dangers and errors

Warning: 230 Volts

This symbol indicates risk to life through high voltages.

•

List

i

Information on operation/special features

Instructions/procedure

?

Test/check

Keypad for control unit

Frequently used abbreviations

Abbreviat

ion Meaning Abbrevia

tion Meaning

TColl Temperature of collector [°C]

Min Minimum value

TCyl

Temperature of storage cylinder

[°C] Max. Maximum value

TTh Temperature for thermostat [°C] K Kelvin unit, corresponds to 1 degree

temperature difference

TCret Temperature of collector – return

line °C Degree Celsius unit

TFrost Temperature - frost protection Td Temperature differential controller

kWh Energy yield in kWh % Percent

xxx Miscellaneous display value

Term explanations

Unit A unit is a component of a system and is responsible for part of its

function.

Hysteresis In control technology, the term hysteresis is used where an upper and

lower threshold value is responsible for switching (see Td Start and Td

Stop).

Shield Electrical shields reduce the influence of electrical and magnetic fields on

the signals in the cables and wires. Coaxial cables are commonly used

for this purpose.

Heat station Place at which energy is stored or transferred. In solar thermal systems,

the storage cylinder is the heat station.

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 5 -

3 D

EVICE DESCRIPTION

3.1 Usage

The solar thermal controllers Solareg Vision

Plus are high-performance, microprocessor-

controlled control devices used to control

the function of solar thermal systems.

The control units are suitable for common

types of solar thermal systems. See system

diagram.

These control units are designed for use in

dry rooms, private homes, business and

commercial premises.

Alternative use or use beyond this remit is

not in accordance with its purpose. Incorrect

usage can result in serious injury or death

to the user or a third party and can harm the

device or system and other material assets.

The manufacturer/supplier shall not be

liable for any damage arising from such

misuse. The risk is borne by the user alone.

3.2 Device features

The Solareg Vision Plus range offers the following features and equipment:

•Self-explanatory, menu-driven

operation

•Digitally adjustable control values

•System monitoring

•Energy yield estimation

•Storage of all entered values

•Large space for wiring

•Supports tube collectors

•Backlight display (on demand)

•Time counter-operating hours

•Diversity system protections

•Independent differential controller

with three time slots

•Third output alternatively for

thermostat, cooling function or the

independent differential controller

Available accessories:

•Temperature sensor PT1000

•Flow meter

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 6 -

4 S

YSTEM DIAGRAMS

i

The following system diagrams are not to be understood as complete hydraulic circuit

diagrams.

TYPE 0:

1 collector, 1 storage

TYPE 1:

1 collector, 2 storages

pump-valve

TYPE 2:

1 collector, 2 storages

2 pumps

TYPE 3:

2 collector arrays, 1 storage

pump-valve

TYPE 4:

2 collector arrays, 1 storage

2 pumps

TColl Measuring point - collector

TCyl Measuring point - storage

cylinder

TCret Measuring point - collector

return line

TTh Measuring point - thermostat

P Pump

DFZ Flow meter

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 7 -

Important notice concerning the valves in diagrams type 1 and type 3:

The system diagrams are propositions.

Regardless of the valve type shown above please follow this instructions:

Type1: one collector, two storages with valve:

•If not powered, the valve should connect the collector array with the storage 1.

•When powered, the valve must connect the collector array with the storage 2.

Type3: two collectors, one storage with valve:

•If not powered, the valve should connect the collector array 1 with the storage.

•When powered, the valve must connect the collector array 2 with the storage.

4.1.1 Over voltage protection

Prior to switching on or commissioning, you must ensure that the cover is

closed properly such that you feel and hear it click into position on both

sides.

SOLAREG II has integrated over voltage protection on every sensor input. Additional

safety measures are usually not required. For the collector sensor an additional

protection item is recommended and can be obtained from Prozeda GmbH. External

protection devices containing capacitors are not allowed as they will distort the

measurement.

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 8 -

5 D

EVICE INSTALLATION

This contro

l unit may be installed only in dry rooms where there is no risk of

explosion. Installation on a flammable base is not permitted.

5.1 Opening the device (only by qualified personnel)

No tools are required to open the device.

