PS Automation PSF-EX User manual

The operating instructions in other languages can be found at the following QR codes:

Please note to scan the QR codes within an Ex-atmosphere only with a suitable end device!

Or follow the Link: www.ps-automation.com/downloads

Version 26/07/2023 Art. No.: 8035498 ©2023 PS Automation GmbH

German French Italian

Subject to change!

Operating Instructions

PSF-EX approval according to

Directive 2014/34/EU (ATEX)

2

Content

1. Product description ....................................................................................................................................................... 3

2. Applicable standards ..................................................................................................................................................... 3

3. Key figures ..................................................................................................................................................................... 4

3.1 Type code ................................................................................................................................................................ 5

4. Symbols used and safety ............................................................................................................................................... 5

5. Intended use ................................................................................................................................................................. 6

5.1 Special conditions ................................................................................................................................................... 7

6. Storage .......................................................................................................................................................................... 7

7. Operating conditions and installation ........................................................................................................................... 7

8. Manual override and setting of the DIP switches ......................................................................................................... 9

8.1 Setting the actuators during commissioning (hood open) ..................................................................................... 9

8.2 Setting the actuators during operation (hood closed) ......................................................................................... 10

9. Valve mounting ........................................................................................................................................................... 11

9.1 Spring Extend (SE) valve mounting ....................................................................................................................... 11

9.2 Spring Retract (SR) valve mounting ...................................................................................................................... 11

10. Opening and closing the hood .................................................................................................................................. 12

11. Electric supply ........................................................................................................................................................... 13

11.1 Safety instructions .............................................................................................................................................. 13

11.2 Connection diagram ............................................................................................................................................ 14

12. Display and functions ................................................................................................................................................ 15

12.1 DIP switches ........................................................................................................................................................ 15

12.2 Operating direction ............................................................................................................................................. 16

12.3 Operating buttons ............................................................................................................................................... 16

12.4 Status display ...................................................................................................................................................... 17

12.5 Automatic commissioning (see also chapter 12.3) ............................................................................................. 17

12.6 Manual commissioning (see also chapter 12.3).................................................................................................. 18

12.7 Manual operation (see also chapter 12.3) .......................................................................................................... 18

13. Operation .................................................................................................................................................................. 19

13.1 Split Range .......................................................................................................................................................... 19

13.2 Valve curve .......................................................................................................................................................... 20

14. Commissioning .......................................................................................................................................................... 20

15. Maintenance and servicing ....................................................................................................................................... 21

15.1 Cleaning ............................................................................................................................................................... 21

15.2 Servicing .............................................................................................................................................................. 21

15.3 Spare parts .......................................................................................................................................................... 21

15.4 Service address: .................................................................................................................................................. 21

16. Decommissioning and disposal ................................................................................................................................. 21

17. Annex ........................................................................................................................................................................ 22

17.1 Accessories .......................................................................................................................................................... 22

17.2 Original declaration of incorporation for incomplete machines and EU declaration of conformity ........................ 23

3

1. Product description

The type PSF-**0*.*-*-Ex actuator is an industrial, multifunctional modulating actuator with fail-safe function for

the operation of industrial valves of various types across a wide range of applications. The actuator is designed

for assembly with valves and their motor operation.

It is used as an electric valve actuator in hazardous areas of device category II 2G (Ex zone 1, Ex d e, device

protection level Gb) or device category II 2D (Ex zone 21, device protection level Db) installed in a fixed position

using mounting columns.

An operating status (LED in Ex d motor assembly housing) can be displayed through an inspection glass in the

hood. The actuator can be operated by 2 push buttons in the cover (the micro switches for this are likewise

located in the Ex d housing).

Programming of the control (DIP switches) is possible in the safe range or in a voltage-free state. For this

purpose, the hood is detached and the fastening screws in the Ex d housing are removed.

To protect against environmental influences, the cover and lower section are powder-coated.

Conduit entries are available in the lower section of the housing for inserting the electrical cables.

The construction, as well as the interaction of the individual components and the housing regarding their

suitability for use in hazardous areas, are tested by PS Automation GmbH and confirmed by the identification

with the type label.

The type PSF-**0*.*-*-Ex actuator essentially consists of:

- the two mounting columns

- the drive shaft and

- the housing section

- the mechanical section (multi-stage spur gear) is located in the lower section of the housing (mounting plate)

- the Ex e/t terminal compartment is located in the upper section of the housing (underneath the cover hood),

this is formed by the hood and the upper side of the lower housing section (mounting plate)

- with conduit entries

- with connection panel for the electrical connections (electrical connection compartment)

- with Ed d motor control housing

2. Applicable standards

EN IEC 60079-0:2018/General requirements

EN IEC 60079-7:2015/Increased safety “e”

EN 60079-31:2014/Protection by housing “t”

EN 60079-1:2014/Flameproof enclosure “d”

EN ISO 80079-36:2016/General requirement

EN ISO 80079-37:2016/Structural safety “c”

4

3. Key figures

Device category II 2GD

EU Type Examination Certificate TPS 22 ATEX 110398 0002 X

Ex marking Ex db eb IIC T6 Gb or

Ex db eb IIC T4 Gb or rather

Ex tb IIIC T80 °C Db or

Ex tb IIIC T100 °C Db

Size (electrical section) approx. 240 x 135 x 181 mm (WxLxH)

(Ex e/Ex t housing)

Actuating power Depending on variant

Operating time 0.3 - 2.0 mm/s

Stroke 40 mm-50 mm

Nominal voltage 24VAC/DC, 100-240VAC

Nominal current maximum 1.8A AC / 1.1A DC

Backup fuse

(only for 100 - 240VAC power supply unit, installed in

power supply unit)

