PSC Solar 10KW User manual

USER MANUAL

Sate

Copyright, copying and plagiarism without any authorization is prohibited

The company is committed to the continuous improvement of the inverter. This information is subject to change without notice. please refer to the

actual product.

3PHASE HYBRID

INVERTER

10-200KW

Contents

I.Brief Introduction............................................................................................................................. ...................3

A. General Instructions..................................................................................................................................... ..3

B. Cautions............................................................................................................................................................3

II.Installation and Wiring of the Inverter...............................................................................................................3

A.Environment for Installation.............................................................................................................................3

B.Inspection before Installation...........................................................................................................................4

C.Installation Position...........................................................................................................................................4

D.Wiring..................................................................................................................................................................4

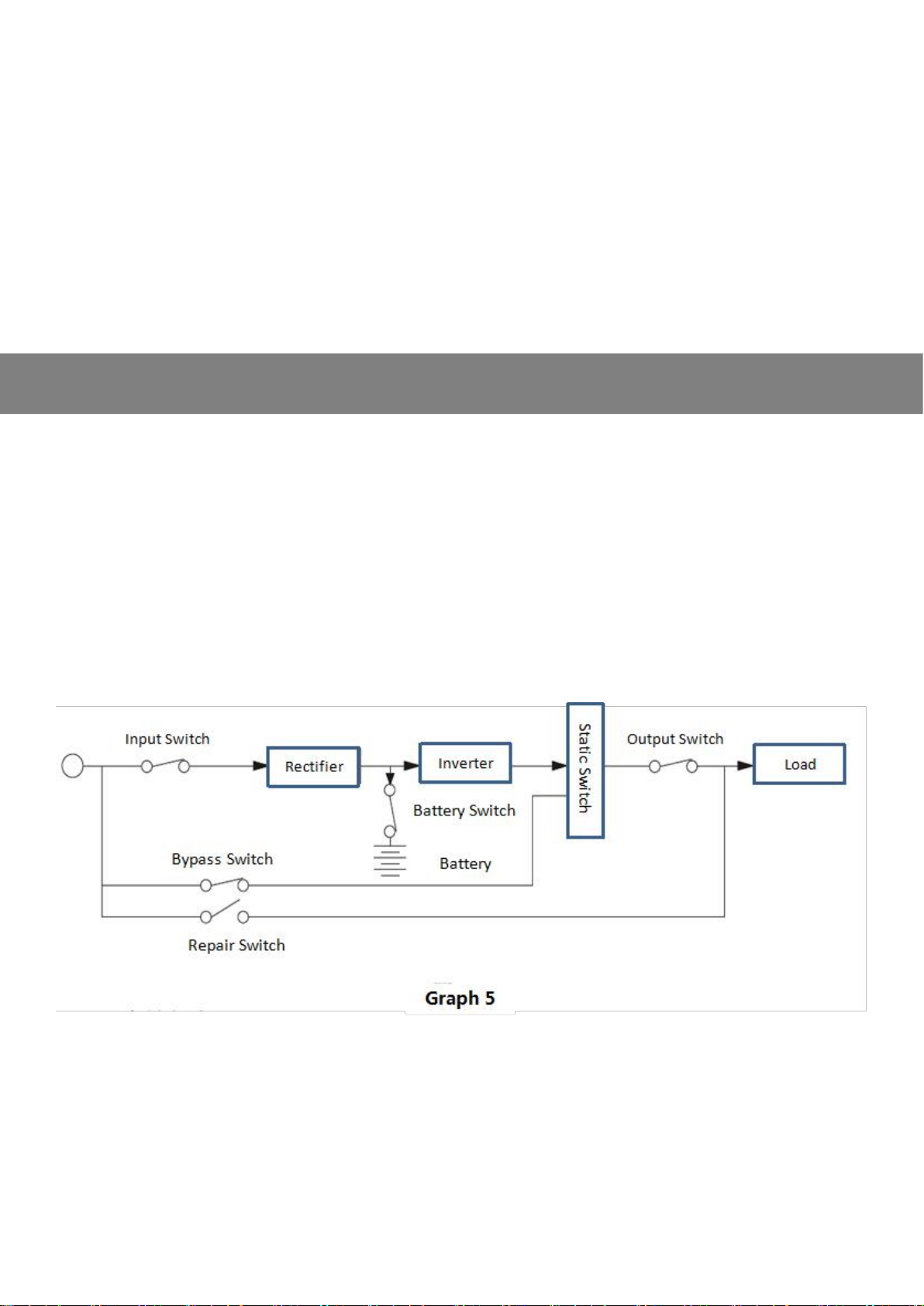

1.Output System for 10-200KW inverter 3 phases type.....................................................................................4

2.Wiring Inspection................................................................................................................................................5

III.Operation of the Inverter -1............................................................................................................................5

A.Procedures of Switching on Single Machine...................................................................................................5

B.Procedures of Regular Switching Off ..............................................................................................................6

IV.Operation of the Inverter -2............................................................................................................................6

A.Mains priority.......................................................................................................................................................6

B.Battery Mode.......................................................................................................................................................6

C.Static Bypass Mode...........................................................................................................................................7

D.Reparing Mode...................................................................................................................................................8

E.SLU......................................................................................................................................................................8

F.Battery..................................................................................................................................................................8

G.Turn to Bypass with Inverter's Off....................................................................................................................8

V.Maintenance........................................................................................................................................................8

A.Periodically Maintenance..................................................................................................................................8

B.Battery Maintenance..........................................................................................................................................9

C.Adjusting a Suitable Working Environment.....................................................................................................9

VI.Parameters For..................................................................................................................................................9

A.Inverter System..................................................................................................................................................9

1.Input Rectifier ....................................................................................................................................................9

2.Output Rectifier..................................................................................................................................................9

B.Battery...............................................................................................................................................................10

C.Inverter..............................................................................................................................................................10

D.Bypass...............................................................................................................................................................11

E.System...............................................................................................................................................................11