The upper part of the casing is locked to the

lower part at two engagement points. The

locking forces are such as to prevent the

casing from being opened accidentally.

Holding the casing at each side, pull firmly towards you and then raise the top part of the

casing until it engages. You can now install and wire up the control unit.

Prior to switching on or commissioning, you must ensure that the cover is

closed properly such that you feel and hear it click into position on both

sides.

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 9 -

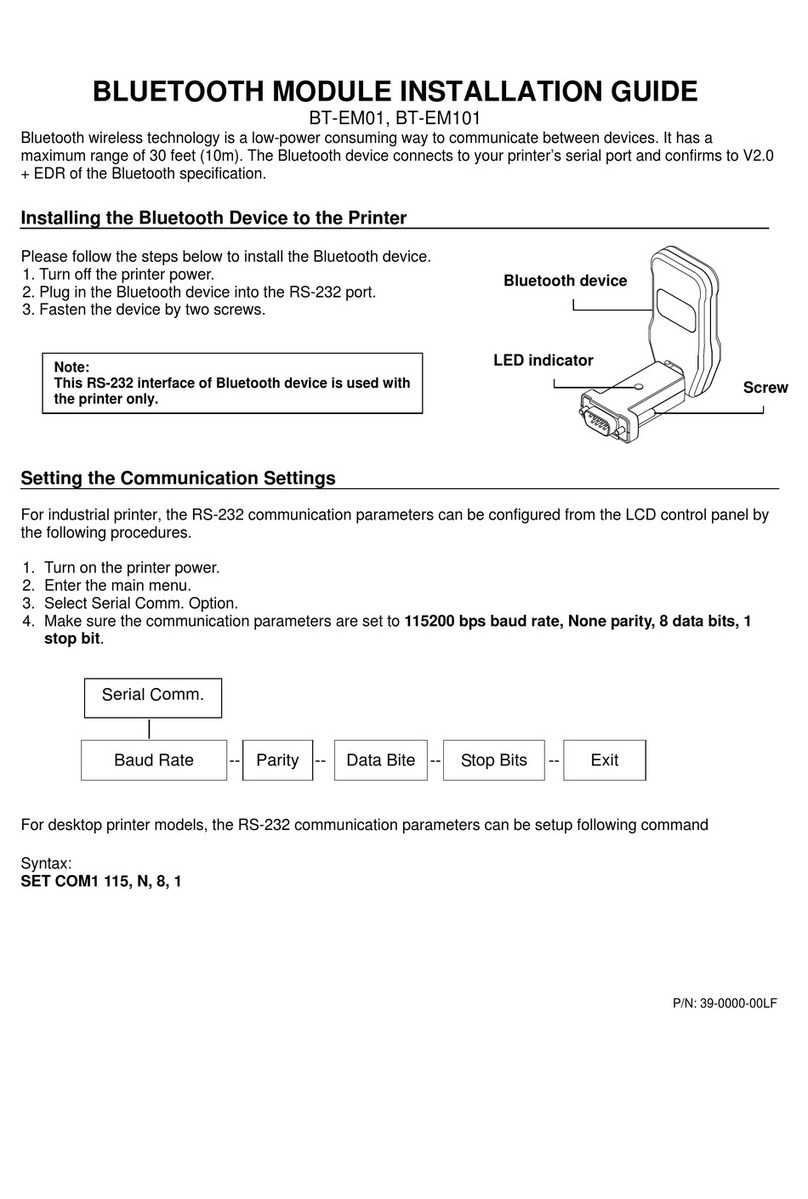

5.2 Wall mounting

When mounting the device on a wall,

proceed as follows:

•Drill the fixing holes using the drilling

template shown.

•Screw in the two top screws leaving

a gap of up to 6 mm.

•Open the device as described and

hang it on the two screws. You can

now fit the two bottom screws.

•To avoid damage to the lower part

of the casing, do not over tighten

any of the screws.

126mm

118mm

84mm

You drill into walls at your own risk. Prior to drilling, please check that there

are no cables, pipes or shafts in the wall; contact the property owner if

necessary.

