PSC Solar SGS Series User manual

Thank you for purchasing our products

Please strictly comply with all warning notes and operating

instructions in this manual. Keep this manual properly for future use.

Please don’t operate Inverter until you carefully read all the safety

and operating instructions.

Safe declare

Operation safety

1. In the use of the product before, please read “safety declare”, to ensure the correct and safe to use. And please

keep the manual.

2. Pay attention to the all warning when operating, according to the requirements for operation.

3. Avoid direct sunlight, rain or in the wet environment using this equipment.

4. This equipment can not be installed near the heat source area.

5. Placed around the Inverter, should have a safe distance, ensure ventilation. When installation, please refer to

specification.

6. When cleaning, please use the dry goods to wipe.

7. In case of fire, please correct use of dry powder fire extinguisher to extinguish fire. If the use of liquid fire

extinguisher will have a risk of electric shock.

8. Before installation should consider floor bearing capacity on the machine and battery.

Warning users:

This is A level Inverter product, that may cause radio interference in the living

environment, in this case, the users can take adequate measures.

Electrical safety

1. Before starting Inverter, please confirm grounding correctly, and check the wiring and polarity is properly

connected.

2. When Inverter needs to move or to be wiring, please shutdown Inverter and disconnect AC input breaker and

battery breaker, or there is a risk of electric shock.

Battery safety

1. Battery life varies with ambient temperature decreases. Regular replacement of batteries can ensure normal work

of Inverter, and to ensure adequate reserve time.

2. Battery can only be maintained by qualified personnel!

3. Replace the battery, must use the same type and model of the battery, and the number must be the same.

4. Battery to involve a risk of electric shock and short circuit current risk. To avoid electric shock accident, when

replacing the batteries, please observe the following warning:

A. Don’t wear watches, rings or other metal objects;

B. Using the insulated tools;

C. Wear rubber shoes and gloves;

D. Can not put metal tools or metal parts on the batteries.

E. Before removing the battery terminals, must disconnect the load.

5. Please do not burn the battery in the fire, so as not to cause an explosion, endanger the personal safety.

6. Non professionals do not open or damage battery, because the battery electrolyte contains strong acid and other

hazardous substances, the skin and eyes are hurt. Such as accidentally contact with the electrolyte, should

immediately with plenty of water for cleaning, and go to the hospital to check.

7. Please do not use the battery short circuit, will cause electric shock or fire.

Operating environment

1. Operating environment will affect Inverter stability, therefore, please prevent Inverter operating in this

environment:

a. The place beyond rated range (temperature 0-40℃, humidity20-90%);

b. The vibration places;

c. The place contains metal dust, corrosive substances and combustible gas;

2. If inverter do not use in long time, need to store it in dry environment, storage temperature: -25-55℃.

Index

Chapter Ⅰ Product Introduction...........................................................................................................1-4

1.1 Synopsis...................................................................................................................................................................1

1.2 Topology.................................................................................................................................................................1

1.3 Operational principle............................................................................................................................................1-2

1.4 Structure configuration.........................................................................................................................................2-3

1.5 Specification............................................................................................................................................................4

Chapter Ⅱ Installation............................................................................................................................5-8

2.1 Environmental requirements...................................................................................................................................5

2.2 Unpacking...............................................................................................................................................................5

2.3 Mechanical size....................................................................................................................................................5-6

2.4 Transport..............................................................................................................................................................6-7

2.5 Method of fix...........................................................................................................................................................7

2.6 Terminal block connect...........................................................................................................................................8

Chapter Ⅲ Wiring..................................................................................................................................9-

13

3.1 Cable diameter choosing.........................................................................................................................................9

3.2 Cable connection..............................................................................................................................................10-13

Chapter Ⅳ Power On and Debugging................................................................................................14-

15

4.1 Preparation............................................................................................................................................................14

4.2 Function test.....................................................................................................................................................14-15

Chapter Ⅴ LCD panel operation........................................................................................................16-29

5.1 LCD panel........................................................................................................................................................16-18

5.2 Display information details..............................................................................................................................18-20

5.3 System control.......................................................................................................................................................21

5.4 System state......................................................................................................................................................21-23

5.5 System setup....................................................................................................................................................23-28

5.6 Inverter alarm and display................................................................................................................................28-29

Chapter Ⅵ Operate and maintenance guide.....................................................................................30-31

6.1 User Guide.............................................................................................................................................................30

6.2 Maintenance Guide................................................................................................................................................31

Chapter Ⅶ Fault diagnosis.......................................................................................................................32

7.1 Fault diagnosis procedure......................................................................................................................................32

7.2 Fault information of ICON....................................................................................................................................32

7.3 Fault information of buzzer..................................................................................................................................32

7.4 SPD (Surge protect device)...................................................................................................................................32

Appendix Ⅰ Start and shutdown inverter operation process...............................................................33

1

Chapter Ⅰ Product Introduction

1.1 Synopsis

SGS inverter is on/off grid with intelligent energy management, which transfers PV energy to gird or load. With

built-in transformer and advanced DSP-based digital control technology, SGS inverter has high reliability,high

efficiency, isolated stable output, abundant intelligent interfaces and supports any kinds of load.

1.2 Topology

It consists of inverter (DC/AC), STS,built-in MPPT charger,isolated transformer and maintenance switch Q3, input

switch Q1, bypass switch Q2 and output switch Q4.

P1

Q2

Q3

Q4

By pa s s

MPPT Inverter

Isolation

Tr ansf or mer

Static switch

I nput Static switch

Out put swi t ch

Mai nt enance swi t ch

Bypass swi t ch

Sol a r s wi t c h

Out put

Bat t e r y

Solar Input

B1

Battery switch

Figure 1-1 Block diagram of Inverter

1.3 Operational principle

T1

G

E

C

G

E

C

G

E

C

G

E

C

GND

IGBT3 IGBT4

N

N

MANUAL SW ITCH

OUT PU T SW IT C H

IN PUT SW ITC H

G

E

C

G

E

C

IGBT5

SCR2

1

2

3

1

2

3

IN-T

IN-S

IN-R

OU-R

OU-S

OU-T

N

N

N

N

N

Isolation Transformer

SCR 1

SCR3

SCR4

SCR5

SCR6

G

M

E

C

Q1

PV+

PV-

31

2

GND

GND

G

M

E

C

Q1

31

2

GND

GND

SPD

EAR TH

BAT+

BAT-

GND

L1

L2

BATTERY SW IT CH

PV SW ITC H

PV-

EAR TH

BAT CONTACTOR

CHARGE REALY

Figure 1-2 Inverter main circuit schematics

2

Battery is charged by external solar charger. If the grid power is available, DC/AC inverter will feed the energy to

the grid.If the grid power is abnormal, DC/AC inverter will power the load with off-grid function. If the battery

voltage is extremely low, DC/AC will work as a charger to charge the battery.

This DC/AC inverter is based on SPWM/SVPWM control technology with built-in transformer. Grid is totally

isolated form PV input so no insulation fail/big leak current problem.