VII.Alarms.............................................................................................................................................................12

A.Alarm1:Fault of Bypass Voltage or Bypass Fuse, SCR................................................................................12

B.Alarm2:Fault of Mains Power or Input Rectifier Switch Disconnects ........................................................12

C.Alarm3:Under-Voltage of the Battery..............................................................................................................12

D.Alarm4:Battery Discharging...........................................................................................................................12

E.Alarm5:Over-loaded........................................................................................................................................13

F.Alarm6:Temporary Bypass..............................................................................................................................13

G.Alarm7:Turn to Bypass due to Over-loaded..................................................................................................13

H.Alarm8:Order to Bypass .................................................................................................................................13

I.Alarm9:Over-heat or Fault of Cooling Fans.....................................................................................................13

VIII.Display Function............................................................................................................................................13

A. General Introduction......................................................................................................................................13

1.Instruction on LCD Indicators..........................................................................................................................13

2.Instruction on Main Screen..............................................................................................................................14

3.Introduction on Display Content................................................................................................................15-17

IX.Connection with Computer.............................................................................................................................18

3rd

A. General Instructions for inverter

The product is the DC power (battery, storage battery) into alternating current (380V, 50Hz sine wave).It consists

of an inverter bridge, control logic, and filter circuit.Widely used in air conditioners, home theater, electric grinders,

power tools, sewing machines, computers, televisions, washing machines, range hoods, refrigerators, VCRs,

massage, fans, lighting, etc.By connecting the cable to the battery, the appliances connected to the output of the

machine will be able to use a variety of electrical appliances. Appliances can be used are: mobile phones, laptop

computers, digital cameras, cameras, lighting, electric shavers, game consoles, handheld computers, power tools,

car refrigerator and all kinds of travel, camping, medical and first aid appliances.This is an all-digital controldesign,

the application of intelligent DSP digital intelligent engine control, take-frequency architecture, the new inverter

products.Particularly suitable for harsh environment area of power and the use of photovoltaic power generation,

pure sine wave output, you can drive all types of loads.

B.CAUTIONS

1.Ground Protection. The ground wire of the input power must be connected to the ground terminal

(with sign "G") of the inverter.

2. It's not allowed to dismantle any wire without permission.

3.Risk of electric shock, do not remove cover. No user serviceable parts inside. Refer servicing to qualified

service personnel. And please read the used manual carefully when service required.

4.Always keep the top metal cover and rear panel fixed. The location should provide adequate air flow around the

nit, in an atmosphere free of excessive dust or corrosive fumes.

5. It's prohibited to remove dirt under power connection. Wet or soaked material is not allowed to use for

cleaning.

6.Risk of electric shock hazardous live parts inside this unit are energized from the battery supply even when the

input AC power is disconnected.

7.To reduce the risk of fire, replace only with same type and rating of fuse.

8.The replacement of the batteries should be conducted by qualified personnel. As the used battery is deemed to

be poisonous material, it should be delivered to recollection agency

9.This unit requires operation environment of around 25℃. When the inverter is not in use for long term, battery

should be charged every 3 months. If the temperature is above 30℃, battery should be charged every 2 months.

10.Install this inverter strictly according to this manual.

A.Environment for Installation

Make sure the indoor envrionment for installation to be:

1.without dust;

2.at appropriate temperature:

Working temperature: 0~40 ℃

Starting temperature: above 0℃

Optimum working temperature: 25℃

Good ventilation is required:

(1)Natural ventilation; applicable in special room without heat.

(2) Manual ventilation:

When the outer case temperature (TA) is higher than the surrounding temperature (TE), air

I.INTRODUCTION

II.INSTALLATION AND WIRING

4th

conditioner is needed.

The closer are these two temperatures, the larger capacity of the ventilation system would be,

based on the following equation:

Q(m³/h)=3. 1+Pdiss(kcal)/(ta-te)(c)

kcal is the unit of Pdiss , adjust Pdiss 10% for allowing the loss of energy.

B.Inspection before Installation

After putting out the Inverter from the packing box, please check :

whether there's any damage on it;

whether the switches are OFF;

any of the mentioned accessories missing;

C.Installation Position

Please make Sure:

1. Nothing is within 40cm to the back of the Inverter;

2. Nothing shall be put on the top of the Inverter;

3. There should be enough space to the front and top of the Inverter for inspection and reparing;

4. Battery cabinet should be placed on the right side of the machine and keep enough space in

between for installing and reparing;

5. Power cable should be installed from the bottom or back of the Inverter.

D.Wiring

Remember to turn off all the switches before connecting Inverter to the main power cable or any

loads.

when wiring the main power cable, please first connect the ground line to the "G" port on

the terminal board. Without ground connection, the machine can't be operated.

