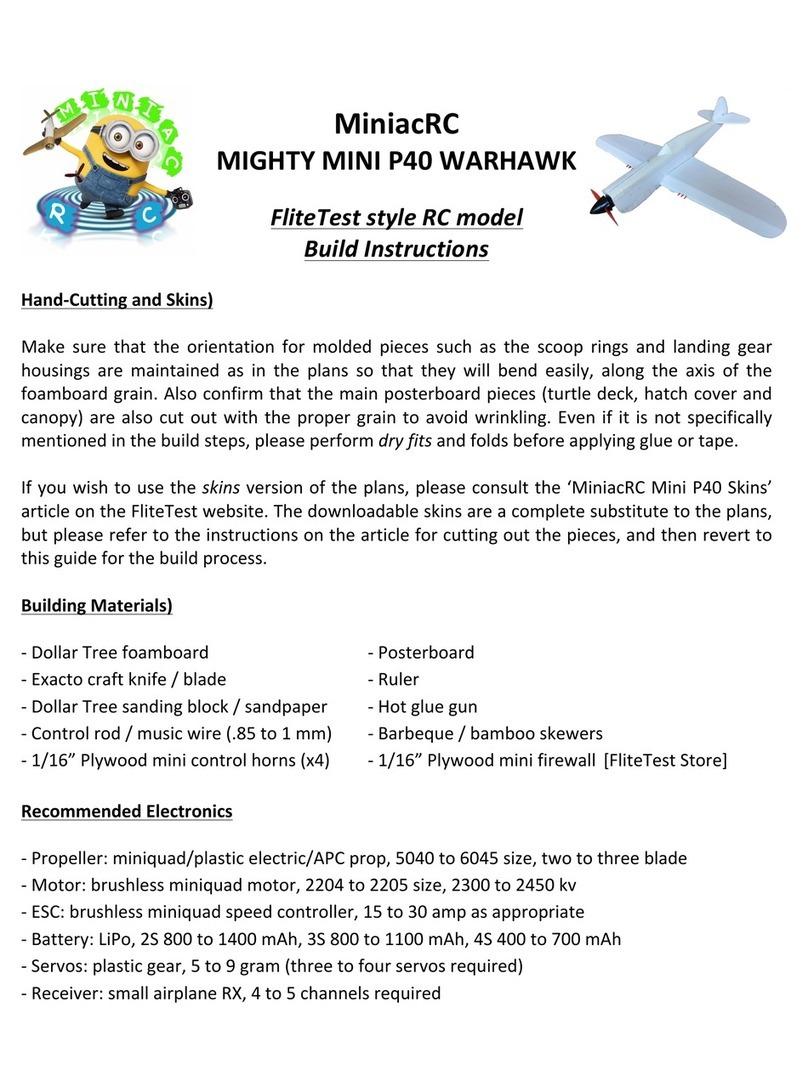

PRR S.P.F. DESIGN G38 ORE JENNIE User manual

c

F

.

.

D

P

E

.