The SGS inverter adopts the newest TI TMS32028F28234 DSP with abundant functions. It implements power

transform and intelligent energy management while providing RS232/RS485 interfaces.

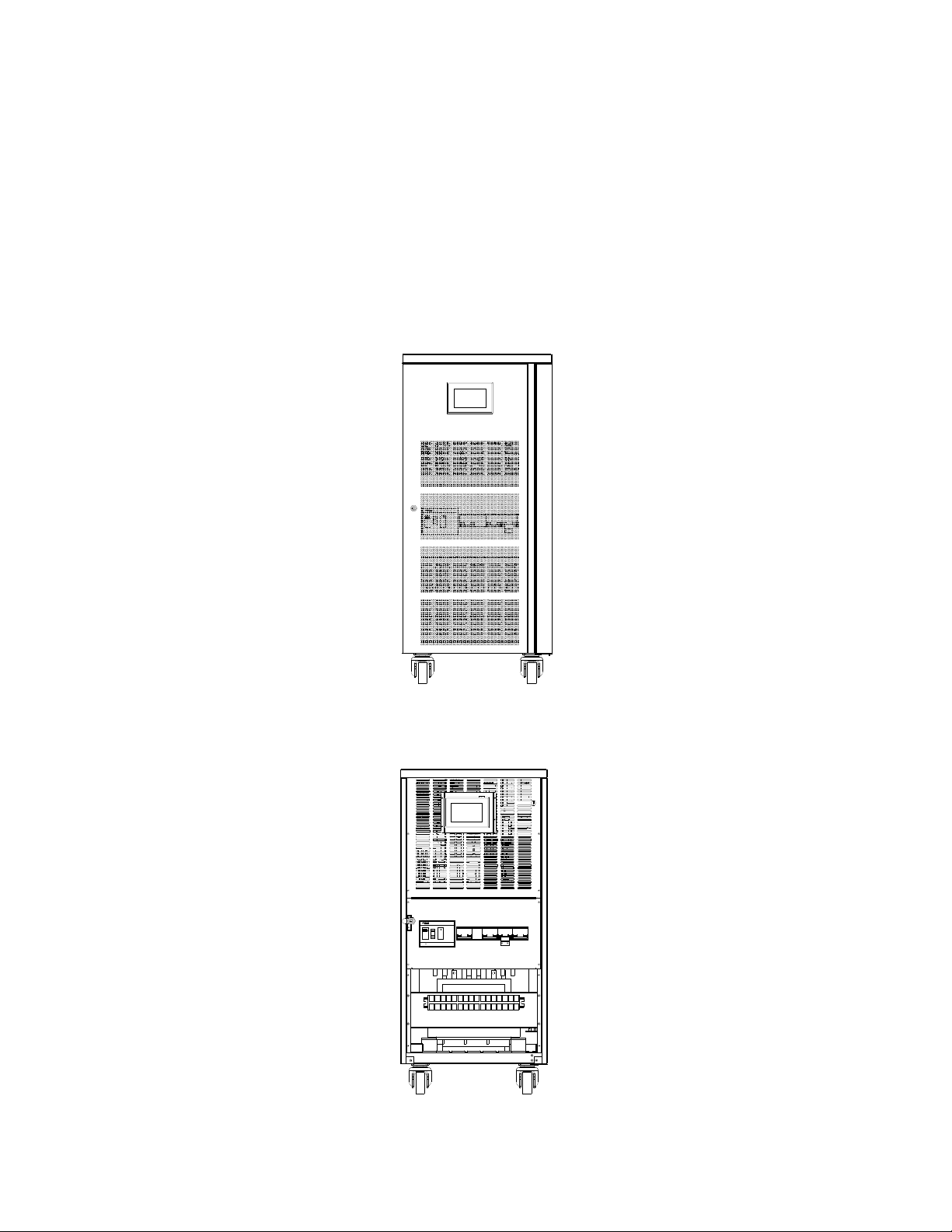

1.4 Structure configuration

The Inverter system make up of INV, front LCD panel, transformers, breakers, fans, aluminum capacitors and so

on.