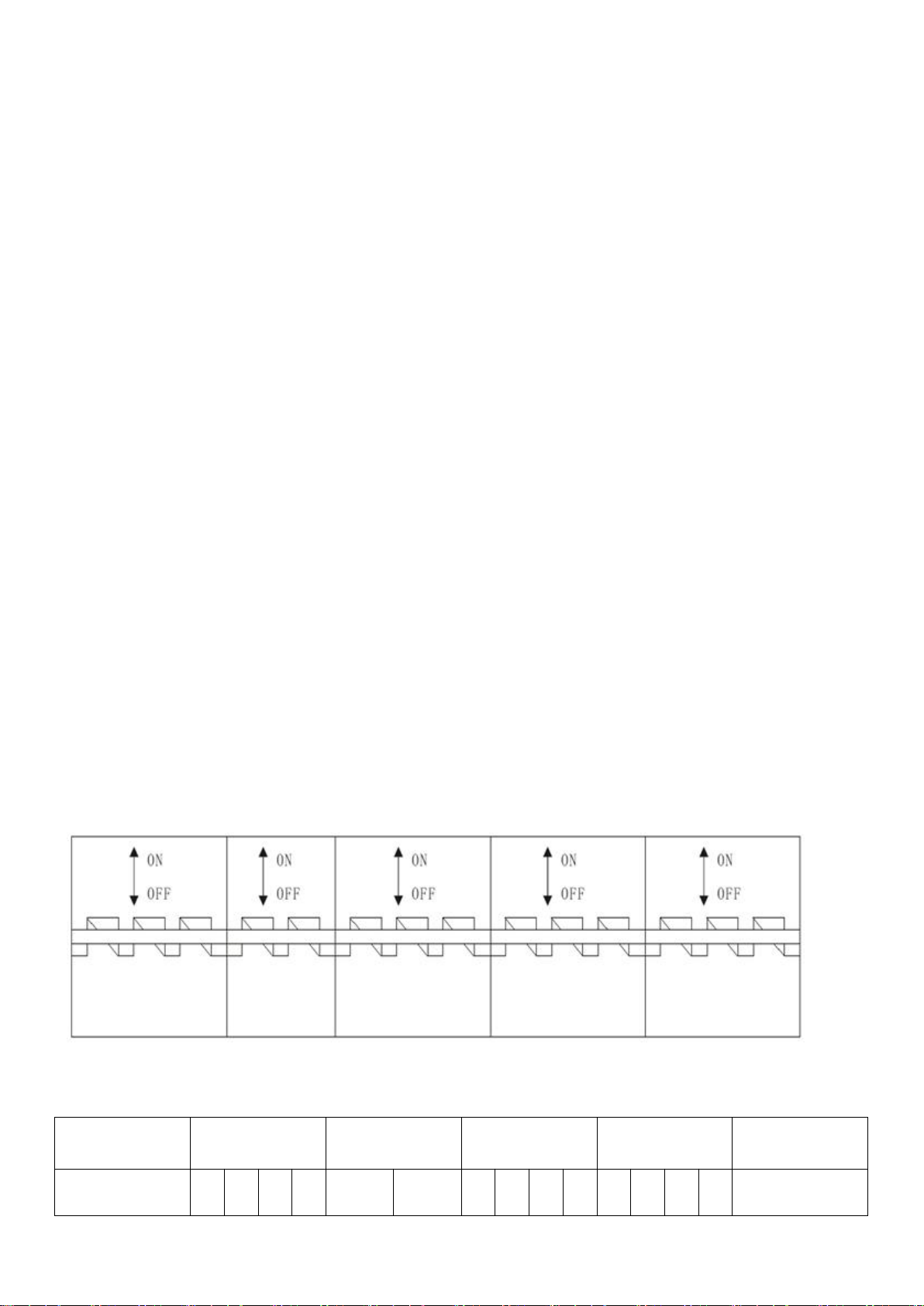

1.Output System for 10-200KW inverter 3 phases type

(1) 3 Phases Input and one neutral line (3ϕ4W 380V)

(2) The positions of Input/Output in the distributor are as below:

(3) The Graph 2 shows all of the terminal boards:

Graph 2

Ground

Rectifier Input

Battery

Bypass Input

Output

Ground

G

N

R

S

T

+

-

R

S

T

N

R

S

T

N

G

Graph 1

5th

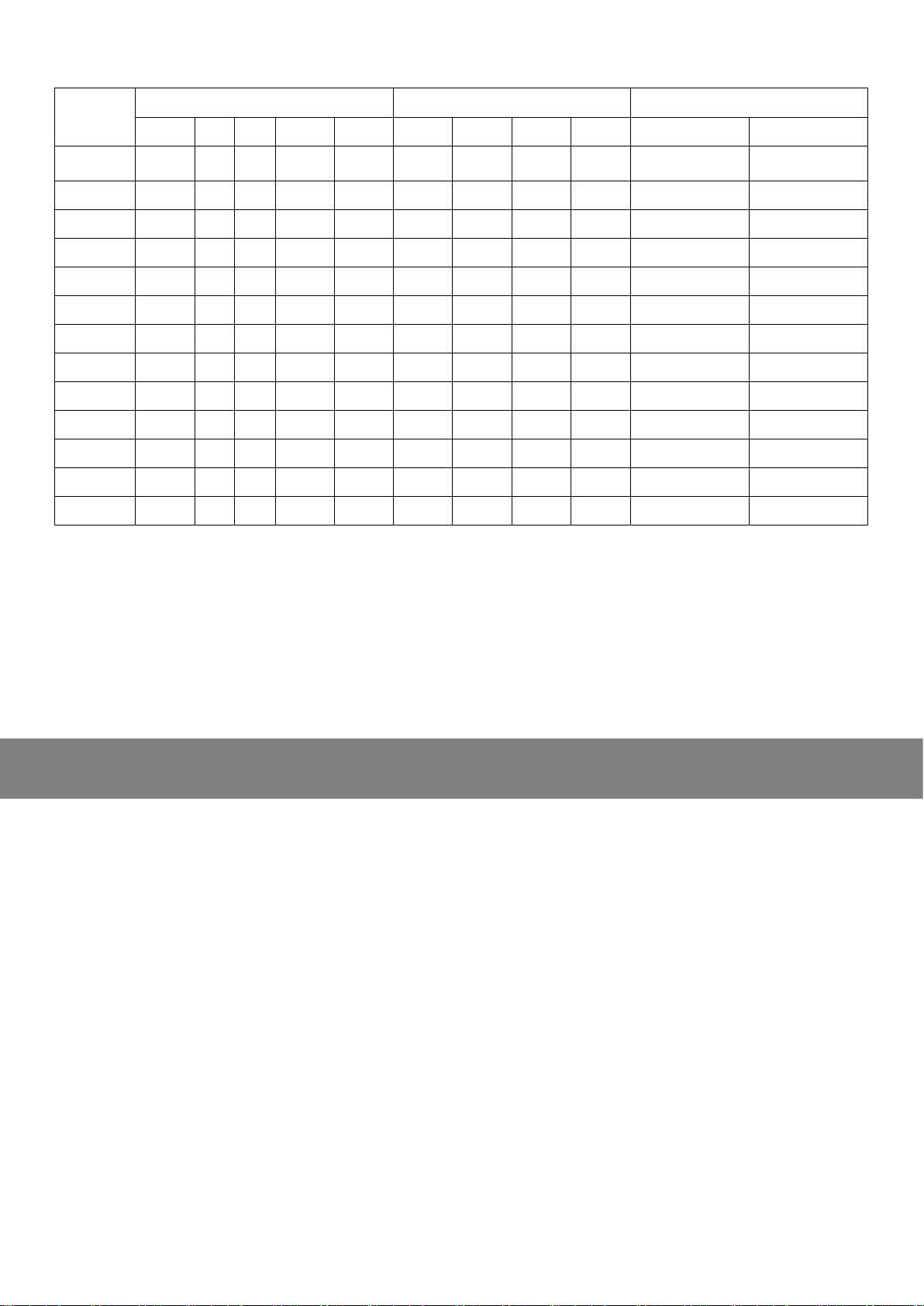

(4) Cable size for Input / Output , shown as the below table: (mm²)

Model

Input (including Bypass)

Output

Battery

R

S

T

N

G

R

S

T

N

Positive

Negative

10KW

6

6

6

6

6

6

6

6

6

10

10

15KW

6

6

6

6

6

6

6

6

6

10

10

20KW

16

16

16

16

6

16

16

16

16

20

20

30KW

16

16

16

16

10

16

16

16

16

20

20

40KW

25

25

25

25

10

25

25

25

25

30

30

50KW

25

25

25

25

25

25

25

25

25

35

35

60KW

35

35

35

35

25

35

35

35

35

50

50

80KW

35

35

35

35

30

35

35

35

35

50

50

100KW

50

50

50

50

30

50

50

50

50

80

80

120KW

50

50

50

50

35

50

50

50

50

80

80

140KW

80

80

80

80

35

80

80

80

80

100

100

160KW

80

80

80

80

50

80

80

80

80

100

100

200KW

100

100

100

100

50

100

100

100

100

120

120

2.Wiring Inspection

After finishing wiring all of the input/output cables, the following should be inspected:

(1) whether the order of the phases is correct;

(2) whether battery input cable is connected with the correct polarity;

(3) whether the ground connection cables of the Input and Output have been connected to the terminal board

firmly.

Notice: The Bypass input cables (R,S,T) and the Rectifier input cables (R,S,T) are paralleled connected.

A.Procedures of Switching on Single Machine

Please switch on the inverter according to the following procedures after wiring all of the necessary cables

properly

1. Close up the input switch of rectifier to start the rectifier of the inverter after confirming that all the phases

have voltage;

If no display on the LCD screen, and there's long buzzes, it indicates that the input phases are not in correct order;

then rectifier switch should be turned off and input power bus should be disconnected until the input phases

(R,S,T) are wired in correct order;

Close up the rectifier switch again and LCD screen shall have display. Then it takes around 30s for

self-inspection before starting the inverter;

The spinning fans indicate that the inverter has started up .

2. The Battery Switch can not be closed up until the inverter has started;

3. Close up the Bypass Switch;

4. Close up the Output Switch.

Note: When the inverter is working normally, the Repair Switch should be disconnected, otherwise the

mains power would go through repair switch directly to the loads.

III.Operation of the Inverter -1

6th

B.Procedures of Regular Switching Off

1. Disconnect the output switch;

2. Disconnect the Bypass Switch;

3. Disconnect the Battery Switch;

4. Disconnect the Rectifier Input Switch;

5. Disconnect the main power switch.

Warning:

1. Please strictly follow the above procedures to turn off the inverter;

2. The above actions should be done continuously until all of the switches are disconnected.

B.Mains priority

AC first , DC standby INVERTER mode

When both utility and battery are connected to the machine, utility will supply power to the loads prior to the battery. When

utility is cut off, the battery will automatically continue to supply power.

Step 1: When utility power is available, it will output directly after voltage being stabilized and charge batteries at the same

time.

Step 2: When utility power is cut off suddenly, the inverter will convert

DC power to AC power automatically to ensure uninterrupted power supply within 5ms.

Step 3: When utility power becomes available again, it will automatically transfer to utility supplying power to loads and

charge batteries at the same time.

See Workflow as below:

B.Battery priority

DC first, AC standby:

When both utility and battery are connected to the inverter, battery will supply power to the loads prior to utility.

When battery capacity is not enough, utility will continue to supply power automatically.

Steps are as follows:

Step 1: When battery has enough power, it will supply power to the loads directly

Step 2: When battery does not have enough power, it will automatically transfer to utility supplying power to the

loads

IV.Operation of the Inverter -2

7th

Step 3: After the battery is fully charged (e.g. by solar or wind charge controller), it will then automatically transfer

to battery supplying power to the loads.

See Workflow as below:

Note: Battery supporting time would be affected by the power consumption of the loads and

temperature. Removing some of the loads can extend battery time.

Under the battery mode, the alarm would buzz interruptedly, and the indicators of Output and Battery on

the control panel would show green light.

The closer to the exhaustion of the batteries, the more frequent would the buzzers go, with battery

indicator flashing at the same time. Inverter will stop working when the batteries exhaust until the

power come back for supplying and charging the batteries.

C.Static Bypass Mode

The inverter will turn to Static Bypass mode under any of the following situations:

1. order of transfer to Bypass (manually or automatically);

2. Output over-loaded;

3. Fault.

Under this mode, the bypass LED indicator on the control panel (Yellow light) will light on.

Note: The static bypass switch should be synchronized with AC power; It can be manually or

automatically set to 0 transfer time from protective load (inverting output) to non-protective load (Bypass

output)

8th

D.Reparing Mode

Used when the inverter needs repairing without cutting the power for the loads.

When Repair Switch is closed, the control panel stops displaying, and eletricity goes from bypass route to the

load and the load will be affected by any interference on the power grid.