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 10 -

6 E

LECTRICAL CONNECTION

You must observe the safety instructions in chapter 1

The device may be opened only if it has been properly

disconnected from the mains and there is no risk of

reconnection.

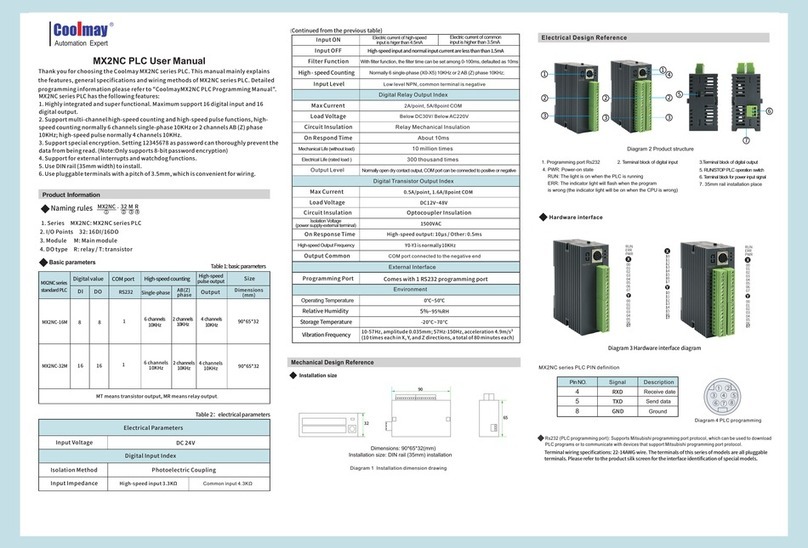

All electrical cables are connected to the

unit in the lower part of the casing. The

terminals on the right-hand side are those

for the (low voltage) connections for sensor

and flow meter. The 230 V connections are

located on the left-hand side. The figure

below shows the terminal field for the

Solareg Vision Plus.

WMM

T1

T2

T3

T4

PE

L

N

N

A2

N

A1

Sicherung

Netzspannungs-

bereich

Kleinspannungs-

bereich

T5

T6

N

A3

PE Earth wire WM

M Flow meter

L Phase mains T1 Temperature sensor for collector 1

N Neutral cable for mains T2 Temperature sensor for storage 1

A1 Phase switching output 1 T3 Temperature sensor for collector 2 /

storage 2

A3 Phase switching output 2 T4 Temperature sensor for collector return

line

T5 Temperature sensor for heating /

cooling* or temperature differential

controller - source

T6 Temperature sensor for frost protection*

or temperature differential controller –

target or common measuring point

(autom. deactivated if not connected

* - free choice T1…T6

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 11 -

General attachment regulations:

For all attachment wires, cut the wire sheath

to a length of approx. 6 – 8 cm and

unisolate the wires by approx. 10 mm from

the ends.

•In the case of flexible cables, provision

must be made inside or outside the

device for strain relief. The wire ends

must be fitted with wire-end sleeves. If

necessary, PG9 screw fittings can be

used for the feedthrough on the 230 V

side.

•The wires are fed into the device

through the designated openings.

•All earth wires must be fixed in the

terminals indicated with “PE” (Earth

potential).

6.1

230 V connections

The following points must be observed for

the 230 V connections:

•Where there is a fixed mains

connection, it must be possible to

interrupt the mains supply to the control

unit outside the control unit by means of

a switch.

Where the mains connection is effected

by means of wire and plug with earthing

contact, this switch may be dispensed

with.

•The control units are designed for

operation with a 230 V /50 Hz mains

supply. The pumps and valves to be

connected must be designed for this

voltage.

•All earth wires must be connected to the

terminals marked PE.

i

The neutral terminals (N) are electrically

connected and are not switched.

i

The switching outputs (A1/A3) are 230

V closers.