Front view

Figure 1-3 10-30kVA

The Front door map

Figure 1-4 10-30kVA

3

Figure 1-5 Left view of 10-30kVA

Figure 1-6 Right view of 10-30kVA

4

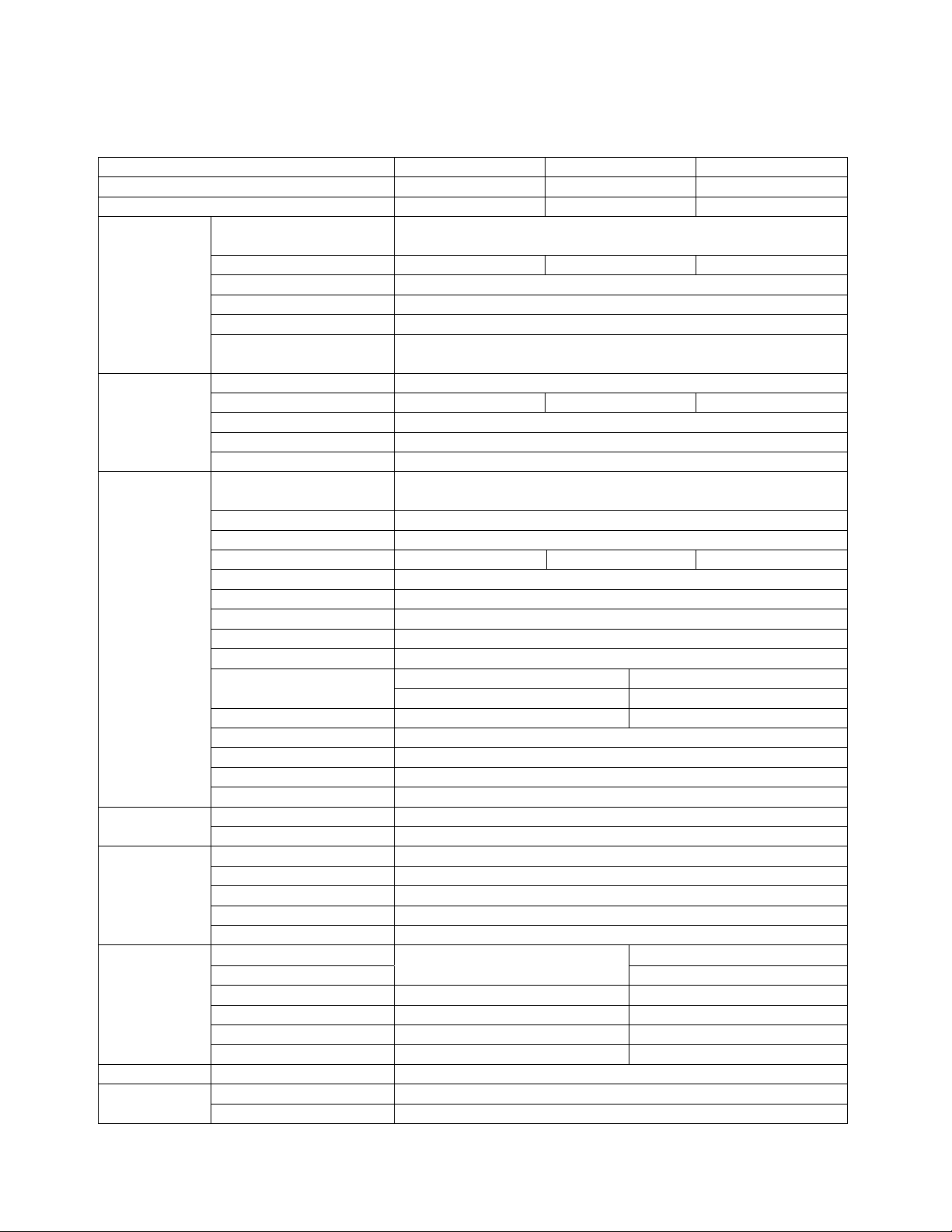

1.5 Specification

Technical parameters

Index 10K 20K 30K

Rated capacity 10kVA 20kVA 30kVA

Rated output power 10kW 20kW 30kW

Solar Input

MPPT Working Voltage and

Range

Actual battery voltage ~ DC480V(375V PV input voltage is

recommended)

Rated Power 10kw 20kw 30kw

Floating Charge Voltage DC275V

Boost charge Voltage 290V

Boost charge time 0.5-4 hours settable(1 hour default)

Over Charge Protection

Voltage DC300V

Battery Input

Rated input voltage 240V

Rated input current 46A 93A 134A

Turn on voltage range 224V~ 290V

DC protection Fuse

Battery reverse protection Support

AC Output

Rated output voltage and

frequency 380VAC,50Hz

Output wiring 3Ф + N + E(Protective earth)

Wave Sine wave

Rated output current 15A 30A 45A

Output voltage precision 380V ±2%

Output frequency precision 50Hz±0.2%

Voltage distortion ≤3% (Linear load)

Output power factor 1

Overload 125%,30 Seconds

Transient response ≤9% R load 0%~ 100%~ 0%

≤6% R load 20%~ 100%~ 20%

Transient recovery ≤60ms voltage recovery to 90% Full RCD load

Efficiency --

Voltage range 200/208/220/230/240VAC (Output power reduces to 90% 208/200V)

Voltage regulation ±2 %

Crest ration 3:1 (maximum)

Protection Short protection Cut off output within 4cycles

Others Low /over voltage、output overload

Environment

Working temperature 0℃~40℃

Altitude <1000m

Noise ≤70dB

Storage temperature -15℃~45℃

Work humidity 20% ~ 95%

EMI/EMS

Conducted IEC62040-02 Class C3

Radiated Class C3

ESD IEC61000-4-2 Level4

RS IEC61000-4-3 Level3

EFT IEC61000-4-4 Level4

Surge IEC61000-4-5 Level4

Safety Safety IEC62040-1

Transportation Drop test --

Vibration test B-WR1-129

Table 1-1

5

Chapter Ⅱ Installation

2.1 Environmental requirements

■ Operating Temperature: 0~40℃

■ Storage temperature: -15℃~45℃

■ Relative Humidity: 20%~95%

■ Cooling Mode: Forced air cooling

■ Altitude: <1000m

■ Verticality: No vibration and the slope should be less than 5°

■ Pollution Level: Grade Ⅱ

Inverter systems should be installed in the clean, cool and ventilated environment. Environment of 20-25℃

operating temperature and 50% Humidity is recommended.

◆◆ NOTE

1. Combustible, explosive or corrosive articles are not allowed to be placed near the Inverter. Inverter will be

damaged in the environment full of metal conductive dust.

2. If Inverter is used at an altitude of 1000m above, output power should be decreased according the following table:

Altitude (m) 1000 1500 2000 2500 3000 3500 4000 4500 5000

Maximum load 100% 95% 91% 86% 82% 78% 74% 70% 67%

2.2 Unpacking

Do not remove the packages before transporting the equipment to the installation site to prevent unexpected

damage. Check the attachment according to the packing list.

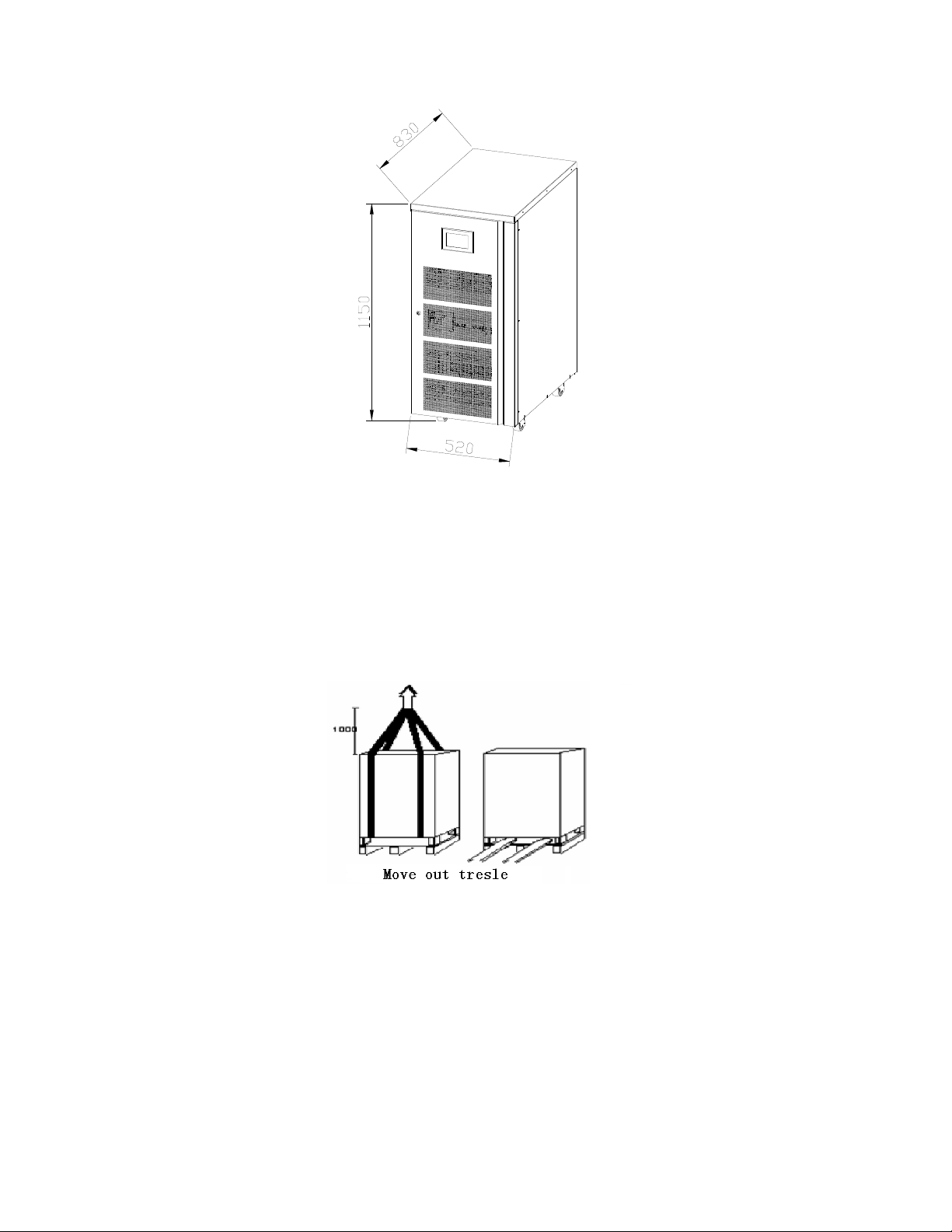

2.3 Mechanical size

The equipments should be fixed in appropriate ways for reliable operation according to the site conditions.