Batteries cannot supply the power for loads; Shown as the Graph 8

Note: Before repairing the machine, manually close up the Repair Switch and disconnect all the other

switches (Input Switch, Output Switch , Battery Switch and Bypass Switch). Then apart from the voltage

on the switch part, there's no current going through the internal components of the inverter and the loads

are still having power supply.

But non-qualified personnel is not allowed to use the Repair Switch.

E.SLU

All of the operation action of this inverter is controlled by DSP chip.

F.Battery

It supplies the power for inverter. Choose battery quantity and capacity according to the type of the

inverter and the required back-up time.

G.Turn to Bypass with Inverter's Off

Under the normal situation, if the orders to turn off the inverter part, the loads will be supplied by power from

static bypass. If the mains power fails, the loads will not have power supply.

Under the emergency situation, if the inverter receives order of turning off the inverter part, the inverter will shut

down completely until the power getting back to normal, then it will start the normal working mode automatically.

Note: Since Input Switch and Battery Switch shall have voltage remains even they are disconnected, only

qualified personnel is permitted to repair the inverter. Otherwise the inverter may be damaged or worse,

accidents occurs to human being.

A.Periodically Maintenance

Batteries and cooling fans are the items that should be inspected periodically.

1. Inspect the cooling fans and clean its dust;

2. Replacing the batteries should be done by qualified personnel. All the disused batteries should be returned to

the related re-collection institute as the disused battery is deemed to be "Poisonous Waste".

V.Maintenance

9th

3. Battery life is related to the designed cycles of charging-discharging and the working temperature. Usually,

under 20 ℃, battery life can be 3~5 years. If the environmental temperature of the battery is above 30 ℃, battery

life would 1.5~2.5 years.

After a few times of charging-discharging cycles, the battery capacity would increase and be stable for the next

hundreds of cycles. Then it will shrink.

B.Battery Maintenance

Battery maintenance should be executed as follows:

1. Keep the environment temperature at around: 20~25 ℃;

2. In the first month, 2~3 times of charging and discharging the batteris is advised;

3. After the first month, batteries should be charged and discharged once every 3 months.

C.Adjusting a Suitable Working Environment

Adjustable items: Battery alarm setting; Automatic Switch-off; Bypass Voltage Range; Bypass Frequency

A.Inverter System

1.Input Rectifier shown as table 1

Model

10KW

15KW

20KW

30KW

40KW

50KW

60KW

80KW

100KW

120KW

140KW

160KW

200KW

Max.

Input

Current

25A

38A

51A

75A

101A

125A

150A

199A

240A

300A

340A

388A

480A

Working

Principle

Online Power supply, with static bypass switch (uninterruptible transfer), output power isolated

Phase

3 phases, R S T +N+G

Nominal

Voltage

380vac ±25%

Nominal

Frequenc

y

50Hz / 60Hz ±10%

Voltage

Harmonic

Distortion

<5%

Soft Start

Time

0~100% 5 seconds

Table 1

2.Output Rectifier shown as Table 2

Model

10KW

15KW

20KW

30KW

40KW

50KW

60KW

80KW

100KW

120KW

140KW

160KW

200KW

Max.

Output

Voltage

216VDC

408VDC

432VDC

Charging

Current

5A ~30A (adjustable)

Table 2

VI.Parameters :

10th

B.Battery

Shown as Table 3

Model

10KW

15KW

20KW

30KW

40KW

50KW

60KW

80KW

100KW

120KW

140KW

160KW

200KW

Max.

Discharge

Current

52A

78A

104A

156A

125A

156A

187A

249A

311A

373A

435A

497A

559A

Battery

Voltage

192 VDC

360VDC

384VDC

Float

Charging

Voltage

216VDC

408VDC

432VDC

Charging

Current

5A ~30A (adjustable)

Table 3

C.Inverter

Shown as Table 4

Model

10KW

15KW

20KW

30KW

40KW

50KW

60KW

80KW

100KW

120KW

140KW

160KW

200KW

Power (KW)

10

15

20

30

40

50

60

80

100

120

140

160

200

Working

Method

SVPWM Full Bridge Inverting

Phase

3 phases, R S T +N+G

Nominal

Voltage

380vac ±1% (Stable Load)

Nominal

Frequency

50Hz / 60Hz ±0.5% (in Battery mode)

Frequency

Variation

<±0.05% (non-synchronized); <±2% (synchronized with Mains power);

Crest

Factory

3:1

Wave Form

Pure Sine Wave

THD

Linear loads: <3%; Non-linear loads: <5%

Fluctuation

of Voltage

for Unstable

Load

from 0~100% : <±5%

Transient

Recovery

Time

<10ms

On-Load

Voltage

Balance:<±1% Unbalance:<±5%

Overload

Capability

125% overload lasting 10Mins, 150% overload lasting 1min.

11th

Inverter

Efficiency

on 100%

load

90

92

92

92

93

93

93

93

95

95

95

95

95

Table 4

D.Bypass

Shown as Table 5

Model

10KW

15KW

20KW

30KW

40KW

50KW

60KW

80KW

100KW

120KW

140KW

160KW

200KW

Input

Current

25A

38A

50A

75A

105A

125A

150A

199A

240A

300A

340A

388A

480A

Phase

3 phases, R S T +N+G

Nominal

Voltage

380vac ±15% (Stable Load)

Nominal

Frequency

50Hz / 60Hz ±0.5% (in Battery mode)

Transfer

time to

bypass

10 ms

Table 5

D.MPPT

Shown as Table 6

Model

MPPT22050

MPPT36040

Input Max Current

45A

35A

PV Max Input Power

11KW

16KW

Nominal Voltage

330Vdc

480Vdc

PV Voltage Range

250~450Vdc

420~650Vdc

Output Max Power

10KW

14KW

Output Nominal Voltage

240Vdc

387Vdc

Output Voltage Range

192~264Vdc

310~425Vdc

Ourput Max Current

50A

40A

Table 6

F.System

Physical data shown as Table 7

Model

10KW

15KW

20KW

30KW

40KW

50KW

60KW

80KW

100KW

120KW

140KW

160KW

200KW

Output Bypass

Current

25A

38A

50A

75A

105A

125A

150A

199A

240A

300A

340A

388A

480A

12th

Efficiency

(100% load)

