PSC Solar OGM Series User manual

8

1

MPPT Module Type

USER MANUAL

8KVA-12KVA OGM

Series

Hybrid Inverter

Sate

Copyright, copying and plagiarism without any authorization is prohibited

The company is committed to the continuous improvement of the inverter. This information is subject to change without notice. please refer to the actual

product.

8

Contents

1.Product introduction ………………………………………………………1

2. Product features……………………………………………………………1

3. Working principle…………………………………………………………1

4. Introduction to working mode ……………………………………………2

5. Appearance introduction…………………………………………………5

6. Installation instructions ……………………………………………………7

7. Operation and maintenance ………………………………………………9

8. Inverter startup procedure ………………………………………………10

9. Emergency shutdown procedure …………………………………………10

10. Operation interface description …………………………………………10

11. Technical parameters …………………………………………………… 16

12. Causes and solutions of common failures ……………………………… 17

13. Packing list ……………………………………………………………… 17

8

2

8KVA-12KVA OGM series MPPT inverter control all-in-one machine is a highly

intelligent product integrating digitization, informationization and networking. It has a

powerful information acquisition system, signal processing system, detection system and

perfect protection system. It is widely used in a variety of electrical environments,

personalized design, and friendly man-machine dialogue. The touch screen LCD is the latest

power display module developed by the company and adopts today's popular intuitive

graphical operation interface. Compared with the general LCD display module, the touch

screen display module has no complicated operation steps. The user can directly click the

analog button on the display to obtain the corresponding information, and the operation is

simple and easy to understand.

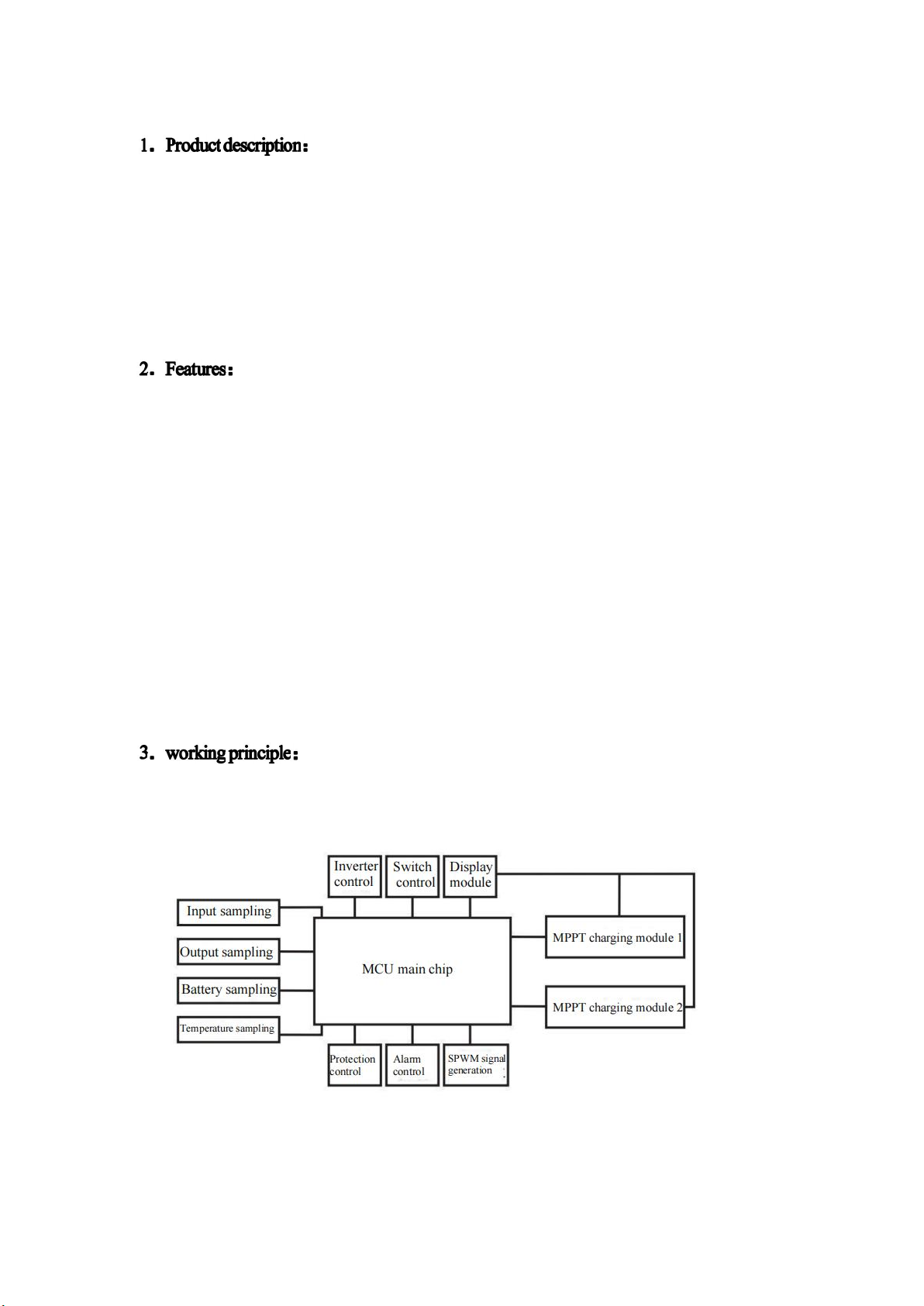

2.1. The inverter adopts DSP, MCU and DDC real-time processing all-digital vector

control technology to accurately control various parameters of the machine and fully

control it.

2.2. The combination of advanced IGBT high frequency pulse width modulation

technology (M PPT ) reduces system noise and power loss, ensuring that customers can

obtain high-quality voltage output and the highest benefits under various workload

conditions.