2AT 230VAC

External housing material GD-AlSi9Cu3 (EX eb/tb housing)

Die cast

Surface treatment

Powder-coated, permissible total coating thickness ≤ 500µm

(incl. type label)

Ambient temperature range

extended

-10 °C ≤ Ta ≤ 40 °C

-10 °C ≤ Ta ≤ 60 °C

Temperature class T6 (at Ta +40 °C) /T4 (at Ta +60 °C)

Max. surface temperature 80 °C (at Ta +40 °C) /

100 °C (at Ta +60 °C)

IP protection class ≥IP64

5

3.1 Type code

Example PSF-402-SE-EX / 24VAC /50-60Hz /9W / 2.0kN /0.33

Drive type

Spring Retract

(Actuator stem retracting,

valve stem extending) /

Spring Extend

(actuator stem extending,

valve stem retracting)

Supply voltage

Frequency

Max. power consumption

Actuating power

Operating speed [mm/s]

4. Symbols used and safety

General dangers in case of non-observance of the safety instructions

The PSF-Ex actuators are built according to the latest state of the art and are operationally safe. Nevertheless,

hazards can arise from the actuators if they are not used by trained or at least instructed personnel and/or are used

improperly or for purposes other than those for which they are intended.

This threatens, for example

Danger to life and limb of the user or third parties,

Dangers to the user's property,

Impairment of safety and function of the actuator.

It must be ensured that every person in charge of the installation, commissioning, operation, maintenance and

repair of the actuators has read and understood these operating instructions and this chapter in particular.

Safety-conscious work

The actuators may only be operated by trained and authorised operating personnel.

The safety instructions listed in this manual, the existing national regulations for accident prevention, as well as

any internal working, operating and safety instructions of the operator must be observed.

The isolating procedures specified in the operating instructions must be observed for all work such as

installation, commissioning, set-up, operation, changes in operating conditions and operating methods as well

as maintenance, inspection and repair.

Before working on potentially live areas, ensure that they are free of voltage.

Observe IEC/EN60079-14 when installing the actuators.

It must be ensured that the actuators are always operated in perfect condition. Externally visible damage and

defects, as well as changes in the operating behaviour which may affect safety, must be reported immediately.

6

Notice of hazards

The following hazard symbols are used in these instructions:

Attention! There are general hazards that can lead to property and/or

personal injury.

Caution! Life threatening electrical voltages may be present! There is a risk of material damage

and/or personal injury with danger to life.

Danger! This symbol warns of an imminent danger to the health of persons. Failure to follow

these notices may result in injury.

Attention! Observe handling instructions. Electrostatic sensitive components.

Further instructions

During maintenance, inspection and repair directly after operation, increased surface temperatures on the

motor housing are to be expected. Danger of burns!

Visible dust deposits must be removed immediately!

The hood may only be opened in an explosion-free environment! When working in hazardous areas, the

European standards EN 60079-14 “Erection of electrical installations in potentially explosive atmospheres” and

EN 60079-17 “Testing and maintenance of electrical installations in potentially explosive atmospheres” must be

observed.

When upgrading and operating the actuator with PS accessories, the operating instructions available for them

must be observed.

Connections for the signal inputs and outputs are separated from the circuits that are dangerous to touch by

double insulation.

5. Intended use

The type PSF-EX actuator is a fixed installed device for use in Ex zone 1, 2, 21 or 22. The type PSF-EX actuator is

not suitable for use in Zone 0 and Zone 20.

The electrical data shown on the type plate as well as the device category for the place of use must be observed.

The operator of an electrical system in a potentially explosive environment must keep the equipment in proper

condition, operate it properly, monitor it and carry out maintenance and repair work.

See also IEC/EN 60079-17/IEC/EN 60079-19.

The PSF-EX actuators are constructed exclusively for use as electronic valve actuators. They are designed for

assembly with valves and their motorised operation.

Any use other than this is considered unintended use. The manufacturer is not liable for damage resulting from

this.

The actuators shall not be used outside the limit values cited in the data sheet, catalogue and/or order

documentation. Infringement negates all liability on the part of the manufacturer for any resultant damages.

Proper intended use also includes compliance with the operating, maintenance and repair conditions from the

manufacturer.

Mounting and adjustment of the actuator as well as its maintenance are not considered as intended use.

Enhanced safety precautions must be implemented in such situations!

7

Assembly/disassembly, operating and maintenance work may only be carried out by suitable skilled personnel

familiar with the work. All generally applicable legal regulations and other binding guidelines for work safety,

accident prevention and environmental protection must be complied with.

Unauthorised modifications to the actuators negate all liability on the part of the manufacturer for any resultant

damages.

5.1 Special conditions

To avoid critical electrostatic charges,

the devices must not be installed in the vicinity of highly charge-generating processes.

the devices are only cleaned with damp or antistatic fabric.

The length of the flameproof joints is partly larger and the distances of the flameproof joints is partly smaller than

the values of table 3 for IIC of EN 60079-1:2014. Information regarding the dimensions of the flameproof joints

can be obtained from the manufacturer.

The fastening screws of flameproof enclosure parts must have a yield strength of at least 640 N/mm².

6. Storage

The following points must be observed for proper storage:

Store only in well-ventilated, dry rooms.

Store on a rack, on wooden pallet or similar to protect from ground moisture.

Cover to protect from dust and dirt.

Protect actuators from mechanical damage.

7. Operating conditions and installation

When setting up and operating explosion-protected electrical equipment, care must be taken to ensure

protection against harmful environmental influences that restrict the intended use of the equipment. These can

be, for example, protection against aggressive liquids or climatic influences. During installation, observe

IEC/EN60079-14 and other applicable national standards and regulations at the place of installation.

The information on the type plate and the applicable documents must be taken into consideration.