6.1.1 Overview: 230 V connections for Solareg Vision Plus

The table below shows the allocation of

switching outputs for the different system

types. The fields with a grey background are

essential to the basic functions of the

system. The white fields are designed for

optional additional functions:

Systems Outputs

Type

Description A1 A2 A3

0 1 collector array, 1 storage cylinder P1 - Cooling or thermostat

or diff. controller

1 1 collector array, 2 storage cylinder (pump-

valve) P1 V1 Cooling or thermostat

or diff. controller

2 1 collector array, 2 storage cylinder (pump-

pump) P1 P2 Cooling or thermostat

or diff. controller

3 2 collector array, 1 storage cylinder (pump-

valve) P1 V1 Cooling or thermostat

or diff. controller

4 2 collector array, 1 storage cylinder (pump-

pump) P1 P2 Cooling or thermostat

or diff. controller

6.2 Attachment of temperature sensor

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 12 -

The Solareg Vision Plus devices work with precise platinum temperature sensors of type

PT1000. Between 3 and 4 sensors are required, depending on the scope of function.

Installation/wiring of temperature sensor:

Install the sensors at the requisite places

on the collector and the storage cylinder.

In so doing, ensure good temperature

transmission and, if necessary, use a

thermally conductive paste.

The cables of the temperature sensors

can be extended. For lengths up to 15 m,

a cross-section of 2 x 0.5 mm² is

required; for lengths up to 50 m, a cross-

section of 2 x 0.75 mm² is necessary. In

the case of long connections (collector),

shielded extension cables must be used.

Do not attach the shield on the sensor

side; instead cut it to length and insulate

it.

To protect the collector sensor within the

control unit, the use of a lightning

protection device (accessories) is

recommended.

The temperature sensors are connected

in accordance with the system diagram.

In the case of temperature sensors, there

is no need to observe the polarity of the

two wires.

To protect the collector sensor within the

control unit, the use of a lightning

protection device (accessories) is

recommended.

Sensor wiring must be laid separately

from 230 V wires.

The sensors TTh, Td1 and TFrost can be freely assigned in the „Basic settings“ menu.

System Inscription on the controller

Type

Description T1 T2 T3 T4 T5 T6

0

1 collector array, 1 storage cylinder

TColl1

TCyl1 - TCret TTh Td1

TFrost

Td2

1

1 collector array, 2 storage cylinder

(pump-valve)

TColl1

TCyl1 TCyl2 TCret

TTh Td1

TFrost

Td2

2

1 collector array, 2 storage cylinder

(pump-pump)

TColl1

TCyl1 TCyl2 TCret

TTh Td1

TFrost

Td2

3

2 collector array, 1 storage cylinder

(pump-valve)

TColl1

TCyl1 TColl2

TCret

TTh Td1

TFrost

Td2

4

2 collector array, 1 storage cylinder

(pump-pump)

TColl1

TCyl1 TColl2

TCret

TTh Td1

TFrost

Td2

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 13 -

7 O

PERATION

/

I

NDICATORS

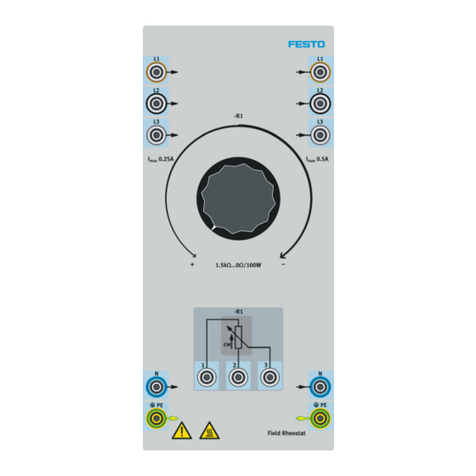

7.1 Overview of displays and operating controls

The Solareg Vision Plus control

unit is operated comfortably and

simply by means of 4 buttons.

The operating buttons allow you

to:

•Access display values

•Enter device settings

The graphic symbols on the

display unit lead you simply

through the operating structure

and provide a clear overview of

the current menu options, display

values and parameters.