S

S

I

G

R

N

R

P

Not intended for children under the age of 14

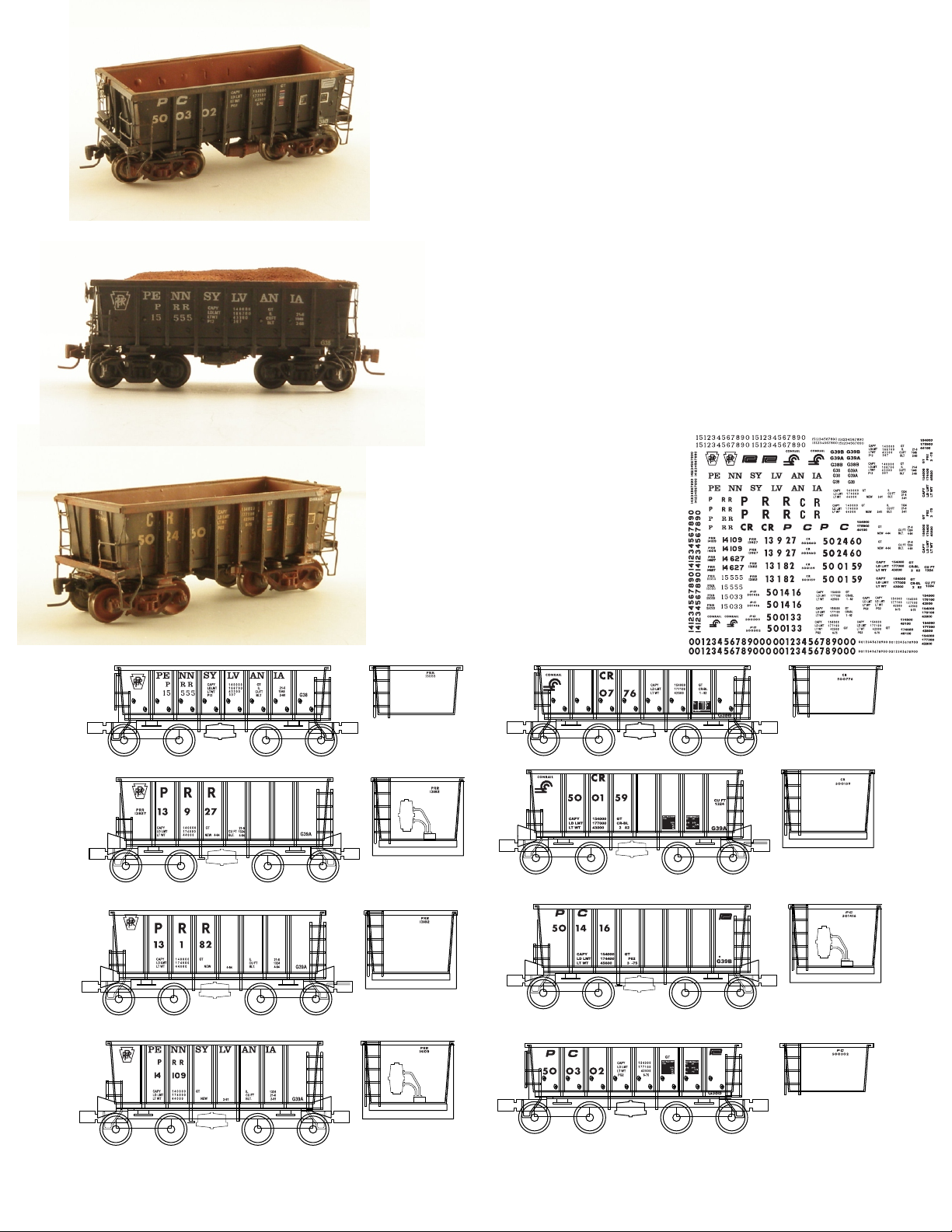

G38 Ore Jennie first built in 1960 in the

Sam Rea shops for the soul purpose of

hauling iron-ore. A thousanf of these

cars were built for the PRR in number

sequence 15000 - 15999, with a

capacity of 140,000 lbs and 1,048 cu.

ft. The G38 lasted well into the 1990’s

hauling ore for three different railroads,

the PRR, Conrail, And Penn Central all

of which can be represented with this

kit.