For cable entries with special installation conditions, (see "X" marking on the cable entry), the relevant

instructions given by the manufacturer must be followed.

The actuators can be operated in the Atex version at ambient temperatures according to the data sheet.

The duty cycles are according to IEC 60034-1, 8: S2 for short-time duty and S4 for modulating operation (for

actuator-specific values, see actuator-specific data sheets).

For protection against humidity and dust, the actuators are designed according to EN 60529 with protection class

IP65.

8

Installation

The conductor must be connected carefully at the terminal points so that the individual wires are not damaged.

The maximum connection data on the type plate and the applicable documents must be taken into consideration.

The device must be integrated into a suitable earthing or equipotential bonding system before commissioning, a

connection part (4 mm²) is available for this purpose on the underside of the actuator. The effectiveness must be

checked before initial commissioning.

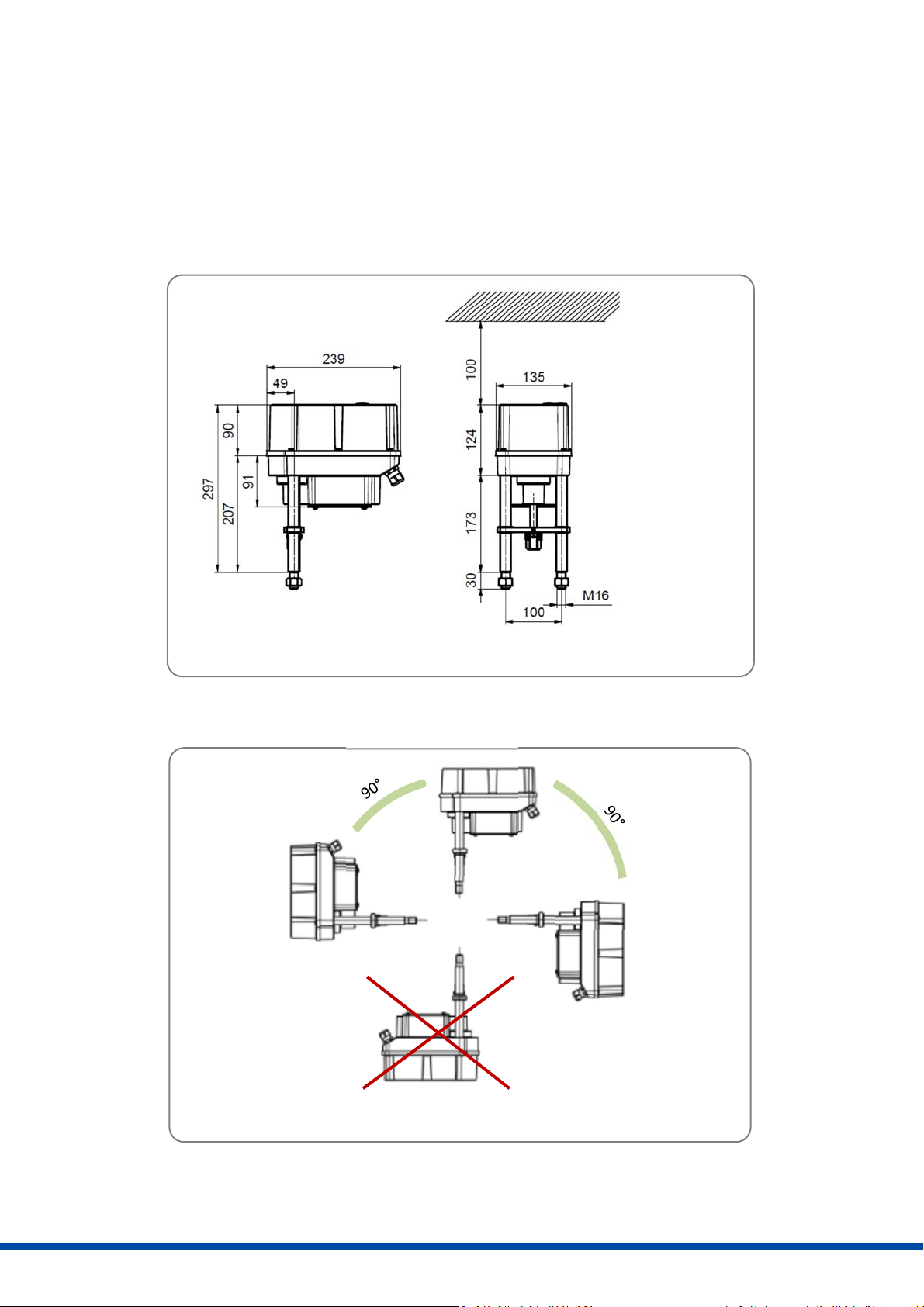

The actuators must be installed with sufficient clearance to remove the hood (Figure 1).

The mounting position is arbitrary with the exception of “hood downwards” (Figure 2).

Figure 1: Installation dimensions

Figure 1: Free space required to remove the hood

Mounting positions

Figure 2: Mounting position

9

8. Manual override and setting of the DIP switches

8.1 Setting the actuators during commissioning (hood open)

When commissioning the actuators, the hood must be opened. The hood may only be opened in non-hazardous

areas and only in a dry environment (see chapter 10 for instructions).

To actuate the actuator during setting work (valve assembly and end position setting), an electrical manual override

by means of a push button is available (for operation, see chapter 12.3).

Programming of the control (DIP switch) is possible in voltage-free state (see chapter 12.1). To do this, first loosen 4

fastening screws of the upper cover of the Ex d control housing, then the upper cover can be removed from the Ex d

control housing. The upper cover of the Ex d control housing must not be damaged in the area of the joint gap when

removing it.