2.3. The output of the machine with isolation transformer and equipped with isolation

transformer will not have DC components in the load, which can effectively protect the

switching power supply of computers, networks and comm unication equipment from DC

current damage. At the sam e time, it can also be used for non-linear loads. It exhibits

excellent dynamic performance, improves the load capacity of the machine, and has good

load compatibility.

2.4. Complete protection functions, with AC input over voltage and under voltage

protection, output over voltage and under voltage protection, output overload short-circuit

protection, battery under voltage warning protection, internal over-temperature protection,

which greatly guarantees the operation of the system Stability and reliability.

2.5. The use of high-power IGBT devices makes the inverter have strong overload capacity

and shock resistance, and at the same time enhances the adaptability to the power grid.

The 8KVA-12KVA OGM series MPPT inverter control all-in-one machine is highly

integrated with digital technology to improve MTBF and reliability. It adopts MCU

high-speed microprocessor control to ensure stable and reliable operation of the equipment.

8

3

4.Work mode introduction:

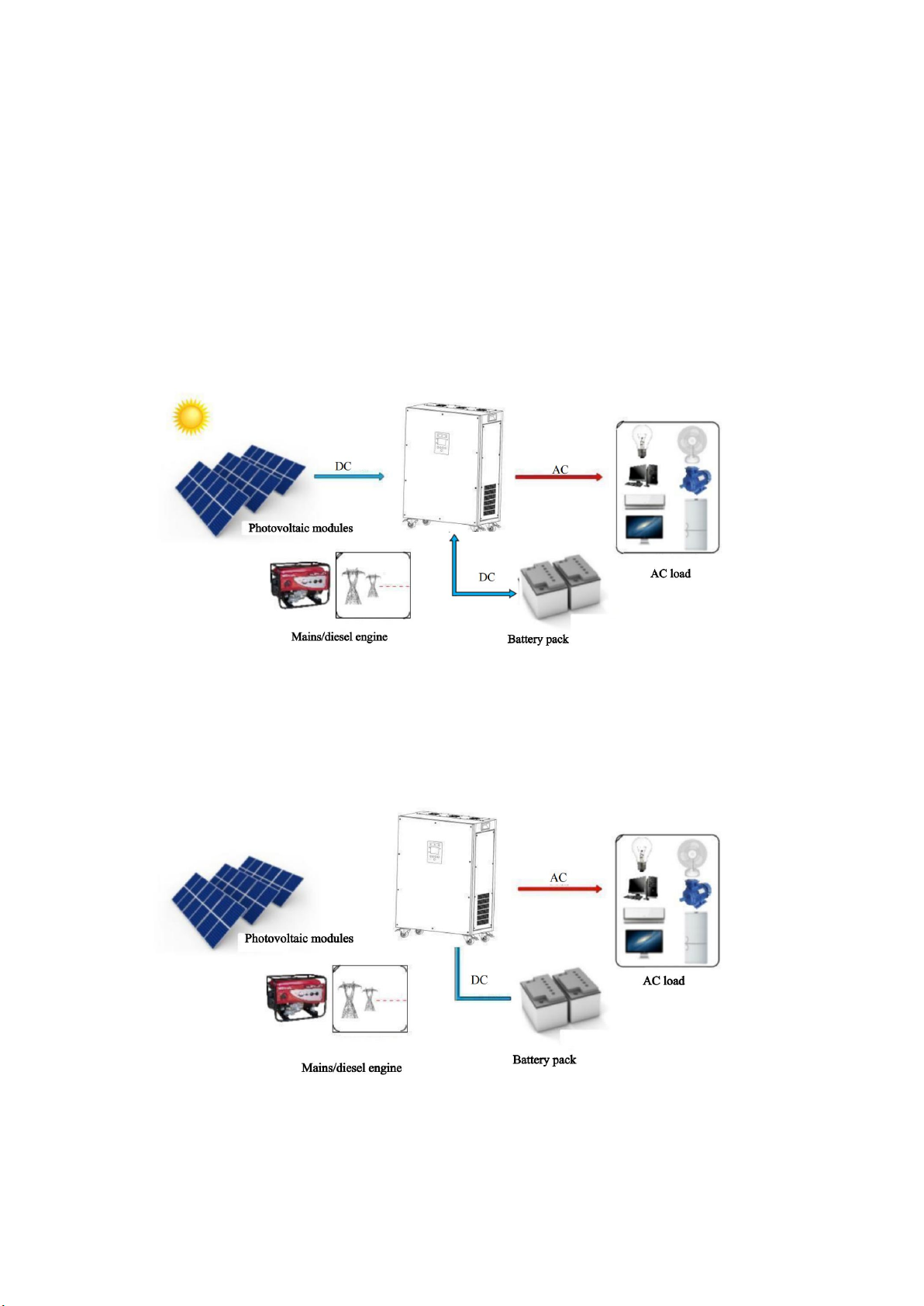

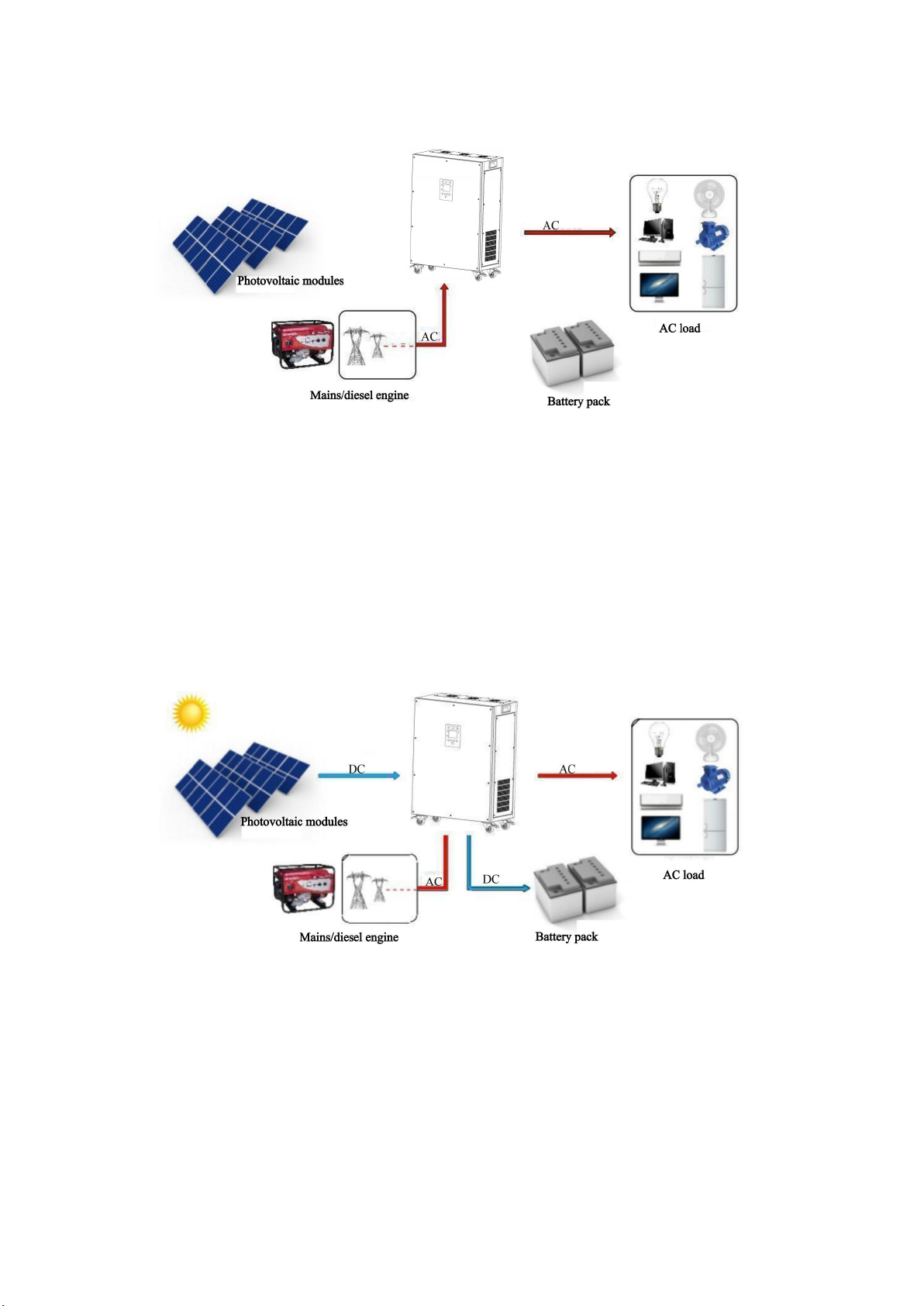

The 8KVA-12KVA OGM series inverters have two working modes: battery priority mode

(DC Priority) and mains priority mode (AC Priority).

4.1. Battery priority mode(DC Priority):

When the battery voltage is normal, regardless of whether the mains (or diesel engine) input

is normal or not, the inverter works by inverting the battery's direct current into alternating current

to supply power to the load. When the battery voltage is too low, the inverter automatically

switches to the mains ( (Or diesel engine) to supply power to the load, but not to charge the battery.

After the battery is fully charged by the photovoltaic panel, the inverter will automatically switch

to battery inverter to supply power to the load. This mode is suitable for new energy systems such

as photovoltaic power generation and wind power generation.

(1) In battery priority mode, when the photovoltaic panel is generating electricity in sufficient

sunlight, the system works as shown in the figure below:

(2) In battery priority mode, when the photovoltaic panel does not generate electricity at night or

on a cloudy or rainy day and the battery voltage is normal, the system works as shown in the

figure below:

(3) In battery priority mode, when the photovoltaic panel does not generate electricity at night or

on a cloudy or rainy day and the battery is low, the system works as shown in the figure below:

8

4

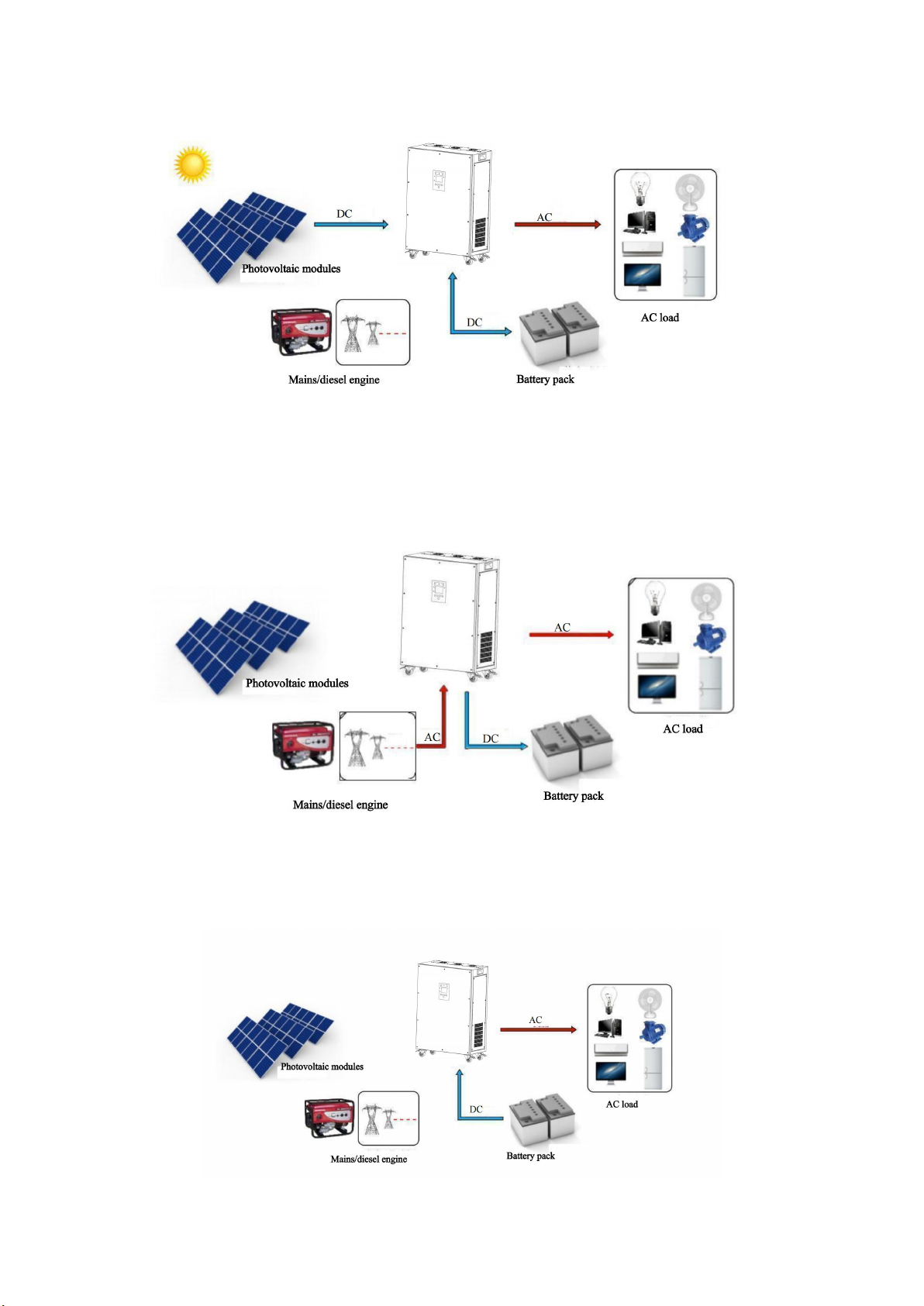

4.2.AC Priority:

When the mains (or diesel engine) input is normal, the inverter works in the mains bypass to

supply power to the load and at the same time to the battery.When the mains power is too

high/low/severe distortion/frequency abnormality/fault and other abnormal conditions, the inverter

will automatically switch to the battery to supply power to the load. After the mains (or diesel

engine) input is normal, the inverter will be reversed. The converter will automatically switch to

the mains bypass to supply power to the load. This mode is suitable for the backup power system,

the inverter is always on, and it is suitable for the unstable mains or the need to ensure the

uninterrupted load to shorten the switching time.

(1) In the mains priority mode, when the photovoltaic panel is fully sunny and the mains input is

normal, the system works as shown in the figure below:

(2) In the mains priority mode, when the photovoltaic panel generates electricity with sufficient

sunlight and the mains input is abnormal, the system works as shown in the figure below:

8

5

(3) In the mains priority mode, when the photovoltaic panel does not generate power at night or on

a cloudy or rainy day and the mains input is normal, the system works as shown in the figure

below:

(4) In the mains priority mode, when the photovoltaic panel does not generate electricity at night

or on a cloudy or rainy day, the mains input is abnormal and the battery voltage is normal, the

system works as shown in the figure below:

8

6

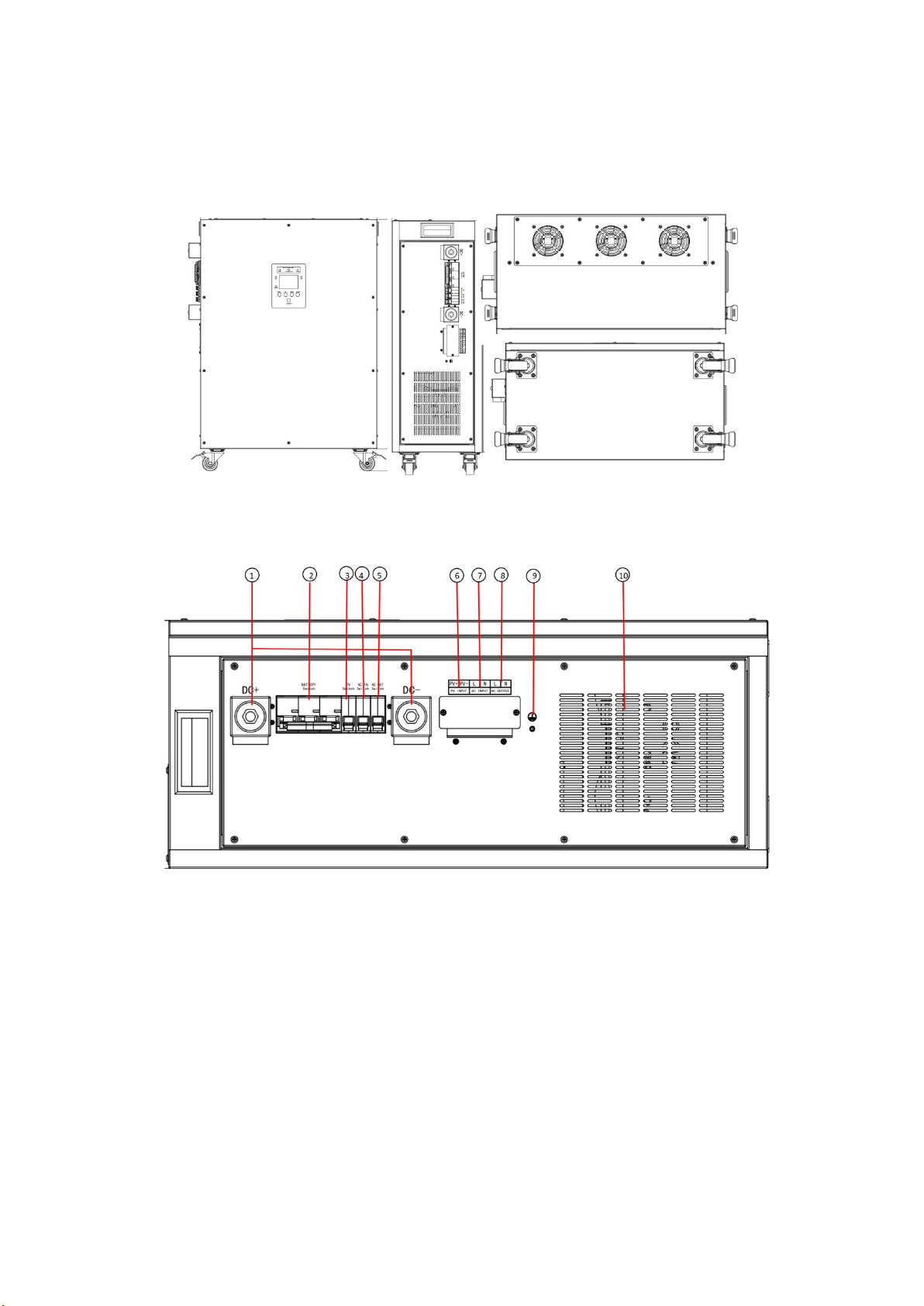

5.Appearance introduction

5.1 Terminal introduction

①DC is the battery input terminal, DC+ is the positive pole, and DC- is the negative pole;

②The battery switch must be disconnected before installation, and the switch can be turned on

after the installation is complete;

③PV Switch is a photovoltaic input switch;

④AC IN Switch is an AC input switch, which needs to be disconnected before installation, and it

can be turned on after the installation is complete;

⑤AC OUT Switch is an AC output switch, it needs to be disconnected before installation, and it

can be turned on after the installation is completed;

⑥PV INPUT is the photovoltaic input terminal, + is the positive pole,-is the negative pole;

⑦AC INPUT is an AC input terminal, which can be connected to the mains for complementation,

and it will not affect the use if it is not connected to the mains;

⑧AC OUT is an AC output port, which can be connected to a load;

⑨is the ground terminal;

⑩Cooling fan;

8

7

6. Installation instructions

Please strictly follow the warnings and operating instructions in the manual and on the

machine and keep this manual properly. Please do not operate this machine before reading all the

safety instructions and operating instructions, otherwise it will damage the equipment and cause

personal safety accidents.

6.1. Unpacking inspection

The inverter power supply has been strictly inspected before leaving the factory, but it may

be damaged during transportation. Therefore, after unpacking, please check whether the following

items are complete and whether the model, power, input voltage, output voltage, etc. are

consistent with the order The specified content matches; if there is an abnormality or the content

does not match, please contact our company as soon as possible.

6.2. Handling

This product should be handled with care during transportation to avoid falling, collision and

strong vibration. It is strictly forbidden to turn the packaging box upside down. Do not lose

accessories, instruction manuals, warranty cards, etc. when unpacking and transporting. In

addition, this product is large and heavy. Please pay attention to safety when handling it to avoid

injury to your body.

6.3. Installation instructions

1. When installing the inverter power supply, it must be done by professionals or with the

assistance of local dealers.

2. Confirm whether the input DC power supply voltage range meets the requirements, ie +15%,

and whether the power supply polarity is correct.

3. Confirm the voltage level of the load equipment, and the power should not be greater than the

rated output power of the inverter power supply.

4. Do not pour liquid into the inverter power supply, or wipe the machine casing with a damp

cloth. The human body cannot be directly when the machine is running

Touch the input and output terminals of the inverter power supply, especially with wet hands,

otherwise it may cause electric shock.

5. If the working environment of the normal inverter power supply needs to be changed, it is not

allowed to change its connection by yourself, and a professional should be

The operator or dealer confirms the operation.

6. The operating environment of the electric power supply should be in a well-ventilated

environment with a temperature range of -25 to 50°C and a relative humidity of 30%-90%.

When using, keep it away from open flames and direct sunlight. No corrosive gas, oil mist, water

splash, salt mist, rain, humidity, and can not operate in condensation and dust environment. If the

altitude is below 1000m, please decide to use|great to use|data to use|drive to use|rate to use|dare to

use|date to use|dream to use|rewrite to use|treat to use if it exceeds this altitude. A certain amount

of heat is normal during use, but the installation environment must be kept clean and clean,

especially not blocking the ventilation holes.

7. Minors are not allowed to use this product.

8. Confirm that the ground wire of the inverter power supply is reliably connected, the live wire

and the neutral wire cannot be reversed, and the wire diameter should meet the conditions for safe

use, The connection line should be as short as possible.

9. Please do not open the inverter power supply case by yourself, otherwise we will not be

responsible for the warranty.

10. No objects can be placed on the top of the equipment; sufficient space for inspection and

repair must be prepared directly in front of and above the equipment, and the power cord must be

wired from the bottom of the machine;

Notice:

A. This product cannot be used for life-sustaining equipment without permission.

B. This inverter power supply is not suitable for ultra-high-precision electronic equipment, it

needs to be confirmed by professional and technical personnel before it can be used

run.

C. If it is used for computer load, the built-in power supply of the computer should be a brand

power supply.

warn!

8

8

It is strictly forbidden to connect the battery in reverse, and it is strictly prohibited to connect the

live wire and the neutral wire in reverse.

It is strictly forbidden to use it in an environment with flammable and explosive gases, and beware

of sparks!

The connection sequence must be the battery first and then the photovoltaic panel. It is strictly

forbidden to reverse the sequence.

6.4. Safety instructions

1. Be sure to read the manual and understand all the contents before use.

2. Do not block the heat dissipation holes of the device with sundries during use to ensure good

ventilation and heat dissipation.

3. Regardless of the working status, please do not remove or connect the equipment cable with

power to avoid danger.

4. The connection cable must choose the appropriate specification, the connection is firm and the

insulation is good.