Description

“Up”

„+“

• Upwards menu item

•

Change value: increase the displayed value by 1; press and hold

the button to increase the values continuously

“Access”

“Down”

„-“

• Access a main menu, downwards menu item

• Change value: lower the displayed value by 1; press and hold the

button to decrease the values continuously

“Scroll left“

“Exit“

“Cancel“

“ESC“

• Scroll to the left on the main menu

• Exit a menu

•Exit a menu item

• Cancel a change to a value without saving

“Scroll right“

“Select”

“OK”

• Scroll to the right on the main menu

• Select a menu item

• Confirm a change to a value by saving

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 14 -

7.2 Display – maximum display

In the following graphic, all symbols that can

appear on the display during operation are

displayed simultaneously. In real-time

operation, depending on the menu position,

only some of these symbols will appear.

Main menu

Display values

Allocation of measuring points

Status display

7.3 Explanation of graphic symbols

The meaning of the individual symbols is given in the table below.

During selection, the active symbol flashes. If the menu is selected using the button, the

corresponding symbol is displayed permanently. All others are hidden.

Graphic symbol

Description

Display during operation

Main menu

“Info” menu

“Program” menu

“Manual operation” menu

“Basic settings” menu

Symbol flashes if it can be selected

13:21

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 15 -

Graphic symbol

Description Display during operation

Display values

Td Temperature difference

min Min. value

Appears when minimum values are

displayed

max Max. value

Appears when maximum values are

displayed

min

0:00

1

Timeframe 1 start Appears when the differential

controller is active (timeframe 1-3) or

tube collector is active (timeframe 4)

Max

23:59

1

Timeframe 1 stop Appears when the differential

controller is active (timeframe 1-3) or

tube collector is active (timeframe 4)

5 x 7 segment display

Display of numbers 00000 to 99999

Display of all numeric values, display

flashes if value is changed

Temperature in degrees Celsius

Temperature difference in Kelvin

h

Operating hours

Display yield in kWh.

Position of sensors

Collector array 1

Collector array 2

Bottom of storage cylinder 2

Bottom of storage cylinder 1

Sensor in return line if there is a

return line monitor

Heating – cooling – diff.

controller. Temperature source

(displays the chosen sensor)

/ Frost protection, universal

measuring point /

Temp. diff. controller,

temperature target

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 16 -

Status display

Solar circuit pump

Symbol rotates when the solar circuit

pump is switched on

Switching output 1 is active Appears if switching output 1 is active

(on).

Switching output 2 is active Appears if switching output 2 is active

(on).

3

Switching output 3 is active Appears if switching output 3 is active

(on).

!

Indicates a system error or

incorrect code entry Display flashes if an error occurs in the

system.

Lights up if the wrong code is entered.

ok?

Safety question for value

changes with save facility Value input can be

refused or

accepted .

Operating hours, yield for

storage cylinder Appears together with operating hours

or yield

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 17 -

7.4 Example of device operation

Once you have familiarised yourself with the

menu descriptions as described in the

“Operating menus“ chapter, you can

practice by carrying out the operating steps.

An operational example is illustrated below.

The starting point is the current collector

temperature on the “Info” menu. Aim:

Change to “Solar circuit Td stop” circuit from

3K to 4K in “Program” menu

White: symbol lights up continuously

Grey: symbol flashes

Button Function

Graphic display following

operational step Description

“Exit“

Exit the “Info” menu

“Scroll

right“

Selection of “Programming” menu

“Access”

max

65°C

Access of “Programming” menu; the first

menu item appears

“Down”

Td min

3 K

Keep pressing until the menu item “S1 Td

min” appears

“Select”

Td min

3 K

Select the parameter shown

“Up”

Td min

4 K

Increase the parameter value from 3K to

4K

“Confirm

”

Td min

4 K

ok?

Confirm the parameter

“Confirm

”

Td min

4 K

Store the parameter

“Exit“

Exit “Programming” menu

“Scroll

left“

Select the “Info” menu

“Access”

60°C

Access of “Info” menu

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 18 -

8 M

ENU STRUCTURE

To facilitate simple operation of the device, the device, operating and display functions are

combined into 4 groups (= main menu).

The four menus

•Information

•Program

•Manual operation

•Basic setting

provide information on your solar thermal system.

The currently active menu is displayed by means of the relevant graphic symbol in the top row

of the display.

Menu Overview of functions contained

Information

Main menu for the automatic control of the solar system.