The top cover of the Ex d control housing must be installed considering the position of the push button and the light

guide (see figure 3). The tightening torque for the Ex d cover screws is 6 Nm, minimum quality of the screws 8.8.

(corrosion resistant).

The operating status (status display LED in the Ex d control housing) is indicated by a light guide in the Ex housing

(see chapter 12.4).

The electrical connection of the actuators is made via the terminal strip. The wiring diagram must be observed

(see chapter 11.2).

Figure 3: Manual override and setting of the DIP switches

Button B1

Light guide

Fastening

screws

(

4X

)

Terminal strip

Button B2

DIP switch S1

DIP switch S2

Top cover detached

Position of buttons

and LEDs

10

8.2 Setting the actuators during operation (hood closed)

To actuate the actuator during setting work in potentially explosive atmospheres (end position setting), an electrical

manual override by means of a push button is provided in the hood (for conditions see chapter 12.3).

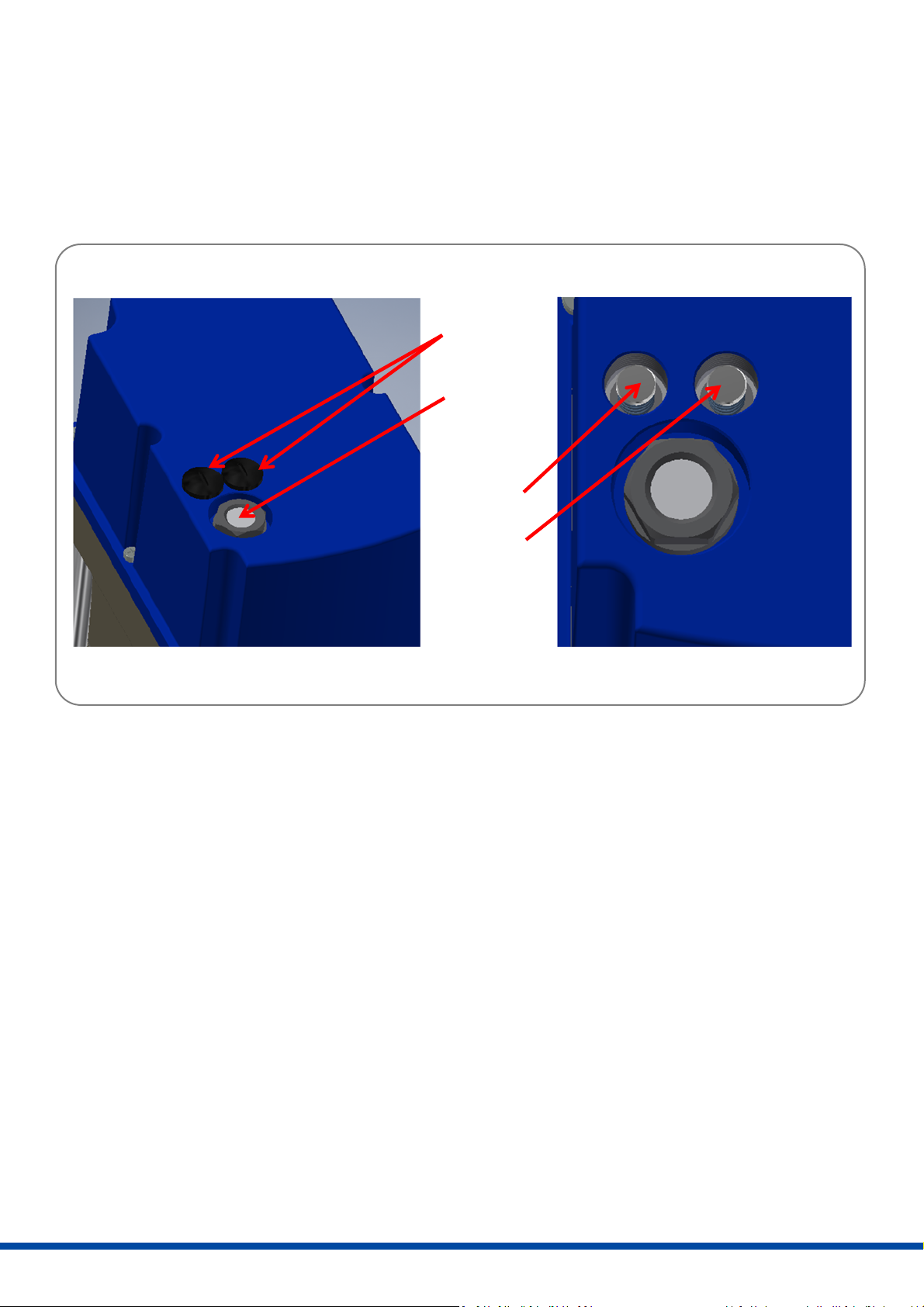

To reach the manual override, the screw plugs must be opened.

An operating status (LED in Ex d control housing) can be displayed through an inspection glass in the hood (see figure

4 and chapter 12.4).