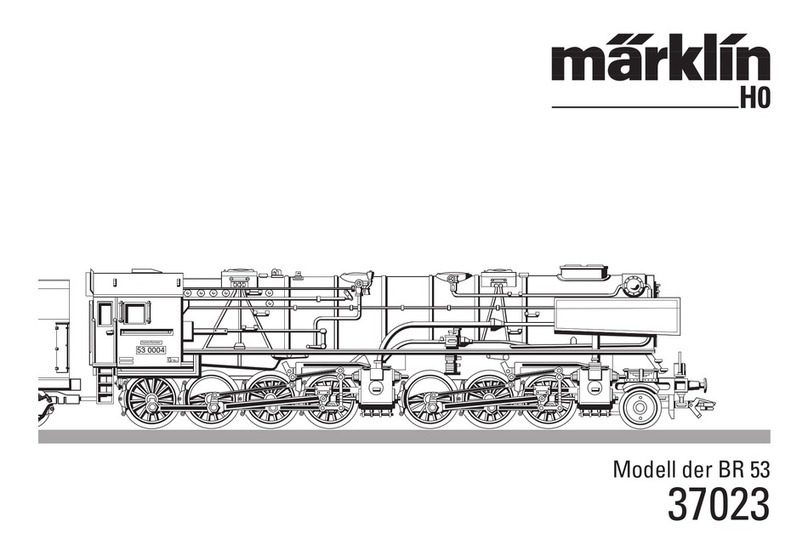

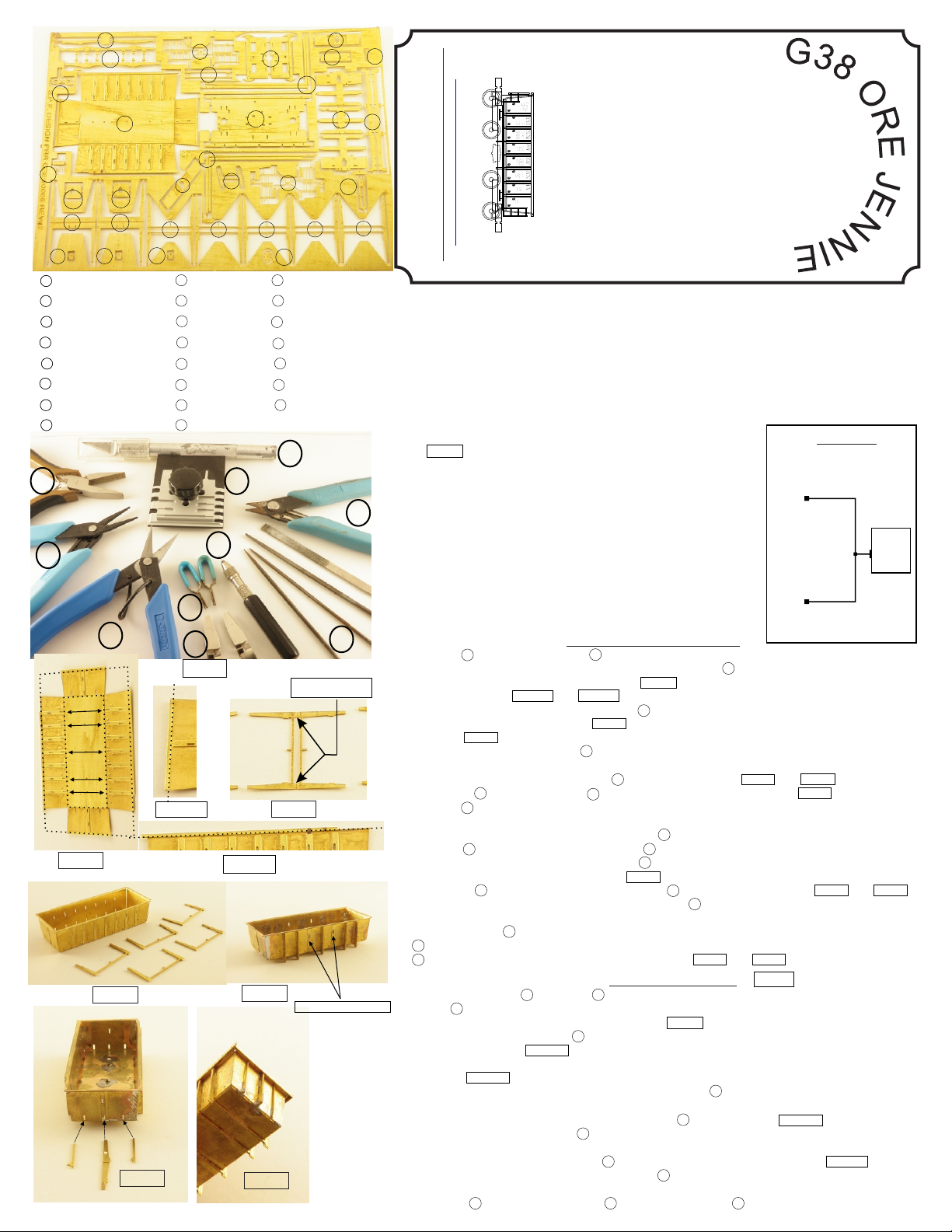

FIG.1

FIG.2

FIG.3FIG.3

FIG.4 FIG.5

( I have made a few changes in the directions for changes and additions see page 5 )

Thank you for your purchase from PRR S.P.F. Design. Begin by unpacking your kit and checking

its contents to the parts list below. Take a few minutes to read all the directions to familiarize

yourself with the parts and methods needed for assembly. The kit is designed to be glued or

soldered together. If you prefer to glue your kit I suggest using a thick CA for a better bond. If you

prefer to Solder the kit together I suggest 60/40 solder, Kester water

soluble flux. Flux is the key to getting solder to flow where you want it without de

soldering other items. The kit is also designed with locking tabs and bend lines to facilitate

assembly . Follow all directions. Should you have any problems, please contact me at

a 700 degree iron, and

quickly

Leave these two open

Here in FIG.1 are some suggested tools and items for

assembling this kit.