• Display of current measured values

• Display of system status

• Display of error messages

• Display of energy yield (if existing)

Program

Change and set the programmable setting values (parameters)

Note: Changes can impede system functions

Manual operation

Switching the connected pumps/valves on and off manually

Basic setting

Information on the basic settings for the system function.

Note: Settings and changes may only be carried out by trained personnel.

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 19 -

8.1 Overview

The diagram shows the entire menu structure of the Solareg Vision Plus.

i

Only the configuration-specific symbols are displayed.

Info Program Manual operation

Basic setting

I I I I

Current collector temperature /

Collector 1 Maximum temperature of

storage cylinder1 Pump1 off/on Collector protection

function

off/on

Minimum collector temperature /

Collector 1 Storage cylinder1 Tdmax

(Td on) Pump2 / Valve1

off/on Collector protection

temperature

Maximum collector temperature /

Collector 1 Storage cylinder1 Tdmin

(Td off)

Heating / Cooling /

Temperature

differential controller

off/on

Re-cooling

off/on

Current storage cylinder temperature

/ storage1 at bottom Maximum temperature of

storage cylinder2

Re-cooling

temperature

Minimum storage cylinder temperature

/ storage1 at bottom Storage cylinder2 Tdmax

(Td on) Tube collector-

off/on

Maximum storage cylinder temperature

/ storage1 at bottom Storage cylinder2 Tdmin

(Td off)

Yield estimation off/on

Current storage cylinder temperature

storage2 at bottom / collector2 Minimum pump rotating

speed in % Glycol type

Minimum storage cylinder temperature

storage2 at bottom / collector2 Start temperature

Heating / cooling Glycol percentage

Maximum storage cylinder temperature

storage2 at bottom / collector2 Hysteresis temperature

Heating / cooling Td Volume flow

Current collector temperature - return

line Temperature differential

controller:

Maximum temperature of

the heating target Tmax

Controlling time in

seconds

Current temperature

heating / cooling /

differential controller heating source

Temperature differential

controller:

Minimum temperature of

the heating source Tmin

Storage cylinder priority

Current temperature

frost protection sensor / differential

controller heating target / univ.

measuring point T6

Temperature differential

controller:

Hysteresis Tdmax

Frost protection

off/on

Operating hours – pump1 Temperature differential

controller:

Hysteresis Tdmin

Frost protection sensor

assignment

Yield storage1 Timeframe start

1,2,3 for the independent

controller, 4 for the tube

collector function

Frost protection:

start temperature

Operating hours – pump2 Timeframe stop

1,2,3 for the independent

controller, 4 for the tube

collector function

Independent controller

assignment:

Cooling, heating,

temperature differential

controller

Yield storage2 Set time Sensor assignment for

the independent controller

Select basic configuration

Installation and Operating Instructions

SDC 204 1316BED035-10B-E Date 12/06

- 20 -

8.2 “Info” menu

In this operating mode, all measured values and operating states are displayed.

i

Only the configuration-specific symbols are displayed.

Resettable values such as minimum and maximum temperatures, daily yield and overall yield

can be reset as follows:

Select value using and buttons

Reset value using the button

Confirm “OK?” message with = no or = yes

Display

e.g.

Description Resetable

75 °C

Current collector(1/2) temperature no

min

12 °C

Minimum collector(1/2) temperature

Resetable to the current temperature yes

max

105 °C

Maximum collector(1/2) temperature

Resetable to the current temperature yes

52 °C

Current storage(1/2) temperature no

min

40 °C

Minimum storage(1/2) temperature

Resetable to the current temperature yes

max

67 °C

Maximum storage(1/2) temperature

Resetable to the current temperature yes

60 °C

Current collector-return line temperature no

60 °C

Heating, cooling, temperature differential controller

heat source

Sensor T1...T6

no

35 °C

Temperature differential controller heat target

no

25 °C

Frost protection sensor (T1...T6)

Displays the measuring point (T6)

(not visible if not connected)

no

1234 h

Operating hours storage load

Resetable to 0 h yes

927

kWh

Yield storage

Resetable to 0 kWh yes

Other manuals for SOLAREG II VISION plus

1

Table of contents