Figure 4: Manual override for setting work in potentially explosive atmospheres

Screw

plugs

Inspection

glass

Button B1

Button B2

Screw plugs removed

11

9. Valve mounting

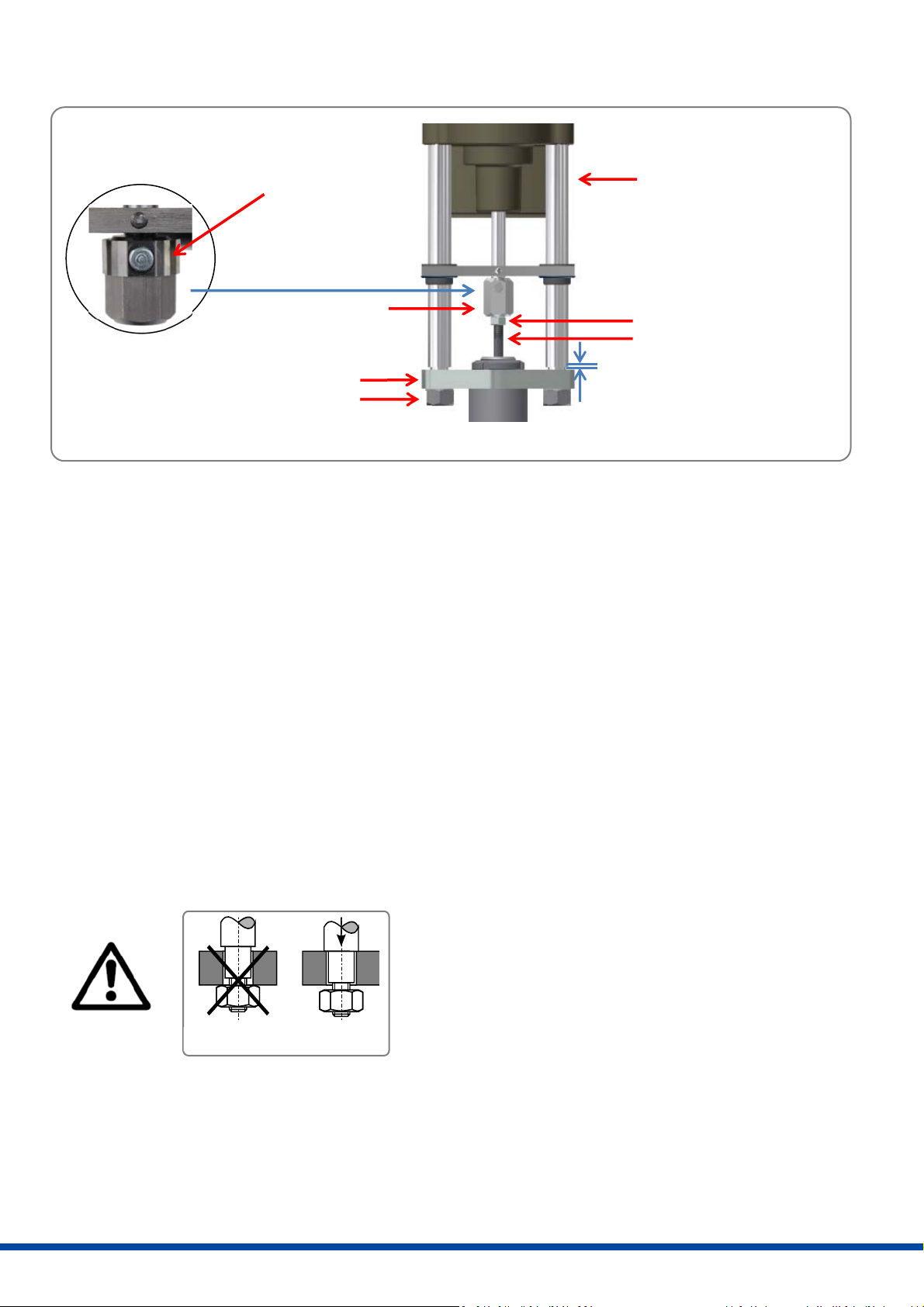

Figure 5: Valve mounting

9.1 Spring Extend (SE) valve mounting

Starting position: Valve stem retracted

1. Fit the drive onto the bracket.

2. Pull off the coupling pin and screw the 13 mm coupling onto the valve stem. A gap of 1 mm must remain between

the pillars and the bracket.

3. Re-insert the coupling pin and tighten the locking nut.

4. Connect the drive electrically (see chapter 11).

5. Retract the actuator stem by means of manual operation (see chapter 12.7) until the pillars rest on the bracket.

6. Screw on and tighten the pillar nuts.

9.2 Spring Retract (SR) valve mounting

Starting position: Valve stem extended

1. Fit the actuator onto the bracket, screw on the pillar nuts and tighten.

2. Connect the drive electrically (see chapter 11).

3. Move the actuator by means of manual operation (see chapter 12.7) until the coupling rests on the valve stem.

4. Pull off the spring-loaded clamp with coupling pin and screw the 13 mm coupling onto the valve stem.

5. Retract the actuator by means of manual operation (see chapter 12.7) until the spring-loaded clamp with

coupling pin can be re-inserted.

Pillar

Valve stem

Locking nut

Coupling

Pillar nut

Bracket

Spring-loaded clamp

with coupling pin

1 mm

TRUE

FALSE

Before tightening the fastening nuts, the pillars must be

seated on the valve bracket. If necessary, correct the

position of the actuator via the manual override. In case of

non-compliance: Damage to the actuator!

12

10. Opening and closing the hood

The hood may only be opened in non-hazardous areas and only in a dry environment.

Take appropriate ESD handling precautions before opening the housing:

Earth the actuator.

Touch earthed housing parts before opening the hood.

Opening:

First loosen all screws with a suitable screwdriver, then

unscrew them completely from the gearbox housing. The

screws are loss-proof. Remove the hood carefully so as not

to damage the seal.

Closing:

Place the cover on the gearbox housing and press lightly.

Lightly tighten all the screws, then tighten them crosswise.

It must be ensured that all screws are firmly tightened to

guarantee protection against ingress of water and dust in

accordance with EN 60529 to IP65. The tightening torque

for the Ex e/t hood is 3 Nm.