A - Flat nose non serrated plier found at any local hardware store

B - Xuron tweezer point pliers

C - Xuron photo etch shears

D/E - Various clamps

F- Pin vice with a #80 drill, # , and 00-90 tap

G - Assortment of needle files

H - Xuron micro sheers

I - Small shop photo etch bending tool www.thesmallshop.com

J - Exacto Knife

A

B

C

D

E

F

G

H

I

J

A

A - Main Body B - Main Ribs C - Center Rib Ends

D - Left And Right End Ribs E - Floor F - Floor Ends

G - Under Floor Bracing H - Center Bracing I - Bolster

J - Bolster Covers K - Air Tank Brackets L - Brake Eccentric

M - Center Ribs N - Brake Tower O - Brake Platform

P - Brake Gear Housing Q - Brake Wheel R - Brake Rod

S - Ladders & Stirrups T - Ladders & Stirrups U - Top Cord

V - Grab Iron Bending Jig W - Coupler Spacers

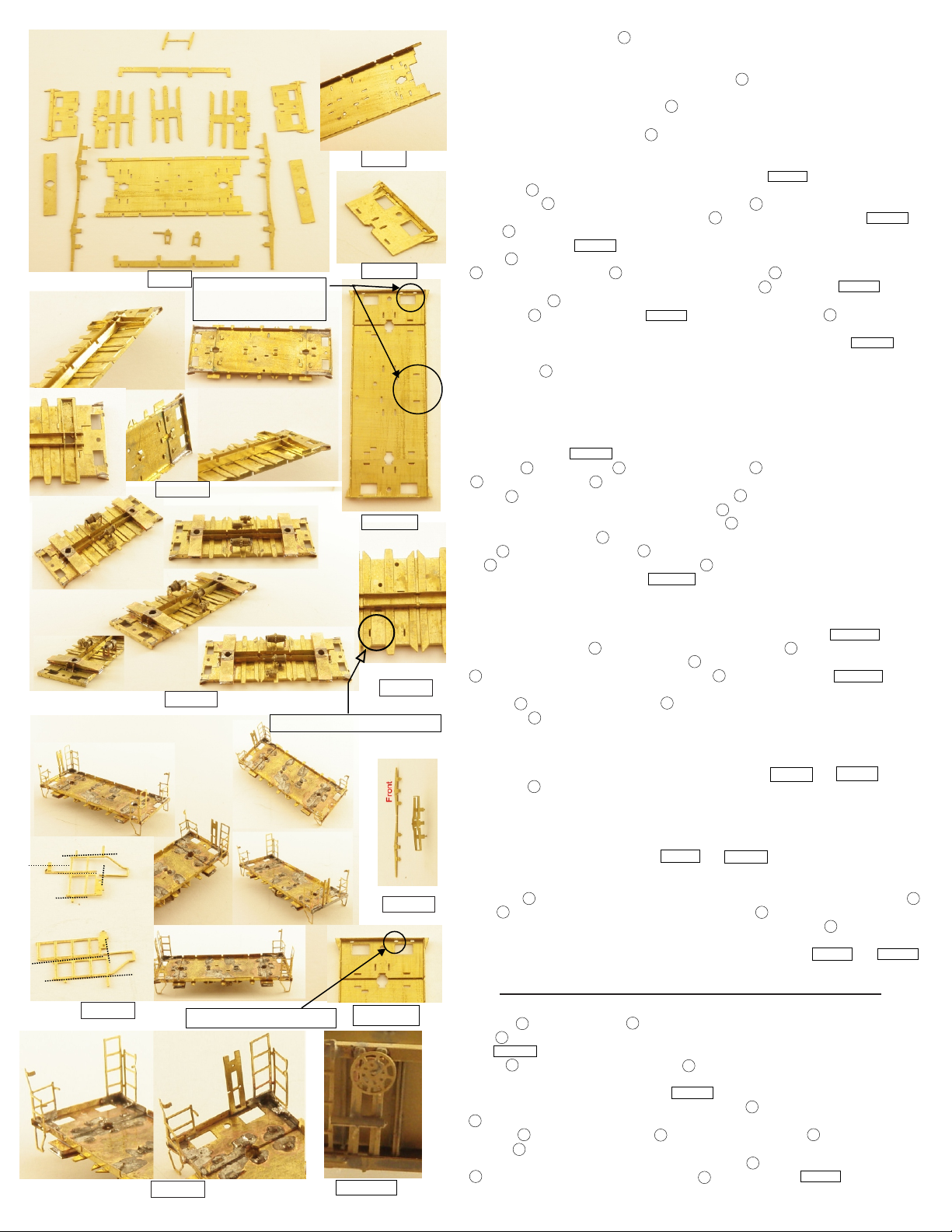

1.) Remove A -Main Body and five B -Main Ribs.

2.) With bend line up, bend the four very outer edges of the A -Main Body towards you 90

degrees. The outer dashed line shown in FIG.2 indicates the four places for these bends.

Refer to close-up FIG.2A and FIG.2B note the bend line is just under the outer etched edge.

3.) With smooth side up, now bend the four A -Main body sides up to form the Main body.

Refer to the inner dashed line in FIG.2 for where to bend.

Refer to FIG.4 to see finished assembly.

4.)

Floor Assembly FIG. 8

10.) Start by removing E -Floor and F -Floor Ends

11.) With , bend both sides of along etched lines up

until a 90 degree angle is achieved. Refer to FIG. 9.

12.) Orient the bend lines up on F -Floor Ends bend the edge with the two small triangles up to

90 degree.

13.)Take notice to the difference in the number of slots in bent in the previous

step. One end has three slots near the initial bend and the other will have only two one in

each corner. Now take notice to the slots in the reference FIG.9b the two horizontal

slots in the center are for the egin with the bends facing up on all

three components. The two close-together slots on the one side of the must be

attached on the same side as the slots, again refer to FIG.9b. Next,

slide each Floor Ends into either side of the making sure the ends are flush and

that all slots on each piece line up.

15.) Remove G -Under Floor Bracing, H -Center Bracing and I -Bolster

With the bend line up, fold the B -Main Ribs along the center bend line away from you until it

doubles itself.

Repeat this process for each of the B -Main Ribs. Refer to FIG.3 and FIG.4

5.) Fasten the B -Main Ribs to the A -Main Body to locations indicated in FIG.5. Take notice

how the A -Main Body tab slots are staggered; the main ribs must be oriented correctly to

match slots.

You may have to file or trim the top edges of B -Main Ribs to achieve proper fitment.

6.) Remove C -Center Rib Ends and the four D -Left And Right Rib Ends.

7.) With the bend line oriented up, fold each C -Center Rib Ends along the center bend line

away from you until it doubles. refer to FIG.6

8.) Attach one C -Center Rib Ends to each end of A -Main Body as shown in FIG.6 and FIG.7

note: you may have to file or trim the top edges of C -Center Rib Ends to achieve proper

fitment.