5. Please do not close any circuit breakers before all equipment is fully connected

6. When inspecting or maintaining the inverter, you must wait for more than 10 minutes after

removing the relevant connecting wires before opening the cover of the device to prevent the

electric charge stored in the capacitor components of the inverter from causing electric shock to

persons.

7. To avoid personal injury and machine damage caused by electric shock, do not open the cover

(shell).

8. It is forbidden to connect the output of the inverter to the mains power grid. The mains line

must be isolated from the inverter line before use, otherwise the inverter will be seriously

damaged.

9. It is strictly forbidden to use it in an environment with flammable and explosive gases or objects,

and beware of flames and sparks.

10. When the AC side of the inverter is loaded, the DC connection must not be directly

disconnected. You must first cut off the DC switch of the inverter and confirm that there is no

voltage before disconnecting the DC connection.

11. When the inverter is live, do not plug or unplug any connectors, and do not open the cover of

the machine!

12. This equipment must not be operated with overload, and equipment failures and damages

caused by overload operation are not covered by the warranty.

6.5Wiring block connection attention:

Before the inverter is installed, disconnect all switches.

According to the picture above, AC INPUT is connected to the mains input (pay attention to the

phase of zero live wire), G is grounding, AC OUTPUT is connected to load appliances (note the

phase of zero live wire), SOLAR PANEL is connected to photovoltaic panels (note the positive

and negative polarity), and BATTERY is connected to the battery ( Pay attention to the positive

and negative polarity), you need to connect the battery first and then the photovoltaic panel;

6.6 Wiring check

Connect all input and output wires, and check the following items:

Whether all the battery cables are connected correctly and in good contact, and the input, output,

and grounding cables are correctly connected to the corresponding terminal block on the device.

6.7. Cable current-carrying capacity parameters: see the table below (subject to

multi-strand copper core cables, unit: mm2)

7. Operation and maintenance

8

9

1. Connect and install the equipment in strict accordance with the relevant operating procedures.

During installation, you should carefully check: whether the wire diameter meets the requirements;

whether the components and terminals are loose during transportation; whether the insulation parts

are well insulated; whether the grounding of the system meets the requirements.

2. It should be operated and used strictly in accordance with the provisions of the product

instruction manual. Especially: Before starting the machine, pay attention to whether the input

voltage is normal; when operating, pay attention to whether the sequence of power on and off is

correct.

3. The equipment has automatic protection for short-circuit, over-current, over-voltage,

over-heating, etc., so there is no need to shut down manually when these phenomena occur; the

protection points for automatic protection are generally set at the factory and do not need to be

adjusted.

4. There is high voltage in the equipment cabinet, and the operator is generally not allowed to

open the cabinet door, and the cabinet door should be locked normally.

5. When the room temperature exceeds 50°C, heat dissipation and cooling measures should be

taken to prevent the equipment from malfunctioning and prolong the service life of the equipment.

6. Regularly check whether the wiring of each part of the equipment is firm and whether there is

any looseness. In particular, carefully check the fan, power module, input terminal, output

terminal and grounding.

7. The operator must be specially trained to be able to judge the cause of the general failure and be

able to eliminate it.

For example, you can skillfully replace fuses, components, and damaged circuit boards. Untrained

personnel are not allowed to operate and use the equipment.

8. Once the alarm is stopped, it is not allowed to turn on immediately. The cause should be found

out and repaired before turning on again.

9. If an accident that is not easy to eliminate or the cause of the accident is unclear, a detailed

record of the accident should be made, and the production factory should be notified in time for

resolution.

10. Virtual connection or damage to the battery pack is one of the main factors causing equipment

failure. It is recommended to check the voltage of the battery and whether the connection

terminals are reliably connected every two months (tools can be used to fasten each terminal), and

remove the rust stains on the terminal in time. Clean the dust inside the equipment regularly, and

disconnect the relevant connecting wires of the inverter during cleaning.

11. When the load is inductive loads such as refrigerators, motors, washing machines, water

pumps, etc., the equipment should be selected at 5-6 times its nominal power, and the load should

be increased one by one. Frequent starting is strictly prohibited.

12. When the inverter fails to work normally, please refer to the instructions in the manual. If it

still cannot be solved, please contact the dealer or the manufacturer as soon as possible. Do not

disassemble the parts by yourself!

8. Start-up procedure of the inverter control integrated machine:

Correctly operating the inverter power supply can better ensure its service life and provide

high-quality input power for your load equipment. The following are the recommended normal

operation steps of inverter power supply for you.

8.1. Normal start-up steps of the inverter power supply

1. Connect the front AC input power;

2. Close the inverter DC input switch (battery switch);

3. After the inverter output indicator INV lights up, close the inverter AC input switch;

4. After confirming that the load can be powered, close the inverter AC output switch;

5. Turn on the load equipment switches one by one;

8.2. Operation steps for normal shutdown of inverter power supply

1. Turn off the load equipment switches one by one;

2. Disconnect the AC output switch of the inverter power supply;

3. Disconnect the AC input switch of the inverter power supply;

4. Disconnect the inverter DC input switch (battery switch);

5. Disconnect the front-level AC input power;

8

10

9. Emergency shutdown procedure:

This operating procedure can only be operated when fire, electric shock, arc or other hazards

occur, but it will cause no danger of AC output.

—— Disconnect all switches downward

Notice:

The company reserves the right not to guarantee the quality of the products in the following

situations.

1. The whole machine and parts have exceeded the free warranty period;

2. Product transportation damage;

3. Incorrect installation, modification or use that is not in accordance with the requirements of the

manual;

4. Exceed the very harsh environment described in this manual;

5. Failure or damage to the machine caused by installation, repair, modification or disassembly by

non-service agencies or personnel of our company.

If the product fails due to the above situation, the customer requires maintenance service. After the

judgment of the company's service department, paid maintenance services can be provided.

