www.sumitomodrive.com 1-800-SM-CYCLO 19.001.61.008

Page 1

Taper Grip® Bushing Installation Guide

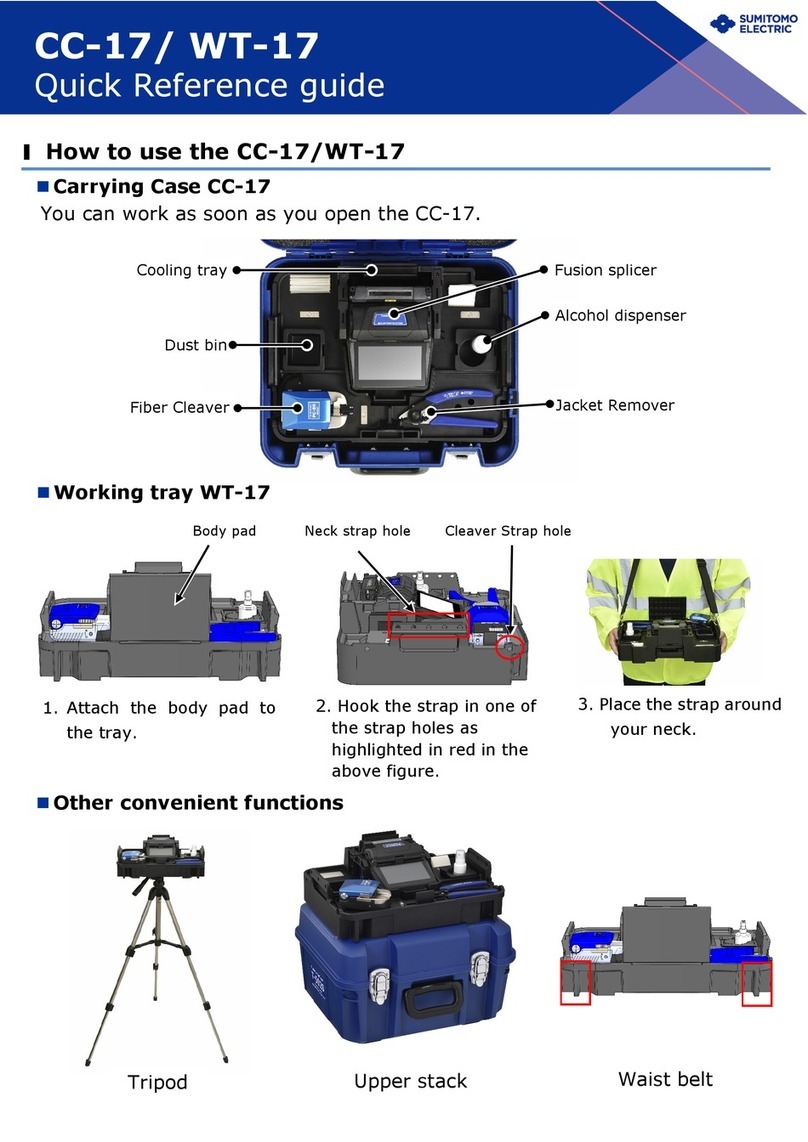

Introduction

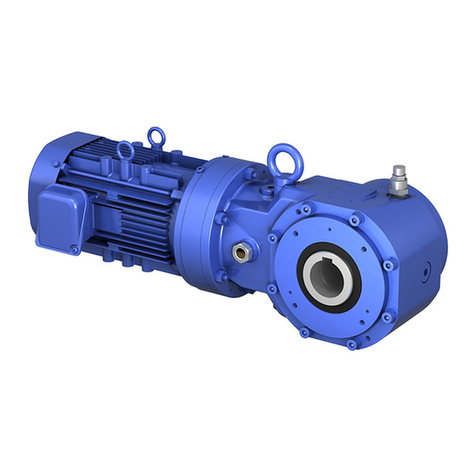

The keyless Taper-Grip® bushing system provides simple and reliable

shaft attachment for Sumitomo Speed reducers and gearmotors. This

system allows bi-directional shaft rotation and stop-start operation with

a powerful, slip-free grip. To assure peak performance of your equip-

ment, please read, understand and follow these installation instructions.

Safety

Disconnect all power sources from the equipment before beginning this

installation procedure. Handle the components with care and avoid all

sharp or machined edges to prevent personal injury or damage to the

components.

Before Installing Unit on Driven Shaft

(Steps 1-7)

Carefully inspect the driven equipment shaft. Remove all burrs, corrosion,

lubricants, and foreign matter from the shaft surface. Verify the shaft

diameter is within the dimensional tolerances shown in Table 1.

Table 1 Driven Shaft Tolerances

Shaft Diameter (inches) Shaft Tolerance (inches)

3/4” – 1-1/8” +0” – 0.0013”

1-3/16” – 2” +0” – 0.0015”

2-1/16” – 3-1/8” +0” – 0.0018”

3-3/16” – 4-3/4” +0” – 0.0021”

4-13/16” – 6-1/2” +0” – 0.0025”

Clean all surfaces of the shaft, the bushing, the thrust collar and the unit

bore with solvent to remove all grease and oil.

Step 1 – Remove the Taper-Grip® bushing safety cover (see Fig. 2).

Step 2 – Remove the cap screws from the bushing. Lightly oil the

threads of the cap screws and partially re-insert them into the threaded

holes in the bushing flange. The ends of the cap screws should not

extend beyond the rear face of the bushing flange.

Step 3 – Slide the thrust collar onto the Taper-Grip® bushing

(see Fig. 3).

Step 4 – Apply a thin layer of anti-seize paste to the male threads of

the Taper-Grip® Bushing only (see Fig.4). Based on tests, Sumitomo

recommends Bostik Never-Seez Regular Grade or equivalent. Ensure

that anti-seize paste does not enter the Taper-Grip® Bushing bore.

Caution: Do not apply anti-seize paste to the female threads in

the hub.

Step 5 – Carefully thread the Taper-Grip® bushing into the hub of the

speed reducer or gearmotor until the thrust collar solidly engages the

unit hub surface and the bushing flange (see Fig. 5). Caution: Do not

cross-thread. Bushing should thread easily into hub.

Step 6 – Unscrew the Taper-Grip® bushing to create a 1mm (0.04”) gap

between the thrust collar and the bushing flange.

Step 7 – Hand-tighten the cap screws until they firmly press the thrust

collar against the unit hub surface. The unit is ready for installation on

the driven shaft.

Fig. 1 Taper-Grip® Bushing Parts

Fig. 3 Slide Thrust

Collar on Bushing

Fig. 5 Thread

Bushing into Hub

Fig. 4 Apply

Anti-seize Paste

Apply thin layer of anti-seize

paste to male threads of

bushing only.

Fig. 2 Remove

Safety Cover