9.) Next, fasten the D -Left And Right Rib Ends to the slots adjacent to either side of the

C -Center Rib Ends Again, it may be necessary to file or trim the top edges of the

C -Center Rib Ends to achieve a good fit. Refer to FIG.6 and FIG.7

E -Floor bend lines oriented up E -Floor

refer to FIG.9a .

13.) Finish the F -Floor Ends by bending the two small triangles down perpendicular to the floor

Refer to FIG.9a .

F -Floor Ends

E -Floor

K -Air Tank Brackets. B

Floor End

K -Air Tank Brackets

E -Floor

FIG.2a

FIG.2b

www.prrspfdesign.weebly.com

BBBBB

JL

MM

N

PPPQ

T

W W

Main Body Assembly

FIG.6 FIG.7

A

C

D

E

F

GH

I

J

K

O

R

S

U

U

V

Parts list

1- G38 Etching

2- decal sheet (optional)

3- air tank

4- triple valve Small

parts

5- air cylinder bag

6- .010 wire

7- printed directions

(optional)

Bend lines

FIG.8

FIG.9

FIG.10

FIG.11

FIG.12

FIG.13

FIG.14

FIG.15

FIG.9a

Be sure these two slot line up

16.) Locate the center piece of G -Floor Bracing and with the bend lines orientated

up bend the two small tabs on either side up to 90 degrees

17.) Orient the bend lines on the outer two pieces of G -Floor Bracing up and

bend the small tabs up at a 90 degree angle.

18.) Position the previously assembled with the bent edges down. You will

be looking at what is to become the underside of the ore car.

19.) Now align the three sections of on top of the floor making sure

all slots have clearance and that all the small tabs are located in

their proper slots of the floor. Also, the small notch in the center section of floor

bracing, must line up with the slot in the floor. refer to FIG.11.

20.) Insert the into the corresponding eight horizontal slots in the

center of the . Do so by going through the . Once

through bend the tabs over on the inside of to secure. Refer to FIG.10.

21.) Bend I -Bolsters into a rectangle keeping all bend lines to the inside of the

rectangle. refer to FIG.12 .

22.) Insert I -Bolsters into the corresponding four vertical slot at each end of

E -Floor Bracing through G -Floor Bracing locking into H -Center Bracing once

through and flush bend over all tabs on the inside of E -Floor.( see FIG.10 ).

23.) Remove both , and note the differences between the two.

24.) Orient the as shown in with the two slots for the

facing you. Inset the air tank bracket with the leg into the right slot.

Insert the other bracket (no leg & longer tab) into the left slot. refer to

26.) Remove the Triple Valve, Air Tank and the Air Cylinder from the parts bag. Install

them as shown in FIG.13.

27.) Remove N -Brake Tower, O -Brake Platform, three P -Brake Gear Housing’s,

Q -Brake Wheel, and R -Brake Rod.

28.) Insert R -Brake Rod long end first into the three P -Brake Gear Housings.

29.) with etch detail up and the single hole up on N -Brake Tower insert the assembly

from previous step 28.) into the single hole on N -Brake Tower.

30.) top this assembly with Q -brake Wheel.

31.) with N -Brake Tower oriented Q -Brake wheel up insert the two small legs

of O -Brake Platform into the two holes in N -Brake Tower making sure that the

offset is to the left as shown in

32.) With the platform now attached to the tower, bend each of the long platform legs

to form an angular support for the platform. Note that there are two etch lines for

each leg. One will form the 45˚ downward angle, and the other will form a short

tab parallel to the brake tower as a location for bonding. Refer to FIG.14b .

33.) Install the completed N -Brake Tower assembly onto the E -Floor

assembly in its proper slot in the Single F -Floor End with three slots. The

N -Brake Tower goes in the inner slot of this F -Floor End refer to FIG.14a .

Once secured trim bottom of tab flush with floor.

E -Floor

G -Floor Bracing

H -Center Bracing

E -Floor G -Floor Bracing

E -Floor

K -Air Tank Brackets

E -Floor FIG.13 K -Air Tank

Brackets

FIG.13

25.) Remove the J -Bolster Covers. With the etched pockets faced down, mount

the covers onto the bolster tabs and form the covers onto the bolsters.