>85%

Communication

Port

RS232

Operating

Temperature

0~40℃;

Operating

Relative

Humidity

5%~95%

Operating

Altitude

>1000M(1% Power dcreased in every 100M increased. Maximum 4000M)

Cooling Method

Force Ventilation

Color

Black

Input Cable

From Bottom and Back

Maintenance

Side

Front / Top/ Flank side

Input Setup

Terminal Board

Output Setup

Terminal Board

Size (mm)

720*565*1140

790*660*1550

1100*900*1500

1380*950*1800

Weight(kg)

220

260

290

400

480

580

650

900

1100

1300

1350

1480

2000

Table 6

A.Alarm1:Fault of Bypass Voltage or Bypass Fuse, SCR

It alarms in the following situations:

1. Bypass input voltage fault;

2. Bypass Input Switch is disconnected;

3. Bypass SCR fuse disconnected or melt due to short circuit.

B.Alarm2:Fault of Main Input Power or Input Rectifier Switch Disconnects

It alarms in the following situations:

1. Input voltage is beyond 176~264 vac;

2. Input frequency is beyond 45~56 HZ;

3. Input Rectifier Switch is disconnected;

4. Rectifier fault.

C.Alarm3:Under-Voltage of the Battery

It alarms in the following situations:

1. Battery is under-voltage;

2. Battery running time is lower than the preset time;

VII..Alarms

13th

D.Alarm4:Battery Discharging

It alarms once the batteries start to discharge. In about 2 minutes, the alarm stops.

It alarms when the batteries capacity is close to exhausted voltage.

(The above happens without "Mute" being pressed)

E.Alarm5:Over-loaded

It alarms when load power exceeds 100% of the output power of the inverter;

Loads need to be reduced, otherwise the inverter will turn to bypass automatically.

F.Alarm6:Temporary Bypass

It alarms in the case of over-loaded, the inverter would turn to bypass mode temporarily , waiting for the inverter

to supply the inverting current.

G.Alarm7:Turn to Bypass due to Over-loaded

It alarms when over-loaded for long time. For example, the inverter can supply normal power for 10 minutes

when under 125% overloaded, then it will turn to bypass mode. If the load is reduced to <125%, the inverter

resume to the normal working mode.

H.Alarm8:Order to Bypass

By typing special order into the inverter , it can switch off the inverter and turn to Bypass without leaving record.

But the inverter will turn back to normal working mode after 1 minute unless a locked time has been set.

I.Alarm9:Over-heat or Fault of Cooling Fans

It alarms when the control system, inverter power module or rectifier power module gets over-heat or the cooling

fan is fault. Then the inverter turns to bypass mode.