Table 2-1 lists the mechanical parameters of the Inverter power.

Table 2-1

Model Length (mm) Width (mm) Height (mm) Rear panel heat dissipation

clearance (mm)

Weight

(kg)

10kVA

830 520 1150 500

--

20kVA --

30kVA --

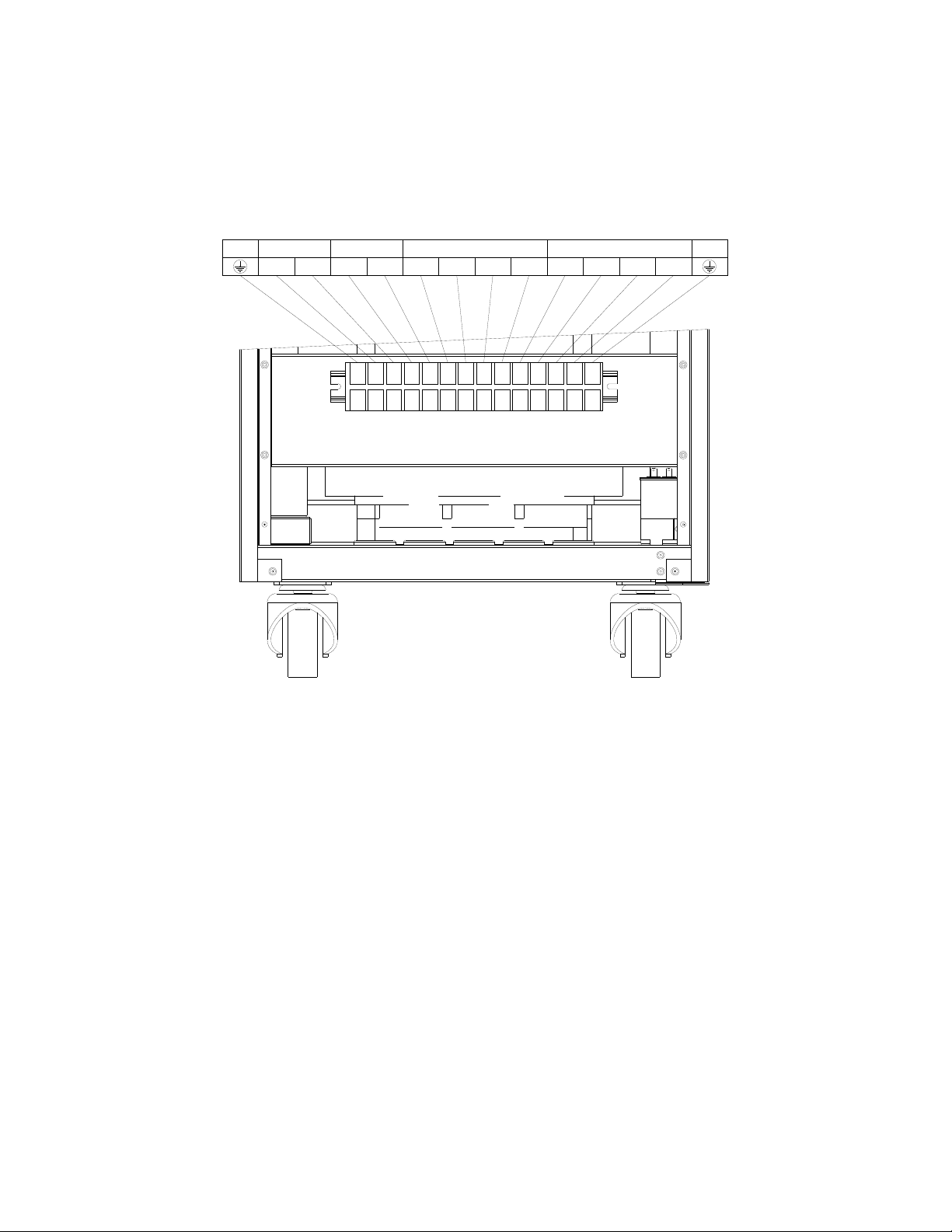

Inverter power supply Dimensions (Unit: mm) Figure 2-1.