Note: For glue users, after formed and fastened, check the fit of the truck

pin. You want it to be a very light press fit

FIG.14b

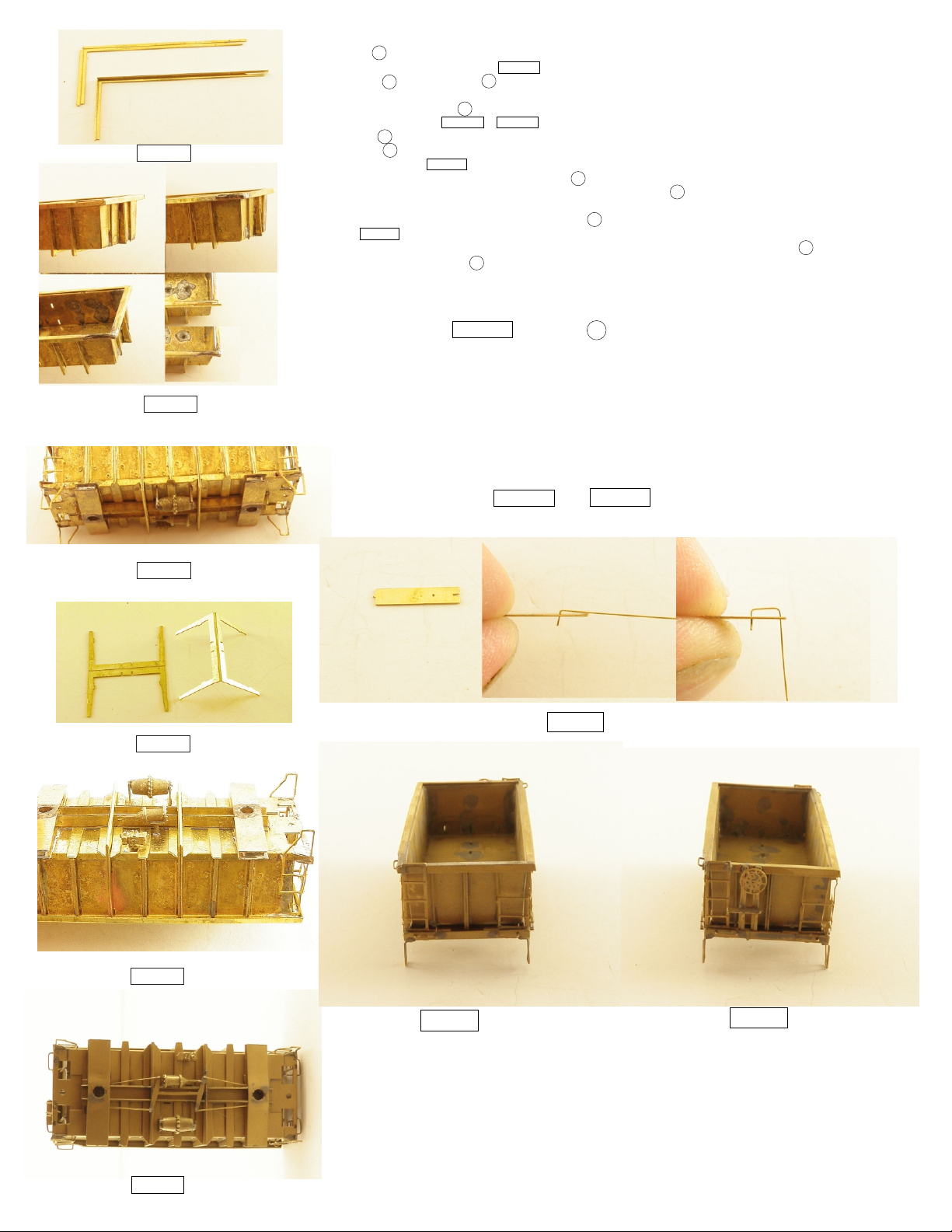

34.) remove S -Ladders & Stirrups and T -Ladders & Stirrups.

35.) Orient the S -Ladders & Stirrups with etch lines up and the stirrups facing you.

Begin by bending the two small ladder supports to the left down at 90 degrees at

their etch lines. Next, bend the top edge of the stirrup at the

etch line down at 90 degrees. Now bend entire the part along center etch line

(between ladders) to form a 90 degree angle. Refer to FIG.14 and FIG.15.

36.) Orient the T -Ladders & Stirrups with etch lines up and the stirrups facing you.

Begin by bending the two small ladder supports on either side down at 90

degrees at their etch lines. Next, bend the top edge of the stirrup at the

etch line down at 90 degrees, as well as the small tab at the top middle of the

ladder/stirrup. Now bend entire part along center etch line (between ladders) to

form a 90 degree angle. Refer to FIG.14 and FIG.15 .

37.) With the E - Floor assembly in hand Insert the tabs of each Ladders & Stirrups S

and T into their designated slots at each end of the E - Floor. Next, insert the

long lower ladder support in the small slots on either side of the E - Floor. Next,

attach the front of the stirrups to the front edge of the floor ends. Trim excess tab

flush with bottom the E - Floor to finish up assembly. Refer to FIG.14 and FIG.15

Main Body and Floor assembly and final detail

38.) remove M -Center Ribs and U -Top Cord

39.) with U -Top Cord oriented bend lines up bend both edges to 90 degrees

see FIG.16

40.) install U -Top Cord on the top edge of A -Main Body. Once attached

form the front edge with the two holes for the grab iron to the contour provided

and then trim off the excess. refer to FIG.17

41.) with a 00-90 tap, tap the two holes at each end of E -Floor for the couplers in the

F -Floor Ends.

42.) Join the E -Floor assembly to the A - Main Body making sure E -Floor is flush up

against A -Main Body.

note: you may have to trim the ladder supports on S -Ladders & Stirrups and

T -Ladders & Stirrups for a proper fit onto A -Main Body see FIG.18

43.) Attach the tops of the long ladders as well as the brake tower to the body.