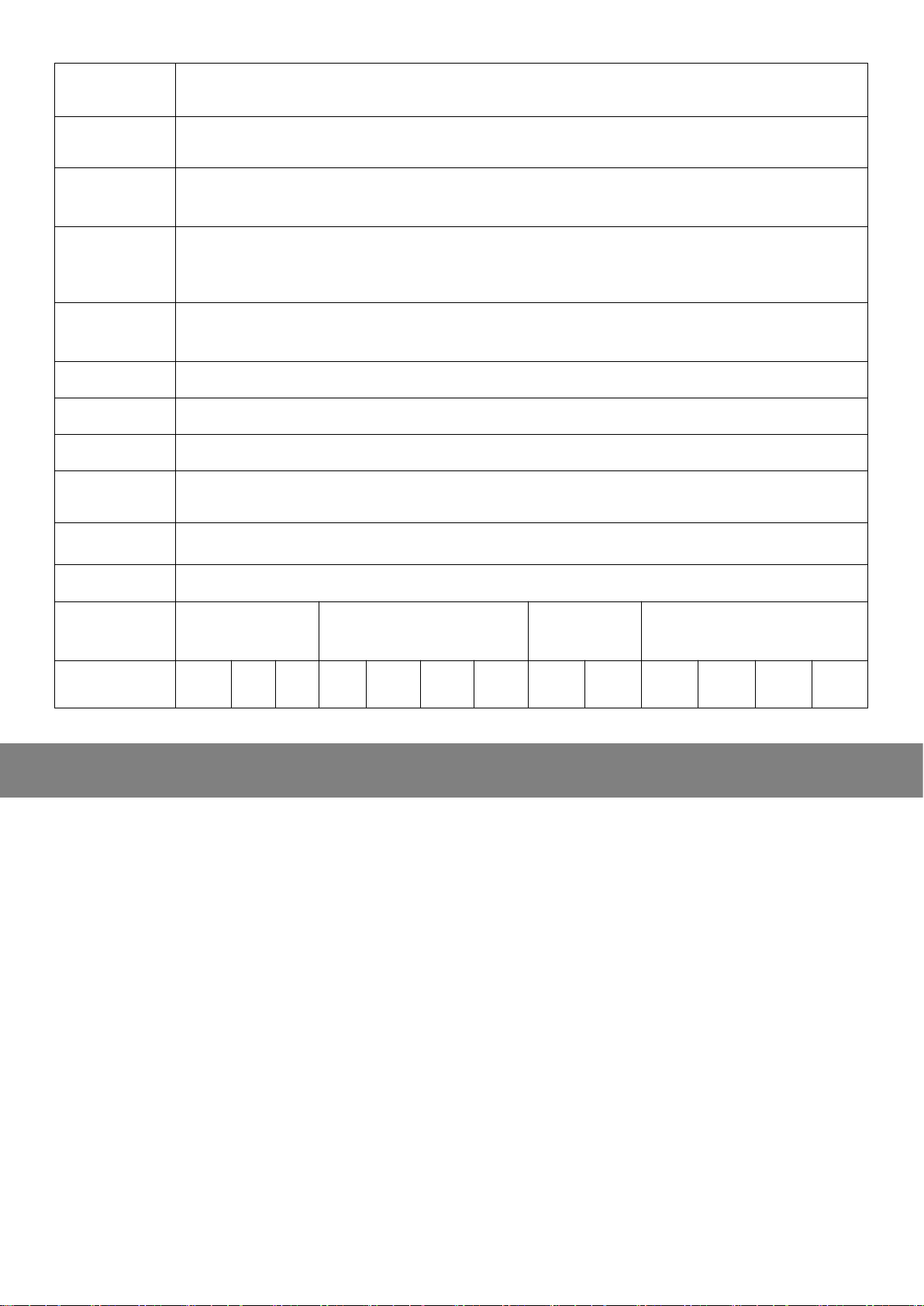

A.General Introduction

1.Instruction on LCD Indicators

The operation control display panel is located on the front door.Through the operation control display panel,

operation control and query all parameters, battery status, and alarm information.As shown in figure 4-1, the

operation control display panel can be divided into three parts according to functions: analog current diagram,

LCD display and menu key, control operation key.The description of operation control display panel is shown in

table 4-1

4-1Operation control display panel part description

LED number

Function

LED number

Function

AC LINE

Ac input LED

BATLOW

Battery low voltage

BATTERY

Battery LED

BYPASS

Bypass LED

VIII.Display Function

14th

INVERTER

Inverter LED

OUTPUT

Load LED

ALARM

ALARM LED

1.2 LED

4-2 Description of led status

Sound warning (buzzer)