6

Figure 2-1 inverter power supply dimensions

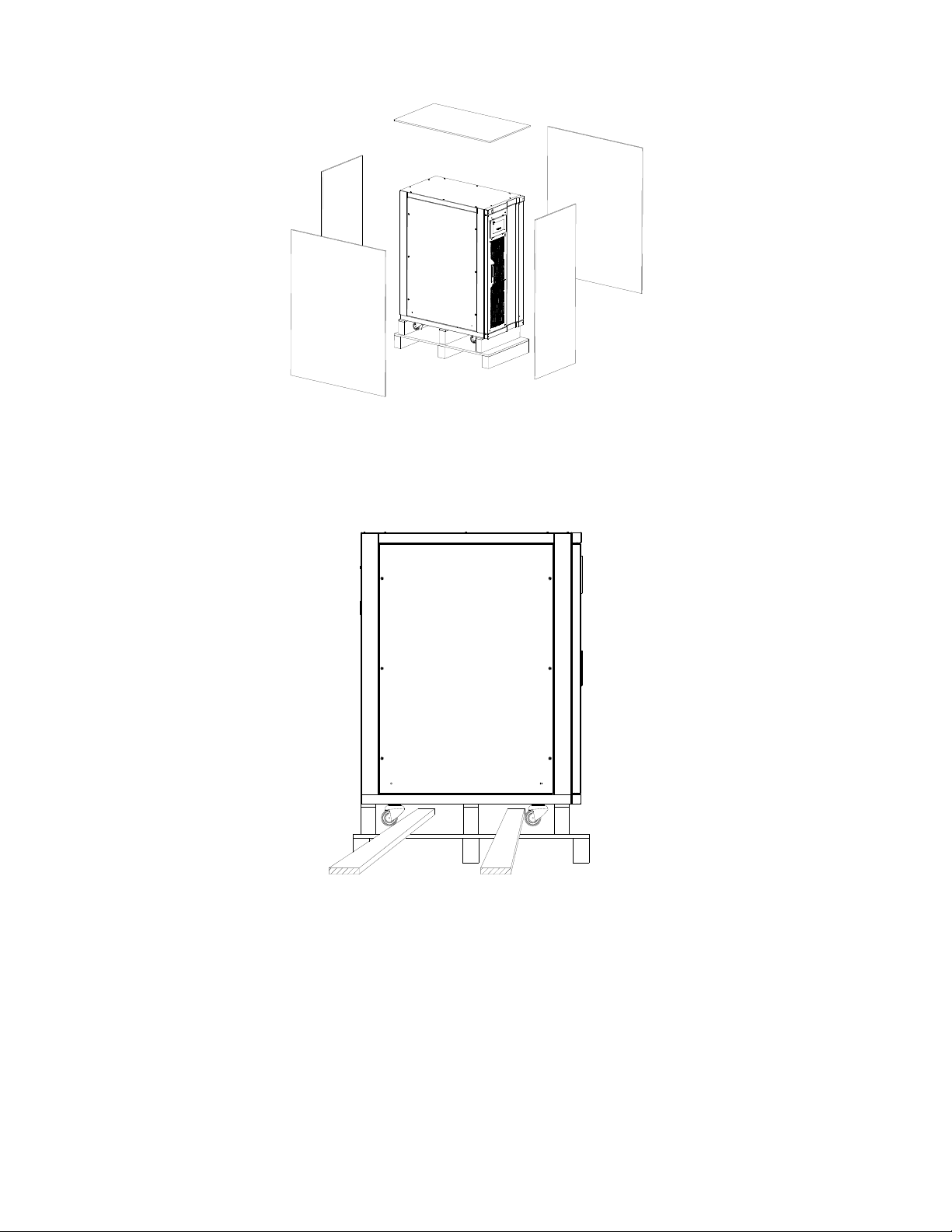

2.4 Transport

Lifting Transport

【Preparation】Two at least 3 meters long, bearing at least 1.5 tons of the cables.

【Transportation】The Inverter power supply cabinet should transport to the installation site before removing the

packages, Lifting the two suspension ropes from the bottom.

Figure 2-2 Illustration of lifting

7

Figure 2-3 Unpacking

Forklift Transport

The equipment could be transported by forklift too. Beware that the Inverter is heavy and take care.

Figure 2-4 Truck crossed the side

2.5 Method of fix

Inverter passes its weight to the ground through four wheels. Use some auxiliary equipment to increase the contact

area if the floor cannot withstand such pressure.

◆◆ NOTE

The cooling air comes from the bottom of the Inverter, so at least 10 cm space should be kept between the bottom

of the Inverter and the floor.

2.6 Terminal block connect

8

Terminal block of the Inverter locates at the front panel with a cover plate for protection. The indications of wiring

are listed in Figure 2-5.

SR NT

PE

PE BATTERY

+-

SOLAR

+-

BYPASS INPUT

TNRS

OUTPUT

Figure 2-5 Terminal block of 10-30kVA

9

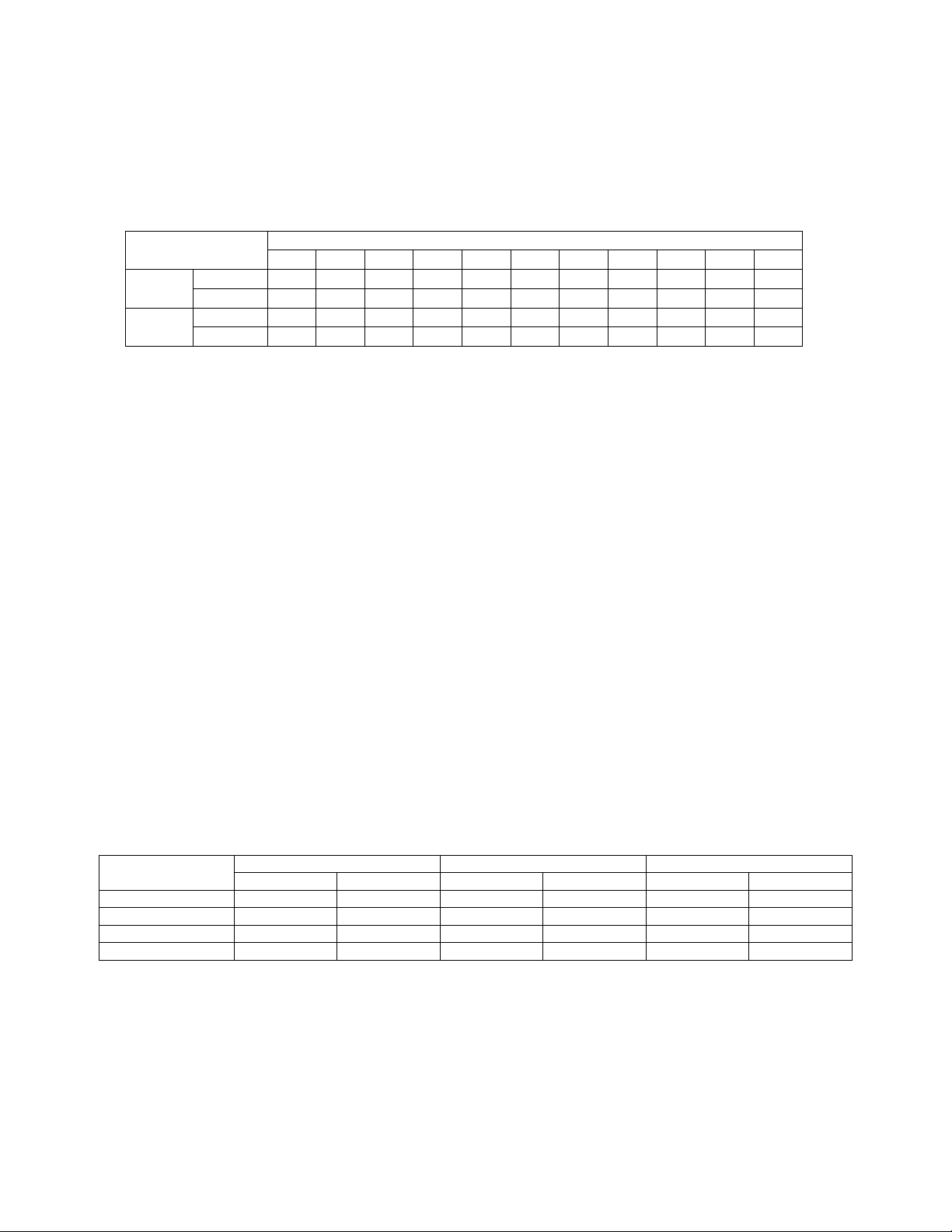

Chapter Ⅲ Wiring

3.1 Cable diameter choosing

3.1.1 Current carrying capacity of cable

Table 3-1 shows the relation between cross-section area and current for safe operation.