FIG.9b

Be sure the upper two

slots line up with these

middle two slots

FIG.14a

FIG.14b

N - Brake Tower assembly

FIG.16

FIG.17

FIG.18

FIG.19

FIG.20

FIG.21

44.) Orient M -Center Ribs with etch lines up. Bend ribs away from you and back against themselves until

they are doubled up. Refer to FIG.19.

A -Main body E -Floor

and right of the center. Make certain the tabs on the center ribs are oriented correctly to match the

slots in the slots in the A -Main body. These are a tight fit, but be patient and work them down until they fit

into place. Refer to FIG.18 & FIG. 20. You may need to trim the top edges to achieve proper fit.

46.) remove L -Brake Eccentric and the provided .010 brass wire.

47.) position L -Brake Eccentric in the center on the bottom of the car with one rod to each side of the brake

cylinder. refer to FIG.21

48.) with a #80 drill bit drill, out the four holes in L -Brake Eccentric

49.) with provided .010 wire make four brake rods to attach to the L -Brake Eccentric.

bend a small 90 at one end of each rod to insert into the #80 holes you drilled out

attach the opposite end onto the underside of I - Bolster cover.

see FIG.21 .

50.) with a #80 drill , drill out the holes for the six grab irons, there are two at each end of F -Floor Ends

one at each top edge of A -Main Body

45.) With the and assemby together, install the center ribs into the two remaining slots

left

Here below in FIG.22 we have V - cut from the

etch.

Start off by bending a small 90 degree bend in the supplied wired with

appropriate tool. Insert this bend into the small hole ,with the long end

towards the supplied slot. Hold down on the bend , bend the long end

down at a 90 degree angle into the provided slot. Now cut the bent

Grab iron free and repeat the process for the six grab irons needed for

the kit. Once they are all bent attach them in the six location described

in step 49.) refer to FIG.23 and FIG.24

Grab Iron Bending Jig

FIG.22

FIG.23 FIG.24

This kit is designed for Micro-trains Trucks. For later Conrail and Penn Central, I would suggest

their Bettendorf trucks.

For G38's, I suggest their Andrews trucks. For the early version of the G38, Bowser makes the

correct trucks. You will just need to ream out the truck pin hole to accept a Micro-trains truck pin.

If you prefer to use BLMA, 70 ton friction bearing trucks, you will need to shim the bolsters for the

correct height ride height.

Use either 1015-1016 Micro-trains couplers; however, with a little bit of shimming you can use Z

scale couplers as well.

Note: Always Consult actual photos and railroad drawings for the most accurate paint colors, graphics and

decal placement.

Prior to painting and applying decals, thoroughly clean the model with mild

soap such as Dawn. If you soldered your kit, soak the model in acetone,

then wash with soap and water.

My recommendation for colors are a gloss black, and for the later Conrail

units, Red Oxide. Remember, these units saw years of service and were

usually quite beat up and dirty, so don't be hesitate to weather your ore car

either.

For great pictures of the Conrail and Penn Central cars, visit Conrail

Historical Society website.

Unfortunately, there are not many photos of the G38 in PRR paint schemes.

However, if you search, PENNSY RAILCAR RESTORATIONS LLC, you will

find some nice photos of a recently restored G38 Jennie for referance.

If you are building Conrail and Penn

Central cars the decals do not include

lube plates ,repacked bearing markings or

ACI labels all of which are available from

Microtrains.

I have added a bracket for the brake cylinder to sit onto so it is easier to get it at the right height. FIG. 25

This new part located at the upper right hand side of the etch above parts H below part V .

With this I have added a two new slots as well one in the floor E located on the same side as the brake

cylinder and triple valve and now a single H has a horizontal slot FIG.26 that will line up with new slot in

the floor E .

In FIG. 27 you can see what the new assembly looks like.

This new part will come into play at step 15.