Figure 6: Opening and closing the hood

Hexagon socket

screw

13

11. Electric supply

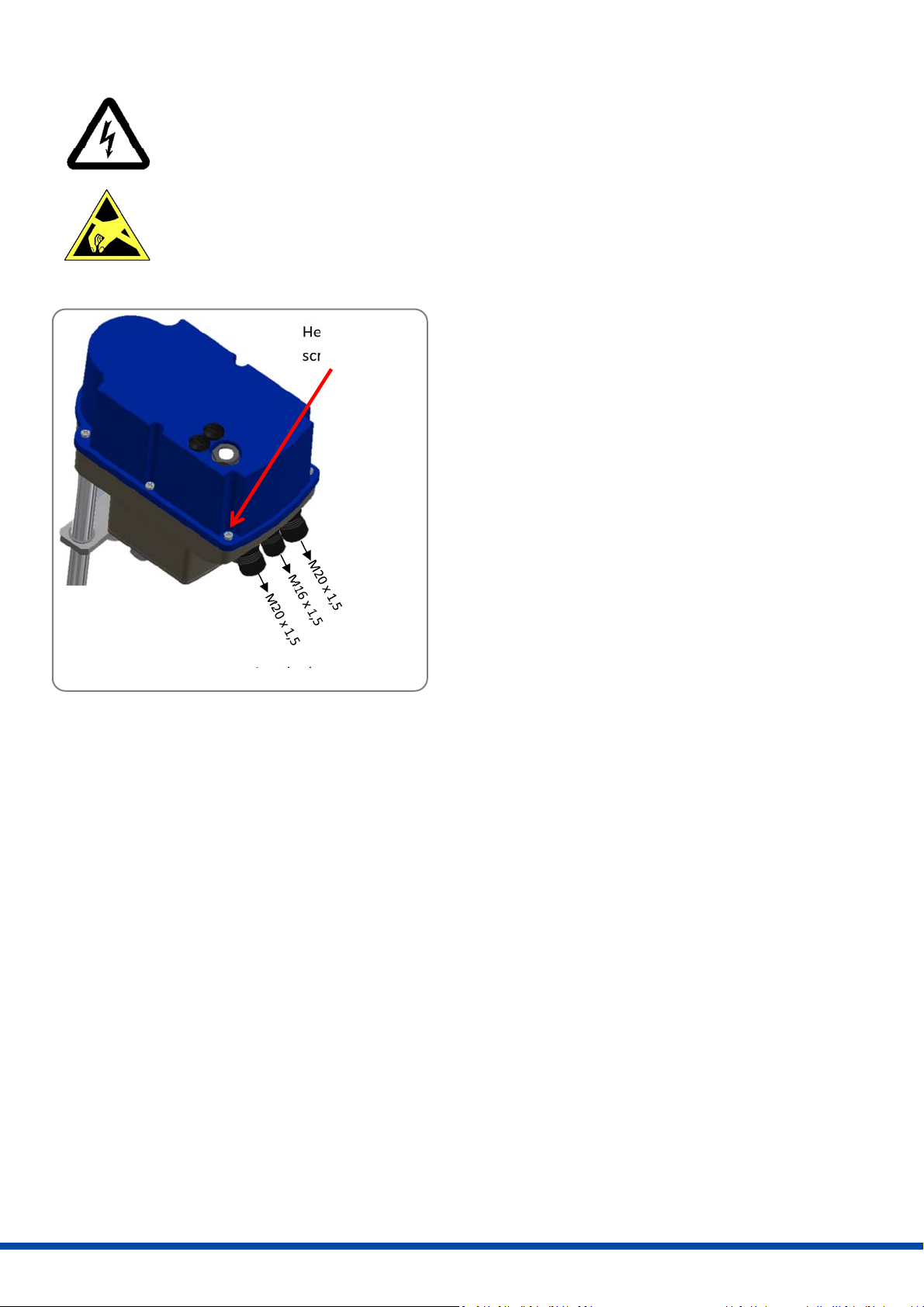

11.1 Safety instructions

During the connection of the mains voltage, this must be disconnected and secured against

unintended reactivation.

The actuator hood must be opened for the electrical connection (see chapter 10).

The mains connection cables must be designed for the nominal current of the actuator.

Yellow-green coloured wiring shall be used only for connecting the protective earth connections.

The cable entry options (cable glands) on the actuator side are located on the lower part of the housing.

For this purpose

- 2x M20 x 1.5

- 1x M16 x 1.5

are available for feeding through the cables from the outside to the inside (see chapter 10).

When guiding the cables through the cable glands, take the maximum bending radius of the cables into account.

Unused entries must be closed by suitable blanking elements.

As the PSF-Ex electrical actuators do not have an internal electrical disconnect device available, a switch or circuit

breaker must be provided in the building installation. This must be located in the vicinity of the device, easily

accessible to the operator and must be identified as a disconnect device for the device.

Furthermore, the building installation must provide over-current protection devices according to IEC 60364-4-41 for

the connection of actuators of protection class I or protection class III at 24 VAC / 24 VDC.

The connection to the terminal block is specified by the manufacturer. The stripping length of the cables is 8 mm and

the tightening torque on the terminal block must be min. 0.6 Nm and max. 0.8 Nm.

All mains connection lines and control lines must be mechanically

secured ahead of the terminals with suitable measures to prevent

unintentional loosening.

Mains connection lines and control lines shall not be routed

together in one line but rather two separated lines shall be used in

all situations!

14

11.2 Connection diagram

Figure 7 shows the electrical connection for standard drives. The wiring diagram in the actuator is binding for the

connection. For the connection of optional accessories, please refer to the respective operating instructions.

Figure 7: Electrical connection Figure 8: Connection for potential equalisation

The protective earth line is connected at the point marked on the actuator.