The alarm sound

Description

Half a second in singing

Battery low pressure alarm

Continue to sing

Battery high voltage, overload warning

LED

STATUS

MEANS

Ac Input LED

Green normally on

AC input works properly

Green flashing

Ac input anomaly

does not light

There is no AC input

Battery LED

Green normally on

Battery discharge inverter

Green flashing

Battery low pressure alarm

does not light

Battery does not work

Bypass LED

Yellow normally on

Load power is supplied by AC power

does not light

Bypass not working

Inverter LED

Green normally on

The load power supply is provided by the inverter

Green flashing

Inverter fault

does not light

The inverter is not working

Load LED

Green normally on

Output, and normal

does not light

There is no output

ALARM LED

Red normally on

There are warning signs

does not light

No alarm fault

BATLOW

Green normally on

Battery low voltage

15th

2. LCD display

graphics

instructions

1

Power input parameters

2

Entry operation

3

Battery voltage

4

Battery capacity % value

5

AC charging current

6

Current running mode

7

Output voltage parameter

8

Output load parameters

9

Mute and cancel the mute button

10

Current time date

11

Inverter on or off

12

Solar Voltage

13

Solar Current

16th

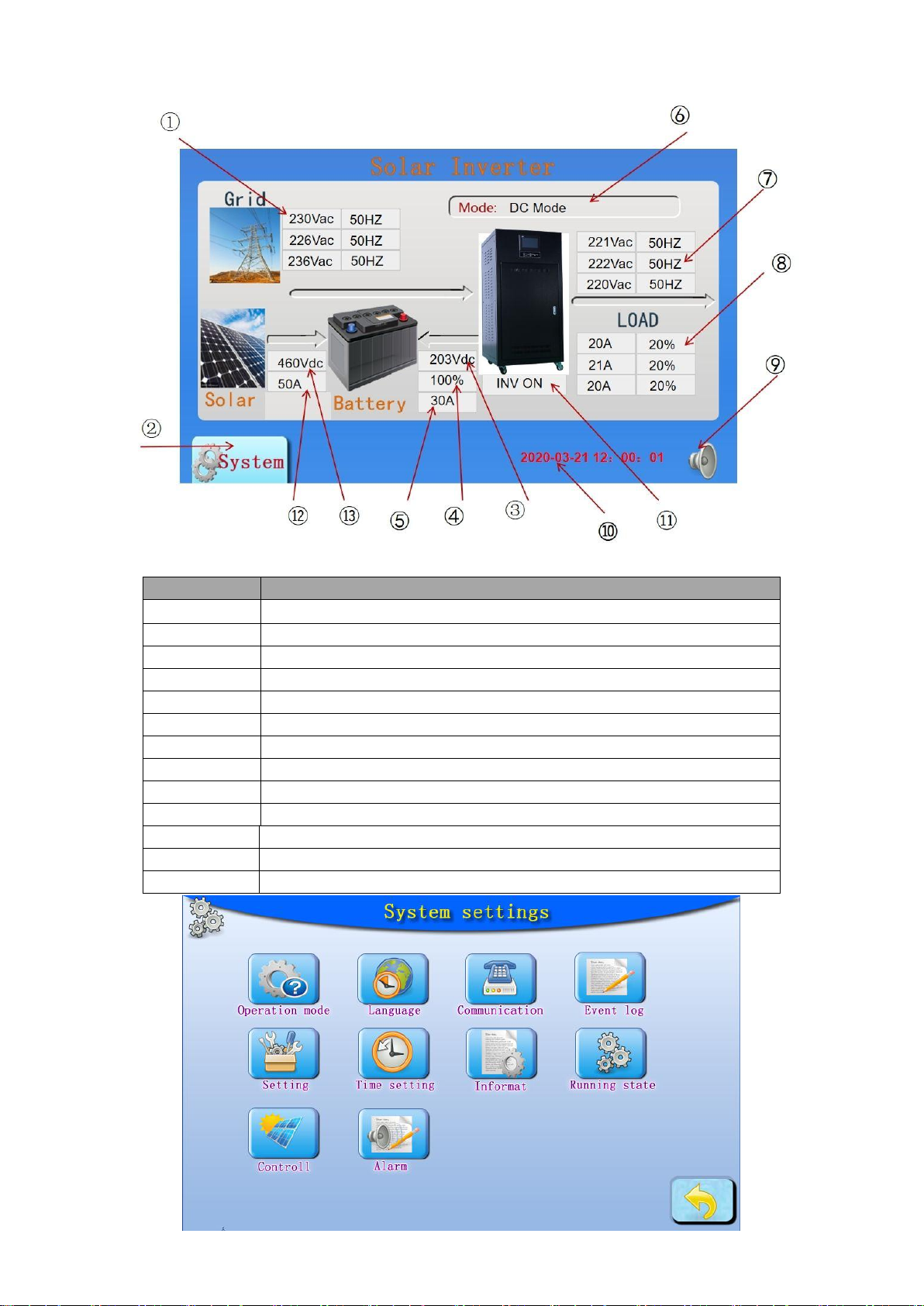

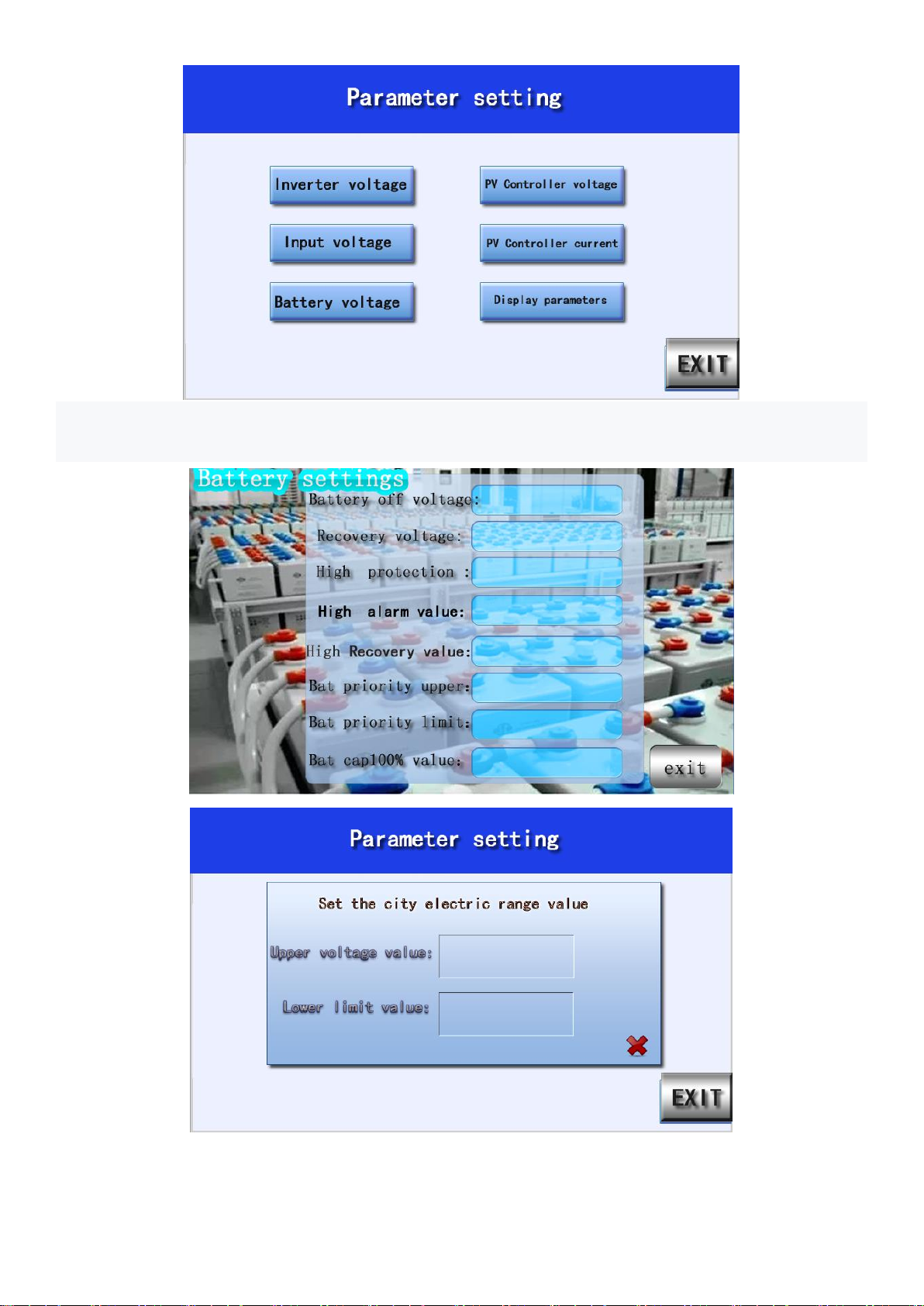

3. Operation Mode Setting:

3C.1 modification parameters:

Enter the password to modify and set parameters.

The factory password is: 123456

17th

3C.2 modify battery parameters:

Click directly in the blank of the battery and input the voltage value the user wants

18th

Packing List

Inverter

1 piece

User Manual

1 piece

Optional Accessories (Extra Charge)

1. N+1 Parallel Redundancy

2. SNMP Network card (Non inbuilt)

3. RS 422/RS 232 transferable port

4. Signal board for dry contact alarm

5. 12-pulse rectifying

6. All kinds of non-regular machine

PSC Solar UK

Physical Office/Warehouse: 41B, Olutoye Cres/Adeniyi Jones, Ikeja, Lagos State,Nigeria

Phone No.: +2348120855444, +2348123655444

Website: www.pscsolaruk.com

Email Address: info@pscsolaruk.com

X.Anexo

This manual suits for next models

12

Table of contents

Other PSC Solar Inverter manuals

Popular Inverter manuals by other brands

Lenze

Lenze i950 Series Mounting and switch-on instructions

Growatt

Growatt SPH Series Installation & operation manual

Westerbeke

Westerbeke 5.5 EGCD Operator's manual

Phonocube

Phonocube PC3.0A1-S user manual

Clenergy

Clenergy PV-ezRack SolarTerrace II-F installation guide

Kemo Electronic

Kemo Electronic M062 quick guide