FIG. 25

FIG. 26

FIG.27

Popular Toy manuals by other brands

Phoenix Model

Phoenix Model westland lysander instruction manual

LRP

LRP Disco Hornet user guide

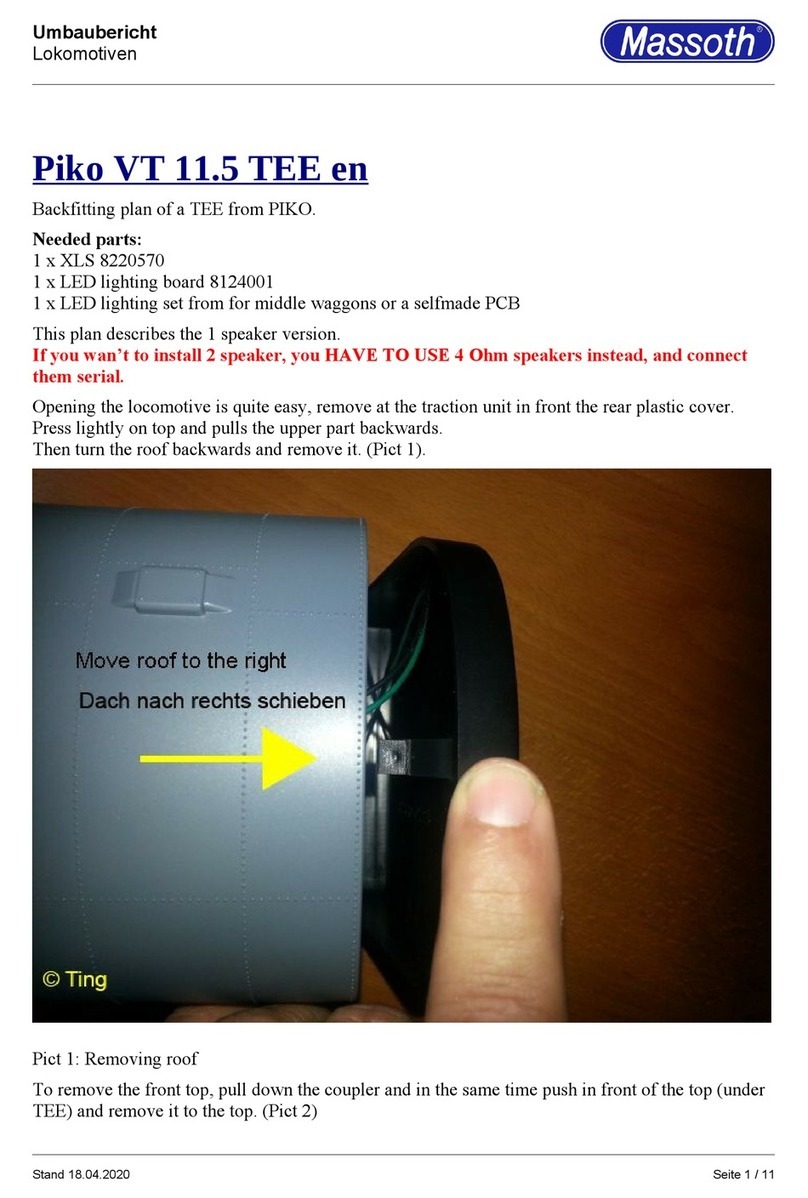

Massoth

Massoth Piko VT 11.5 TEE manual

Horizon Hobby

Horizon Hobby blade 230 s instruction manual

Miniature Aircraft USA

Miniature Aircraft USA X-cell WHIPLASH Nitro Assembly instructions

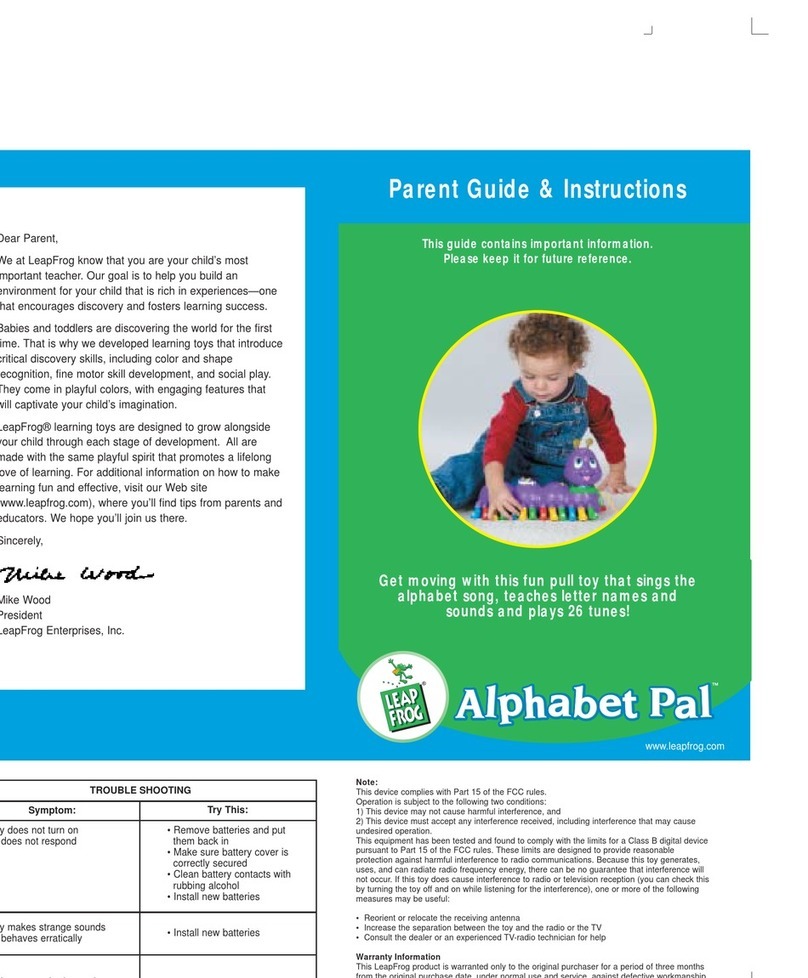

LeapFrog

LeapFrog Alphanet Pal Parent guide & instructions