The connection for equipotential bonding is made at the external equipotential bonding connection

of the actuator

Ensure that all connecting cables are stripped to the correct length so that they are protected against

electric shock

15

12. Display and functions

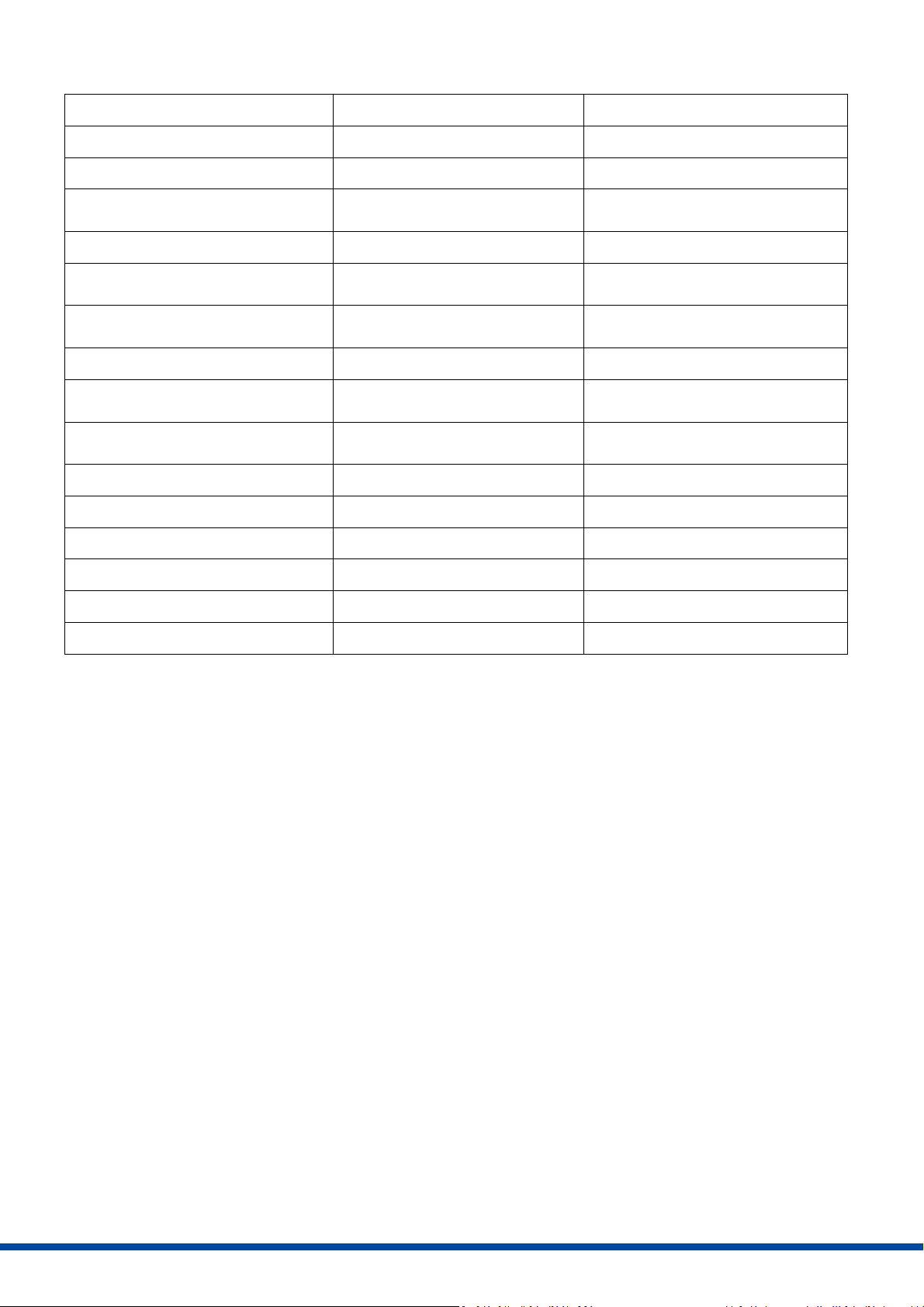

12.1 DIP switches

S1

Function

1 2

3 4 5 6

7

8

Signal Set value Position feedback

Voltage On On Off Off Off On Off On

Current Off Off On On On Off On Off

S2

function

1

2

3 1)

4 1)

5

6

7

8

9 1)

10

Control via set value On

Control via binary inputs Off

Extend valve stem with increasing set value On

Retract valve stem with increasing set value Off

Automatic

commissioning

Closing with force / opening with force On On Off

Closing with force / opening with stroke On On On

Closing with force / opening with 20 mm

stroke On Off x

Closing with force / opening with 30 mm

stroke Off On x

Closing with force / opening with 40 mm

stroke Off Off x

Manual

commissio

ning

Closing with force / opening with

required stroke On On

On

Set value range / feedback signal: 0-10 V / 0-20 mA On

On On

Set value range / feedback signal: 2-10 V / 4-20 mA Off On On

Set value/split range 5-10 V/10-20 mA On On Off

Set value/split range 6-10 V/12-20 mA Off On Off

Set value/split range 0-5 V/0-10 mA On Off On

Set value/split range 2-6 V/4-12 mA Off Off On

Cut-off by force with valve stem extended On

Cut-off by force with valve stem retracted Off

LINEAR valve curve set value/position Off

QUICK OPENING valve curve set value/position On

1) When changing switches S2-3 and S2-4, a new calibration must be carried out so that this new operating mode becomes

effective!