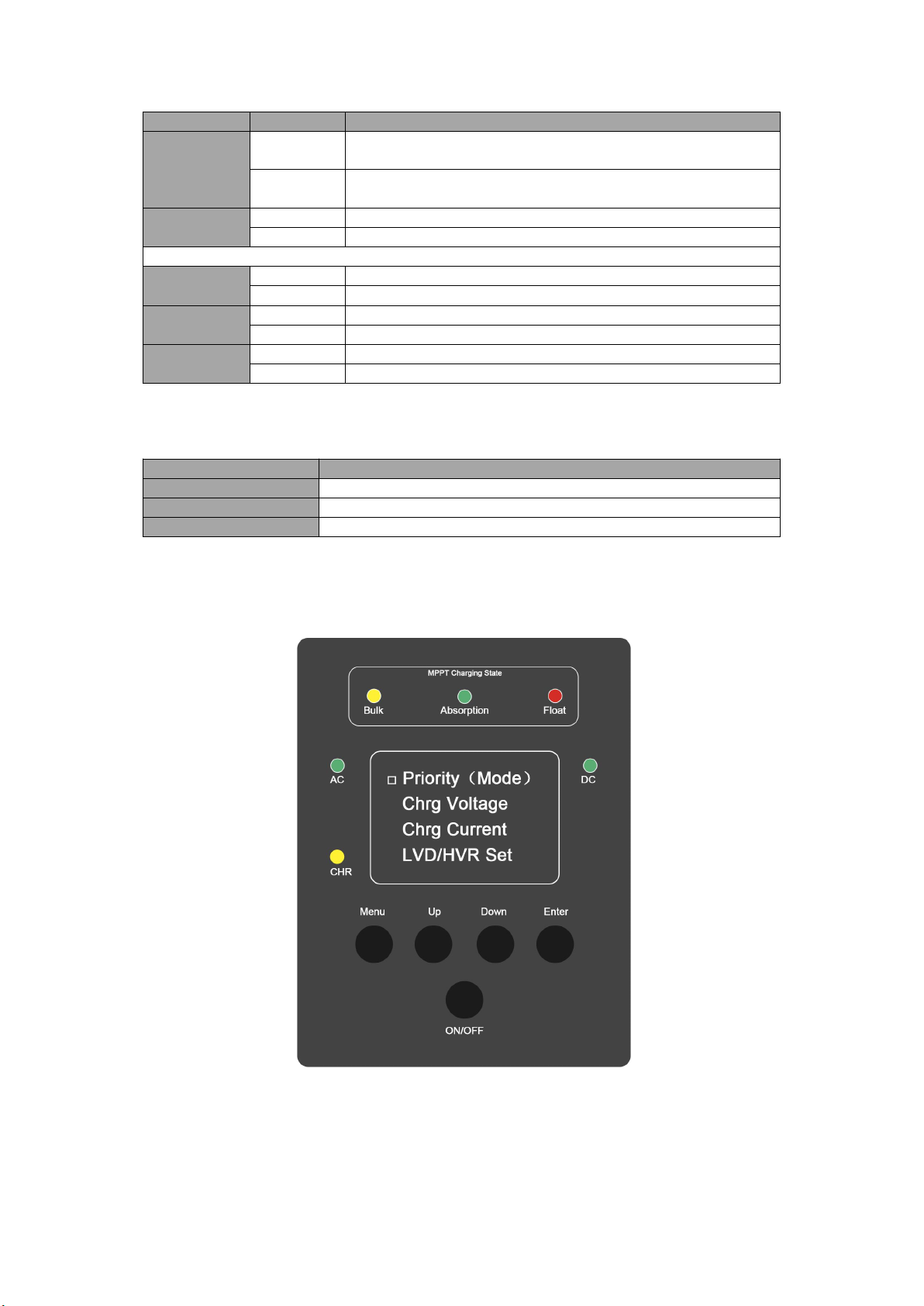

10. Operation interface description:

10.1 Open the main interface

The operation control display panel is located on the front. By operating the control display panel,

you can control and query all parameters, battery status, and alarm information. This series of

inverters can choose whether to need MPPT. The interface with MPPT is shown in Figure 3-1, and

the interface without MPPT is shown in Figure 3-2. The following instructions are introduced in

accordance with Figure 1, as shown in Figure 3-1. The operation control display panel can be

divided into three parts according to functions: MPPT light display, LCD display and menu keys,

and control operation keys. The description of the components of the operation control display

panel is shown in Table 10-1.

Figure 10-1 Operation Control Display Panel (with MPPT)

8

11

Figure 10-2 Operation Control Display Panel (without MPPT)

Table 10-1 Description of the operation control display panel components

explicit

identification

description

explicit

identification

description

Priority

Current priority mode

54.3v

Current battery voltage

AC/IN

AC input value

DC

Current output mode

AC/Out

AC output value

1500w

50%

Current power and load

percentage

Note: The above values are the demonstration values, for reference only

Table 10-2 Key press description:

Key identification

meaning

MENU

Enter the menu

UP

Select up

DOWN

Select down

ENT

Determine or return

ON/OFF

Turn on or turn off,Press the on / off button for 5 seconds.

10.2 LED indicator lamp

Table 10-3 Description of the indicator lamp status

pilot lamp

state

meaning

AC

The yellow

is often

bright

The machine is running and in the main power output mode

The yellow

is not bright

8

12

pilot lamp

state

meaning

DC/INV

Green is

often bright

Battery inverter running in the state of the machine, from the

battery inverter power output

Green, not

bright

CHR

light on

The equipment is charged via the main power supply

MPPT Charging State

Bulk

light on

In fast charge mode

light off

Not under fast charge

Absorption

light on

In equal charge mode

light off

Not in equal charge mode

Float

light on

In float mode

light off

Not in floating charge mode

10.3 Sound alarm (buzzer)

Operation can be accompanied by two different sound alarms as described in Tables 3-4.