Current (A)

sectional area (mm2)

Cross-section area (mm2)

1 1.5 2.5 4 6 10 16 25 35 50 70

25℃ rubber 21 27 35 45 58 85 110 145 180 230 285

plastic 19 24 32 42 55 75 105 138 170 215 265

35℃ rubber 20 25 33 42 54 80 103 136 168 215 267

plastic 18 22 30 39 51 70 96 129 159 201 248

3-1 Wire sectional area - current

3.1.2 Selection of power cables

Wires for mains input, bypass input, output, PE and battery need to be power cables. BVR or RV-type soft cables

of AC450V/750V, 70℃ are recommended.

How to determine the current?

The first method is calculating, relative parameters are listed below:

Total efficiency of: 0.9

Output phase voltage:220V

Lowest battery voltage: 240V

Battery current = (Load (watt) / 240

Solar current = (Rated power/ 300 )

Output current = (Load (VA) output value / 220 /3)

If you are not sure about the power of your load, refer table 3-2 cable diameter choosing.

Cable selection

Recommended current density range of power cable is 3 ~ 5A/mm2. The maximum voltage drop on the cable

should be less than 3V to avoid overheat.

Cross-section area of neutral line should be 1.5~1.7 times as the one of phase line. PE (protective earth) line should

be same as one of phase line and minimum value is 10mm2.

10k current and cable sectional area are listed in Table 3-2.

Current/Cable 10kVA 20kVA 30kVA

Current (A) Cable (mm2) Current (A) Cable (mm2) Current (A) Cable (mm2)

Battery 46 6 93 16 134 25

Bypass 15 4 30 4 45 6

Output 15 4 30 4 45 6

Solar 37 6 74 10 108 16

Table 3-2 Rated current and recommended cable cross-section area

◆◆Caution

Voltage of the battery breaker should meet the following requirements for reliable operation: ≥300VDC

3.1.3 Signal wire

Signal wire should be shielded multi-conductor cable.

10

3.2 Cable connection

3.2.1 Power Cable

Mains input and bypass input shares the same input in our factory to support single AC input. Figure 3-1, indicates

that the customer does not have to connect bypass.

If customer wants to operate the Inverter with dual AC input, remove the power cable between mains input and

bypass first in the terminal block, then connect mains input and bypass input independently.

SR NT

PE

PE BATTERY

+-

SOLAR

+-

BYPASS INPUT

TNRS

OUTPUT

Figure 3-1

◆◆Caution

1. All switches should be in the "OFF" state before wiring.

2. Install the recovery plate of the block terminal for good ventilation.

3. PE should be connected because of big leakage current for safety. The resistance between cabinet and Earth

should be less than 1Ω.

3.2.2 Signal Cable

Communication interfaces locate at the top rear panel, including RS232, Modbus, RS485 and dry contact.

11

Figure 3-2 10kVA Inverter Schematic diagram of the interface

1.Modbus card 2. RS232

Note: RS232 and SNMP cannot be used at the same time.

RS232 connection

RS232 communication line is included in the attachment. Connect it between Inverter and supervision terminal.

The definition of each pin is shown in Figure 3-6.

Figure 3-3 RS232 ports

Pin2: Inverter receiving Pin 3: Inverter sending Pin 5: GND Other pin: Do not connect.

SNMP card connection (Option )

Please refer to SNMP guideline for further information.

Dry Contact Interface (Option )

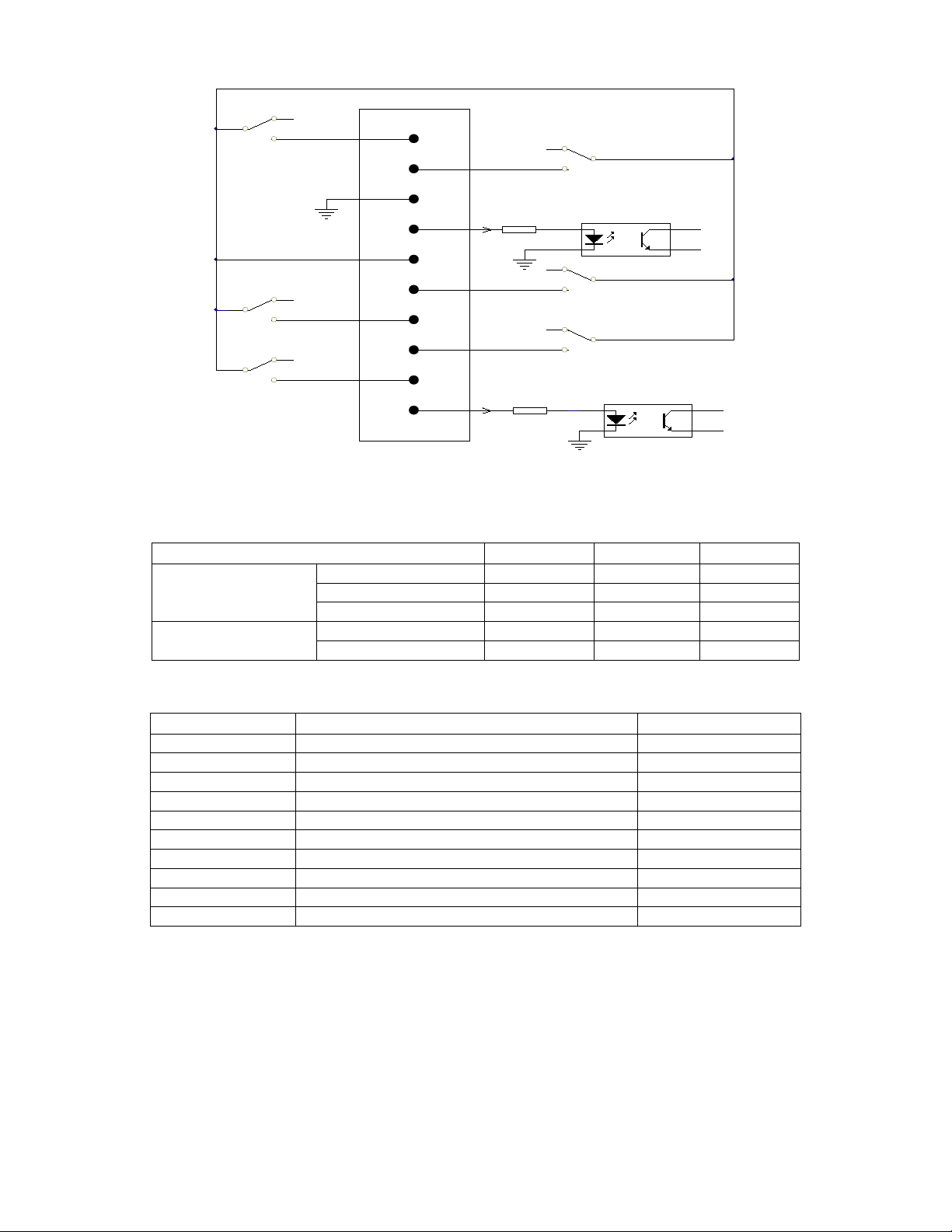

Definition of dry contact interface is shown in figure.