16

12.2 Operating direction

12.3 Operating buttons

Function Action Button B1 Button B2 LED sequence

Manual

operation

Activate Press for > 3 sec. Press for > 3 sec. Both LEDs flash

alternately

Retract valve stem Press Green LED flashes

Extend valve stem Press Red LED flashes

Stop Both LEDs flash

alternately

Exit Press for > 3 sec. Press for > 3 sec. Red or green LED

lights up

Automatic

commissioning

Start Press for > 7 sec. Both LEDs light up

Calibration ended

Green LED flashes 7x

(when calibration is

complete),

Green LED flashes

rapidly

(if calibration fails)

Exit Press once Red or green LED

lights up

Manual

commissioning

Activate Press for > 7 sec. Both LEDs flash

alternately

Retract valve stem Press Green LED flashes

Extend valve stem Press Red LED flashes

Start Press for > 3 sec. Press for > 3 sec. Both LEDs light up

Exit Press once Red or green LED

lights up

SE = Spring Extend: Actuator stem extends, valve stem retracts

SR = Spring Retract: Actuator stem retracts, valve stem extends

SE = Spring Extend: Actuator stem extends, valve stem retracts

SR = Spring Retract: Actuator stem retracts, valve stem extends

Figure 9: Operating direction

17

12.4 Status display

Green LED Red LED

Actuator not calibrated Off Flashes rapidly

Normal operation / actuator moves On Off

Normal operation / actuator

stationary Off On

Manual mode active Flashes alternately Flashes alternately

Manual mode: Valve stem is

extended Off Flashes

Manual mode: Valve stem is

retracted Flashes Off

Automatic commissioning running On On

Automatic and manual

commissioning successful Flashes 7 x - 1.5 sec. off On

Automatic commissioning

failed Flashes rapidly On

Over-voltage Flashes 1 x - 1.5 sec. off On

Under-voltage Flashes 2 x - 1.5 sec. off On

Memory error Flashes 3 x - 1.5 sec. off On

Set value error (< 1 V, < 2 mA) Flashes 4 x - 1.5 sec. off On

Torque fault Flashes 5 x - 1.5 sec. off On

Under/over-temperature Flashes 6 x - 1.5 sec. off On

Blue LED: Ready-to-operate indicator lights up when the supply voltage is applied. LED illumination facilitates

reading of the DIP switch position.

12.5 Automatic commissioning (see also chapter 12.3)

Check secure connection between valve and actuator.

To start automatic commissioning, press button B2 for at least 7 seconds.

- Option 1: “Opening with force - Closing with force”: The actuator moves to the open-end position by force

and back again to the closed end position.

- Option 2: “Open with calibrated stroke” (20/30/40 mm): The closed end position is saved and the stroke is

calculated based on the setting. If the possible travel path is less than the present stroke, the stroke for

operation is automatically reduced to the resulting maximum possible value.

After successful commissioning, the green LED flashes seven times.

Then press button B1 to return to normal operation.

After successful commissioning, check the determined or adjusted stroke by setting the set value and the valve

position.

Unsuccessful commissioning is signalled by the green LED flashing rapidly. Check valve installation.

For commissioning, it is necessary that a residual stroke of at least 1 mm is available in "Closing direction with

force" before the actuator has reached its mechanical stop. Furthermore, the actuator must be able to perform

a stroke of at least 5 mm.

18

12.6 Manual commissioning (see also chapter 12.3)

Check that the gland between the valve and the actuator is secure.

To activate the individual calibration, press button B1 > at least 7 seconds.

The actuator can be moved manually with buttons B1 and B2 until the desired open-end position of the valve is

reached.

The calibration of the two end positions is started and saved by pressing B1 and B2 simultaneously for at least 3

seconds.

After successful calibration, the green LED flashes seven times.

Then press button B1 to return to normal operation.

Check the adjusted stroke by setting the set value and measuring the actual value.

Unsuccessful calibration is signalled by the green LED flashing rapidly.

For commissioning, it is necessary that a residual stroke of at least 1 mm is available in "Closing direction with

force" before the actuator has reached its mechanical stop. Furthermore, the actuator must be able to perform

a stroke of at least 5 mm.

12.7 Manual operation (see also chapter 12.3)

Press and hold buttons B1 and B2 simultaneously for at least 3 seconds to activate manual operation.

Press button B1 to retract the valve stem.

Press button B2 to extend the valve stem.

Press and hold buttons B1 and B2 simultaneously for at least 3 seconds to exit manual operation.

19

13. Operation

The operator of an electrical system in a potentially explosive environment must keep the equipment in proper

condition, operate it properly, monitor it and carry out maintenance and repair work. See also IEC/EN 60079-

17/IEC/EN 60079-19.

During operation, all internal parameters, such as the required motor torque and the current position, as well as the

operating states of the actuator are continuously monitored. This ensures that the actuator is positioned with

optimal accuracy and that the valve is always closed correctly.

13.1 Split Range

With the setting "Set value signal/Split range" switch position S2-2/7/8, the set value is split into a lower or upper

range. This means that several actuators can be controlled with only one set value signal.

Figure 10: Split Range

Set Value

Actuator 1

Actuator 2

20

13.2 Valve curve

Switch position S2-10 can be used to select the relationship between the set value and the actuator position. Two

curves are available. With the linear valve curve, the actuator position in % corresponds to the set value in %. The

"Quick Opening Curve" enables fast valve opening with a small set value.

14. Commissioning

The electrical connection and commissioning with mains voltage applied may only be

carried out by trained specialist personnel!

Do not touch any connection lines during commissioning!

Before the equipment is initially commissioned, it must be checked for its suitability in the

relevant zone on the basis of its marking. The values specified on the type plate and in the

applicable documents must not be exceeded.

Commissioning and use may only take place when the operating equipment is correctly

arranged within the system and is undamaged and clean.

Opening the hood (see chap. 10), placing the actuator on the valve (see chap. 9), making the

electrical connection (see chap. 11).

Carry out automatic (see chapter 12.5) or manual commissioning (see chapter 12.6).

Close the hood (see chapter 10).

Stroke %

Figure 11: Valve curve

Other manuals for PSF-EX

1

Table of contents

Other PS Automation Industrial Equipment manuals