Table 10-4 Sound alarm description

alarm call

meaning

Continue to cry

Power boot self-inspection

Two short sounds

Set the save

A short sound

key

10.3 System settings

(1) Settings: Home-Menu-Enter the System Settings page, select needs and enter by pressing up

and down.

(2) Priority (Mode) settings: Press up and down to select the mode and enter, and then the machine

will restart and run the new mode.

8

13

(3) AC charging voltage setting: Press up and down, which will display in the lower left corner,

(4) AC charging current setting: press up and down to select the charging current.Choosing an OA

means that charging stops automatically after charging.Press Enter to confirm, and the machine

will restart.

8

14

(5) DC priority mode instruction: (battery high voltage automatically changed to inverter, low

voltage to power supply).

In this mode, the inverter preferentially uses a DC power supply (battery), when the battery power

is fully charged by the total or solar power,

Turning to the user setting the HVR, the inverter automatically becomes an inverted output.When

the low power sets the LVD as the user,

Working mode changes to the power output.Press the upper and lower keys to select the voltage,

and the menu sets the HVR and LVD.Then press Enter to confirm, and the machine will restart

and run the new mode.

(6) MPPT charging current setting

Refer to the AC charging settings.

8

15

11.technical parameter

12. The causes and treatment methods of common failures:

Since the inverter itself has complete protection functions, once an abnormality or failure

occurs, the inverter will be shut down or the output will be stopped, and the LCD display will

indicate the corresponding abnormal information and the working status of the inverter

respectively.

Technical Parameter :

Inverter Mode

8KVA OGM

10KVA OGM

12KVA OGM

Rated power

6KW

8KW

10KW

Battery voltage

48V

Chassis size (W * D* Hmm)

580*370*730

740*400*930

Package size(W * D *Hmm)

650*420*840

820*480*1050

Net weight(kg)

65

85

95

Gross weight(kg)

80

100

110

Input

Phase

L+N+G

Mains input range

110V:85~138VAC;220V:170~275VAC

Frequency Range

45Hz~65Hz

Output

Output voltage

Inverter mode: 110VAC/220V±5%; Mains mode:

110VAC/220VAC±10%;

Frequency range(Mains

mode)

Automatic tracking

Frequency range(inverter

mode)

50Hz/60Hz±1%

Over load (Mains mode)

Mains mode: (100%~110%: 10 minutes; 110%~130%: 1 minute;

>130%: 1 second;)

Over load(inverter mode)

Inverter mode: (110%~110%: 30 seconds; 110%~130%: 10 seconds;

>130%: 1 second;)

Current peak ratio

3:1max

Switching time

<10ms (typical load)

Wave

Pure sine wave

Efficient

>85% (80% resistive load)

Protective function

Battery over voltage and low voltage protection, overload protection,

short circuit protection, over temperature protection, etc.

Built~in solar controller (optional)

Maximum charging current

100A

150A

Battery voltage

48V

PV input voltage range

65V ~250V

Maximum photovoltaic

input power

4800W

7200W

Cooling method

Air-cooled

Environmental conditions

Operating temperature

0~40℃(battery life will be shortened in an environment >25℃)

Operating humidity

<95% and no condensation

Operating altitude

<1000m (1% per 100 m, up to 5000 m)

Noise

<58dB (1 meter distance)

Manage

show

LCD+LED

Computer communication

interface

RS232 (optional)

* The above data is for reference, if there is any change, please refer to the actual product.

8

16

When the inverter fails to work normally, please refer to the instructions in the manual. If it still

cannot be solved, please contact the dealer or the manufacturer as soon as possible. Do not

disassemble the parts by yourself!

13.Packing list:

If the user cannot understand the contents of the manual or wants more detailed help when using it,

please contact the dealer or consult our company, we will be happy to serve you.

PSC Solar UK

Physical Office/Warehouse: 41B, Olutoye Cres/Adeniyi Jones, Ikeja,

Lagos State,Nigeria

Phone No.: +2348120855444, +2348123655444

Website: www.pscsolaruk.com Email Address: info@pscsolaruk.com

Failure phenomenon

cause of issue

Approach

In the absence of AC

input, the inverter cannot

start

DC input abnormal

Check whether the connecting wire of the DC

(battery) input is connected correctly, with good

contact and correct polarity, and measure whether

the voltage between the two terminals of the DC

(battery) input is normal.

DC input switch is open

Check the DC input switch

Output overload or short

circuit

Turn off the load and check whether the load cable

is damaged or short-circuited

AC input failed

Abnormal AC input

Check whether the AC input cable is connected

correctly, in good contact and the phase is correct,

and measure whether the AC input voltage and

frequency are normal.

AC input switch is open

Check the AC input switch

Without AC input, the

machine has no AC output

AC output switch is open

Check the AC output switch

DC input over voltage

Discharge the battery to a normal value and then

reconnect and boot

DC input under voltage

Wait for the photovoltaic module to charge the

battery to the normal value, or switch the mains

priority mode to charge the battery to the normal

value, then the output can be restored

Output overload or short

circuit

Turn off the load and check whether the load cable

is damaged or short-circuited

Machine high temperature

alarm

The internal temperature of

the machine is too high

Check whether the fan is faulty and whether the

cooling holes are blocked

Machine overload alarm

Load power exceeds rated

value

Remove non-critical loads

Number

Name

Quantity/Unit

Remark

1

Inverter host

1 set

2

user's manual

1 copy

3

Warranty Card

1 piece

This manual suits for next models

3

Table of contents

Other PSC Solar Inverter manuals

Popular Inverter manuals by other brands

Delta

Delta M Series Operation and installation manual

Centech

Centech 60601 Owner's manual & safety instructions

Tripp Lite

Tripp Lite PowerVerter RV3012OEM Specifications

Delta

Delta M50A-260 Installation and operation manual

Delta

Delta RPI-H3 Operation and installation manual

Delta

Delta RPI-H3 owner's manual