12

ALARM

REMOTE SHUTDOWN

1

2

3

4

5

6

8

10

7

9

BYP A SS ON

UPS ON

GND

GND

UPS FAULT

INPUT MAINS FAULT

LOW BATTERY

GND

COMMON

REMOTE START

1.6K

1.6k

This interface provides only a circuit of “On” state (Low impedance) and “Off” state (High impedance), so external

power supply may need for appropriate operation. Voltage of external power supply is 12V.

The following table shows the absolute parameters of critical components of the interface.

Parameter SYMBOL MAX UNIT

DIODE

Reverse Voltage VR 6 V

Forward Current IF 80 mA

Peak Forward Current IF (peak) 1 A

Relay contact DC Volta

g

e VDC 24 V

DC Current IDC 3.0 A

Pin Definition:

Pin Specifications Input and output

1 FAULT Output

2 ALARM Output

3 GND Input

4 REMOTE SHUTDOWN Input

5 COMMON Output

6 BYPASS ON Output

7 LOW BATTERY Output

8 INVERTER ON Output

9 MAINS INPUT ABNORMAL Output

10 REMOTE ON Input

◆◆Note

1. Pin4 and Pin10 are used for remote control. When Pin4 or Pin10 receives a high pulse of 3-10s, inverter will be

shutdown or turned on (Signal less than 3s or longer than 10s is invalid).

2. When inverter is in line mode, function of remote shutdown is not available.

13

Function Description:

Phenomenon Description Reason

PIN1、PIN5 shorted FAULT Inverter internal fault

PIN2、PIN5 shorted ALARM

1.Battery mode

2.Low battery

3.Inverter internal fault or alarm

PIN3 GND OF INPUT

PIN4 REMOTE SHUTDOWN External input signal, high active, remote shutdown

PIN5 COMMON OF OUTPUT

PIN6、PIN5 shorted BYPASS ON Inverter in bypass mode

PIN7、PIN5 shorted LOW BATTERY Battery voltage Low

PIN8、PIN5 shorted INVERTER ON Inverter Works in the line mode or battery mode

(inverter works)

PIN9、PIN5 shorted MAINS INPUT FAULT Mains AC abnormal

PIN10 REMOTE ON External input signal, high active, turn on inverter

remotely.

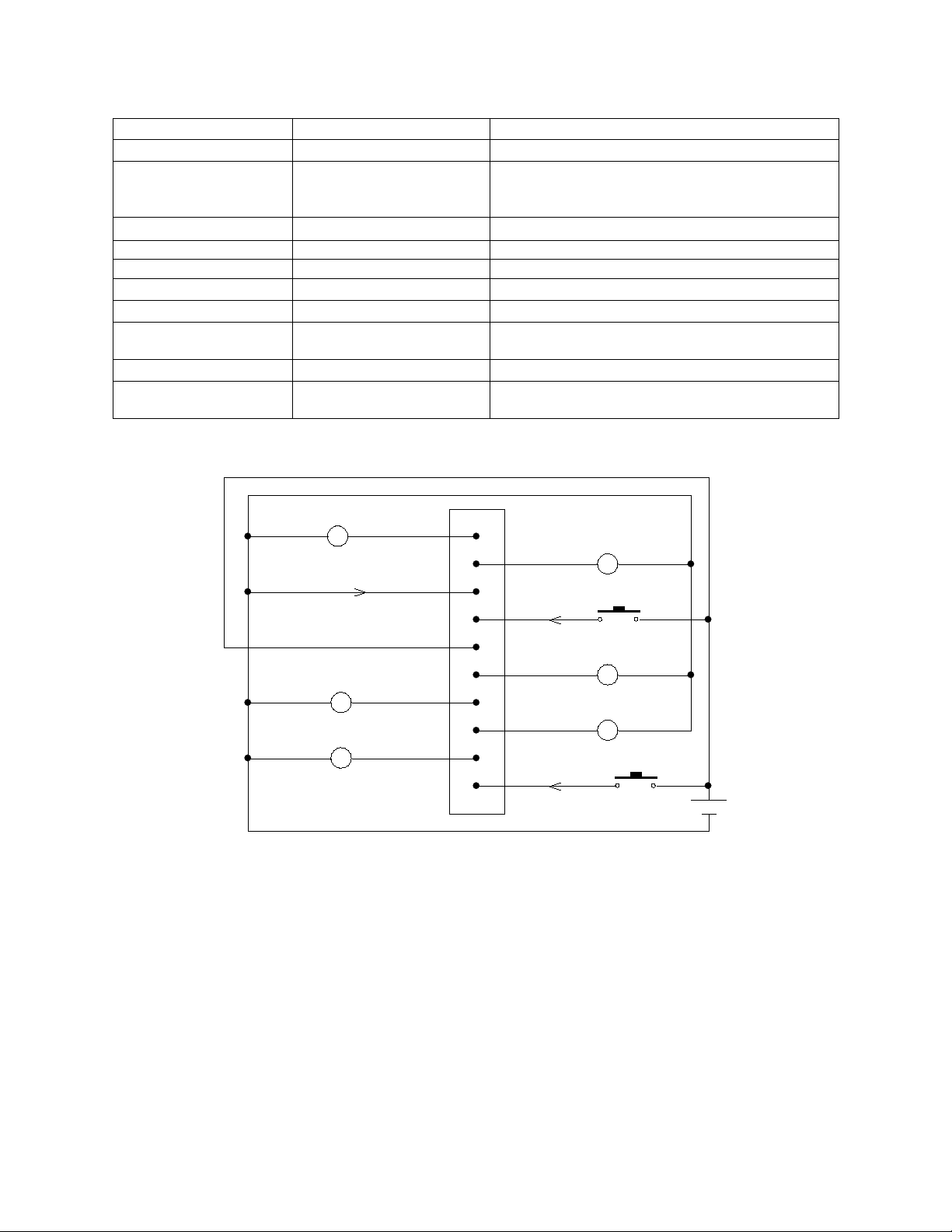

Application demonstration

1

2

3

4

5

6

7

8

9

10

FAIL

ALARM

GND

REMOTE

COMMON

BYPASS ON

BATTERY LOW

INVERTER ON

UTILITY FAILURE

REMOTE ON

SHUTDOWN

12V

A 6-24VDC source is connected between Pin 5 and Pin3. Keys of remote start and remote shutdown are used for

remote control. And the lights are used to indicate the status of Inverter for remote supervision.

14

Chapter Ⅳ Power On and Debugging

4.1 Preparation

4.1.1 Input breaker description

Bypass breaker Q2--- Switch on/off bypass AC, to the bypass STS

Maintenance breaker Q3--- Switch on/off connection between bypass and output

Output breaker Q4--- Switch on/off inverter output

Battery breaker B1—Switch on the battery bank.

Solar breaker P1—Switch on the solar bank.

◆◆ Note

Repair break Q3 is designed for repairing. Only qualified technical personnel are allowed to operate this breaker.

4.1.2 Power on steps

Make sure all the breaks are in “OFF” state before connecting any cables. Check the AC input, battery input

voltage before switching on the breakers. Connect the neutral line if your load is single-phase load.

◆◆ Note

Do not connect any load to the Inverter to prevent unexpected damage!

Inverter power supply system start in the following order:

Step 1:Turn on battery breaker B1 and Solar breaker P1, bypass breaker Q2 and output breaker Q4. The buzzer will

beep and LCD will be lightened. Wait 1 minutes to start the DC/DC . Inverter is working in bypass mode

and battery is charged.

Step 2: Click the "Menu" option to enter the function menu page. Click the "System Control" icon. Select the

"Inverter ON" icon, the main screen shows the inverter is starting. 20s later the inverter will work and the

LCD flow chart shows the energy flow.

◆◆ Note

1. Do not click the LCD screen frequently. Otherwise the screen will be locked.

2. When the LCD screen was locked, unlock the screen according to the indication.

Remarks: In normal situation do not use this function!

4.2 Function test

Mainly check the various working mode of the handover, fault alarm (sound and sound) and LCD screen display

instructions and other functions.

4.2.1 LCD display and control panel

A detailed Icon description of the series on a single Inverter power steps in Figure 4-1. The process of checking the

various indicator lights blinking, LCD touch screen keys.

15

Figure 4-1 Display Control Panel

Analog fault condition (closing the input mains) to make an alarm, Check the "sound and light alarm" function,

select "Menu" to enter to check the real-time display of inverter information.

16

Chapter Ⅴ LCD panel operation

5.1 LCD panel

5.1.1 Description

Description of LCD panel is shown in Figure 5-1.

1. Maintenance bypass breaker status 2. Bypass breaker status

3. PV input breaker status 4. PV charger status

5. Inverter Status 6. Battery status

7. Bypass Static Switch 8. Inverter static switch

9. Output breaker status 10.Battery breaker status

Figure 5-1 LCD Panel

Press the "Menu" key to enter the function menu page. Menu panel consists of six functional areas (Figure 5-1-1-1):

System control, System state, Rating, Fault Record, System Setup, About me.

Figure 5-1-1-1 LCD panel function area

17

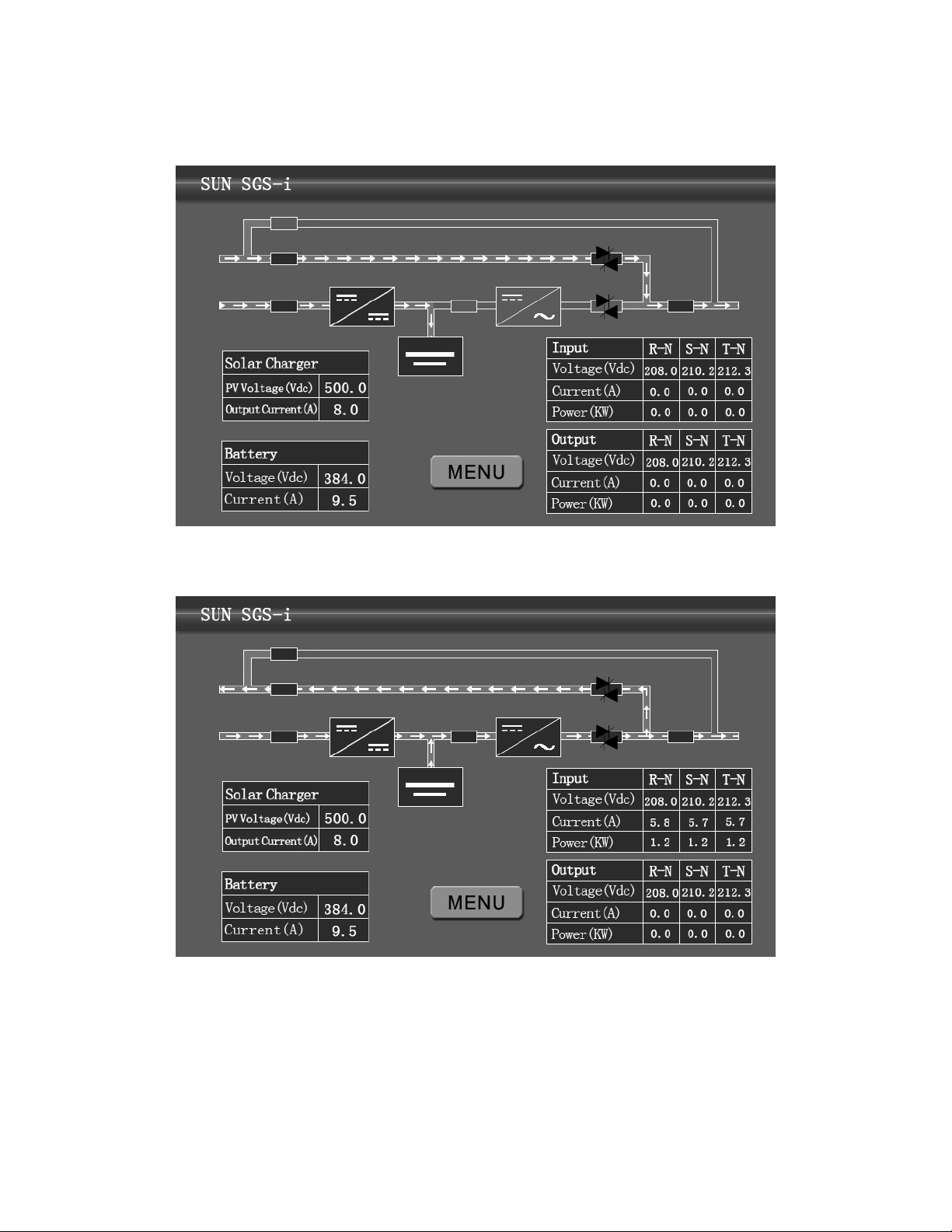

5.1.2 HOME page description

Some common inverter work situation will be described blow.

【Bypass mode】: Bypass mode flow figure as show in Figure 5-1-1-2.

Figure 5-1-1-2 Bypass mode flow figure

【On grid mode】: On grid mode flow figure as show in Figure 5-1-1-3

Figure 5-1-1-3 On grid mode flow figure

The flow figure of other work mode will not describe here.

5.1.3 MENU page description

Function key area contains six keys (Figure 5-2):

【System Control】: Inverter On/Off control (Figure 5-3).

【System state】: Check the input, output and other real-time status information.

【Rating】: Display Inverter machine model, rated capacity, rated input, rated output and battery voltage and other

Table of contents

Other PSC Solar Inverter manuals

Popular Inverter manuals by other brands

Delta

Delta M Series Operation and installation manual

Centech

Centech 60601 Owner's manual & safety instructions

Tripp Lite

Tripp Lite PowerVerter RV3012OEM Specifications

Delta

Delta M50A-260 Installation and operation manual

Delta

Delta RPI-H3 Operation and installation manual

Delta

Delta RPI-H3 owner's manual